Method for preparing high-temperature resistant silicon carbide

A silicon carbide, high temperature resistant technology, applied in the field of ceramic materials, can solve problems such as limiting the scope of use, and achieve the effects of uniformity, easy control and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

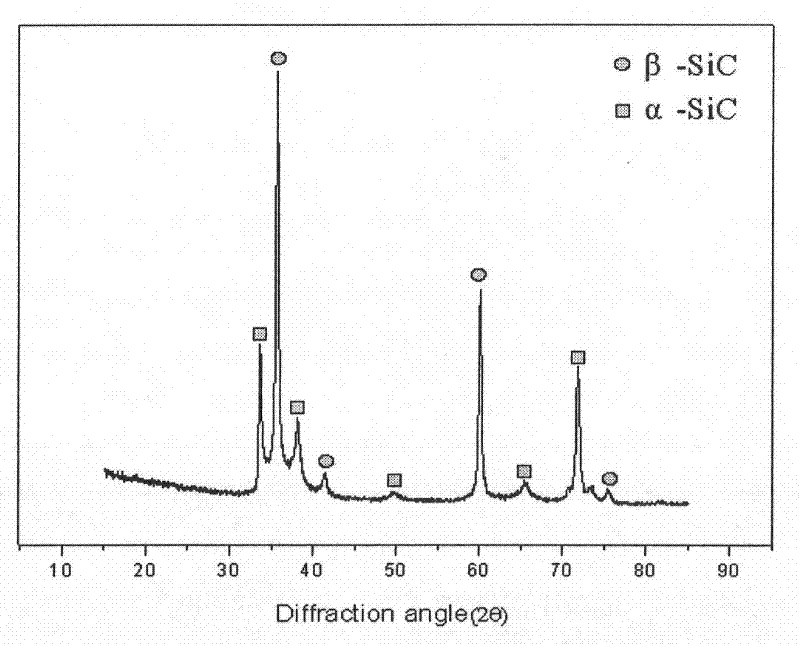

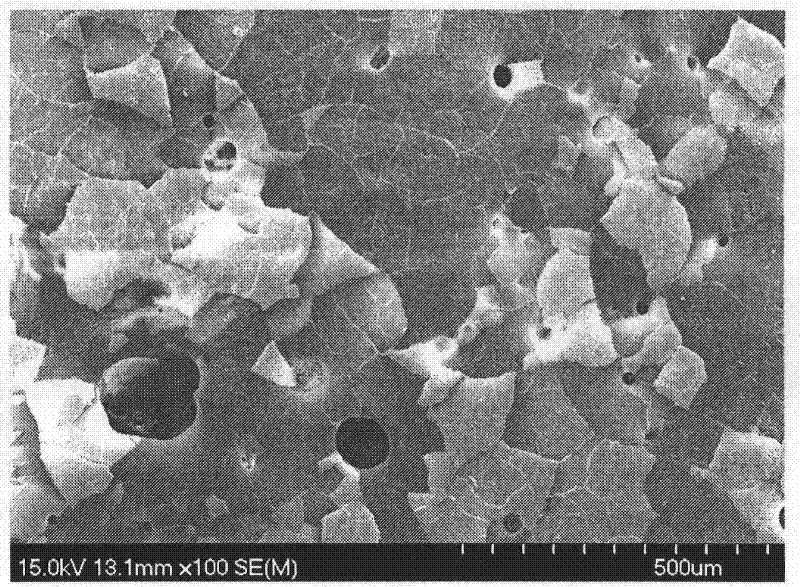

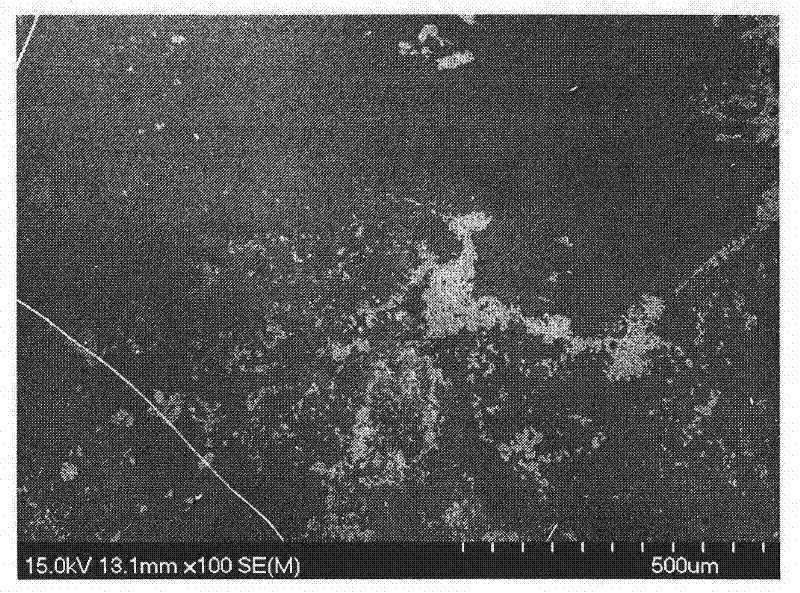

Image

Examples

Embodiment 1

[0027] Embodiment 1, a kind of preparation method of high temperature resistant silicon carbide, carries out following steps successively:

[0028] 1) Add aluminum acetylacetonate to the liquid polycarbosilane, place it on a magnetic stirrer for stirring, the stirring time is 4 hours, the temperature is 80°C, and the mass fraction ratio of liquid polycarbosilane to aluminum acetylacetonate is: 9:1 ;

[0029] 2) Put the uniformly mixed raw materials into the cross-linking cracking furnace, first evacuate to -0.09MPa, then fill with argon to 0MPa, and keep the argon in circulation, the flow rate is 50-80ml / min, at 0.5-1.5℃ / The heating rate of min is increased to 200°C and 400°C in turn, and the temperature is kept for 4 hours respectively, and the cross-linking and curing are completed;

[0030] 3) ball milling the solid obtained above for 4 hours at a speed of 1200 cycles / min;

[0031] 4) The powder obtained by ball milling is formed by cold isostatic pressing to obtain a di...

Embodiment 2

[0035] Embodiment 2, a kind of preparation method of high temperature resistant silicon carbide, carry out following steps successively:

[0036] 1) Add aluminum acetylacetonate to the liquid polycarbosilane, place it on a magnetic stirrer for stirring, the stirring time is 4 hours, the temperature is 80°C, and the mass fraction ratio of liquid polycarbosilane to aluminum acetylacetonate is: 9:1 ;

[0037] 2) Put the uniformly mixed raw materials into the cross-linking cracking furnace, first evacuate to -0.09MPa, then fill with argon to 0MPa, and keep the argon in circulation, the flow rate is 50-80ml / min, at 0.5-1.5℃ / The heating rate of min is increased to 200°C, 400°C and 900-1100°C in turn, and the temperature is kept for 4 hours respectively, and the cross-linking cracking is completed;

[0038] 3) ball milling the solid obtained by cross-linking cracking, the ball milling time is 2 to 4 hours, and the rotation speed is 1200 cycles / min;

[0039] 4) Combine the above si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com