Patents

Literature

39results about How to "Excellent slag removal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant flux-cored wire for stainless steel

InactiveCN106514047AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantRare earth

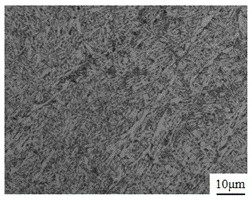

The invention discloses a wear-resistant flux-cored wire for stainless steel. The wear-resistant flux-cored wire consists of a flux core and a stainless steel sheath coating the outer side of the flux core, wherein the flux core comprises the following raw materials in parts by weight: 15-22 parts of chromium powder, 1-4 parts of titanium powder, 0.5-2 parts of nickel powder, 1-4 parts of silicon calcium alloy, 1-4 parts of magnalium, 4.5-7 parts of ferromanganese, 2-5 parts of ferromolybdenum, 2-4 parts of ferrocolumbium, 4-8 parts of rare earth ferroalloy, 4-8 parts of vanadium-nitrogen alloy, 6-9 parts of carbonate, 3-6 parts of graphite and 100-150 parts of iron powder. The wear-resistant flux-cored wire for stainless steel has favorable wear resistance, corrosion resistance, heat resistance and mechanical property; a deposited metal structure is compact, pore-free and crack-free; and the wear-resistant flux-cored wire for stainless steel can be favorably combined with a base material and is stable in performance.

Owner:天长市通联焊业有限公司

Wear-resisting and high-hardness flux core wire

InactiveCN107252994AHigh hardnessHigh strengthWelding/cutting media/materialsSoldering mediaSilicon alloyRare earth

The invention discloses a wear-resisting and high-hardness flux core wire. The wear-resisting and high-hardness flux core wire is composed of a flux core and a low-carbon cold-rolling steel tape sheath wrapped on the outer side of the flux core. The flux core comprises, by weight, 20-25 parts of low-carbon ferrochromium, 1.5-3 parts of titanium powder, 1-2 parts of nickel powder, 5-8 parts of calcium-silicon alloys, 2-4 parts of magnesium-aluminum alloys, 3-5 parts of electrolytic manganese, 1-2 parts of ferromolybdenum, 2.5-4 parts of ferroniobium, 1-2 parts of ferrovanadium, 3-5 parts of rare earth iron alloys, 3-5 parts of carbonate, 3-4 parts of graphite, 120-150 parts of iron powder, 0.5-1.5 parts of tungsten powder and 2-4 parts of calcium fluoride. The wear-resisting and high-hardness flux core wire has good welding performance, deposited metal tissue is compact, air holes and cracks are avoided, combination with base metal is good, performance is stable, and deposited metal has good wear resistance, corrosion resistance, high hardness and other performance.

Owner:天长市通联焊业有限公司

Alkaline welding rod coating capable of improving welding process property

InactiveCN1586798AFine splash particlesReduce manufacturing costWelding/cutting media/materialsSoldering mediaIron powderManganese

The alkaline welding rod coating with raised welding performance consists of: marble 39-45 wt%, silica mud 3-10 wt%, fluorite 16-25 wt%, metal Mn 2-4 wt%, Si-Fe alloy 0.5-3 wt%, Ti-Fe alloy 8-12 wt%, cellulose 0.5-1.0 wt%, titania 3-9 wt%, atomized iron powder 6-15 wt% and graphite+Na2CO3 1-2.5 wt%. The said components are mixed, and the mixture is then coated with sodium water glass as adhesive onto low alloy steel welding core to produce alkaline low alloy steel welding rod or onto carbon steel welding core to produce alkaline carbon steel welding rod. The alkaline welding rod with the welding rod coating has excellent welding performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Acid electrode with good process performance

InactiveCN101954554AImprove all-position welding adaptabilityImprove restriking performanceWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses an acid electrode with good process performance, and belongs to the technical field of welding materials. The electrode consists of a core wire and a coating. The coating is characterized by comprising the following components in percentage by weight: 25 to 35 percent of titanium pigment and rutile, 15 to 20 percent of selected ilmenite, 5 to 10 percent of marble and dolomite, 5 to 10 percent of white mud, 3 to 8 percent of mica, 8 to 15 percent of potash feldspar, 4 to 7 percent of quartz sand, 8 to 13 percent of manganese-silicon, 2 to 4.5 percent of chalk, 1 to 1.5 percent of sodium carbonate, 3 to 5 percent of organic matters and 0.5 to 2 percent of rare earth magnesium powder, atomized iron powder and aluminum powder, wherein the grain size of each component is 40 to 200 meshes. Potassium sodium water glass is used as a bonding agent; the modulus is 2.4 to 2.7; and the Baume concentration is 36 to 39. After uniformly mixing the components of the coating of the electrode, adding the water glass and stirring uniformly to obtain a mixture, a carbon steel covered electrode is manufactured by extruding the mixture on a core wire H08A; or a low-alloy steel electrode is manufactured by extruding the mixture on a low-alloy steel core wire. The electrode of the invention has the characteristics of high arc reignition, slag detachability and all-position welding adaptability, and low cost of electrode raw material.

Owner:SHANDONG JIANZHU UNIV

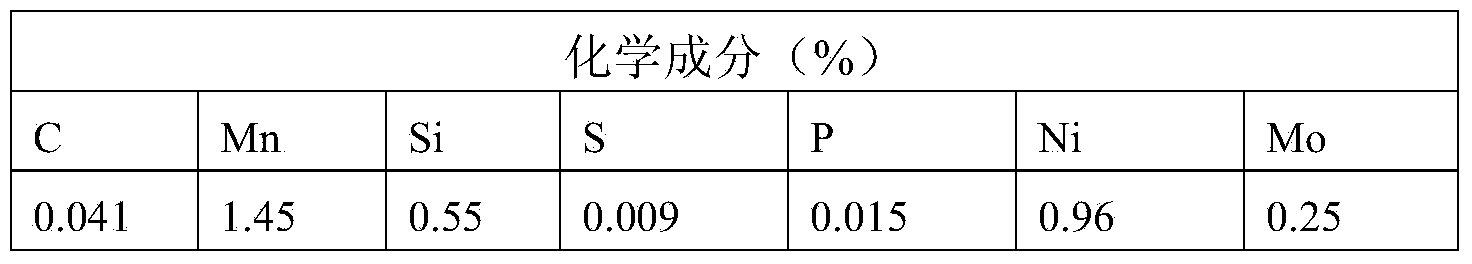

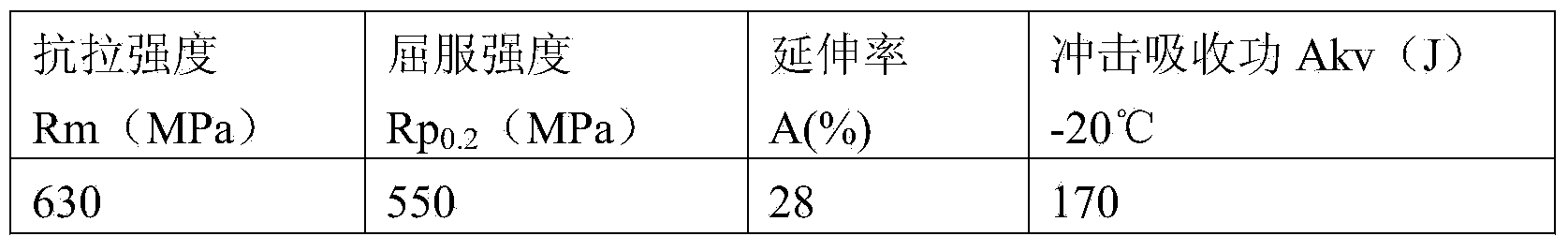

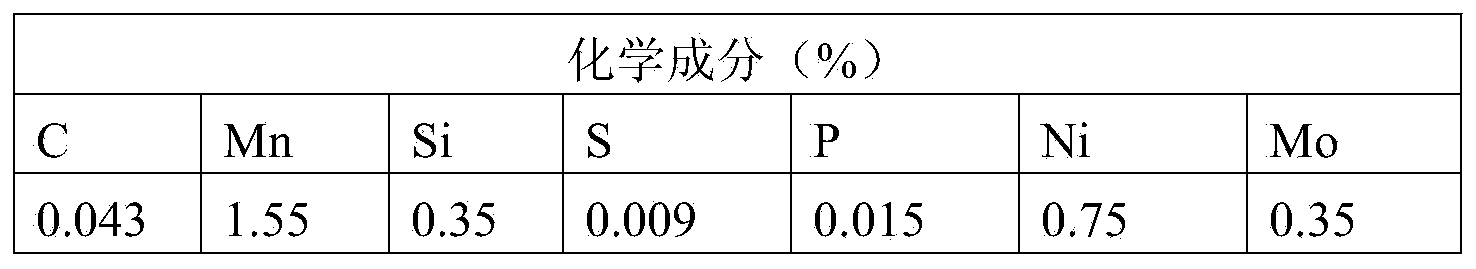

Ultralow-hydrogen high-toughness welding rod for welding of water-diversion steel penstock in hydropower station

ActiveCN103921019ASolving recipe problemsImprove dehydrogenation capacityWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention provides an ultralow-hydrogen high-toughness welding rod for welding of a water-diversion steel penstock in a hydropower station. A coating of the welding rod comprises, by mass, 40%-50% of marble, 2%-4% of dolomite, 18%-30% of fluorite, 2%-6% of quartz, 1%-3% of dehydrated feldspar, 1%-3% of zircon sand, 2%-4% of potassium titanate, 3%-6% of atomized ferrosilicon, 4%-8% of electrolytic manganese, 7%-12% of ferrotitanium, 1%-3% of light rare earth silicon iron, 0.5%-1.0% of ferromolybdenum, 2%-4% of nickel powder, and 0.5%-1.0% of rare earth fluoride. All the components are mixed according to the ratios to form the coating of the welding rod, potassium and sodium mixed water glass is added, an H04E welding core is coated with the mixture through a welding rod pressure coater, and the coated welding core is dried and shaped to form the electric welding rod. The deposited metal diffusible hydrogen content of the welding rod is 1.8 ml / 100 g, the low temperature impact toughness at minus 20 DEG C is stabilized within the range from 160 J to 180 J, and the welding requirement of the water-diversion steel penstock in a 610 MPa hydropower station can be met.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

