A method for removing slag from ladle

A ladle and iron slag technology, applied in the field of steelmaking, can solve the problems of large amount of sulfur returned in smelting, unclean slag removal, and high loss of refractory materials, and achieve the advantages of reducing the amount of sulfur returning, improving the effect of slag removal, and improving service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

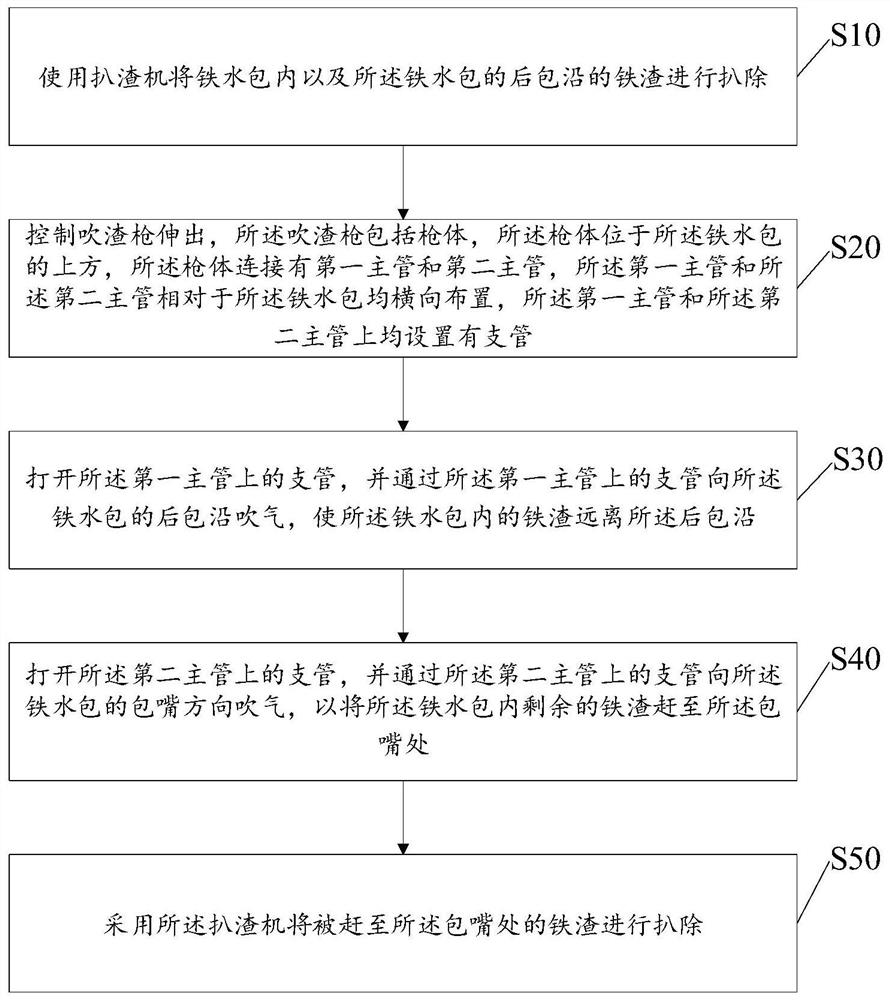

[0031] Please refer to figure 1 , In this embodiment, a ladle slag removal method is provided, and in order to cooperate with the method, a slag blowing gun is also provided in this embodiment.

