Sodium-free flux and process for treatment of molten aluminum alloy with the same

A technology of aluminum alloy and molten metal, which is applied in the field of processing molten aluminum by injecting flux into a rotary degassing device to achieve uniform dispersion, high slag removal effect, and maintenance of slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

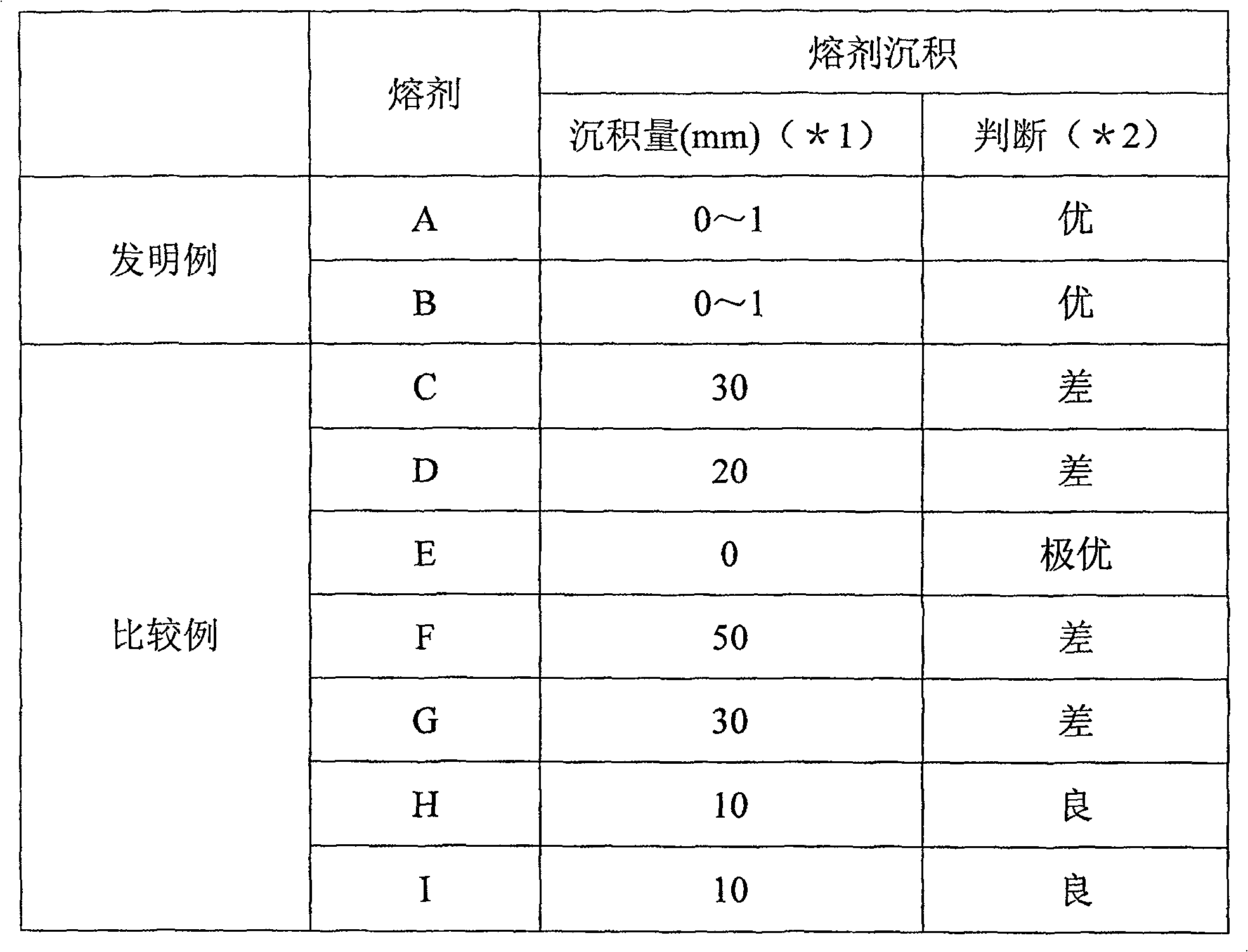

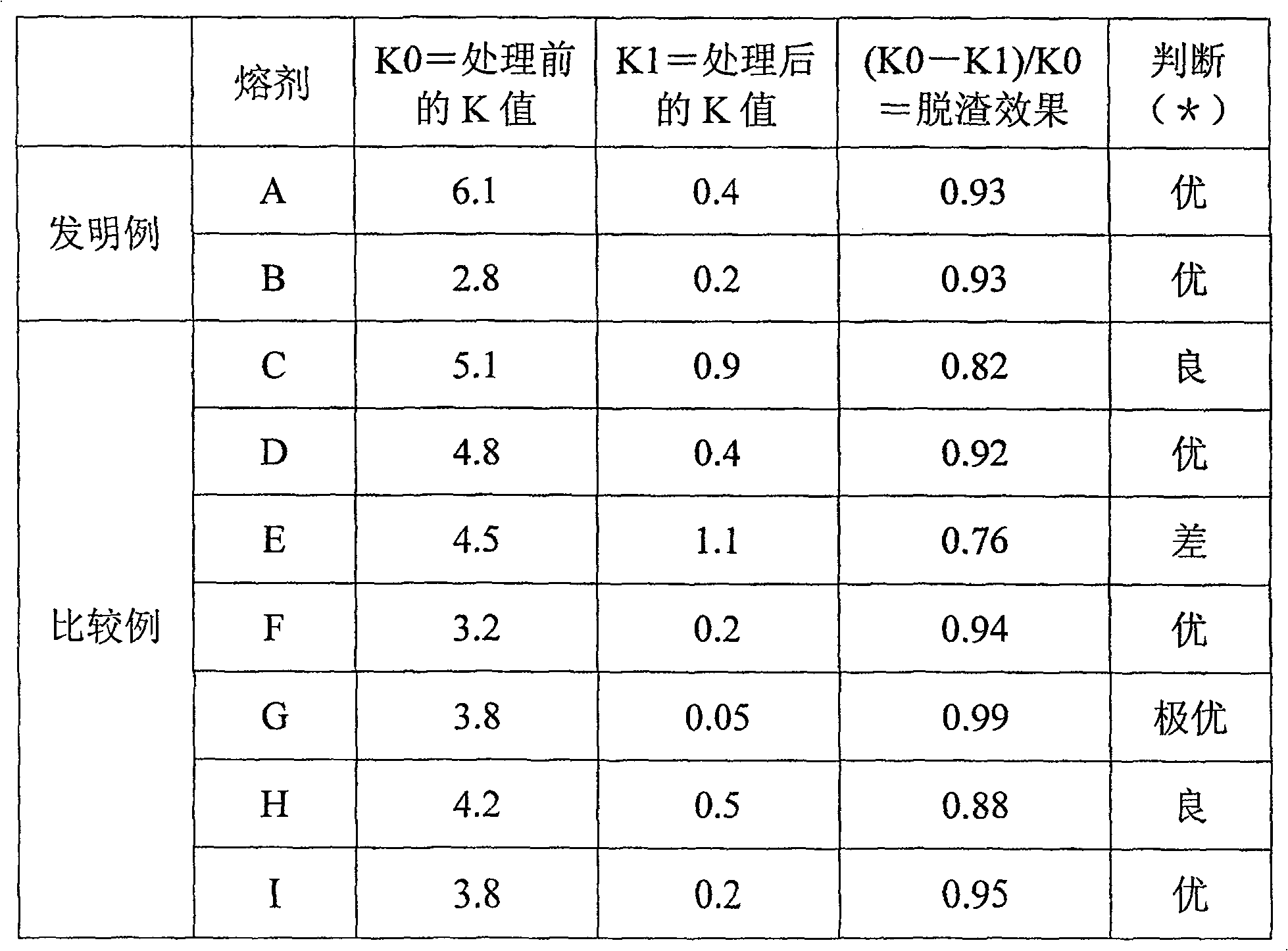

[0042] 〔Evaluation test of flux adhesion and deposition〕

[0043] Using fluxes within and outside the composition range of the present invention to process molten aluminum alloys through flux injection into a rotary degasser to evaluate flux adhesion and deposition at the bottom of the rotor.