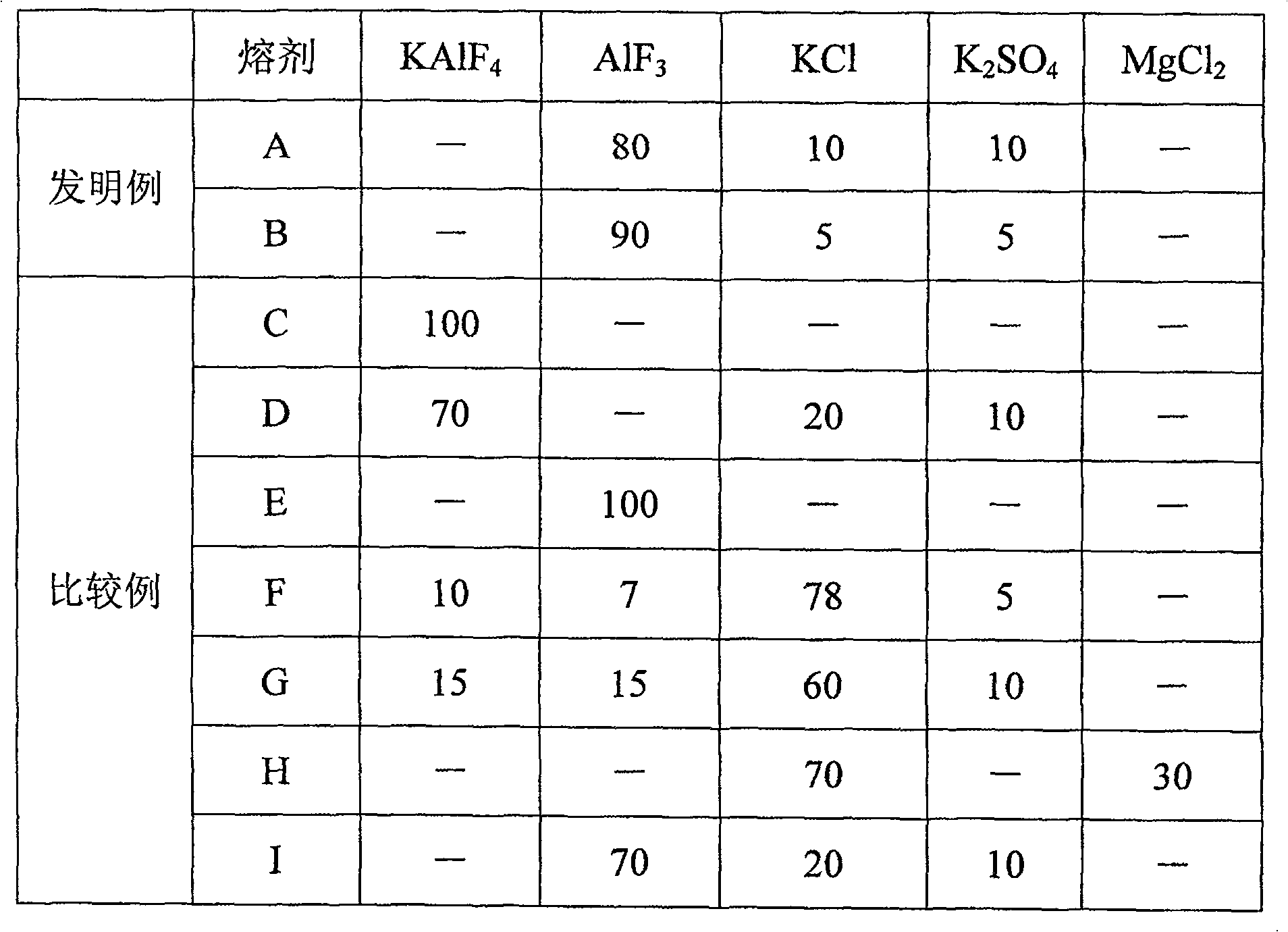

Sodium-free flux and process for treatment of molten aluminum alloy with the same

The invention provides a non-sodium-based flux that prevents unreacted flux from adhering and depositing when the flux is injected into a rotary degassing device, thereby ensuring a high slag removal effect, and a non-sodium-based flux for processing molten aluminum alloys and its treatment Method of melting aluminum alloys. The non-sodium flux contains, by mass percentage: AlF3: 80-95%, KCl: 2.5-10%, K2SO4: 2.5-10% as essential components, and the rest are other chlorides, fluorides and nitrates. A method for processing molten aluminum, comprising: maintaining the above-mentioned rotating rotor immersed in the above-mentioned molten aluminum alloy; injecting inert gas and flux into the molten metal from the above-mentioned nozzle, and rotating the rotor at a speed of 200-450rmp to make the molten metal The inclusions in the molten metal float together with the fine bubbles and flux to the surface of the molten metal to achieve degassing and slag removal.

Owner:NIPPON LIGHT METAL CO LTD

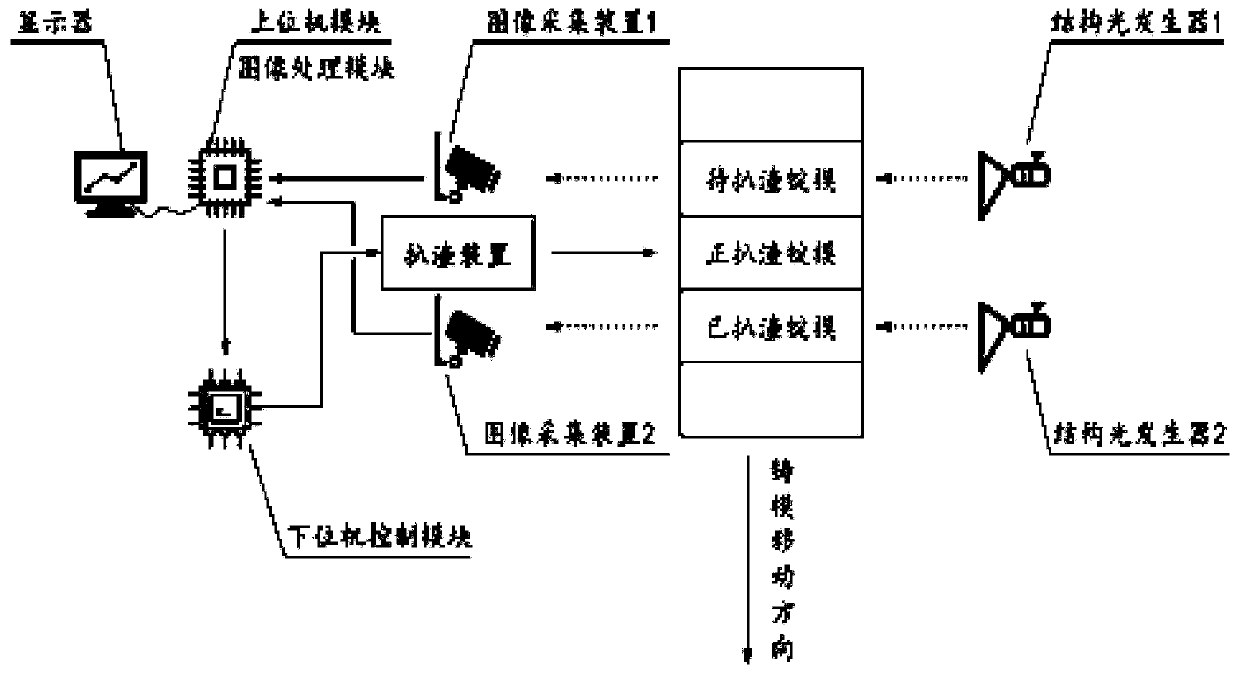

Metal cast ingot slag-off system and method

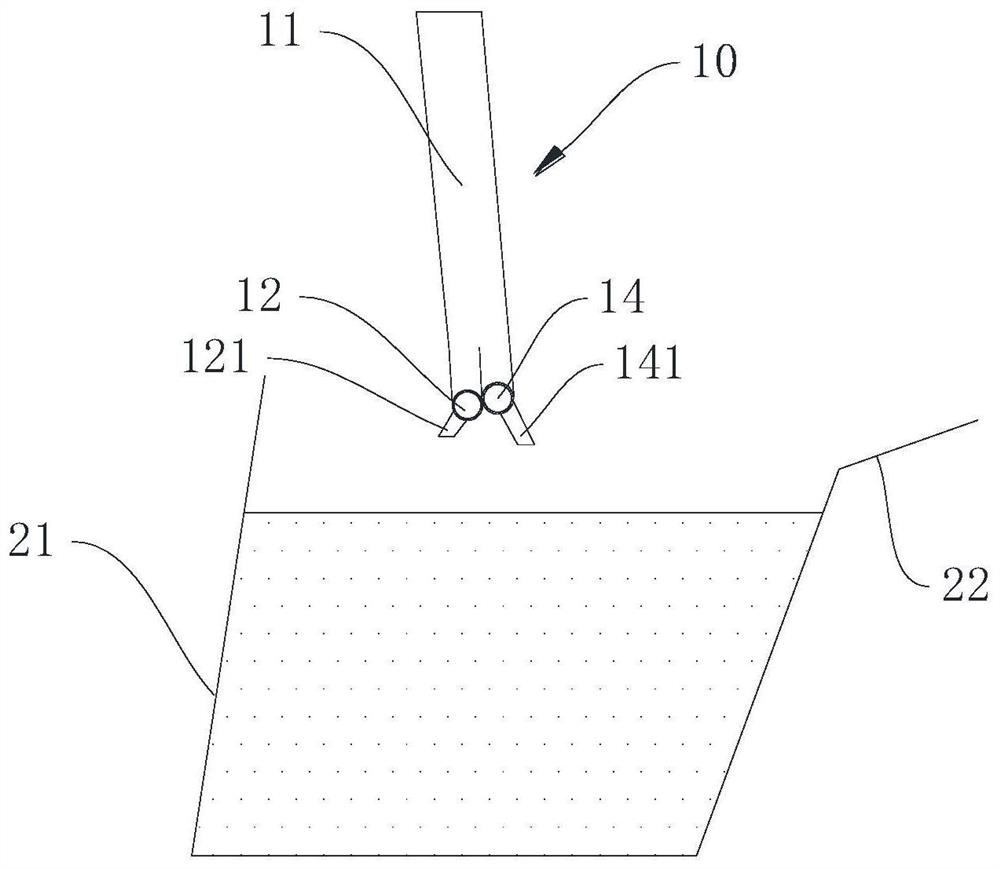

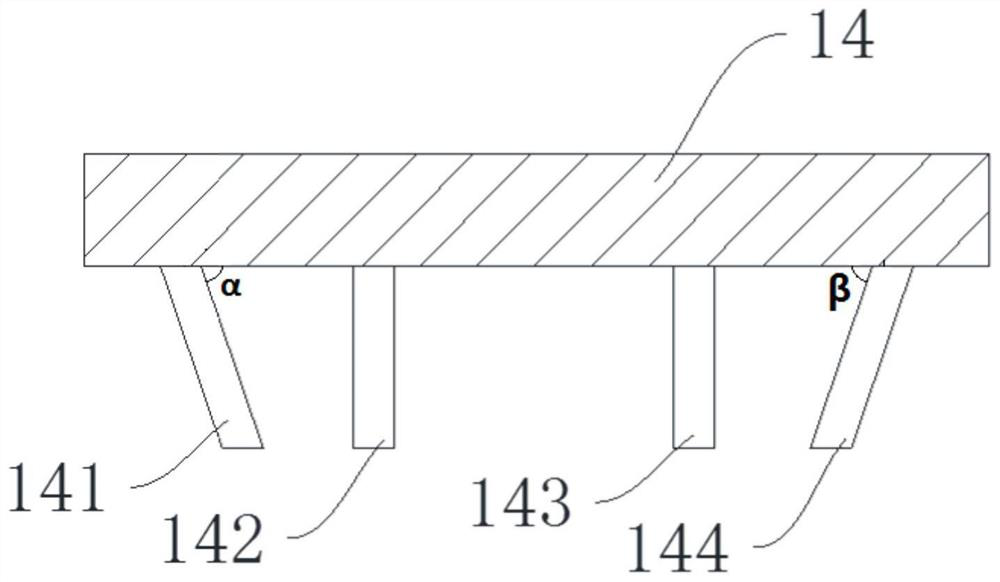

InactiveCN110666150AImprove adaptabilityExcellent slag removal performanceCasting cleaning apparatusUsing optical meansImaging processingIngot casting

The invention discloses a metal cast ingot slag-off system and method. The metal cast ingot slag-off system comprises a conveyer set, a structured light generator, an image capture device, an image processing module, an upper computer module, a lower computer control module, a display and a slag-off device. The structured light generator is arranged on one side of the conveyer set. The image capture device and the structured light generator are arranged in a pair, and the image capture device is located on the other side of the conveyer set and is used for capturing corresponding emitted lightand transmitting an image to the image processing module. The image processing module processes the image and data and calculates the thickness of a slag layer on a cast ingot before slag-off operation. The image processing module feeds back the thickness data of the slag layer to the upper computer module. The upper computer module compares the slag layer thickness with the preset slag layer thickness, a judgment is made, and an order is sent to the lower computer control module. The lower computer control module controls the slag-off device to conduct primary slag-off operation, supplementslag-off operation or discharging according to the received order. The thickness of the slag layer generated in the cast ingot casting process can be fast detected in real time, and thus movement parameters of a slag-off cutter on the slag-off device are controlled dynamically.

