A kind of high-niobium flux-cored welding wire used for hard surface repair of roller press and preparation method thereof

A technology of flux-cored welding wire and roller press, applied in the field of welding, can solve the problem of no slag removal, and achieve the effect of reducing slag sticking and improving slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

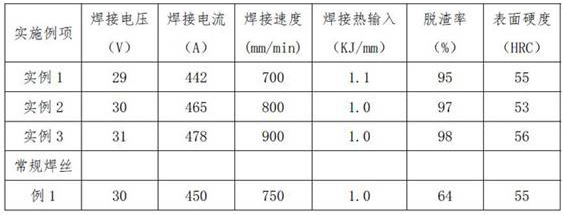

Examples

preparation example Construction

Embodiment 1

[0042] The cold-rolled SPCC low carbon steel strip of 16X0.3 (width 16mm, thickness 0.3mm) is selected and rolled into a U shape. take the oxygen

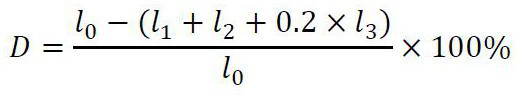

[0043]

[0045] is the total length of the weld bead;

[0046] is not the slag removal length;

[0048] is the slightly sticky slag length.

Embodiment 2

[0051] The cold-rolled SPCC low carbon steel strip of 16×0.3 (width 16mm, thickness 0.3mm) is selected and rolled into a U shape. take the oxygen

[0052]

[0054] is the total length of the weld bead;

[0055] is not the slag removal length;

[0056] is a severe sticky slag length;

[0057] is the slightly sticky slag length.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com