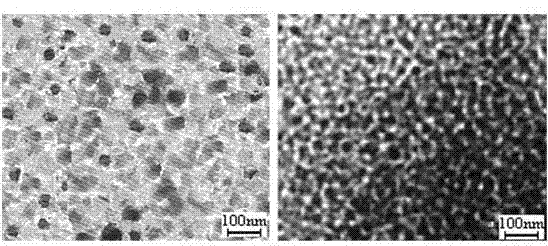

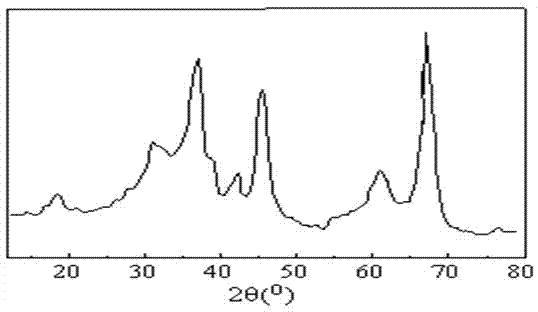

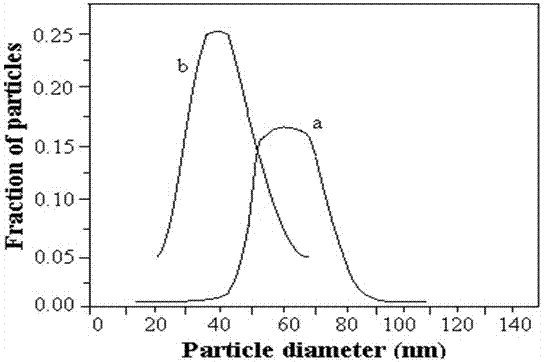

Method for synthesizing nanometer gama-Al2O3 by adopting solvent replacement/azeotropic distillation drying method and applications thereof

An azeotrope, drying technology, applied in the direction of alumina/aluminum hydroxide, flocculation/precipitation water/sewage treatment, etc., can solve problems such as easy agglomeration, prevent hard agglomeration, inhibit coalescence and growth, and expand application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples describe the present invention in further detail.

[0038] The present invention tells about γ-Al by experiment 2 o 3 Preparation and application of:

[0039] Reagents and instruments:

[0040] Concentrated ammonia water, crystalline aluminum chloride, NaOH, HCl, n-butanol, commercially available polyaluminum chloride, organic polymer dispersant (polyethylene glycol HO(CH 2 CH 2 O) n H (Polyethylene Glycol, PEG MP: 600 to 800 and 5000), silver nitrate solution (0.1mol L -1 ), were analytically pure, and the experimental water was twice distilled water.

[0041] 500mL distillation flask, spherical condenser, crucible, electric heating constant temperature water bath H.H.S11-2K, far infrared fast dryer 766-3, electromagnetic centrifuge LXJ-64-01, contact voltage regulator TDGCZ-1KVA, X-ray microscopic tomography Technology XMT-8000, SB-3200 ultrasonic oscillator, LWMC-205 adjustable power microwave chemical reactor with reflux system, DZF6050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com