Owner:CINF ENG CO LTD

Sulfur-fixing agent for hot metal pretreatment of magnesium injection and deep desulphurization and desulphurization method thereof

InactiveCN101392310AGood ability to absorb sulfur and fix sulfurImproved sulfur absorption and fixation capacitySteelmakingSulfur

The invention relates to a sulfur-fixing agent for hot metal pretreatment magnesium injection deep desulphurization and a desulphurization method, which pertains to the technical field of hot metal pretreatment in the steelmaking process. The sulfur-fixing agent is added before hot metal charging or during hot metal charging in the hot metal pretreatment and the addition range is 2.0 kg / t to 4.0 kg / t iron which contains the following components by the weight percentages: CaO: 68 percent to 90 percent; MgO: 5 percent to 12 percent, SiO2: 1 percent to 5 percent, CaF2: 8 percent to 12 percent, Al2O3: 0 percent to 3 percent, MnO: 0 percent to 2 percent, S: less than 0.025 percent, and P2O5: less than 0.06 percent. The weight percentages of various slagging constituents in the sulfur-fixing agent are as follows: quick lime: 80 percent to 95 percent and fluorite: 5 percent to 20 percent. The sulfur-fixing agent has the advantages that: slag formed by adding the sulfur-fixing agent into the molten iron after magnesium injection has very high sulfur absorption capability, relatively small viscosity and relatively low melting point; after magnesium injection, a slag conglomeration agent is added to cause the slag to conglomerate into blocks which are easy to remove and resulfurization is prevented.

Owner:SHOUGANG CORPORATION

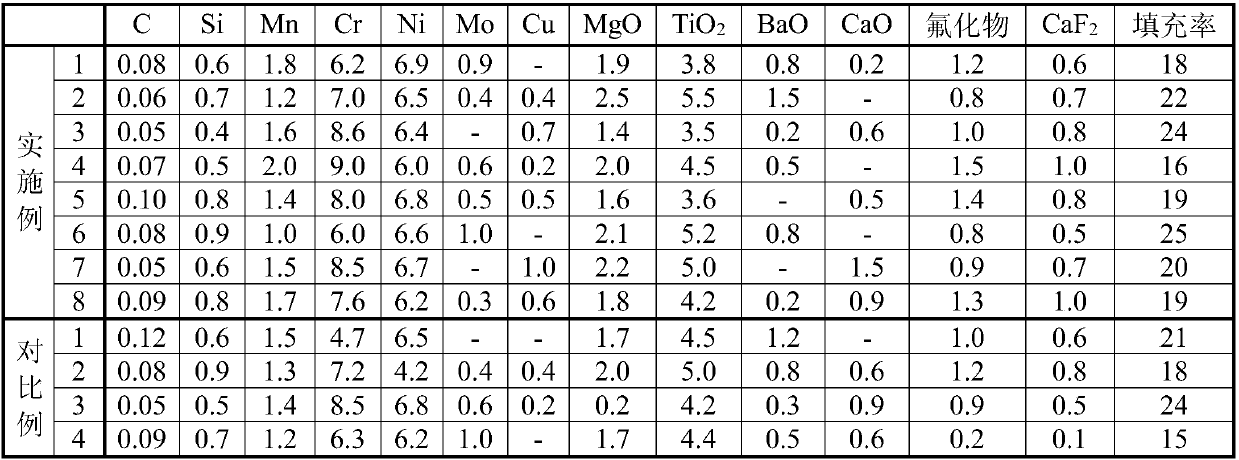

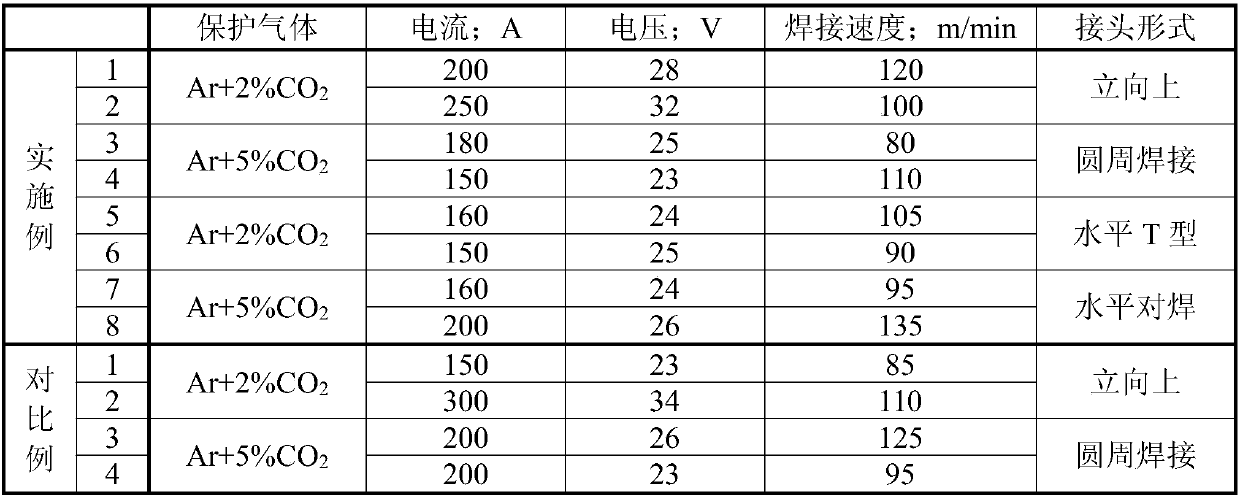

Flux-cored wire for gas shield welding for high-strength steel

InactiveCN107914097AReduce oxygen contentImprove surface qualityWelding/cutting media/materialsSoldering mediaFerricWeld metal

The invention relates to a high-strength steel gas-shielded welding flux-cored wire, which is composed of a steel sheath and a core powder, in terms of total weight percentage, C 0.04-0.10%, Si 0.3-0.9%, Mn 0.5-2.0%, Cr 5-10%, Ni 5.0-8.0%; in the core powder, the conversion value of Mg oxide MgO is 0.5-3.5%, the conversion value of Ti oxide TiO2 is 2-7%, and MgO / TiO2=0.2-0.8, fluorine Compound conversion value 0.5‑1.5, and an appropriate amount of arc stabilizer, the rest is iron. The tensile strength of the prepared weld metal is above 980MPa, which is suitable for all-position welding.

Owner:张宇

Corrosion-resistant high-toughness flux-cored wire

InactiveCN106514046AReduce oxygen contentGood dehydrogenation performanceWelding/cutting media/materialsSoldering mediaHardnessWear resistance

The invention discloses a corrosion-resistant high-toughness flux-cored wire. The corrosion-resistant high-toughness flux-cored wire is composed of a flux core and a stainless steel outer skin coating the outer side of the flux core. The flux core comprises the components in percentage by mass: 0.1-0.2% of C, 0.6-0.9% of Si, 0.1-0.3% of Mg, 0.2-0.4% of Al, 0.3-0.6% of B, 1.2-2% of Mn, 3.5-5% of Ni, 14.5-19% of Cr, 1.8-2.5% of Ti, 0.05-0.15% of Sr, 0.08-0.15% of Mo, 0.04-0.12% of V, 0.02-0.35% of Zr, 0.08-0.15% of Nd, 0.01-0.02% of Sc and the balance Fe and inevitable impurities. The corrosion-resistant high-toughness flux-cored wire disclosed by the invention is good in toughness, hardness, strength, corrosion resistance and wear resistance, and the service life of a metal member is prolonged.

Owner:天长市通联焊业有限公司

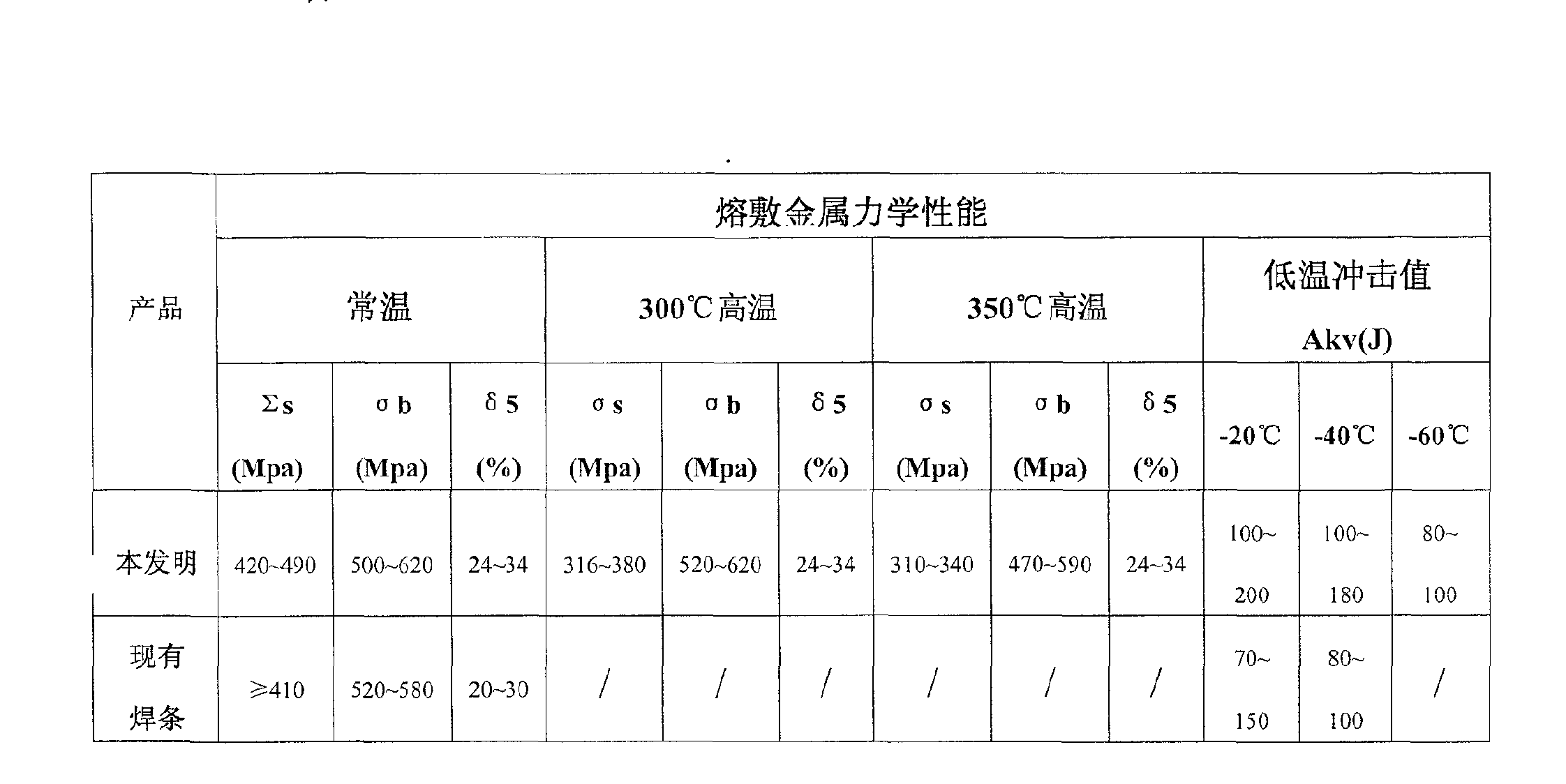

High tenacity coating material for low-alloy steel covered arc-welding electrode

ActiveCN101092010AReduce slag alkalinityImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCarbon steelMechanical property

The invention relates to the field of structural steel welding material, especially relating to a high-flexibility, low-alloy welding rod coating whose basic composition includes: CaO:58-60wt%; CaF2:25-27wt%; SiO2:5-8wt%; TiO2:3-5wt%; Al2O3+Na2O+K2O: 3-5wt%; uniformly mixing their powders and making it; adding water glass to the above powders and blending uniformly and then press-coating the mixture on the welding rods made of low-carbon steel core wire, and the metals coated with it have considerably excellent mechanical property and low-temperature shock flexibility.

