Metal cast ingot slag-off system and method

A metal ingot and slag removal technology, applied in metal processing equipment, foundry equipment, instruments, etc., can solve the problems of unstable workers' attention, harsh working environment, misjudgment, missed judgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

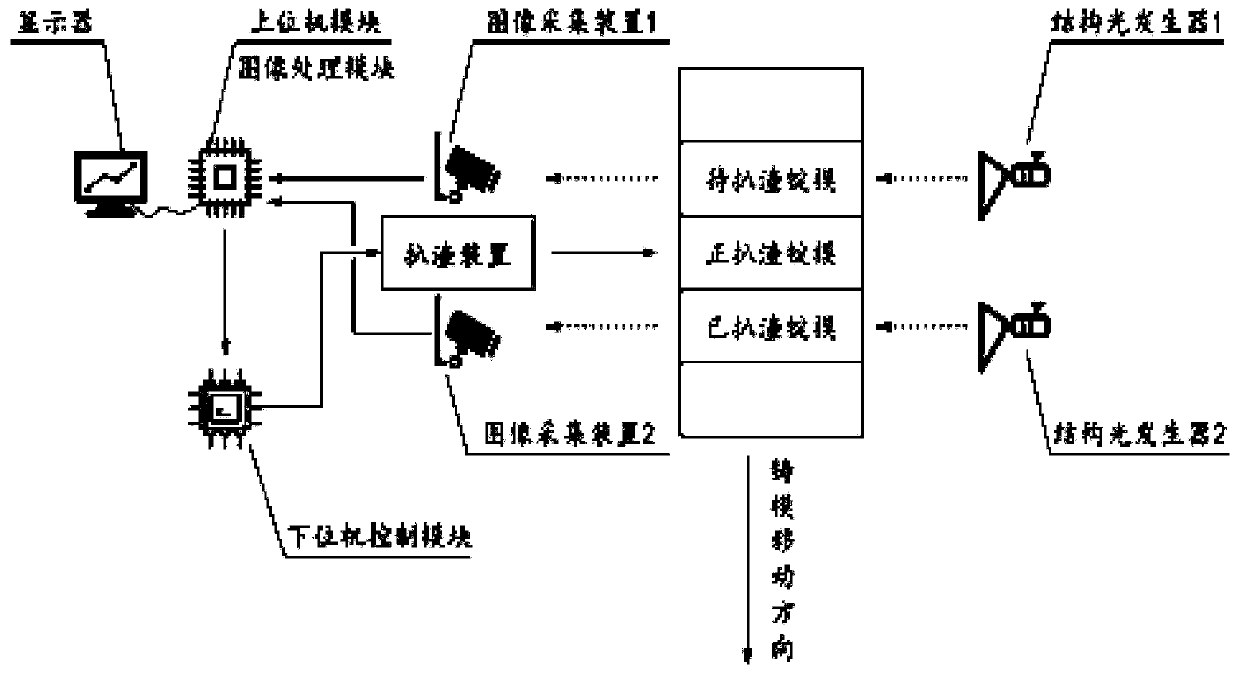

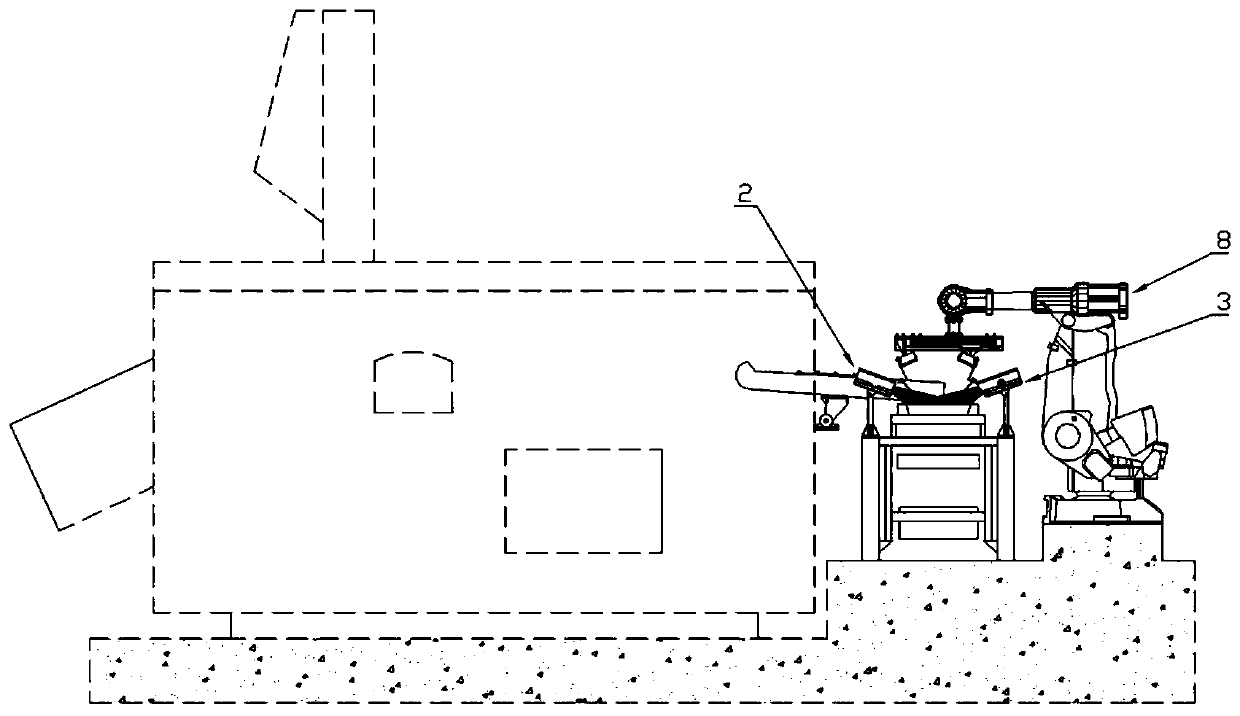

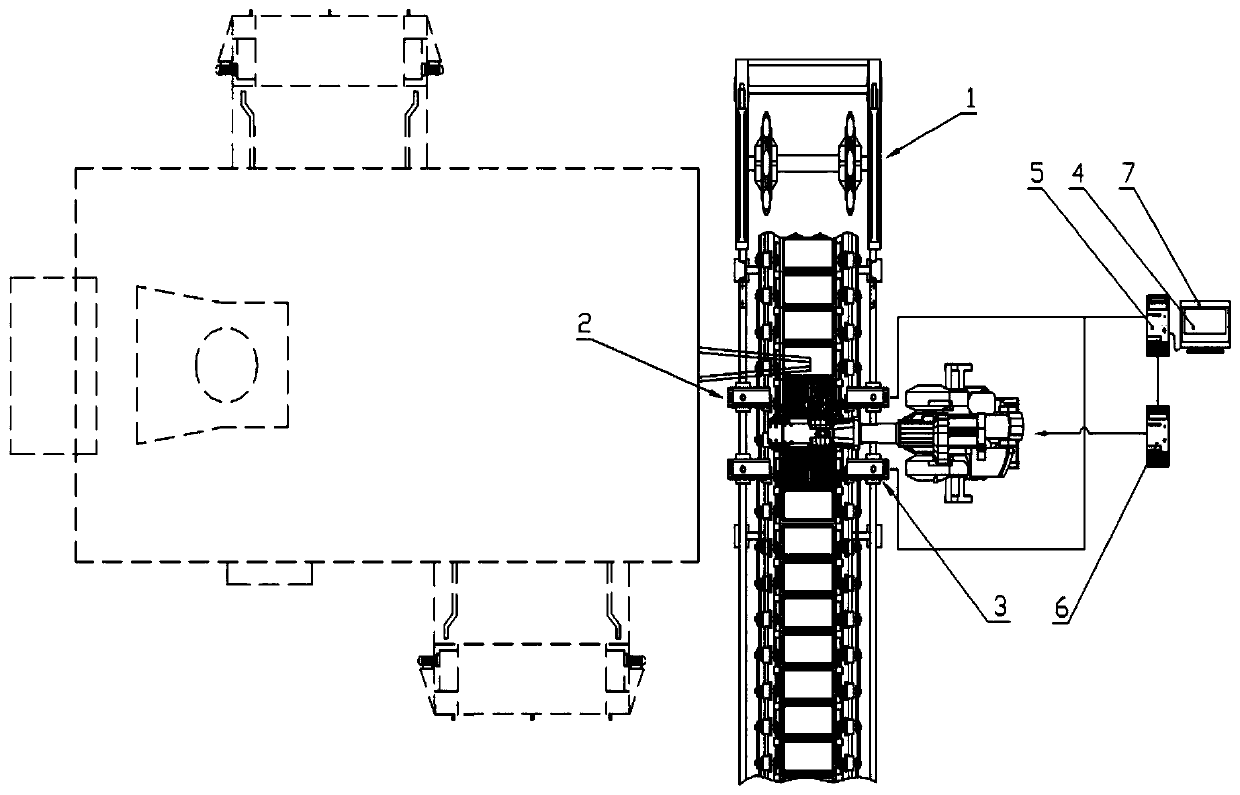

[0045] Such as figure 1 As shown in -3, the metal ingot slag removal system disclosed in this embodiment includes a conveyor unit 1, a structured light generator 2, an image acquisition device 3, an image processing module 4, an upper computer module 5, and a lower computer control module 6. Display 7 and slag removal device 8.

[0046] Conveyor unit 1 adopts chain conveyor unit.

[0047] The structured light generator 2 can be a laser scanner or a projector, and can generate multi-line structured light, dot matrix structured light, grid structured light or surface structured light, etc.

[0048] The image acquisition device 3 may adopt a high-resolution camera, a CCD camera, or the like. When using a high-resolution camera to collect the structured light reflected by the slag layer in the mold, in order to ensure the accuracy and quality of the image obtained, the camera is controlled at a constant temperature to avoid instability caused by the change of the ambient tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com