High-flexibility waste-wool-base biological plastic and preparation method thereof

A technology of bioplastics and flexibility, which is applied in the field of waste wool-based bioplastics and its preparation, can solve the problems of decreased moisture absorption performance, and achieve the effects of improving flexibility, good biocompatibility, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

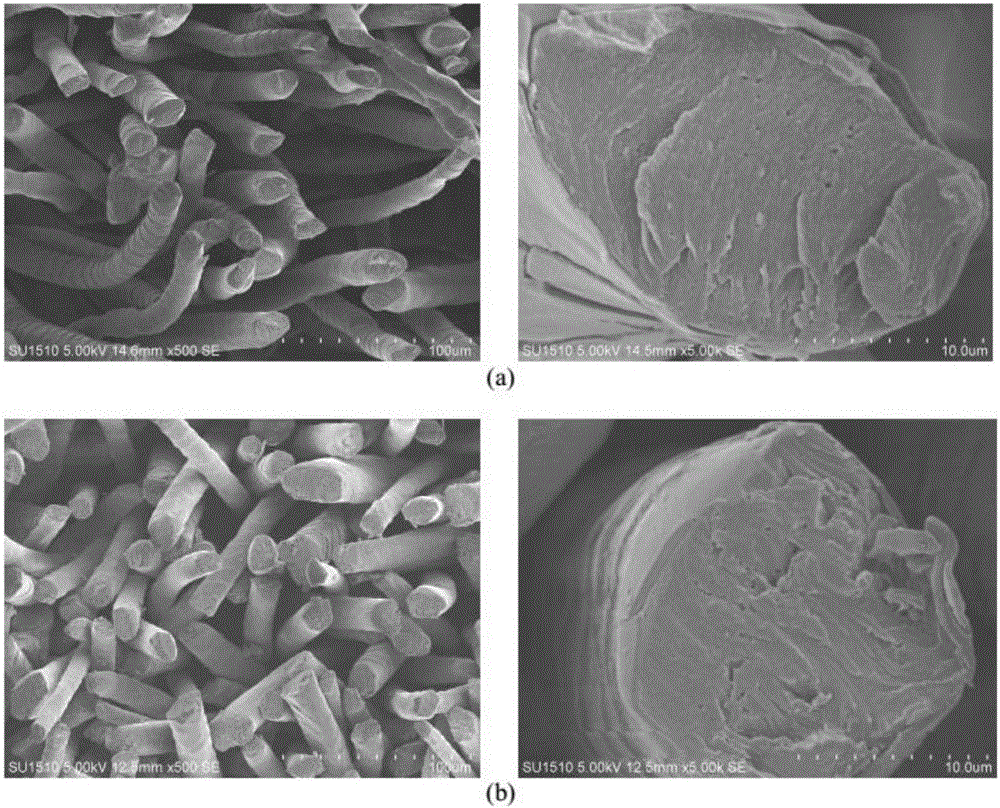

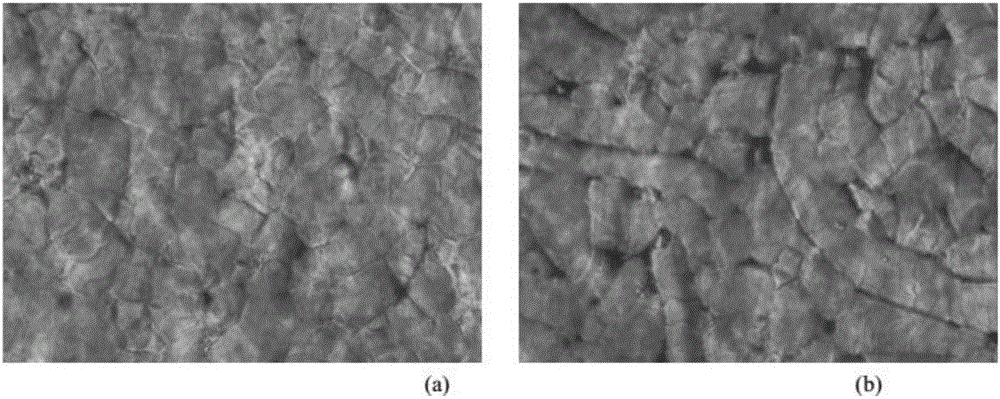

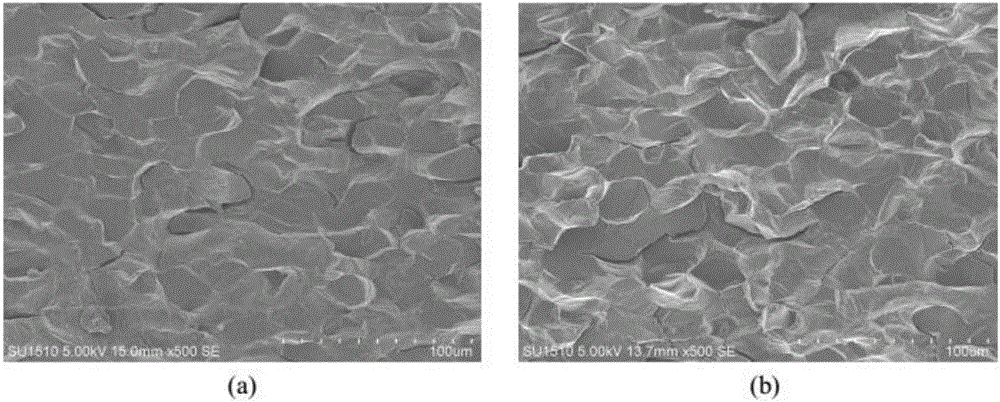

[0041] Wool-based bioplastics were prepared as follows:

[0042] (1) Shorten the wool fiber to 3-5mm, put it in hot water, add detergent and wash it several times repeatedly to remove the grease on the wool surface; put the washed wool into the buffer solution with pH=8 prepared in advance , the bath ratio is 1:30, hot water pretreatment is carried out in OPS-40IS vertical pressure steam sterilizer, the pretreatment conditions are: temperature 130 ℃, time 40min; the wool after pretreatment is washed repeatedly to neutrality;

[0043] Preparation method of the buffer solution: take 500ml of 0.1mol / L potassium chloride solution, add 3.09g of boric acid to dissolve it, measure 25ml of boric acid-potassium chloride solution and 4.0ml, 0.1mol / L NaOH solution, mix evenly, add water to dilute to 200ml .

[0044] (2) Pour into liquid nitrogen, let the wool fiber saturated with water freeze rapidly, and then dry in a freeze dryer for 24 hours.

[0045] (3) Use a nano ball mill to pul...

Embodiment 2

[0053] Wool-based bioplastics were prepared as follows:

[0054] (1) Shorten the wool fiber to about 4mm, put it into hot water, add detergent and wash it several times repeatedly to remove the grease on the wool surface; put the washed wool into the buffer solution with pH=8 prepared in advance, The bath ratio is 1:30, and hot water pretreatment is carried out in the OPS-40IS vertical pressure steam sterilizer. The pretreatment conditions are: temperature 120°C, time 50min; the pretreated wool is washed repeatedly;

[0055] Preparation method of the buffer solution: take 500ml of 0.1mol / L potassium chloride solution, add 3.09g of boric acid to dissolve it, measure 25ml of boric acid-potassium chloride solution and 4.0ml, 0.1mol / L NaOH solution, mix evenly, add water to dilute to 200ml .

[0056] (2) Shred the wool, pour liquid nitrogen into it, freeze the wool fiber saturated with water quickly, and then dry it in a freeze dryer for 16 hours.

[0057] (3) Use a nano ball mi...

Embodiment 3

[0064] Wool-based bioplastics were prepared as follows:

[0065] (1) Shorten the wool fiber to about 4mm, put it into hot water, add detergent and wash it several times repeatedly to remove the grease on the wool surface; put the washed wool into the buffer solution with pH=8 prepared in advance, The bath ratio is 1:30, hot water pretreatment is carried out in OPS-40IS vertical pressure steam sterilizer, the pretreatment conditions are: temperature 135°C, time 30min; the pretreated wool is washed repeatedly;

[0066] Preparation method of the buffer solution: take 500ml of 0.1mol / L potassium chloride solution, add 3.09g of boric acid to dissolve it, measure 25ml of boric acid-potassium chloride solution and 4.0ml, 0.1mol / L NaOH solution, mix evenly, add water to dilute to 200ml .

[0067] (2) Shred the wool, pour liquid nitrogen into it, freeze the wool fiber saturated with water quickly, and then dry it in a freeze dryer for 20 hours.

[0068] (3) Use a nano ball mill to pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com