Cutting device for oil well down-hole pipe column and use method of cutting device

A downhole pipe string and cutting device technology, which is applied in the direction of wellbore/well parts, earthwork drilling and production, etc., can solve the problems of difficult pulling out of stuck well pipe strings, tedious workover process and long time, so as to reduce the labor intensity of employees, The effect of reducing workover construction steps and reducing workover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

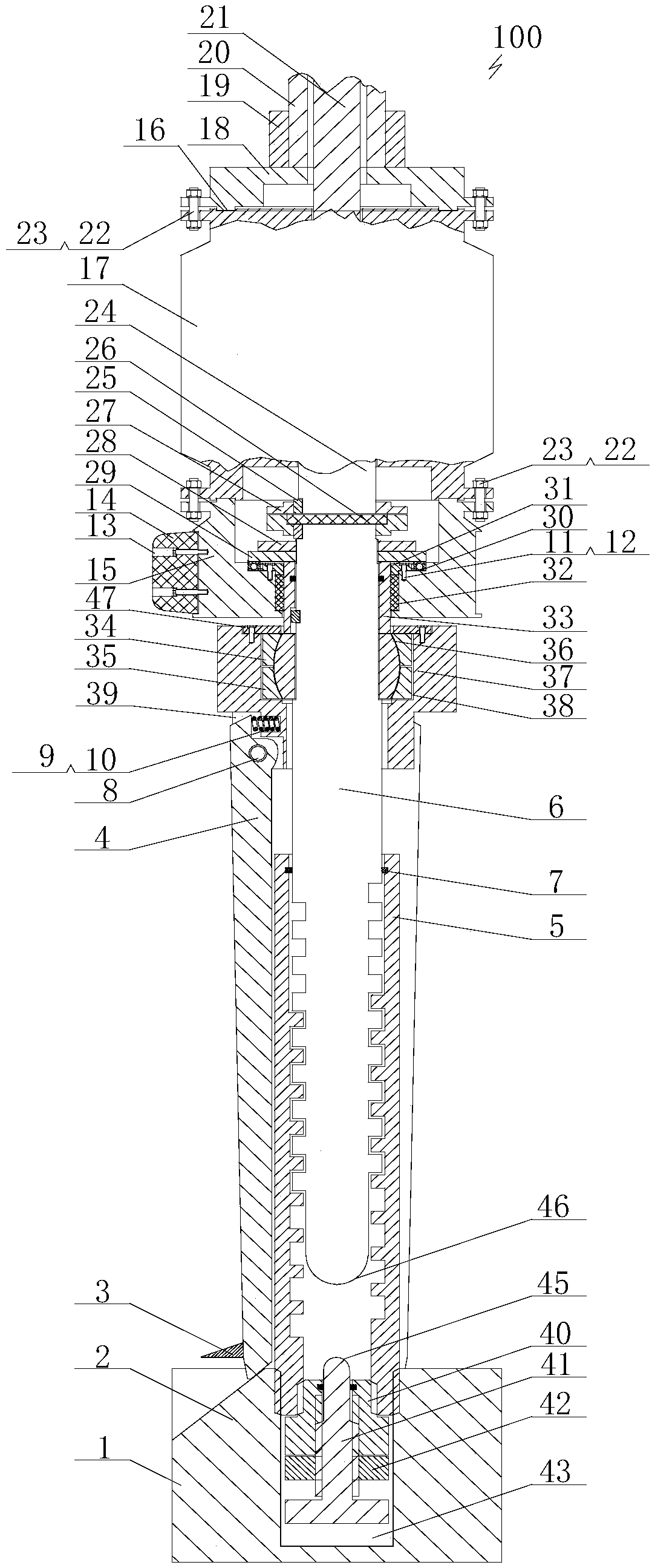

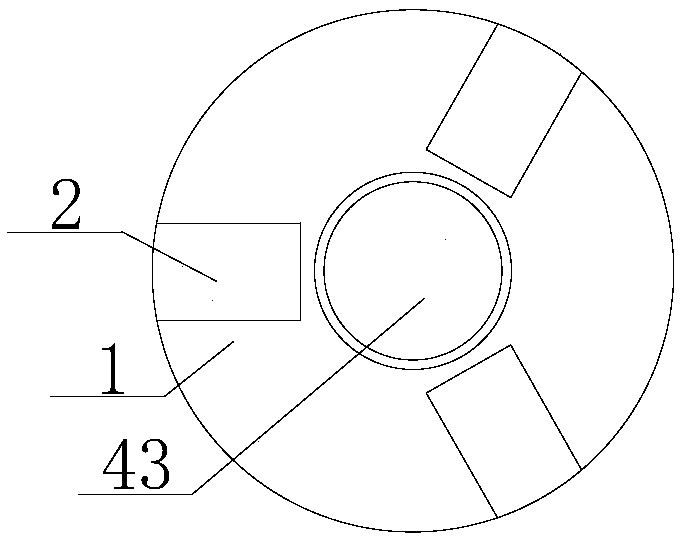

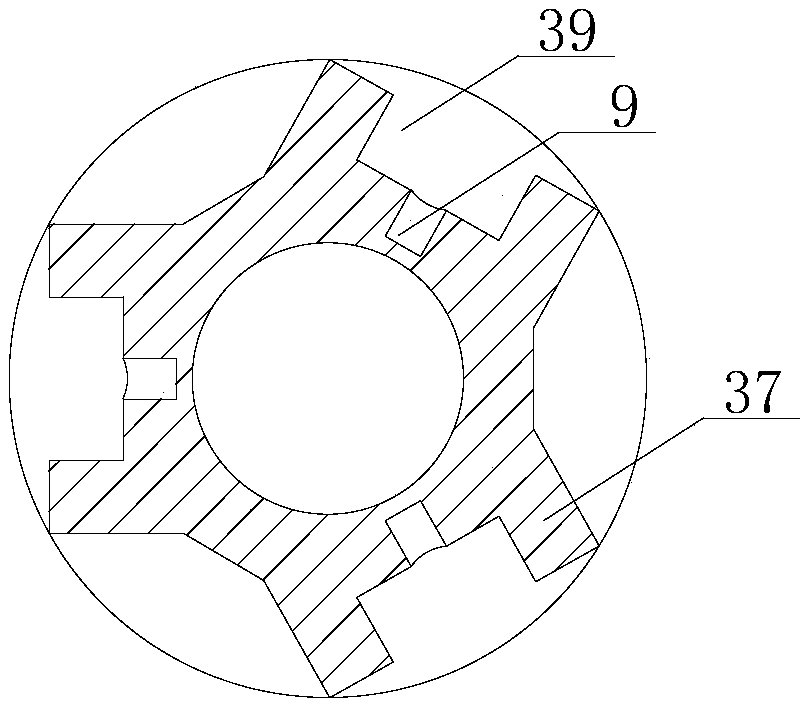

[0061] Figure 1 to Figure 15 As shown, the present invention provides an oil well downhole pipe string cutting device 100, which includes a main shaft 6, a cutting part is rotatably sheathed on the outer wall of the main shaft 6, and the cutting part includes a knife arm that can swing radially, expand and contract and can rotate circumferentially 4. The cutter arm 4 is provided with a scraper 3 capable of rotating and cutting the oil well downhole tubing string 52 from the inside (the inside of the oil well downhole tubing string 52 (the oil well downhole tubing string 52 scraped by the scraper 3 is the part stuck in the well). In this embodiment, the scratching knife 3 is welded on the knife arm 4; the top of the main shaft 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com