Owner:上海焊接器材有限公司

Welding wire for low alloy steel

InactiveCN106695168AReduce oxygen contentImprove crack resistanceWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention discloses a welding wire for low alloy steel. The welding wire is prepared from components as follows: C, Si, Cu, Mg, Nb, Al, K, Mn, Ni, Cr, Ti, Sr, Mo, V, Nd, Ce and the balance of Fe and inevitable impurities. The welding wire for low alloy steel has good welding performance, during welding, electric arc is stable, small splashing is produced, welding fluid liquidity is good, the weld surface is uniformly covered with welding slag, so that interfacial tension of the welding slag and deposited metal is increased, slag detachability is improved, formation of the obtained weld is good, the weld surface is free of cracks and pores, and the deposited metal has good mechanical properties.

Owner:天长市通联焊业有限公司

Coating of austenitic stainless steel electrode, electrode, preparation method and application

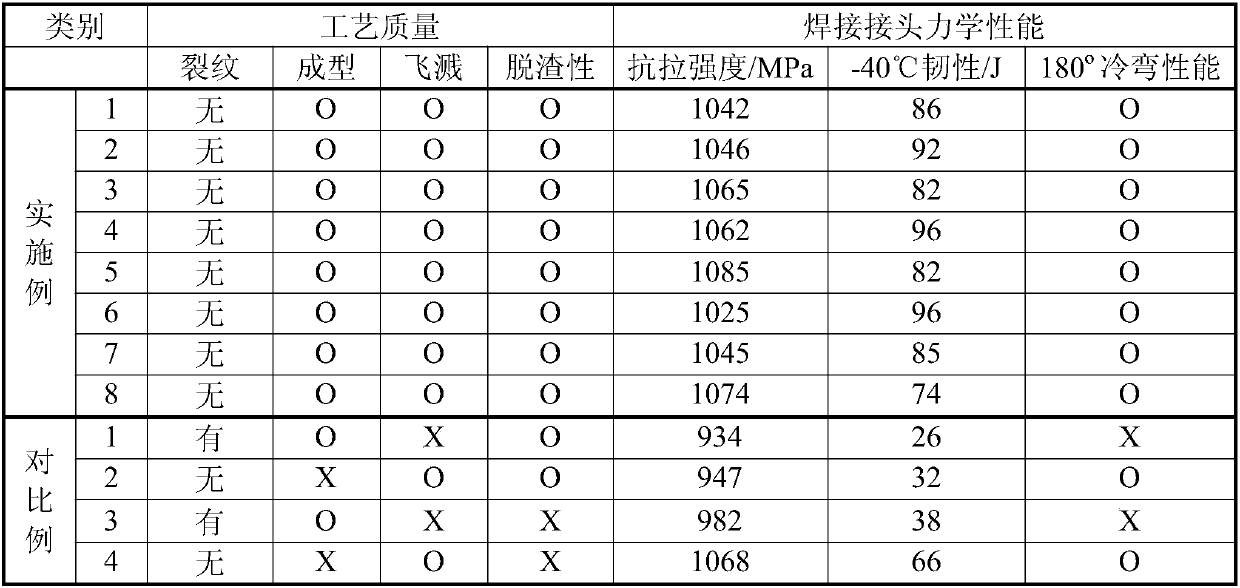

ActiveCN112658532AExcellent slag removal performanceArc stabilizationEnergy inputWelding/cutting media/materialsFerrosiliconManganese

The invention discloses a coating of an austenitic stainless steel electrode, the electrode, a preparation method and an application, and solves the problems that the existing electrode is poor in mechanical property and difficult to meet the welding requirement. The raw materials of the coating of the electrode comprise the following raw materials in parts by weight: 7.0-10.0 parts of marble, 0.5-1.5 parts of barium carbonate, 2.0-4.0 parts of fluorite, 3.0-5.0 parts of fluoride, 4.0-6.0 parts of rutile, 0.5-2.0 parts of mica, 0.5-1.5 parts of electrolytic manganese, 0.5-1.5 parts of ferrotitanium, 0.5-1.5 parts of ferrosilicon, 3.0-5.0 parts of ferrochromium, 3.0-5.0 parts of metallic nickel, 0.0-1.5 parts of ferro-molybdenum, 0.5-1.0 part of nitride ferrochrome sodium carbonate and 0.2-0.5 part of sodium carbonate. The electrode further comprises an iron-chromium-nickel-molybdenum-manganese-nitrogen alloy core wire. The coating has the advantages of excellent mechanical properties of deposited metal, capability of meeting the special requirements of required welding and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Slag conglomeration agent for hot metal pretreatment of magnesium injection and deep desulphurization and use method thereof

The invention relates to a slag conglomeration agent applied to hot metal pretreatment magnesium injection deep desulphurization and an application method thereof, which pertain to the technical field of hot metal pretreatment in the steelmaking process. The slag conglomeration agent is sealed and packaged at 3kg to 7kg after magnesium injection or scattered on the slag surface evenly in the formof particulate. The addition amount is 0.5 kg / t to 1.0kg / t iron which contains the following components by the weight percentages: MgO: 32 percent to 40 percent, SiO2: 0.4 percent to 1.1 percent, S: 0.010 percent to 0.025 percent, water: 0 percent to 0.5 percent, and the rest is CaO and inevitable impurities. The weight percentages of various slagging constituents in the slag conglomeration agentare as follows: light-burned dolomite: 85 percent to 100 percent, and quick lime: 0 percent to 15 percent. The slag conglomeration agent has the advantages that: the slag conglomeration agent can be added immediately after magnesium injection to cause slag to form into blocks which are easy to remove, and resulfurization is prevented by adding acid slag conglomeration agent that is generally adopted.

Owner:SHOUGANG CORPORATION

Active agent for laser welding of aluminum-magnesium alloy and application of active agent

ActiveCN107775213AExcellent slag removal performanceImprove performanceWelding/cutting media/materialsSoldering mediaActive agentSilicon dioxide

The invention provides an active agent for laser welding of aluminum-magnesium alloy and an application of the active agent and solves the problem about welding penetration of a thick plate by aluminum alloy laser welding. The active agent is prepared from the following raw materials in percentage by mass: 45%-55% of silicon dioxide, 16%-22% of calcium oxide, 10%-18% of manganese dioxide and 29%-5% of carbonate of calcium. According to the active agent, non-toxic components are used for substituting for highly toxic fluoride; due to the addition of Ca, Mn and the other elements, the arc shapeand the surface tension of a welding molten pool are changed, and the deslagging property of the active agent and the appearance of the aluminum-magnesium alloy after welding are enhanced; performanceof the active agent is enhanced by strictly controlling the particle size range. The laser welding quality of the aluminum alloy is ensured while the welding penetration is enhanced.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

Coating material for low-alloy steel electrode with high tenacity

ActiveCN100467196CReduce slag alkalinityImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCarbon steelMechanical property

The invention relates to the field of structural steel welding material, especially relating to a high-flexibility, low-alloy welding rod coating whose basic composition includes: CaO:58-60wt%; CaF2:25-27wt%; SiO2:5-8wt%; TiO2:3-5wt%; Al2O3+Na2O+K2O: 3-5wt%; uniformly mixing their powders and making it; adding water glass to the above powders and blending uniformly and then press-coating the mixture on the welding rods made of low-carbon steel core wire, and the metals coated with it have considerably excellent mechanical property and low-temperature shock flexibility.

Owner:上海焊接器材有限公司

Sodium-free flux and process for treatment of molten aluminum alloy with the same

The invention provides a sodium-free flux which is to be used in treating a molten aluminum alloy in a rotary flux injection / degassing apparatus and which can inhibit the adhesion and build-up of unreacted flux and attain high deslaging effect; and a process for treatment of a molted aluminum alloy with the flux, more specifically, a sodium-free flux which consists by mass of 80 to 95 % AlF3, 2.5 to 10% KCl, and 2.5 to 10 % K2SO4 as the essential components and at most 5 % total of other chlorides, fluorides and nitrates as the balance component; and a process for treatment of an aluminum alloy which comprises keeping the rotor of the above apparatus in a state immersed in a molten aluminum alloy, injecting an inert gas and the above flux into the molten aluminum alloy from nozzles, and rotating the rotor at 200 to 450 rpm to thereby make inclusions contained in the molten alloy float up to the surface of the molten alloy together with fine bubbles and the flux and thus carry out degassing and deslaging.

Owner:NIPPON LIGHT METAL CO LTD

Slag conglomeration agent for treating magnesium and magnesium alloy

Owner:SOUTHWEST UNIV

Alkaline welding rod coating capable of improving welding process property

InactiveCN1295056CFine splash particlesReduce manufacturing costWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The alkaline welding rod coating with raised welding performance consists of: marble 39-45 wt%, silica mud 3-10 wt%, fluorite 16-25 wt%, metal Mn 2-4 wt%, Si-Fe alloy 0.5-3 wt%, Ti-Fe alloy 8-12 wt%, cellulose 0.5-1.0 wt%, titania 3-9 wt%, atomized iron powder 6-15 wt% and graphite+Na2CO3 1-2.5 wt%. The said components are mixed, and the mixture is then coated with sodium water glass as adhesive onto low alloy steel welding core to produce alkaline low alloy steel welding rod or onto carbon steel welding core to produce alkaline carbon steel welding rod. The alkaline welding rod with the welding rod coating has excellent welding performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

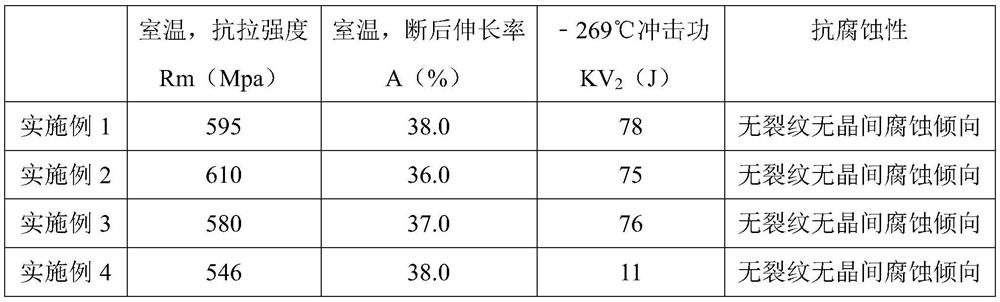

An ultra-low hydrogen high toughness welding rod for welding penstocks in hydropower stations

