Refractory castable for ladle

A refractory castable and castable technology, applied in the field of refractory castables, can solve the problems of poor wide applicability, poor desulfurization effect, and poor slag resistance, and achieve long service life, low production cost, and strong slag resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The castable for ladle of the present invention can be prepared by weighing each raw material once according to the component contents described in Table 1, and uniformly kneading by force.

[0012] Various components involved in the present invention are common raw materials, which can be purchased conveniently in the chemical raw material market.

Embodiment 2

[0014] The castable for ladle of the present invention can be prepared by weighing each raw material once according to the component contents described in Table 1, and uniformly kneading by force.

Embodiment 3

[0016] The castable for ladle of the present invention can be prepared by weighing each raw material once according to the component contents described in Table 1, and uniformly kneading by force.

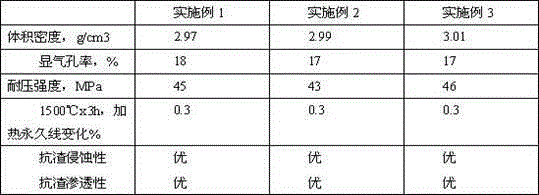

[0017] Table 1: The content of each component in the castable for ladle (unit: kg)

[0018]

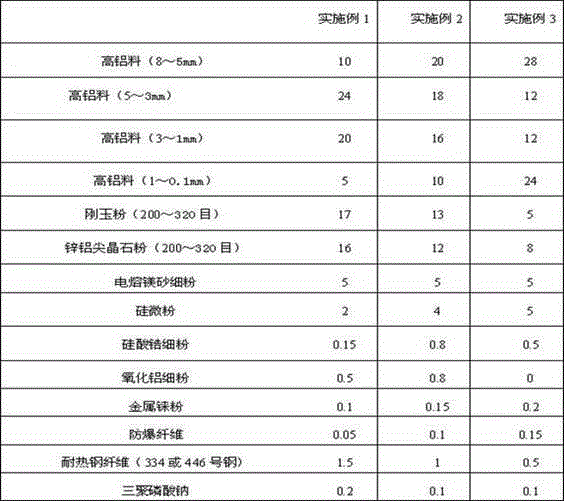

[0019] The performance parameter table of the castable for ladle of the present invention obtained in Examples 1-3 after being kept at a temperature of 1500° C. for 3 hours.

[0020] Table 2 Performance parameter list of castables for ladle after calcination

[0021]

[0022] From the data in Table 2, it can be seen that the castable after calcination has micro-expansion, which ensures that the castable maintains the integrity of the lining during use, and has excellent resistance to molten iron and slag erosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com