Automatic deslagging device of smelting furnace

A smelting furnace and slag removal technology, used in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as increased labor costs, continuous aluminum alloy processing, and high-yield operating efficiency constraints, reducing labor intensity and improving operating efficiency. , Improve the effect of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

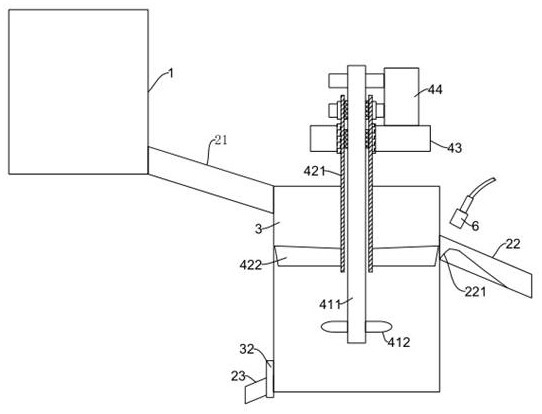

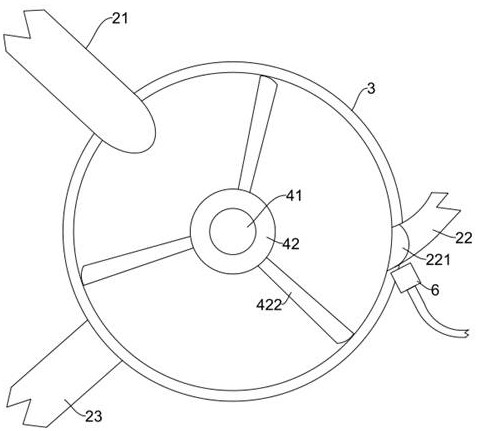

[0023] like Figure 1-Figure 4 As shown, the automatic deslagging device of the smelting furnace includes a liquid storage tank 1, a first discharge channel 21, a slag removal furnace 3, a stirring mechanism 4, a second discharge channel 22 and a third discharge channel 23; The feed end of channel 21 communicates with the discharge end of liquid storage tank 1, and the discharge end of first discharge channel 21 communicates with the feed end of deslagging furnace 3; Mechanism 4 comprises a first stirring element 41, a second stirring element 42, a first bearing frame 43 and a gearbox 44, the first stirring element 41 comprises a first stirring shaft 411 and a first stirring blade 412, and the second stirring element 42 comprises a first stirring element 41. Two stirring shafts 421 and the second stirring blade 422, the second stirring shaft 421 is rotationally connected with the first bearing frame 43, the second stirring blade 422 is set on the outer wall of the second stirr...

Embodiment 2

[0029] like Figure 1-Figure 4 As shown, for the above embodiments, this embodiment optimizes the structure of the second discharge channel.

[0030] In the automatic deslagging device of the smelting furnace, a slope surface 221 is provided inside the end of the second discharge channel 22 close to the deslagging furnace 3 , and the height of the slope surface 221 gradually increases along the direction away from the inside of the slagging furnace 3 . By setting the slope surface 221, when the scum carries molten aluminum into the slope surface 221, due to the inclination angle of the slope surface, the molten aluminum will flow back into the deslagging furnace 3, reducing the consumption of aluminum in the process of slag removal and greatly saving Cost (during continuous operation, the temperature at the inner wall and side wall opening 31 of the deslagging furnace is relatively high, which provides high-temperature environment support for the reflow of molten aluminum).

Embodiment 3

[0032] like Figure 1-Figure 4 As shown, for the above embodiments, this embodiment optimizes the structure of the second stirring blade.

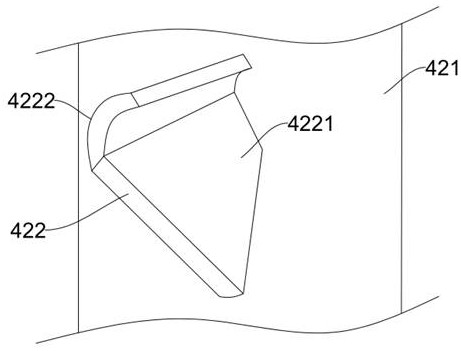

[0033] In this smelting furnace automatic deslagging device, the second stirring blade 422 includes a centrifugal blade 4221 and a concave plate 4222, and a plurality of centrifugal blades 4221 are arranged symmetrically on the outer wall of the second rotating shaft 421, and a concave plate is arranged on the top of the centrifugal blade 4221 4222, the concave surface of the concave plate 54 is arranged along the rotation direction of the centrifugal blade 4221. Centrifugal blade 4221 is beneficial to beat scum to the inner wall of slag removal furnace 3 through the centrifugal force generated by rotation, and setting concave plate 4222 can increase the amount of scum "collected" by second stirring blade 422 during the rotation process, and It can reduce excessive scum and leak from the top of the centrifugal blade 4221, improving the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com