Lubricating grease and preparation method thereof

A technology of lubricating grease and lithium-based lubricating grease, applied in lubricating compositions, petroleum industry, additives, etc., to achieve good extreme pressure resistance, high yield, good load bearing and anti-wear and anti-friction capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of ZIF-71 material: according to molar ratio is dihydrate zinc acetate (Zn(OAc) 2 2H 2 O, Sigma-Aldrich (Shanghai) Trading Co., Ltd.): 4,5-dichloroimidazole (dcIm, Fluorochem Ltd): formic acid (HCOOH, Aladdin Reagent (Shanghai) Co., Ltd.) = 1.0:3.0:1.0 Feed preparation. 1.0 mmol (0.219 g) Zn(OAc) 2 2H 2 O, add 10 mL methanol (CH 3 OH, Aladdin Reagent (Shanghai) Co., Ltd.); 3.0 mmol (0.411 g) of dcIm and 1.0 mmol (0.046 g) of formic acid were added to 10 mL of methanol, mixed after dissolution, and stirred at room temperature for 30 minutes. After the reaction, centrifuge at 2000 rpm for 2 minutes, wash with absolute ethanol three times, and air-dry the product at room temperature.

[0021] The preparation method of basic lithium-based grease: Weigh 150.0 g of base lubricating oil, pour 50.0 g of base lubricating oil into the grease making kettle, start the stirrer, heat up to 75 ± 5 ℃, and put in 14.6 g of octadecanoic acid (C 18 h 36 o 2...

Embodiment 2

[0025] Adopt the ZIF-71 material prepared in embodiment 1;

[0026] The preparation method of base lubricating grease is the same as in Example 1, the difference is: 14.6 g octadecanoic acid (C 18 h 36 o 2 , Aladdin Reagent (Shanghai) Co., Ltd.) was replaced by 15.4 g 12-hydroxy-octadecanoic acid (C 18 h 36 o 3 , Ti Xiai (Shanghai) Chemical Industry Development Co., Ltd.).

[0027] Add 3.0g of ZIF-71 material directly to 97.0g of basic lithium base grease as a grease additive, use a three-roller mill to roll and grind 3 times, so that the ZIF-71 material is evenly mixed in the base grease, and 3.0wt% ZIF-71 is obtained. grease samples.

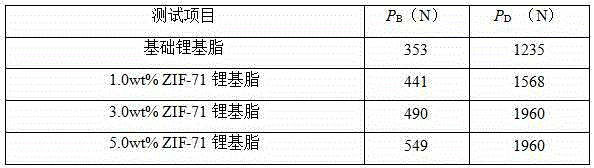

[0028] Using the four-ball friction and wear testing machine to evaluate the maximum non-jamming load ( P B ) and sintering load ( P D ), the method is the same as in Example 1. The measured data are shown in Table 1.

Embodiment 3

[0030] The ZIF-71 material and base grease prepared in Example 1 were used.

[0031] Add 5.0g of ZIF-71 material directly to 95.0g of basic lithium base grease as a grease additive, use a three-roller mill to roll and grind 3 times, so that the ZIF-71 material is evenly mixed in the base grease, and 5.0wt% ZIF-71 is obtained grease samples.

[0032] Using the four-ball friction and wear testing machine to evaluate the maximum non-jamming load ( P B ) and sintering load ( P D ), the method is the same as in Example 1. The measured data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com