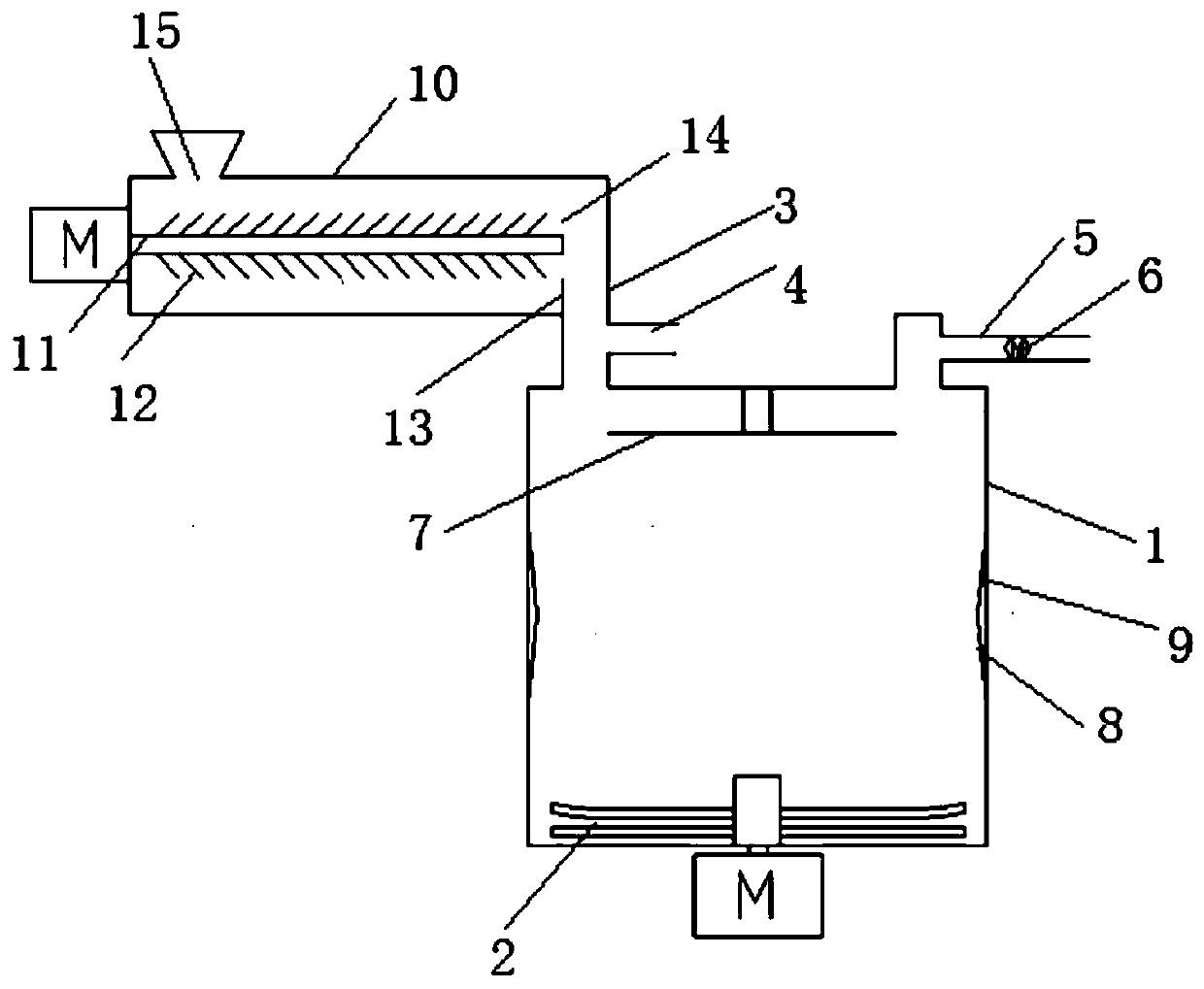

Powder drying and dispersing device

A dispersing device and drying technology, which is applied in the direction of drying gas arrangement, drying solid materials, and promoting the preliminary treatment of solid material drying, which can solve the problems of insufficient powder dispersion and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

