Oxygen lance nozzle end face high-temperature protection coating and preparation method thereof

A technology of oxygen lance spray head and protective coating, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of large difference, coating peeling and failure, etc., achieve high density, reduce surface temperature, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

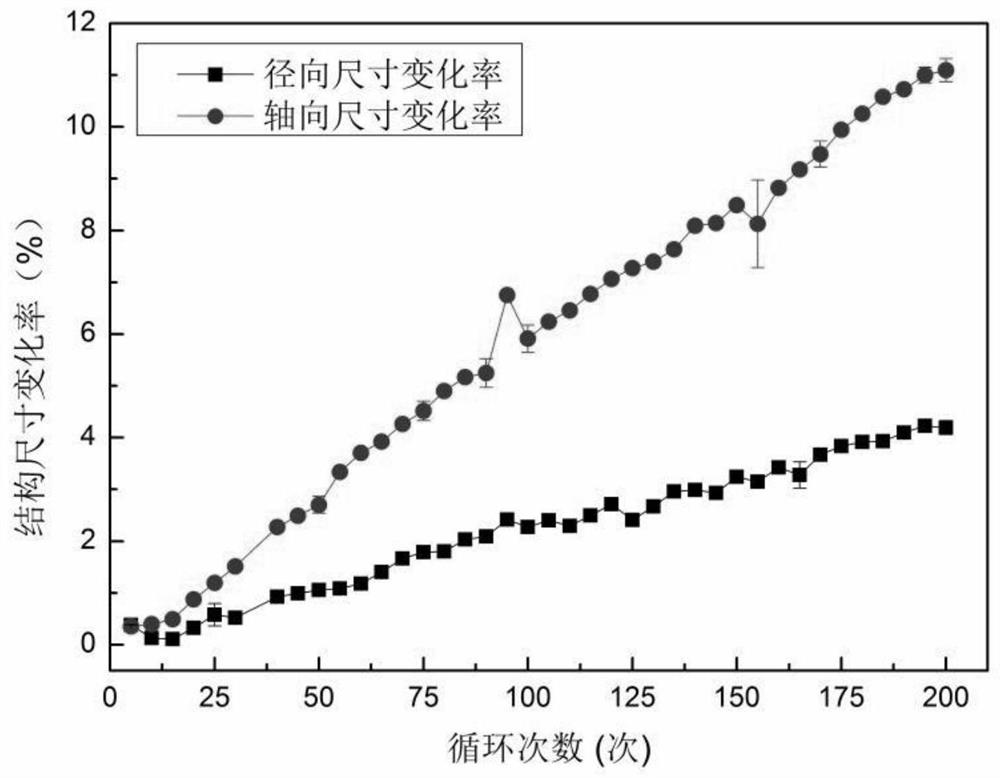

Examples

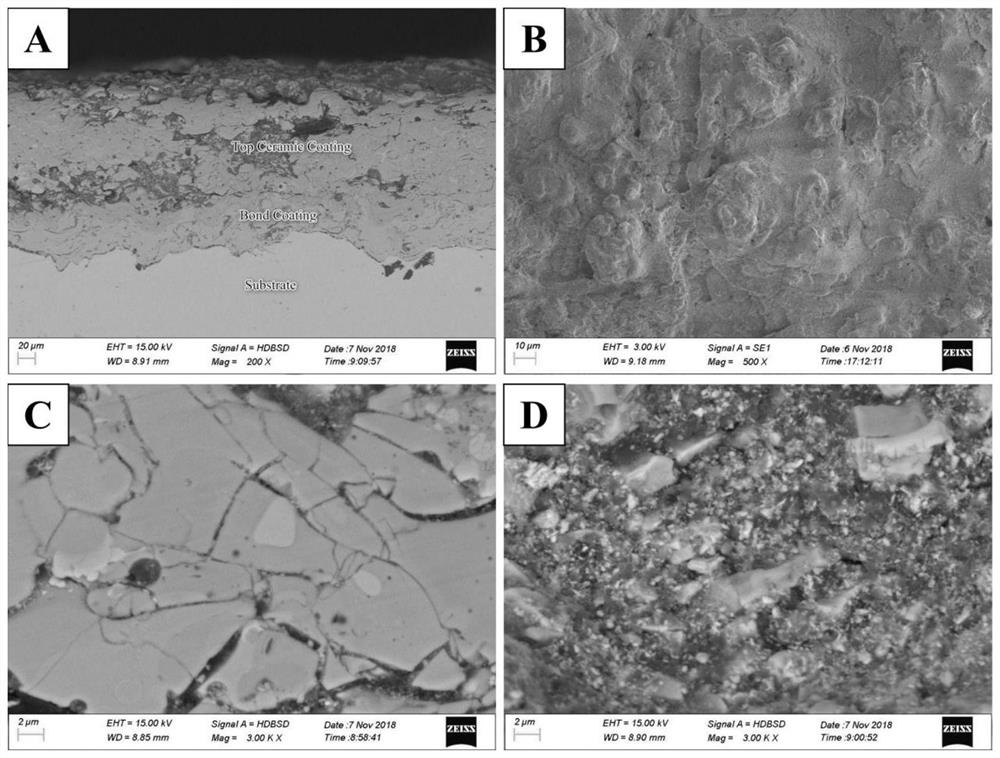

Embodiment 1

[0039] A high-temperature protective coating on the end face of an oxygen lance nozzle, which is composed of a bonding layer and a ceramic anti-sticking layer. ZrO 2 -24MgO layer. Among them, the mass percentages of Ni, Co, Cr, Al and Y in the NiCoCrAlY layer are 28:35:26:10:0.5, ZrO 2In the -24MgO layer, the mass percentage of MgO is 23%, and the rest is ZrO 2 .

