Oil-pumping workover rig

A workover rig and oil pumping technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the waste of manpower, financial and material resources, inconvenient workover of oil pumping workover rig, and low oil pumping efficiency, etc. problems, to achieve the effect of reducing workover costs, large pumping traction force, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

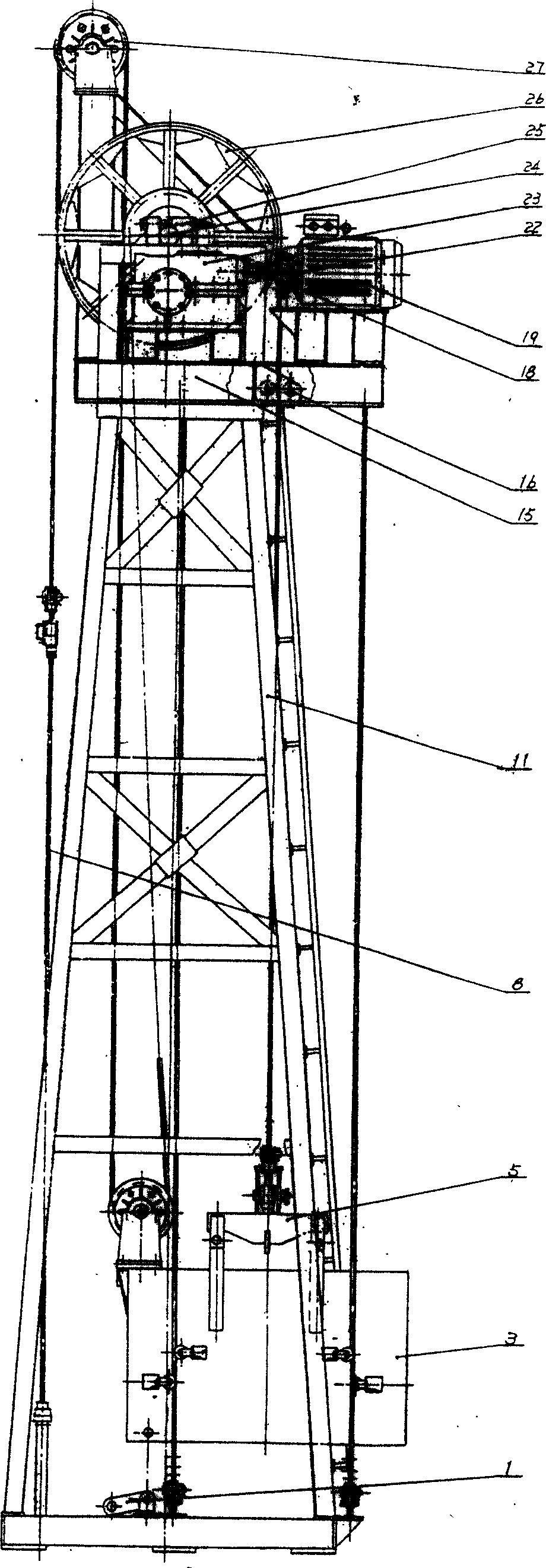

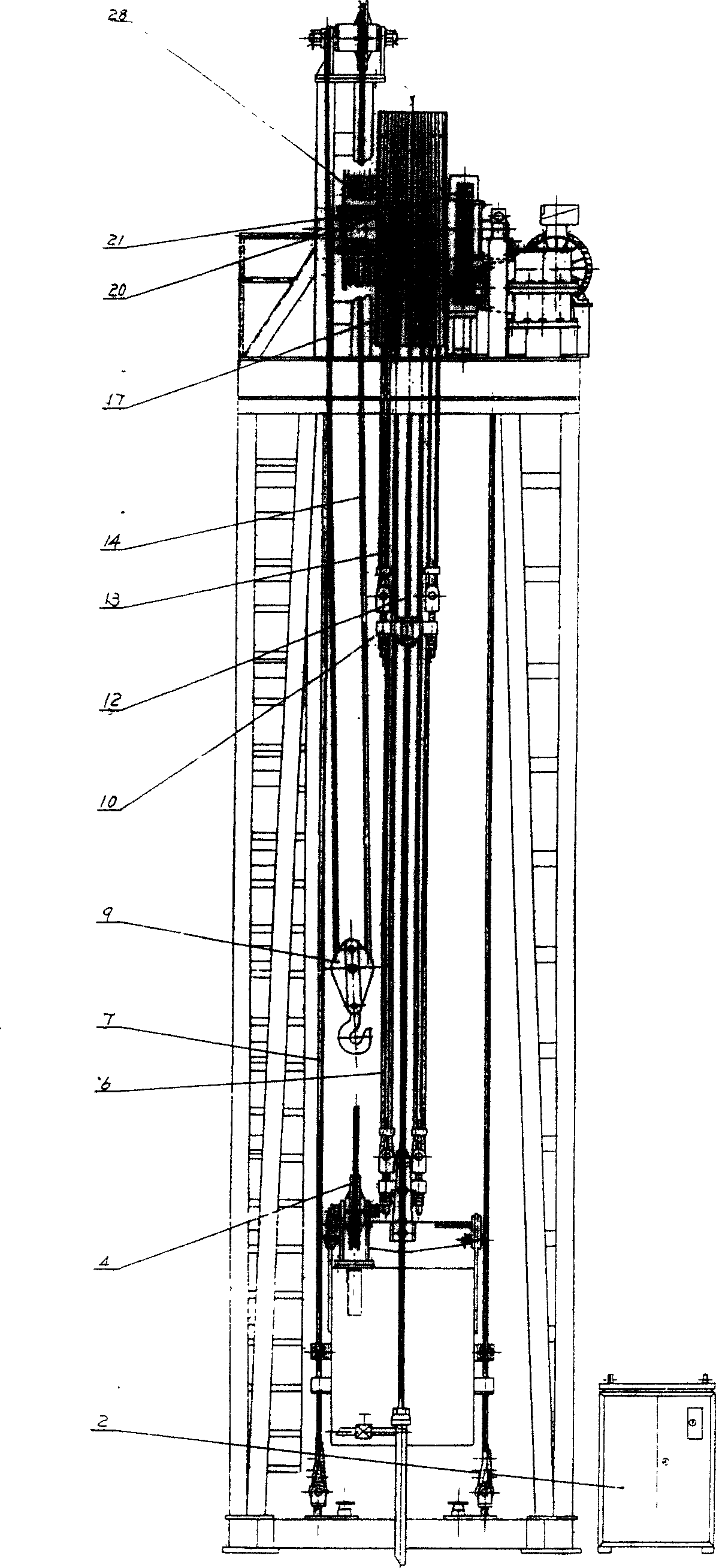

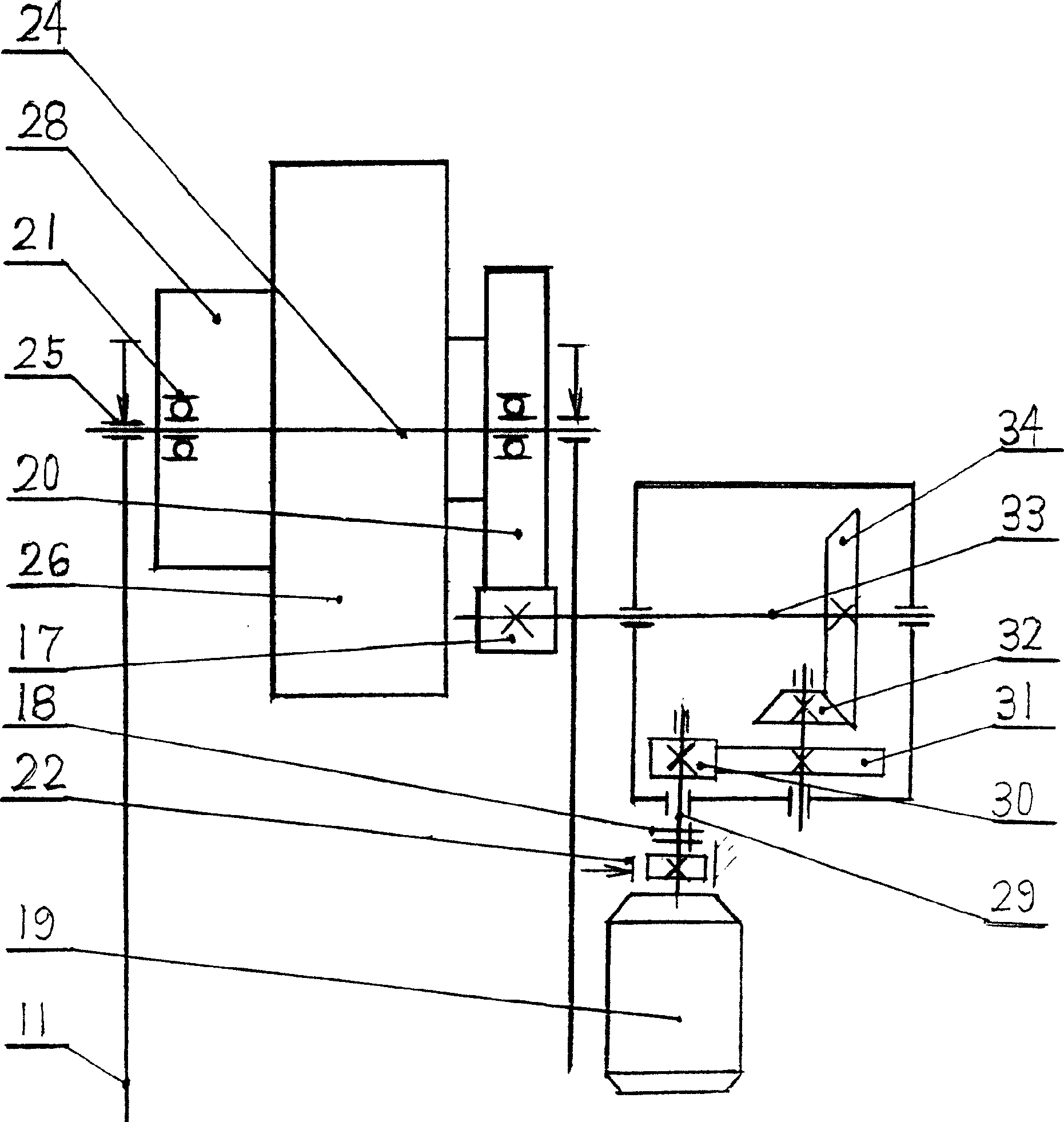

[0011] refer to figure 1 , 2 , the present invention includes a main frame 11, an electric control cabinet 2, a counterweight 3, a rope suspension 10, an oil pumping rod 8, a motor 19, a pinion 17, a large gear 20, a sky wheel 26, a winch wheel 28, and a reduction box 23 , the oil pumping rod 8 is connected with the rope suspension 10, the motor 19 is connected with the reduction box 23 through the coupling 18 and the brake 22, the large gear 20, the sky wheel 26 and the winch wheel 28 are fixed to each other, and are installed on the sky through the bearing 21. On the wheel shaft 24, the sky wheel shaft 24 is fastened with the sky wheel shaft fastener 25, the top of the counterweight 3 is provided with the lower guide wheel 4 and the rope hanger 5, the top of the main frame 11 is provided with a support platform 15, and the support platform 15 is provided with an upper Guide wheel 27, clamper 16, sky wheel shaft tightener 25 pass through clamper 16 to be provided with protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com