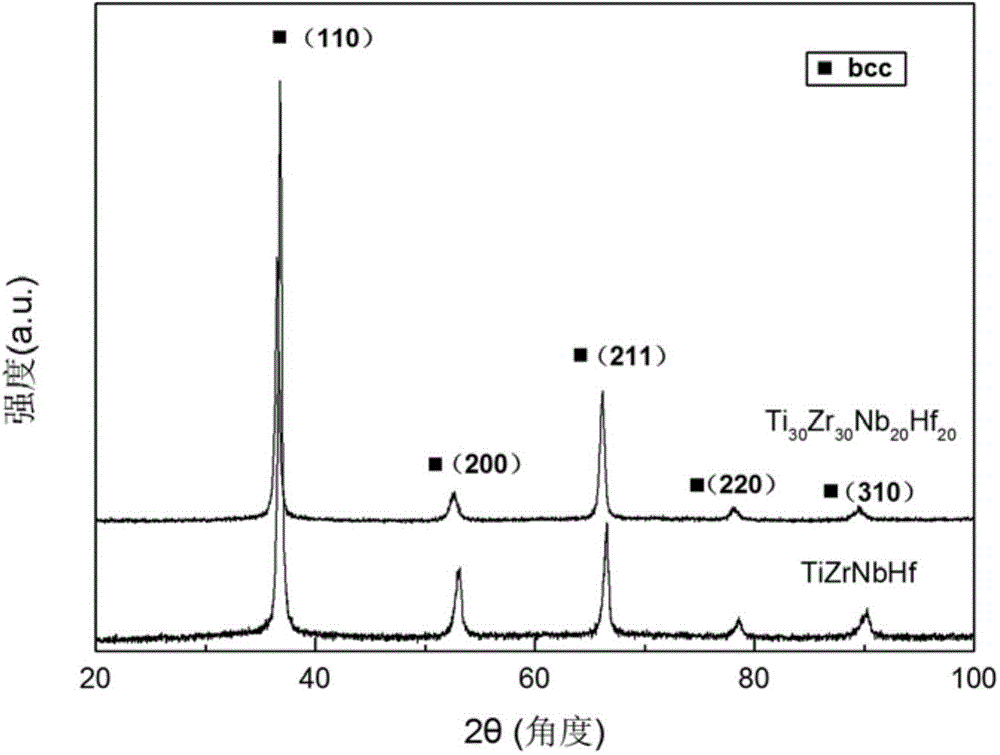

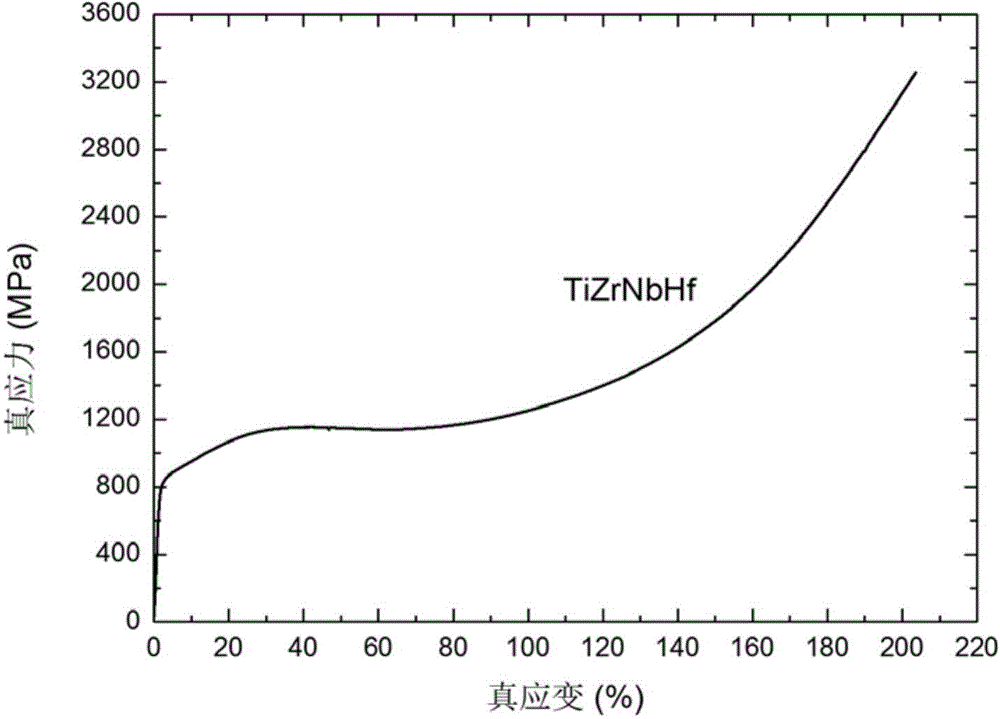

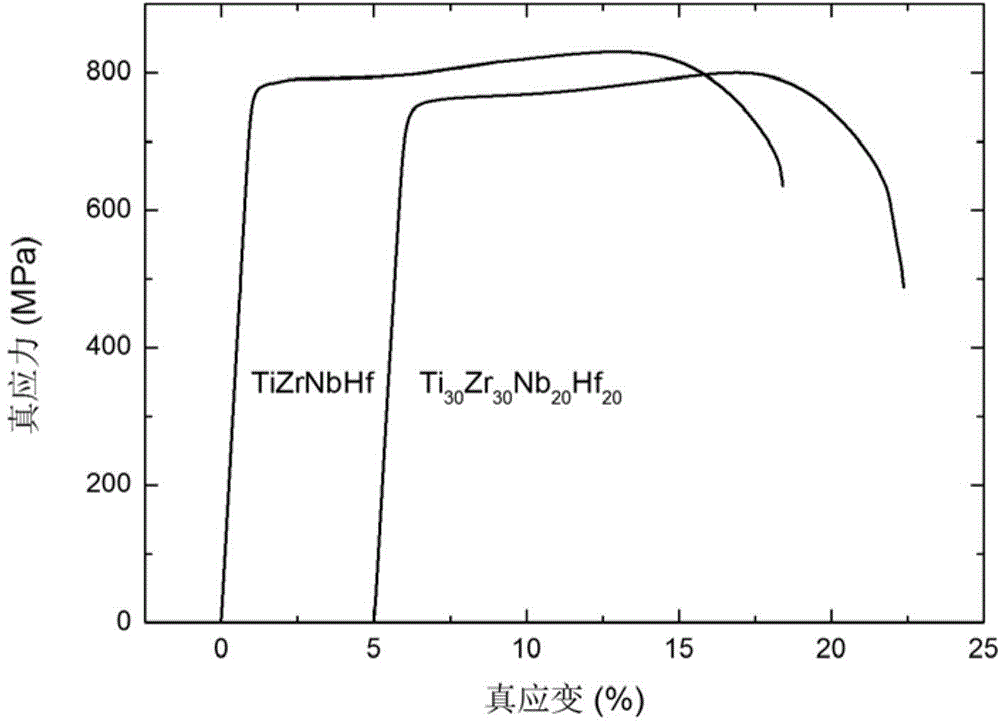

High-strength low-elasticity modulus TiZrNbHf high-entropy alloy and preparation method thereof

A low elastic modulus, high entropy alloy technology, applied in the field of metal materials and their preparation, can solve the problems of no tensile properties, achieve good application prospects and excellent structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. The preparation of high entropy alloy, the preparation process is as follows:

[0016] 1) Raw material preparation: The alloy smelting raw materials used in the present invention are high-purity (≥99.9%) Ti, Zr, Nb and Hf elements, and the raw materials are removed from scale by means of grinding wheels, and accurately weighed and proportioned according to the molar ratio. Clean it with ultrasonic vibration in alcohol and use it for smelting alloys. The alloy composition is shown in Table 1.

[0017] Table 1 Nominal composition (at.%) of TiZrNbHf high-entropy alloys (HEAs)

[0018]

[0019] 2) Preparation of high-entropy alloys: the invention uses a vacuum non-consumable electric arc furnace to smelt alloys. When smelting, place the proportioned raw materials in a water-cooled copper crucible, and evacuate the furnace chamber to 5×10 -3 After Pa is below, fill the furnace cavity with argon to half the atmospheric pressure. Before smelting the target alloy each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com