Water-soluble soldering flux and acid washing method of copper product

A water-soluble, flux technology, applied in the field of welding flux, can solve the problems of liquid tin splash, reduce the utilization rate of tin, a large amount of tin dross, etc., and achieve the effect of suppressing splash, improving the utilization rate, and reducing the adhesion residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention has no special requirements on the preparation method of the water-soluble soldering flux, preferably, the above-mentioned components are mixed according to the stated amounts and stirred evenly.

[0027] The present invention also provides a copper pickling method, comprising:

[0028] Mixing the water-soluble flux described in the above technical scheme with water to obtain pickling solution;

[0029] The copper material is pickled by using the pickling solution.

[0030] The present invention mixes the water-soluble flux described in the above technical solution with water to obtain pickling solution. In the present invention, the water is preferably deionized water. In the present invention, the mass ratio of the water-soluble flux to water is preferably 1:3-4, more preferably 1:3.2-3.7, and still more preferably 1:3.4-3.6.

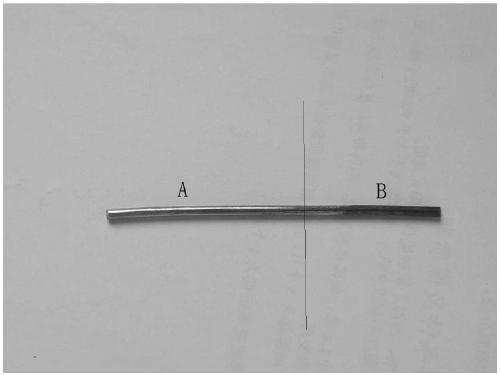

[0031] After obtaining the pickling solution, the present invention uses the pickling solution to pickle the copper m...

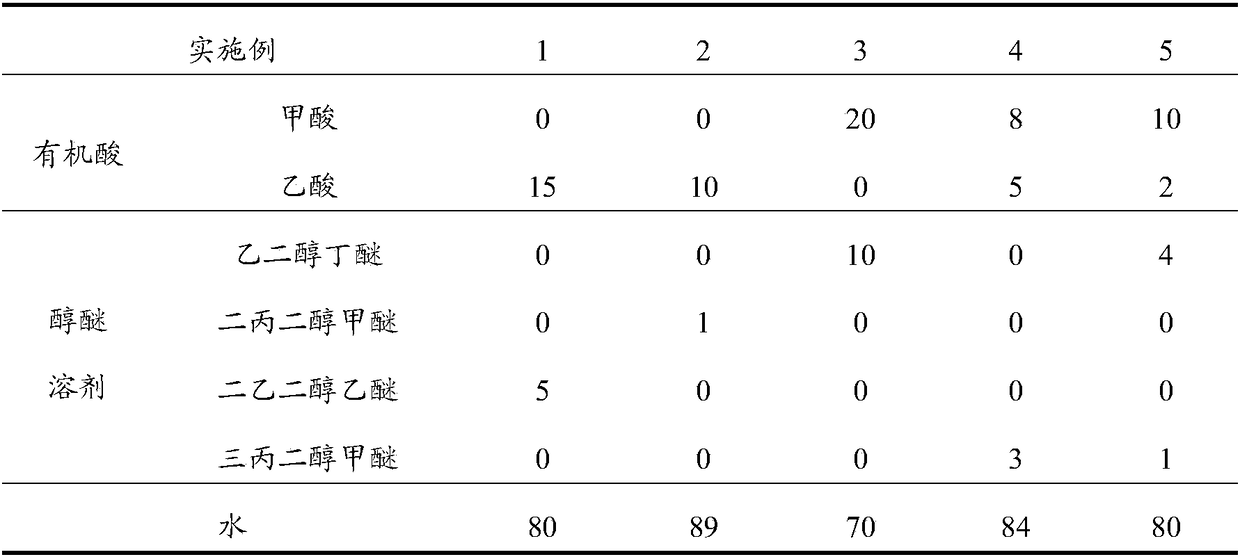

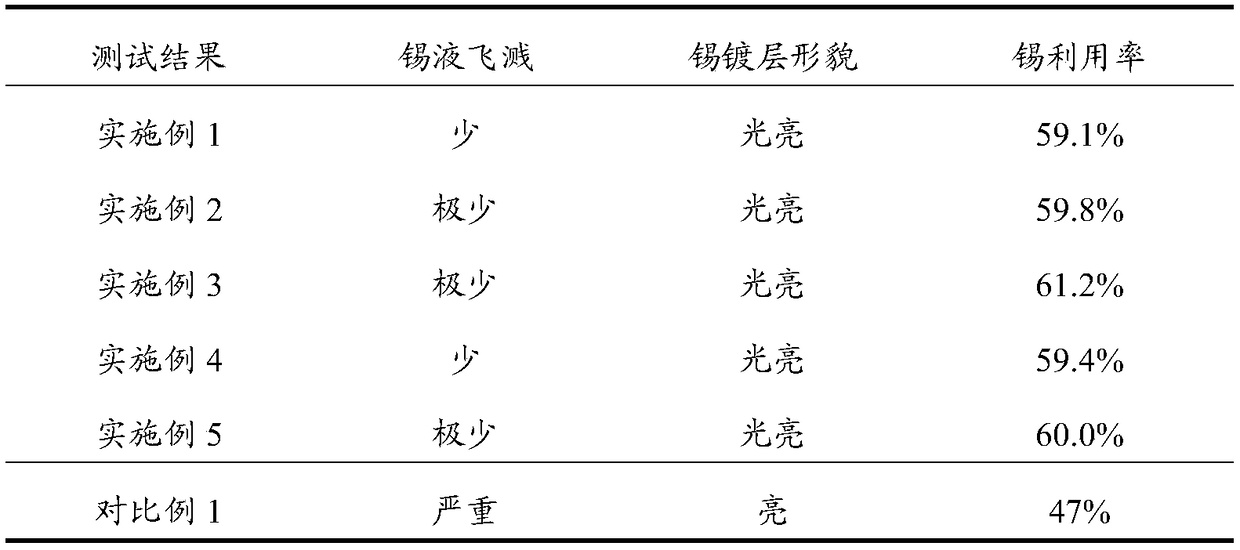

Embodiment 1

[0037] Mix the components according to the dosage shown in Table 1 to obtain a water-soluble flux; mix the obtained water-soluble flux with water at a mass ratio of 1:3 to obtain a pickling solution.

[0038] Pass the copper wire through the pickling solution at a speed of 40m / min for pickling and then tinning. The interval between tinning and pickling is 1.05s, that is, the distance is 70cm; the temperature of the tin solution is 250-260°C.

Embodiment 2

[0040] Water-soluble flux was prepared according to the dosage in Table 1. The copper wire passed through the pickling solution at a speed of 45m / min, and the interval between pickling and tin plating was 0.9s. Others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com