ActiveCN103921019BSolving recipe problemsImprove dehydrogenation capacityWelding/cutting media/materialsSoldering mediaPotassiumRare earth

The invention provides an ultralow-hydrogen high-toughness welding rod for welding of a water-diversion steel penstock in a hydropower station. A coating of the welding rod comprises, by mass, 40%-50% of marble, 2%-4% of dolomite, 18%-30% of fluorite, 2%-6% of quartz, 1%-3% of dehydrated feldspar, 1%-3% of zircon sand, 2%-4% of potassium titanate, 3%-6% of atomized ferrosilicon, 4%-8% of electrolytic manganese, 7%-12% of ferrotitanium, 1%-3% of light rare earth silicon iron, 0.5%-1.0% of ferromolybdenum, 2%-4% of nickel powder, and 0.5%-1.0% of rare earth fluoride. All the components are mixed according to the ratios to form the coating of the welding rod, potassium and sodium mixed water glass is added, an H04E welding core is coated with the mixture through a welding rod pressure coater, and the coated welding core is dried and shaped to form the electric welding rod. The deposited metal diffusible hydrogen content of the welding rod is 1.8 ml / 100 g, the low temperature impact toughness at minus 20 DEG C is stabilized within the range from 160 J to 180 J, and the welding requirement of the water-diversion steel penstock in a 610 MPa hydropower station can be met.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Amorphous smelting flux and preparation method and application thereof

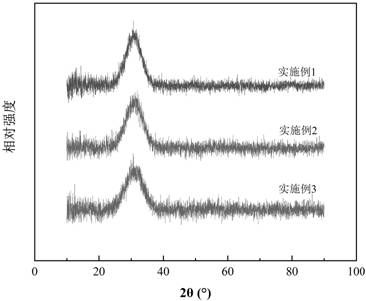

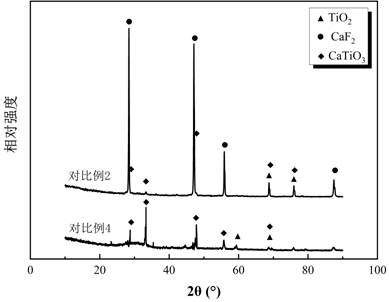

ActiveCN113695788AAdjust oxygen contentAdjust contentArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld seam

The invention relates to the technical field of welding, in particular to an amorphous smelting flux and a preparation method and application thereof. The amorphous smelting flux is prepared from the following components including, by mass percent, 20%-25% of CaF2, 30%-35% of CaO, 30%-35% of SiO2 and 5%-15% of TiO2. The amorphous smelting flux has the advantages of being free of moisture absorption, good in slag detachability, capable of effectively reducing the contents of harmful elements such as P and S in a welding seam and the like by adopting the specific components and dosages thereof. Meanwhile, the flux is in an amorphous state, the welding seam obtained after welding is uniform in composition, the mechanical property of the welding seam is excellent, and particularly the low-temperature toughness of the welding seam is good.

Owner:NORTHEASTERN UNIV LIAONING

Method for treating fused aluminium alloy through flux spraying method

InactiveCN109402437AEvenly dispersedExcellent slag removal performanceRare earth5005 aluminium alloy

The invention relates to a method for treating fused aluminium alloy through a flux spraying method. The aluminium alloy is prepared from, by weight, 13-45 parts of Si, 0.5-5 parts of Mg, 0.05-0.20 part of Mn, 0.1-0.4 part of Cu, 0.10-0.20 part of Cr, 0.1-0.3 part of Zn, 0.1-0.6 part of Fe, 0.1-1 part of rare earth (RE) and the balance aluminium; in the step of treating the fused aluminium alloy through the flux spraying method, a spray gun is used, inert gas is used as a carrier, powder flux is sprayed in the direction vertical to the flowing direction of aluminium alloy liquid, even dispersion of the flux in fused aluminium is achieved, and the residue removal effect is obviously improved; meanwhile, the application amount of flux powder can be lowered, and the efficient method of treating the fused aluminium alloy through energy saving is established.

Owner:徐州一宁铝业科技有限公司

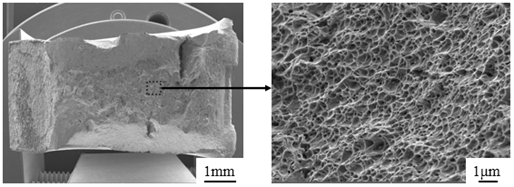

Sintered flux for welding hsla steel and preparation method thereof

ActiveCN113695789BReasonable distribution contentPromote formationArc welding apparatusWelding/cutting media/materialsSlag (welding)Toughness

The invention relates to the field of welding technology, in particular to a sintered flux for welding HSLA steel and a preparation method thereof. The sintering flux for welding HSLA steel includes the following components in terms of mass percentage: CaF 2 50%~60%, ZrO 2 25%~35%, SiO 2 13%~17% and Na 2 O 2%~5%; the welding method is submerged arc welding. The sintered flux has good surface morphology, low temperature toughness and slag removal performance in the welding process, uniform weld composition and structure, high tensile strength of weld metal, no defects, strong stability during welding, and high safety performance .

Owner:NORTHEASTERN UNIV LIAONING

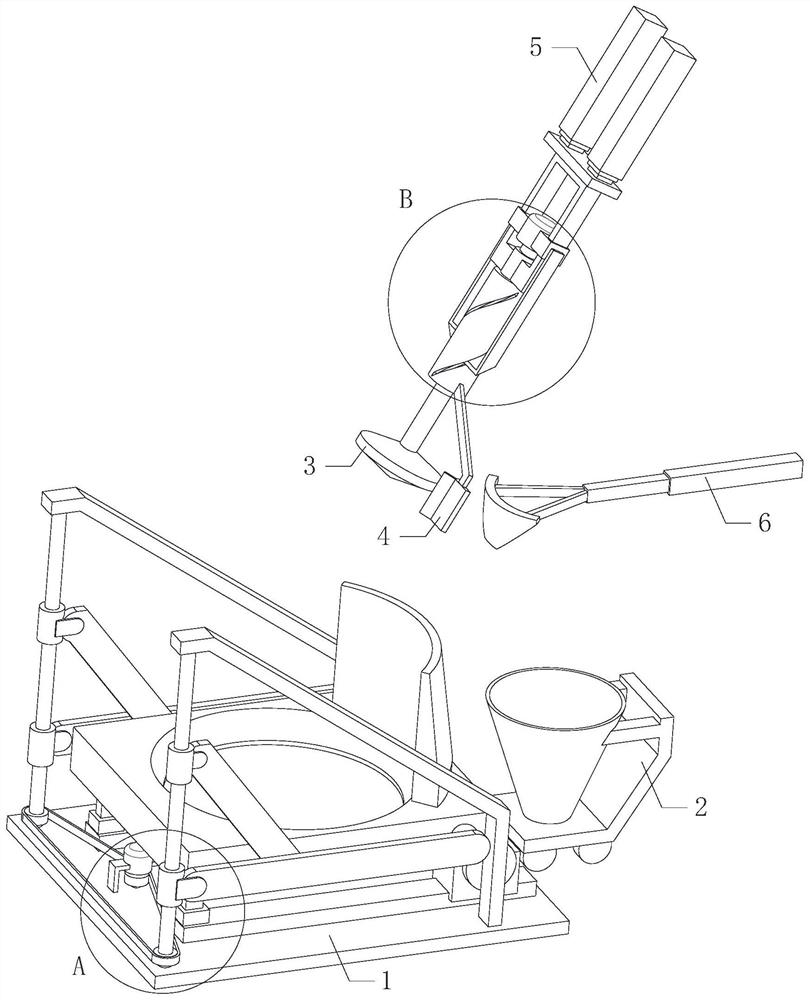

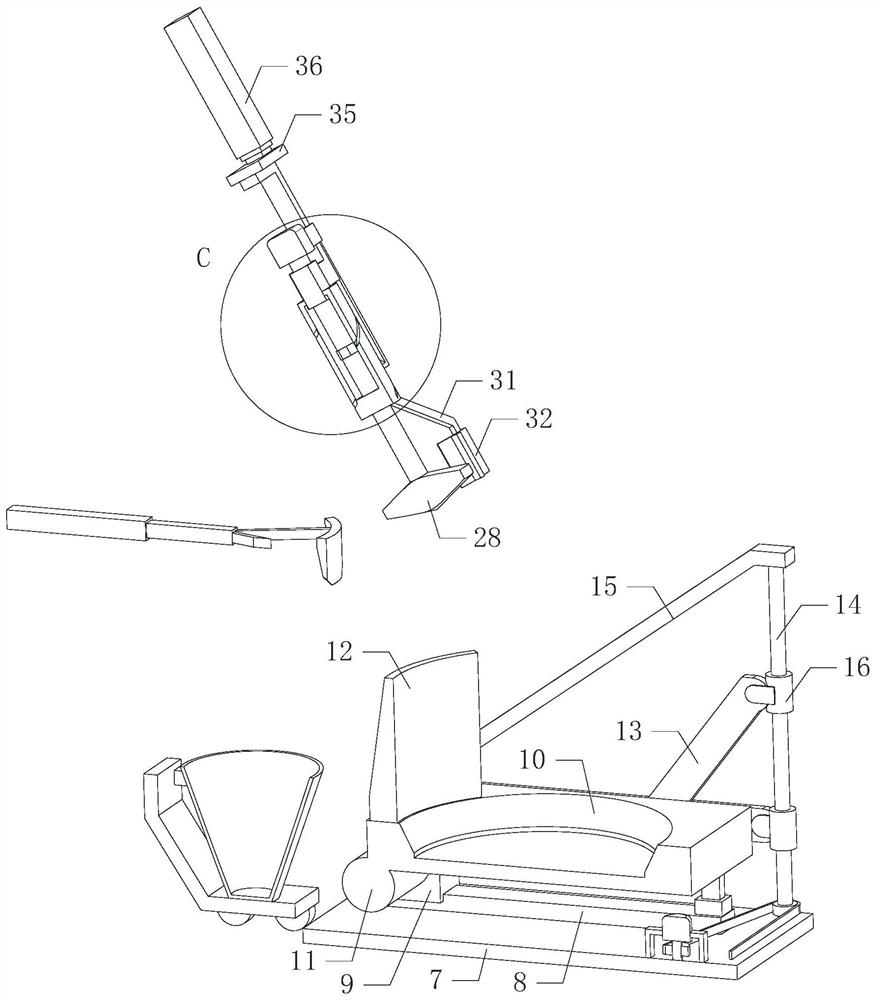

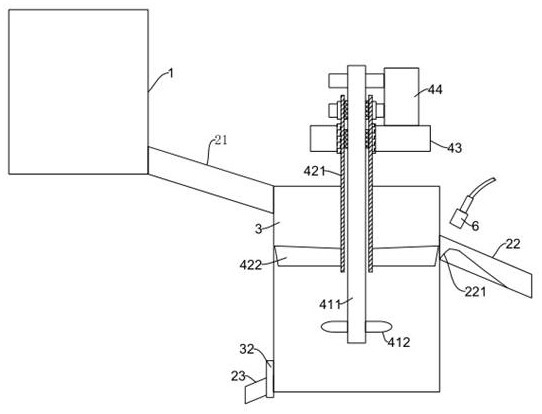

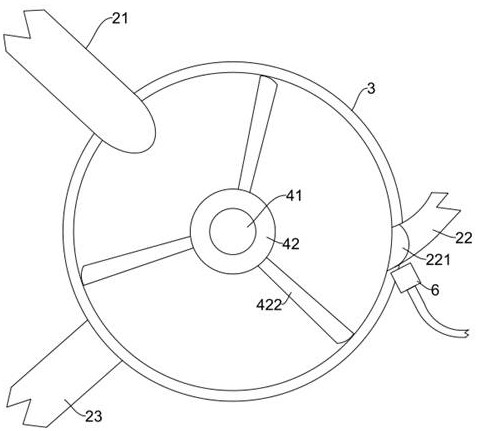

Safe and reliable molten iron pretreatment automatic slagging-off method and system

InactiveCN113337671AEfficient removalHigh degree of automationCasting cleaning apparatusProcess efficiency improvementEngineeringMolten steel

The invention relates to the technical field of steel smelting, in particular to a safe and reliable molten iron pretreatment automatic slagging-off method and system. The system comprises an inclination mechanism, a collection vehicle, an oscillation mechanism, an arc-shaped reciprocating type scraping mechanism, a pushing mechanism and a slagging-off device. According to the slagging-off manner, the automation degree of slagging-off work can be effectively improved, the slagging-off manner is simplified, manpower and time are saved, the working efficiency is improved, residues in a ladle are effectively removed, the slagging-off effect and the purity of molten steel are effectively improved, meanwhile, the situation that workers are scalded by the ladle during manual slagging-off is avoided, and practicability is improved.