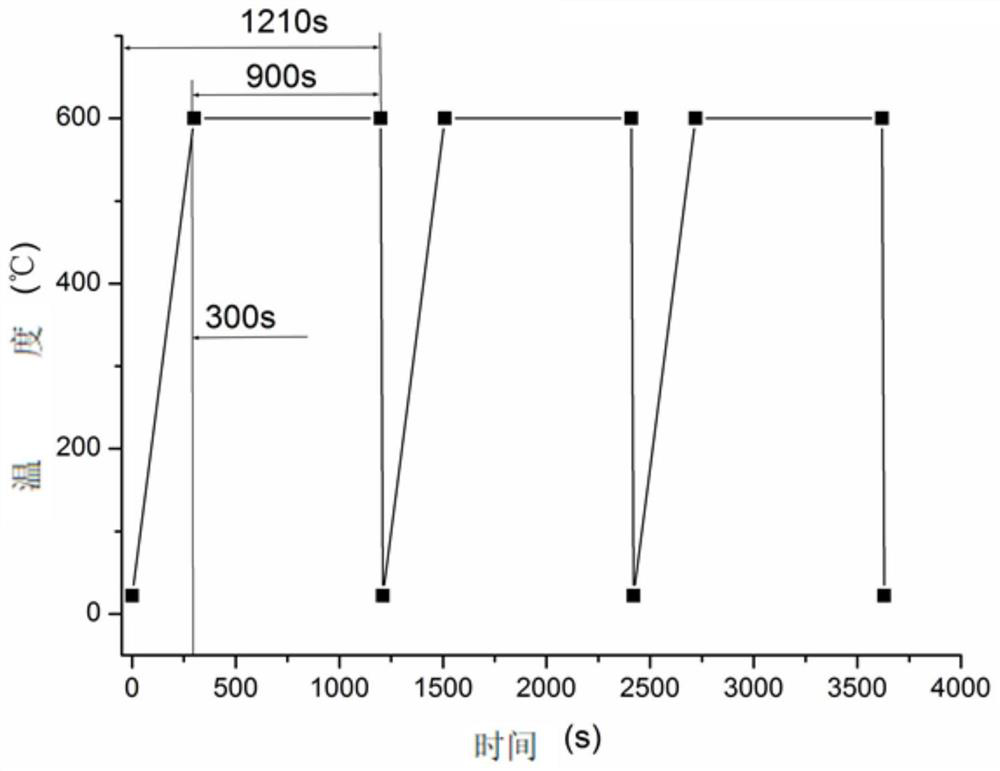

[0040] The preparation method for preparing the high-temperature protective (composite) coating on the end face of the converter oxygen lance nozzle provided by this embodiment, the steps are as follows:

[0041] Step 1. Use metallographic sandpaper to polish the end face of the converter oxygen lance nozzle to remove surface oxides and pollutants. Clean the sample ultrasonically with alcohol for 10 minutes and dry it for later use;

[0042] Step 2, the sample needs to be sandblasted before spraying, and the sandblasting particle size is 30 mesh;

[0043] Step 3, the metal bonding layer material NiCoCrAlY is sp...

Embodiment 2

[0069] A high-temperature protective coating on the end face of an oxygen lance nozzle, which is composed of a bonding layer and a ceramic anti-sticking layer. ZrO 2 -24MgO layer. Among them, the mass percentages of Ni, Co, Cr, Al and Y in the NiCoCrAlY layer are 27:34:25:8:0.3, ZrO 2 In the -24MgO layer, the mass percentage of MgO is 15%, and the rest is ZrO 2 .

[0070] The preparation method for preparing the high-temperature protective (composite) coating on the end face of the converter oxygen lance nozzle provided by this embodiment, the steps are as follows:

[0071] Step 1. Use metallographic sandpaper to polish the end face of the converter oxygen lance nozzle to remove surface oxides and pollutants. Clean the sample ultrasonically with alcohol for 12 minutes and dry it for later use;

[0072] Step 2, the sample needs to be sandblasted before spraying, and the sandblasting particle size is 20 mesh;

[0073] Step 3, the metal bonding layer material NiCoCrAlY is sp...

Embodiment 3

[0076] A high-temperature protective coating on the end face of an oxygen lance nozzle, which is composed of a bonding layer and a ceramic anti-sticking layer. ZrO 2 -24MgO layer. Among them, the mass percentages of Ni, Co, Cr, Al and Y in the NiCoCrAlY layer are 29:37:28:12:0.8, ZrO 2 In the -24MgO layer, the mass percentage of MgO is 30%, and the rest is ZrO 2 .

[0077] The preparation method for preparing the high-temperature protective (composite) coating on the end face of the converter oxygen lance nozzle provided by this embodiment, the steps are as follows:

[0078] Step 1. Use metallographic sandpaper to polish the end face of the converter oxygen lance nozzle to remove surface oxides and pollutants. Clean the sample ultrasonically with alcohol for 15 minutes and dry it for later use;

[0079] Step 2, the sample needs to be sandblasted before spraying, and the sandblasting particle size is 20-30 mesh;

[0080] Step 3, the metal bonding layer material NiCoCrAlY i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com