Sintered flux for welding hsla steel and preparation method thereof

A sintered flux and post-welding technology, applied in welding equipment, welding equipment, welding media, etc., can solve the problems of weld metal performance degradation, etc., and achieve high tensile strength, optimized formability, and optimized physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

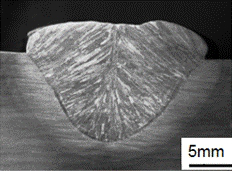

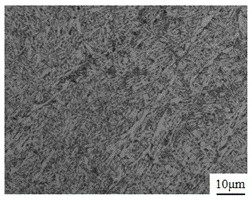

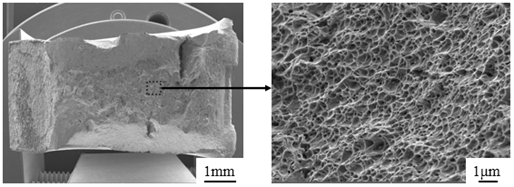

Image

Examples

Embodiment 1

[0064] The sintering flux for welding HSLA steel provided by the present embodiment comprises the following components in terms of mass percentage: CaF 2 53%, ZrO 2 30%, SiO 2 15% and Na 2 O 2%.

[0065] The preparation method of the sintered flux for welding HSLA steel provided by the present embodiment comprises the following steps:

[0066] (1), 530gCaF 2 , 300gZrO 2 and 110gSiO 2 Putting into a V-shaped mixer with a frequency of 0.5Hz and stirring evenly, then adding 170g of water glass (the modulus is 2.8, and the water content of the water glass is 50%) to it, after mixing and stirring for 50min, a mixed material is obtained; The mixed material is placed in an XH433 PS granulator for granulation to obtain mixed granules with a particle size of 20-50 mesh;

[0067] (2) Place the mixed particles with a particle size of 20~50 mesh in a tube furnace and dry at 350°C for 2 hours, then place the dried mixed particles in a muffle furnace and sinter at 460°C for 3 hour...

Embodiment 2

[0071] The sintering flux for welding HSLA steel provided by the present embodiment comprises the following components in terms of mass percentage: CaF 2 54%, ZrO 2 30%, SiO 2 13% and Na 2 O 3%.

[0072] The preparation method of the sintered flux for welding HSLA steel provided by the present embodiment comprises the following steps:

[0073] (1), 540gCaF 2 , 300gZrO 2 and 80gSiO 2 Putting into a V-shaped mixer with a frequency of 0.5 Hz and stirring evenly, then adding 255g water glass (the modulus is 2.8, and the water content of the water glass is 50%) to it, after mixing and stirring for 55min, a mixed material is obtained; The mixed material is placed in an XH433 PS granulator for granulation to obtain mixed granules with a particle size of 20-50 mesh;

[0074] (2) Place the mixed particles with a particle size of 20-50 mesh in a tube furnace and dry at 350°C for 2 hours, then place the dried mixed particles in a muffle furnace and sinter at 490°C for 3 hours ...

Embodiment 3

[0078] The sintering flux for welding HSLA steel provided by the present embodiment comprises the following components in terms of mass percentage: CaF 2 59%, ZrO 2 25%, SiO 2 13% and Na 2 O 3%.

[0079] The preparation method of the sintered flux for welding HSLA steel provided by the present embodiment comprises the following steps:

[0080] (1), 590gCaF 2 , 250gZrO 2 and 80gSiO 2 Putting into a V-shaped mixer with a frequency of 0.5 Hz and stirring evenly, then adding 255g water glass (the modulus is 2.8, and the water content of the water glass is 50%) to it, and after mixing and stirring for 60min, a mixed material is obtained; The mixed material is placed in an XH433 PS granulator for granulation to obtain mixed granules with a particle size of 20-50 mesh;

[0081] (2) Place the mixed particles with a particle size of 20~50 mesh in a tube furnace and dry at 300°C for 2.5 hours, then place the dried mixed particles in a muffle furnace and sinter at 500°C 3h, to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com