Owner:江苏坤洋翰光能源技术集团有限公司

Beta-amylase production system and production process thereof

PendingCN114350483AReduce adhesionStrengthen the deslagging effectBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryProcess engineering

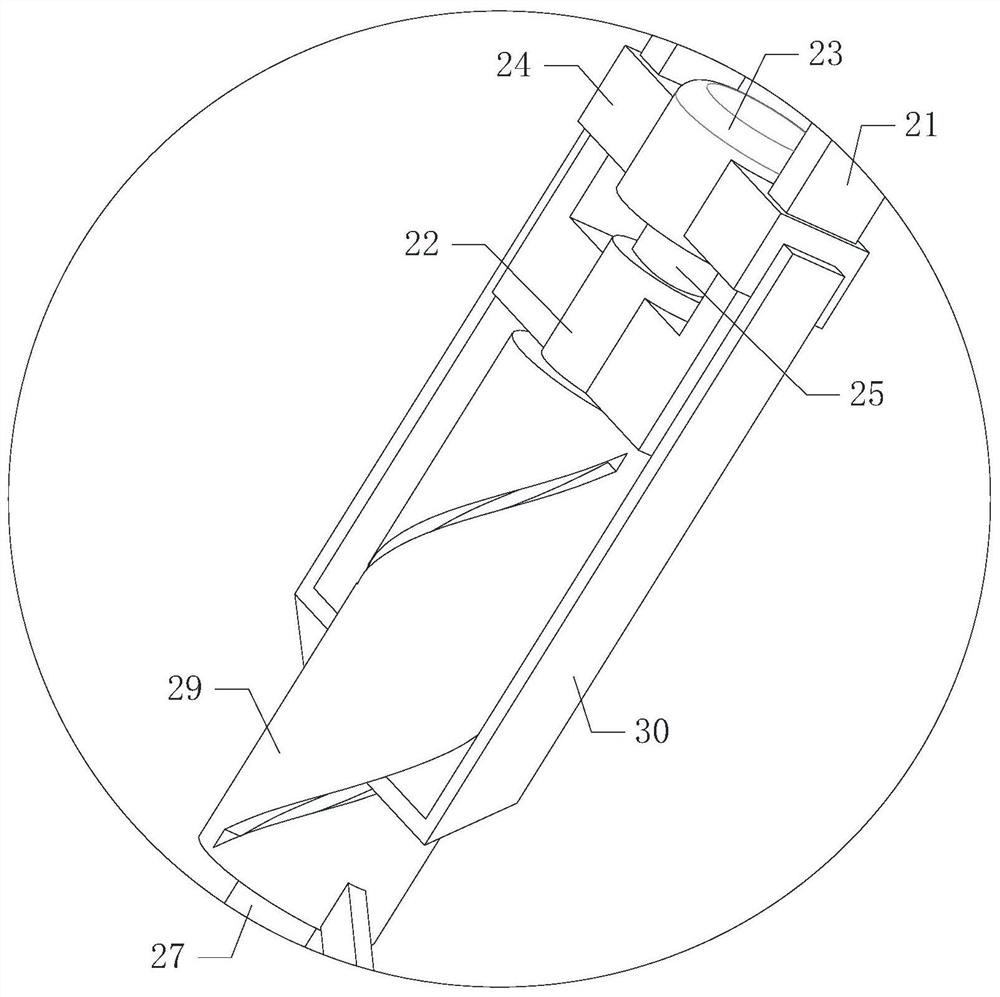

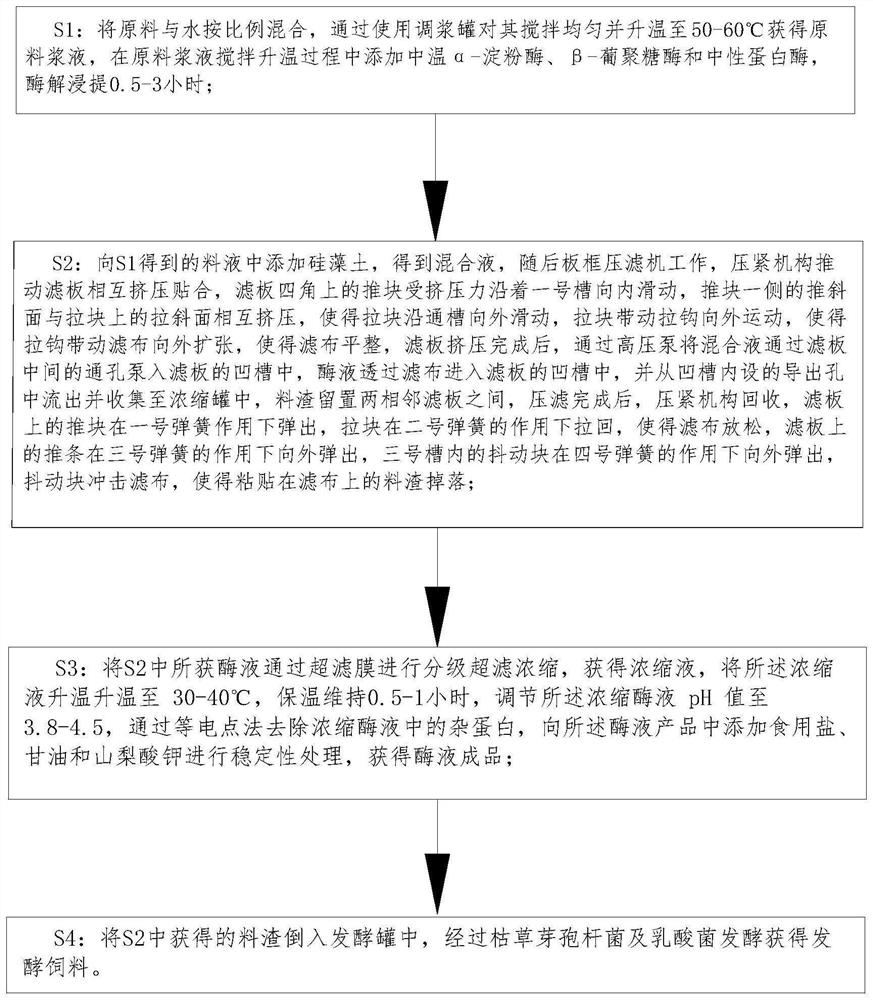

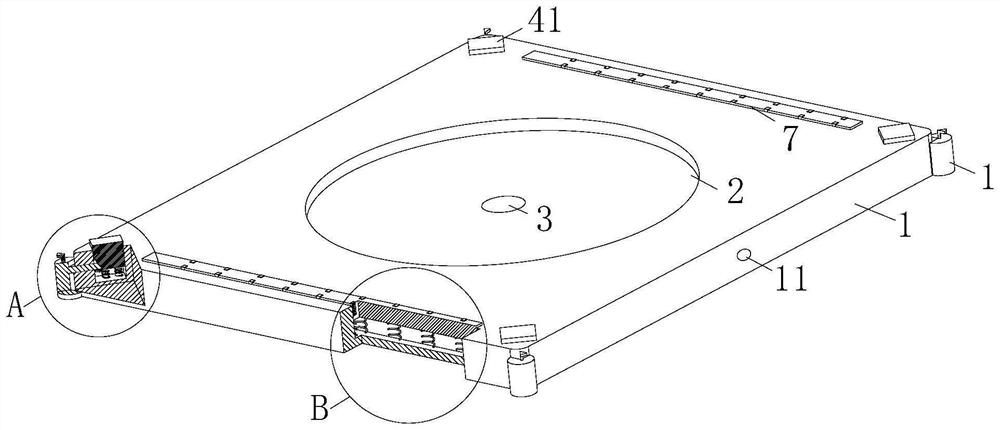

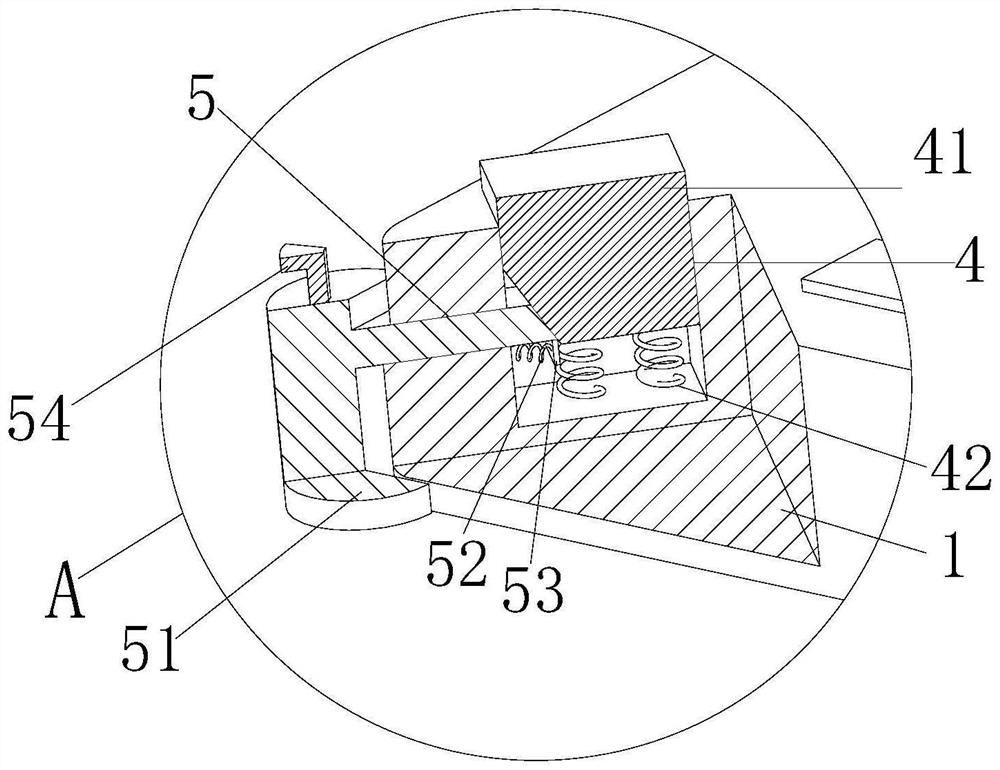

The invention relates to the technical field of biological enzyme preparations, in particular to a beta amylase production system and a production process thereof. The beta-amylase production system comprises a size mixing process, a filtering process, a concentration and impurity removal process, an enzyme liquid stabilizing process and a material residue treatment process. Wherein in the filtering process, a plate-and-frame filter press is used for carrying out filter-pressing separation on feed liquid; grooves, through grooves, push blocks, pull blocks, first springs and second springs are arranged on the filter plate of the plate-and-frame filter press, in the extrusion process of the filter plate, the push blocks located at the four opposite angles of the filter plate slide downwards along the first grooves, the push blocks push the pull blocks to slide outwards along the through grooves in the downward sliding process, and in the outward sliding process of the pull blocks, the pull blocks are pushed to slide outwards along the through grooves. The drag hooks drive the filter cloth to expand outwards, so that the filter cloth is tensioned outwards along the four corners of the filter plates, the filter cloth is automatically leveled in the pressing process, and the situation that the leakage amount of mixed liquid between the filter plates is large due to the fact that the filter cloth is wrinkled in the pressing process is prevented.