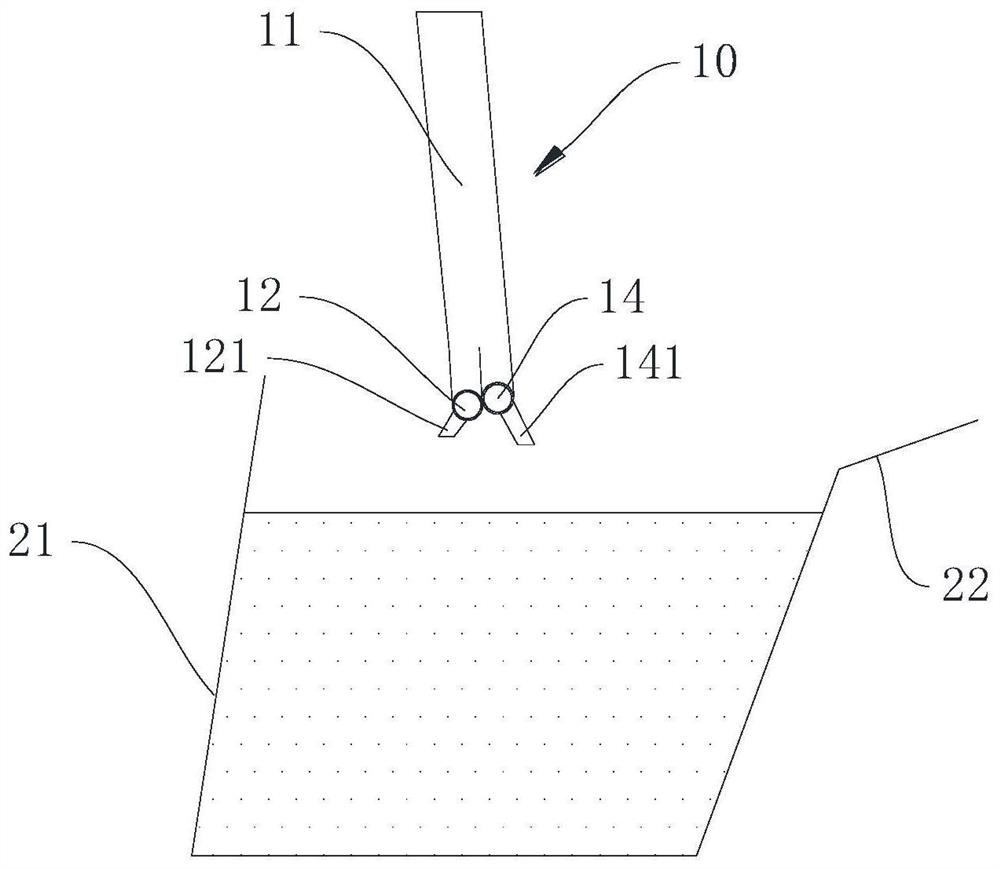

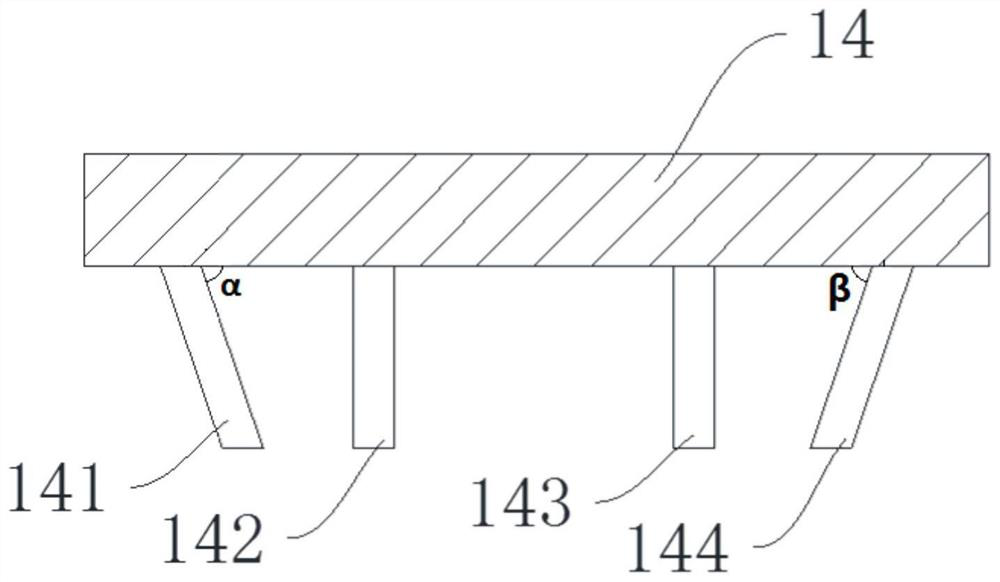

[0032] Please refer to figure 2 and image 3 , The slag blowing gun 10 includes a gun body 11, and the gun body 11 is located above the ladle 21. Specifically, the gun body 11 can be arranged vertically relative to the ladle 21, and the gun body 11 can swing at a certain angle. Consistent with the direction of rotation of the ladle 21. Specifically, the gun body 11 passes through the desulfurization mixing head platform, and has a support guide device. The gun body 11 is telescopic, for example, the telescopic speed is 15m / min, and the installation angle is generally consistent with the inclination angle of the molten iron ladle 21 when removing slag. The gun body 11 is connected with a first main pipe 12 and a second main pipe 14, the first main pipe 12 and the second main pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com