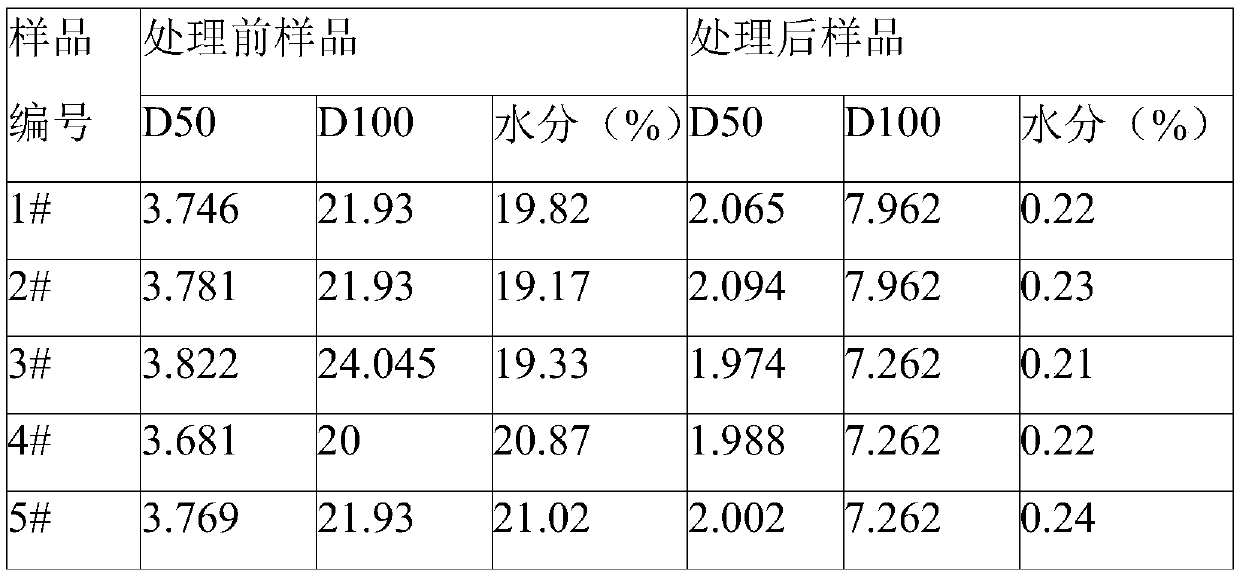

[0053] Add 250 kg of calcium carbonate filter cake from the feed port 15 of the crushing cylinder 10, and after stirring for 30 minutes, the discharge port of the drying cylinder 1 starts to discharge, and the samples are taken every 50 kg, and a total of 5 samples are taken for testing. Test, the results are as follows:

[0054] Table I:

[0055]

Embodiment 2

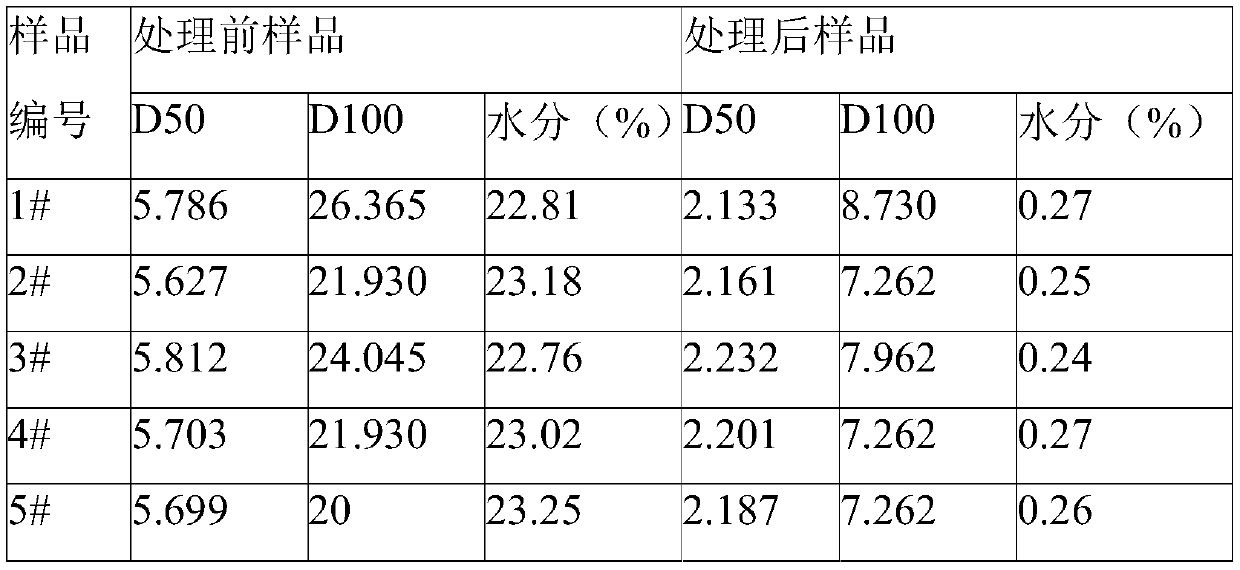

[0058] 250 kilograms of magnesium hydroxide filter cakes are added from the feed port 15 of the crushing cylinder 10, and after 30 minutes of stirring, the discharge port of the drying cylinder 1 starts to discharge, and the samples are taken every 50 kilograms, and a total of 5 samples are taken. Test, the results are as follows:

[0059] Table II:

[0060]

Embodiment 3

[0062] Add 250 kilograms of aluminum hydroxide filter cake from the feed port 15 of the crushing cylinder 10, and after 30 minutes of stirring, the discharge port of the drying cylinder 1 starts to discharge. Samples are taken every 50 kilograms, and a total of 5 samples are taken Tested and got the following results:

[0063] Table three:

[0064]

[0065] Combining with the specific examples above, it can be seen that the drying effect of the present invention is good, the material can be dried and fully dispersed in a short time, and the material is heated evenly during the drying process, the drying is thorough, the dispersion efficiency is high, the quality is good, and the dispersion is uniform , no reunion phenomenon.

[0066] When using the device of this scheme to dry and disperse the powder filter cake, after the powder slurry is separated by the filter press system, the filter cake is cut into small pieces during the conveying process of the crushing cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com