Carbon fiber winding paving variable cross-section adhesive transmission shaft and combined type mould thereof

A combined, variable-section technology, applied in the directions of shafts, couplings, shafts and bearings, can solve the problems of destroying the performance and strength of carbon fiber, difficulty in winding and demoulding carbon fiber, etc., to improve adhesive strength, reduce excess strength and Weight, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

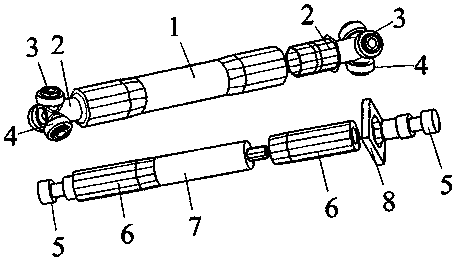

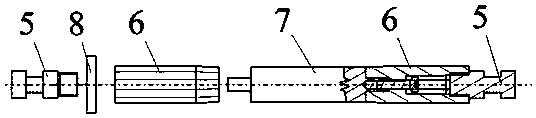

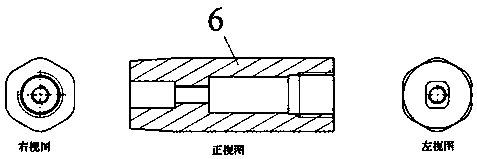

[0034] The technical solution of the present invention is: use carbon fiber anisotropy to design different ply angles to optimize the force and reduce weight while ensuring sufficient strength; the variable section can fully transmit torque and connect with the joint surface; The joints are glued and connected with high-strength glue, and the one-piece joint is integrated with the universal joint to connect with the transmission system. The spline-free connection improves the strength and reduces the weight. The combined mold realizes convenient carbon fiber processing and molding, and is suitable for different processing equipment.

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0036]In the carbon fiber transmission shaft provided by the present invention, variable cross-section winding carbon fiber tube 1, the two ends of the carbon fiber tube are bonded with an integral joint 2, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com