Owner:路莹

Automatic deslagging device of smelting furnace

PendingCN113566586AReduce labor intensityImprove work efficiencyCharge manipulationLiquid storage tankEngineering

The invention relates to the field of metal smelting preparation, in particular to an automatic deslagging device of a smelting furnace, which comprises a liquid storage tank, a first discharging channel, a deslagging furnace, a stirring mechanism, a second discharging channel and a third discharging channel; a stirring mechanism is arranged on the deslagging furnace and comprises a first stirring part, a second stirring part, a first bearing frame and a gearbox, the first stirring part comprises a first stirring shaft and a first stirring blade, the second stirring part comprises a second stirring shaft and a second stirring blade, and the second stirring shaft is rotatably connected with the first bearing frame; a side wall opening is arranged on the upper portion of the deslagging furnace, a feeding end of the third discharging channel is communicated with the bottom of the deslagging furnace, and a feeding end of the second discharging channel is communicated with the upper portion of the deslagging furnace through the side wall opening; and in the vertical direction, the upper portion of the second stirring blade is not lower than the lowest point of the side wall opening, and the lower portion of the second stirring blade is not higher than the lowest point of the side wall opening. Continuous and automatic refining and deslagging are realized, the labor intensity is reduced, and the operation efficiency is improved.

Owner:河南恒通新材料有限公司

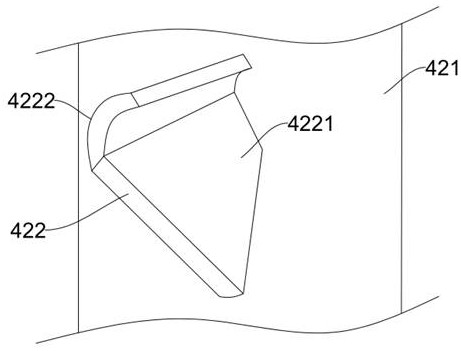

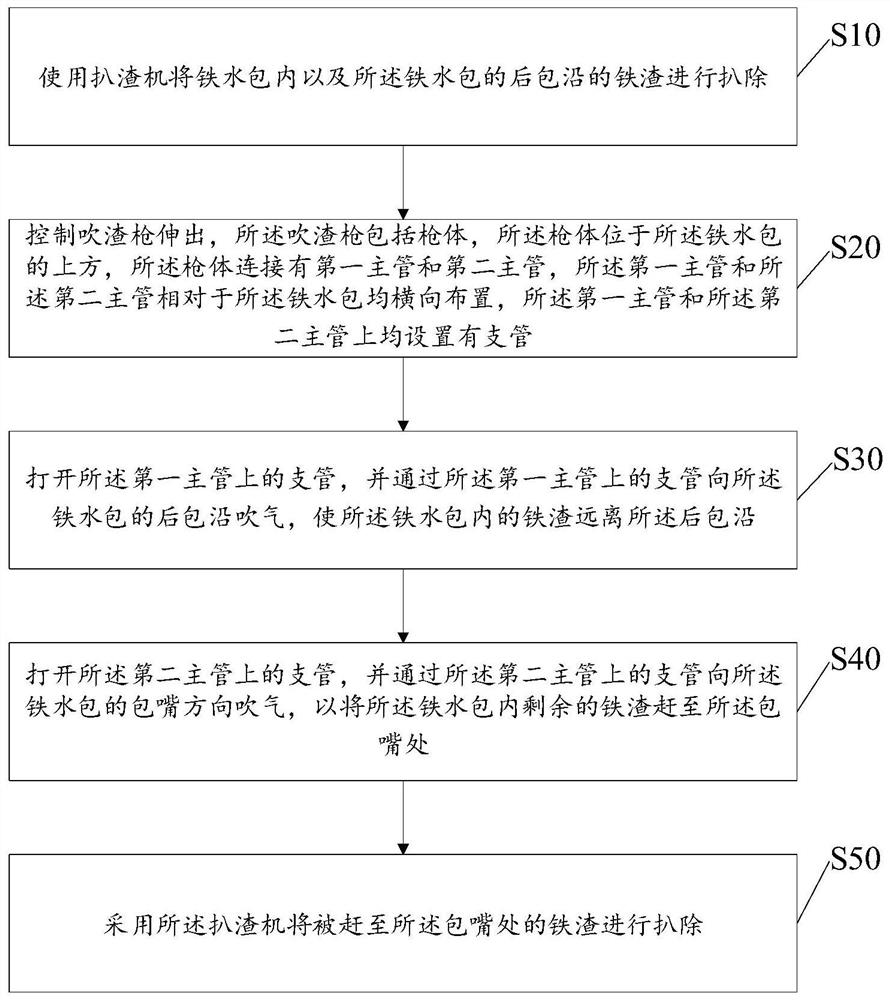

A method for removing slag from ladle

The embodiment of the present invention provides a ladle slag removal method, the method comprising: using a slag removal machine to remove the iron slag in the ladle and the rear edge of the ladle; controlling the extension of the slag blowing gun; Open the branch pipe on the first main pipe, and blow air to the back edge of the ladle through the branch pipe on the first main pipe, so that the iron slag in the ladle is away from the back edge of the ladle; the branch pipe on the second main pipe, and blow air towards the nozzle of the ladle through the branch pipe on the second main pipe, so as to drive the remaining iron slag in the ladle to the nozzle; The slag scraper will be driven to the iron slag at the mouth to remove it. The invention solves the problem that the current slag removal tool has high refractory material loss and unclean slag removal, which leads to a large amount of sulfur returned in subsequent smelting and is unsafe.

Owner:BEIJING SHOUGANG CO LTD

A kind of amorphous melting flux and its preparation method and application

ActiveCN113695788BAdjust oxygen contentAdjust contentArc welding apparatusWelding/cutting media/materialsSlag (welding)Weld seam

The invention relates to the field of welding technology, in particular to an amorphous melting flux and its preparation method and application. Amorphous melting flux is made of the following components in mass percent: CaF 2 20%~25%, CaO 30%~35%, SiO 2 30%~35% and TiO 2 5%~15%. The amorphous smelting flux has the advantages of no moisture absorption, good slag detachability, and effective reduction of harmful elements such as P and S in the weld by adopting specific components and dosages thereof. At the same time, the flux is in an amorphous state, and the composition of the weld seam obtained after welding is uniform, and the mechanical properties of the weld seam are excellent, especially the low temperature toughness of the weld seam is good.

Owner:NORTHEASTERN UNIV LIAONING

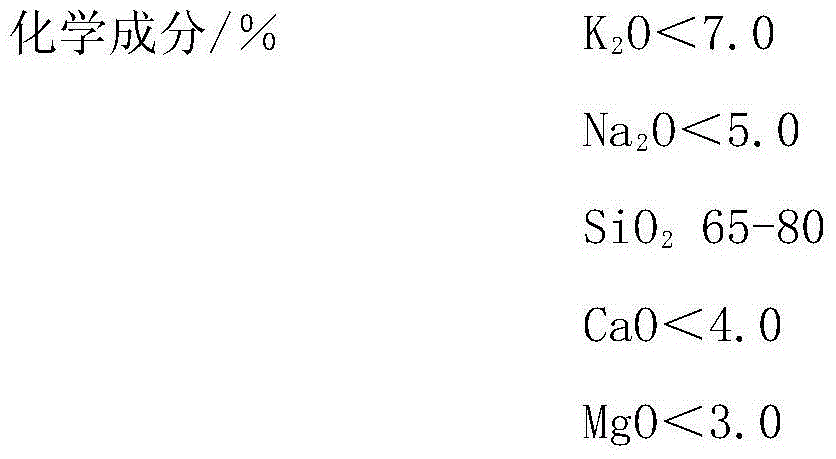

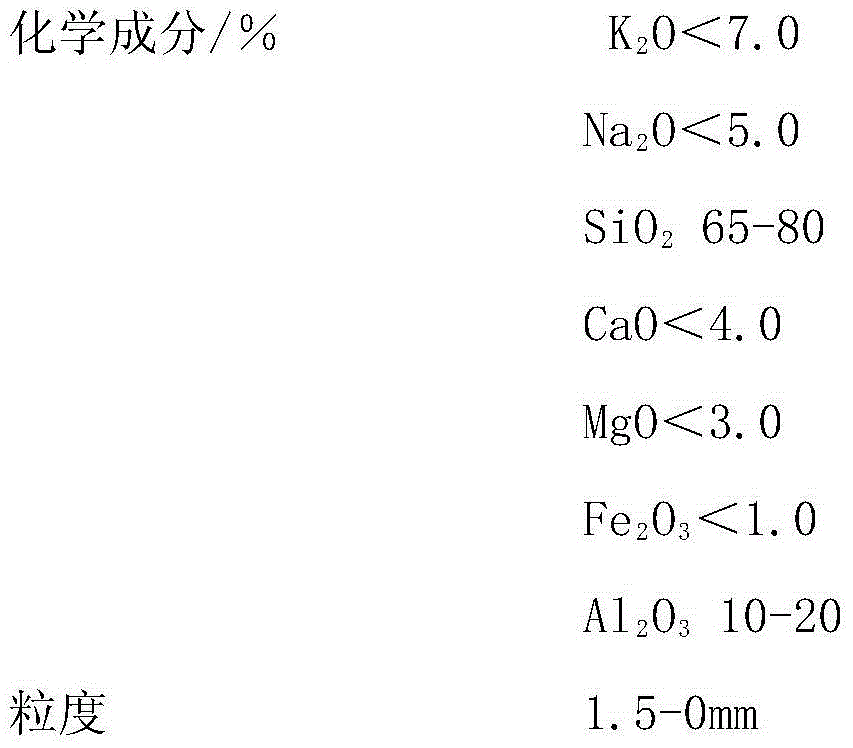

Slag fluxing agent for molten steel and production method of slag fluxing agent

The invention relates to a slag fluxing agent for molten steel and a production method of the slag fluxing agent. The slag fluxing agent comprises components in parts by weight as follows: 30-50 parts of potassium feldspar, 30-50 parts of low albite and 10-20 parts of fused quartz sand, wherein in the potassium feldspar, the content of K2O is smaller than 10%, the content of Na2O is 3%-5%, and the content of SiO2 is larger than 65%; in the low albite, the content of K2O is smaller than 1%, the content of Na2O is smaller than 10%, and the content of SiO2 is larger than 65%; the content of SiO2 in the fused quartz sand is larger than 99%. The slag fluxing agent has high slag accretion capability, can cleanly remove slag, reduces iron loss, improves the slag removal effect, can remove wall hanging residues, absorbs inclusions in steel, purifies the molten steel and has high slag fluxing performance; the content of original slag accounting for about 5% of the molten steel can be reduced to about 1% after slag fluxing, the quality of steel is improved to a great extent, and use demands of a user are met.