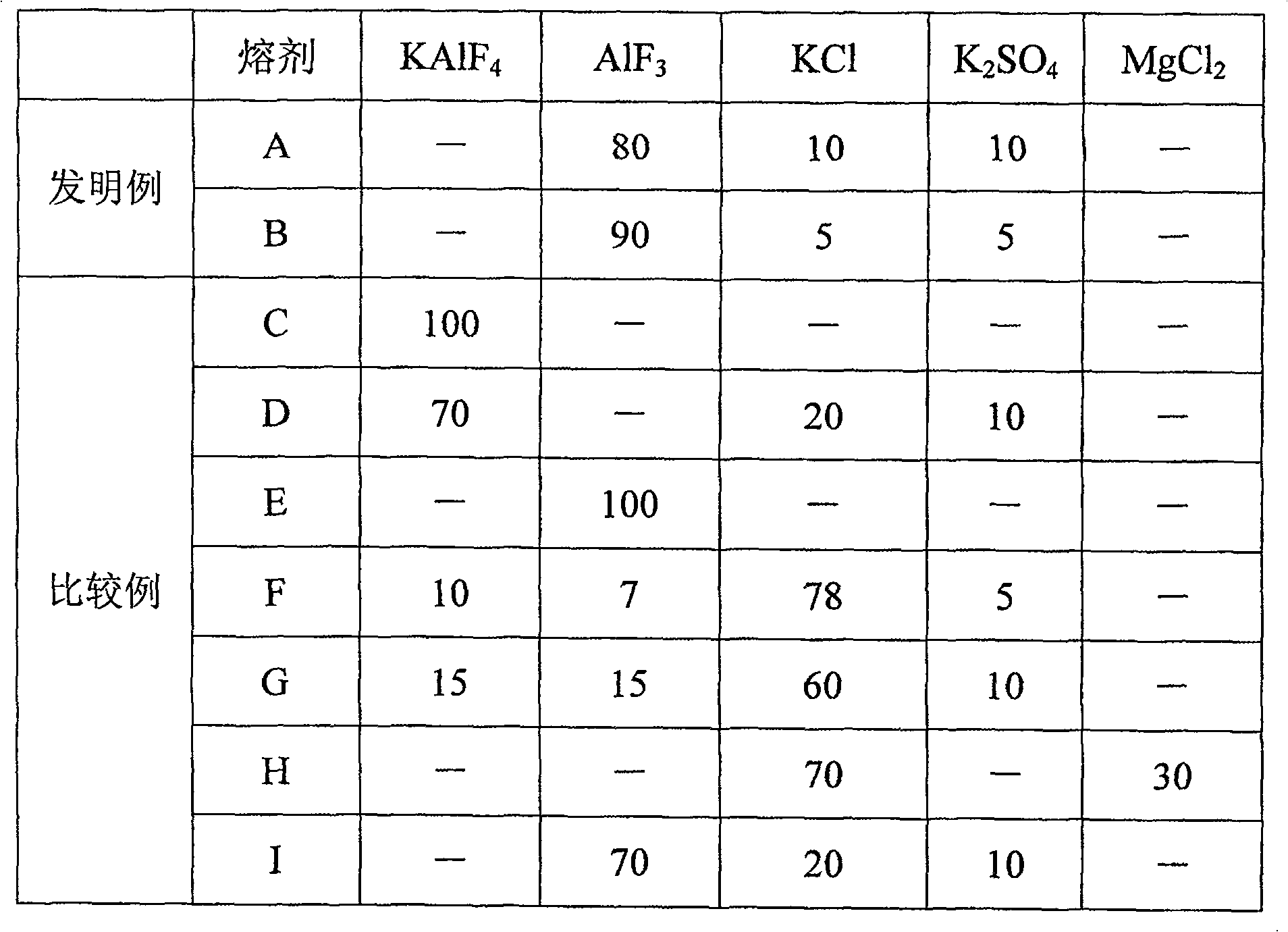

[0044] The components of the fluxes used are shown in Table 1. Fluxes A and B are inventive examples with components within the scope of the present invention, and fluxes C to I are comparative examples with components outside the scope of the present invention.

[0045] The composition (mass %) of each flux of table 1

[0046]

[0047] 230 kg of molten AC4C alloy was placed in a holding furnace at 740 °C. In this state, the molten metal was processed by injecting the rotary degasser with a flux rotating in one direction at a speed of 300 rpm. In the first stage, a flux of a predetermined composition at a feed rate of 40 g / min and nitrogen at a flow rate of 30 L / min were simultane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com