An ultra-low hydrogen high toughness welding rod for welding penstocks in hydropower stations

A pressure steel pipe, ultra-low hydrogen technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of limited moisture absorption performance of electrode coating, many inclusions in deposited metal, and inability to stabilize impact toughness To achieve the effect of improving dehydrogenation capacity, improving refining effect and reducing hydrogen partial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the percentage by weight of each component in the drug skin is shown in the following table:

[0025] Raw material name

weight percentage

Raw material name

weight percentage

marble

40

Electrolytic manganese

5

4

Atomized ferrosilicon

6

18

Light Rare Earth Ferrosilicon

1

3

ferro-titanium

9

Dehydrated feldspar

3

0.5

Zircon sand

3

3

4

0.5

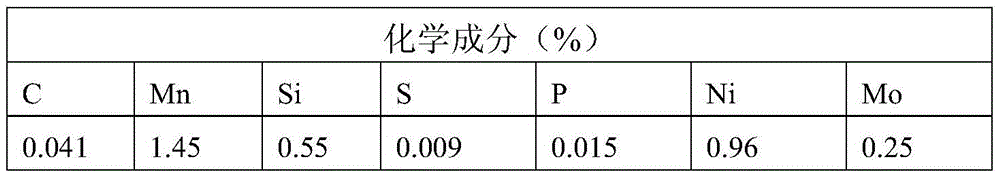

[0026] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0027]

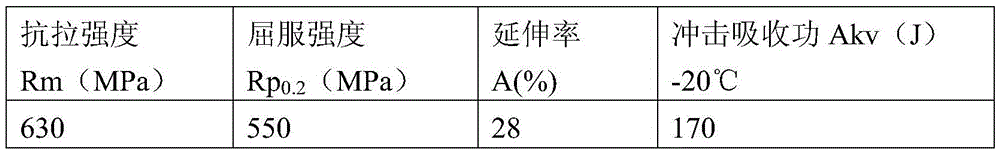

[0028] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0029]

[0030] The hydrogen content of the deposited metal of the electrode prepared...

Embodiment 2

[0032] Embodiment 2: the percentage by weight of each component in the drug skin is shown in the following table:

[0033] Raw material name

weight percentage

Raw material name

weight percentage

marble

45

Electrolytic manganese

6

2

Atomized ferrosilicon

3

23

Light Rare Earth Ferrosilicon

2

2

ferro-titanium

7

Dehydrated feldspar

1

1

Zircon sand

2

2

3

1

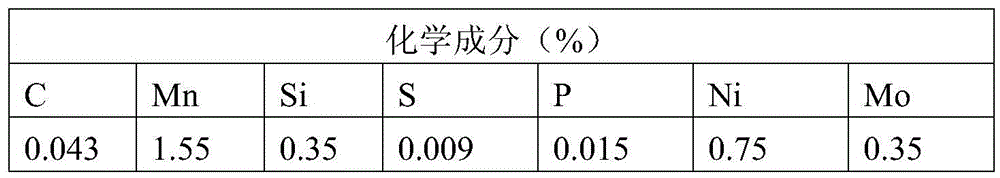

[0034] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0035]

[0036] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0037]

[0038] The hydrogen content of the deposited metal of the electrode prepared acc...

Embodiment 3

[0040] Embodiment 3: the percentage by weight of each component in the drug skin is shown in the following table:

[0041] Raw material name

weight percentage

Raw material name

weight percentage

marble

50

Electrolytic manganese

4

dolomite

2

Atomized ferrosilicon

4

18

Light Rare Earth Ferrosilicon

3

quartz

2

ferro-titanium

8

Dehydrated feldspar

1

0.5

Zircon sand

1

nickel powder

4

Potassium titanate

2

Rare earth fluoride

0.5

[0042] The deposited metal composition of the electrode prepared according to the above ratio is shown in the following table:

[0043]

[0044] The mechanical properties of the deposited metal of the electrode prepared according to the above ratio are shown in the following table:

[0045]

[0046] The hydrogen content of the deposited metal of the electrode prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com