Owner:海城市金福锋科技有限公司

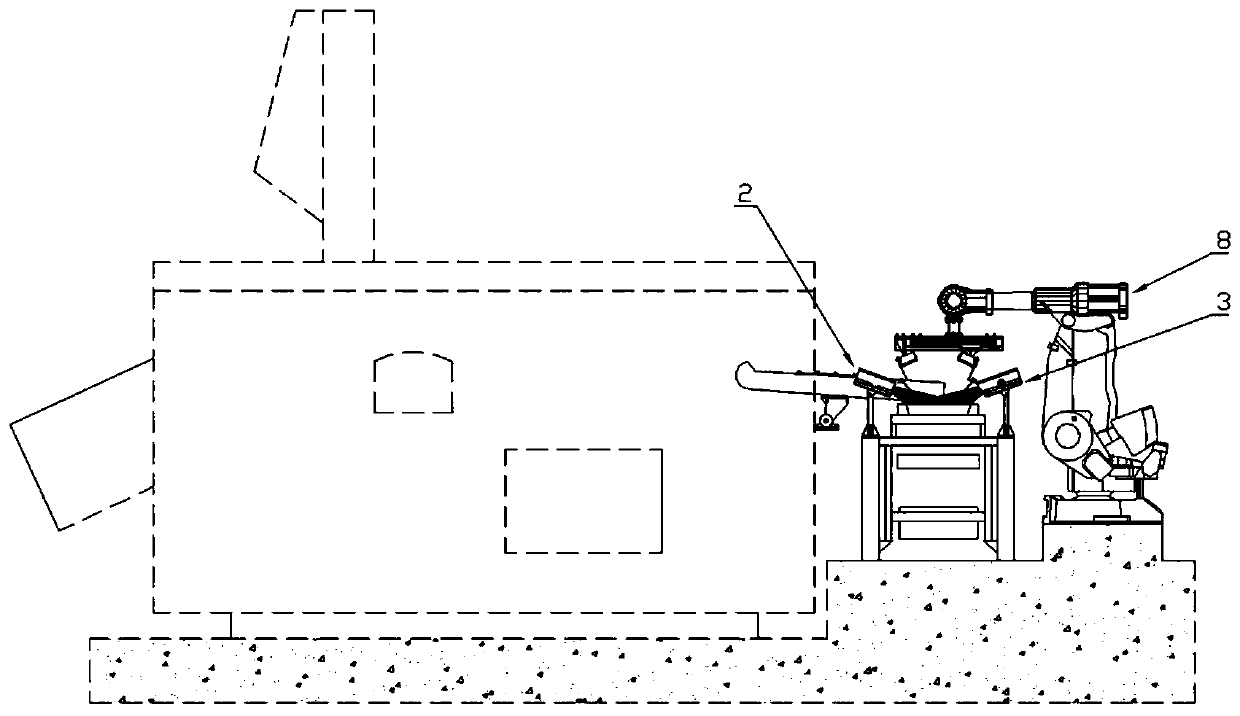

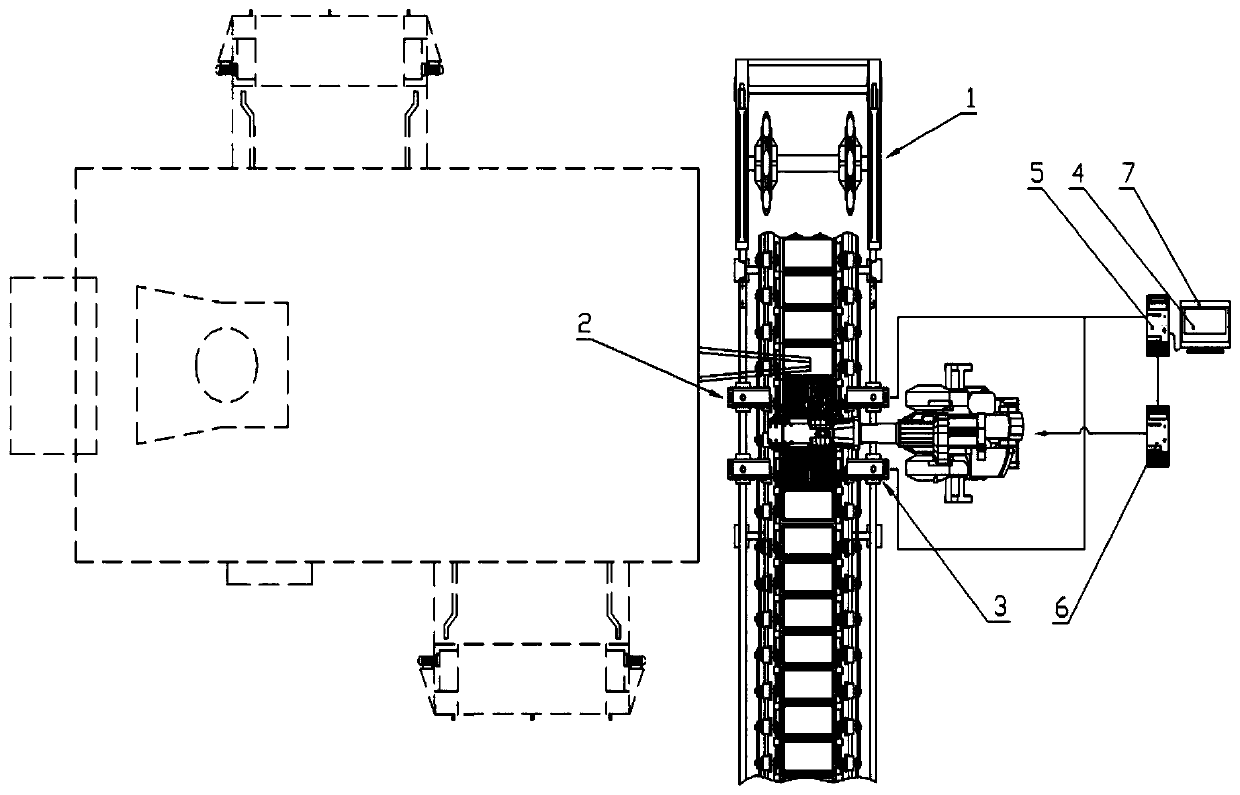

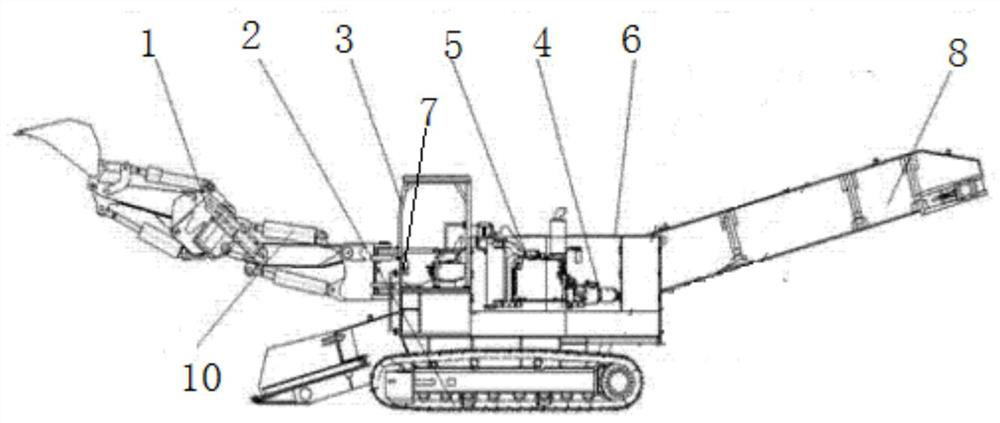

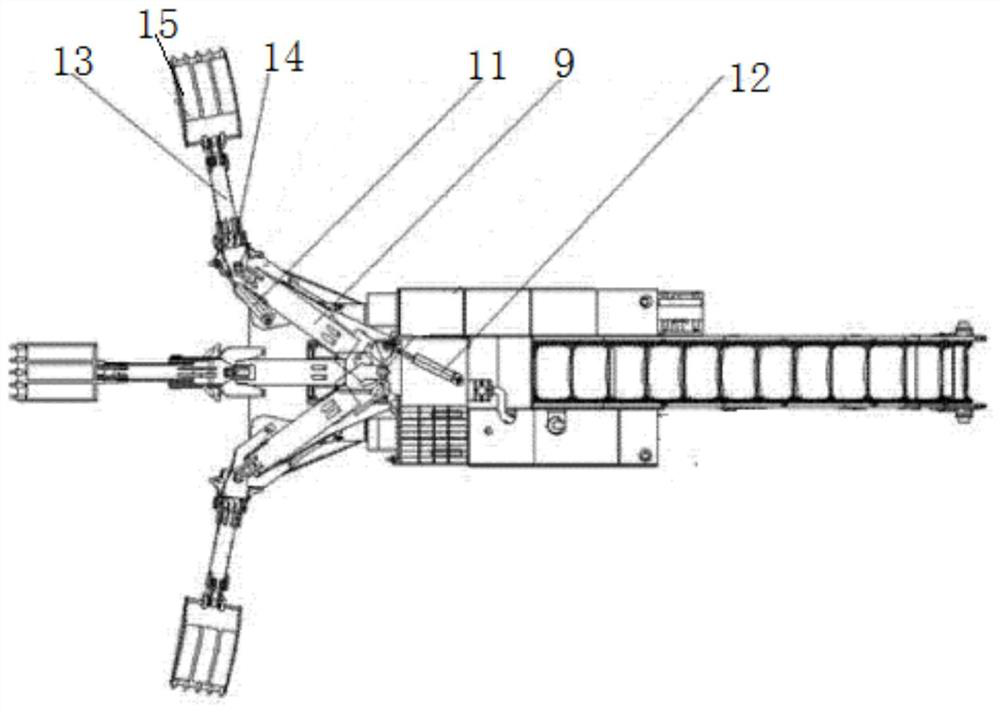

A slag scraper for fast construction of underground excavation subway

ActiveCN110080795BRealize excavation workIncrease pick widthDust removalFire preventionMining engineeringRemote control

A slagging-off machine for underground excavation subway rapid construction comprises a slagging-off device (1), a moving device (2), a driving control room (3), a driving device (4), a dust suppression water spraying device (5), a main machine frame (6), a control device (7) and a material slag conveying device (8). A driving device (4) and a driving control room (3) are connected above the mainframe (6), one side of the driving device (4) is connected with a transmission device (5), the bottom of the main frame (6) is connected with a moving device (2), and the main frame (6) is further connected with a control device (7) and a slag conveying device (8); and a slagging-off device (1) is connected to the main frame (6) at one end of the driving control room (3). The invention belongs tothe intelligent equipment industry, and the slagging-off machine can greatly increase the slagging-off width, greatly improve the working efficiency, improve the stability of the whole machine, achieve the purposes of dust removal, dust suppression and remote control, and has higher practicability and scientificity.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com