Elastic anti-channeling cement slurry and preparation method thereof

A cement slurry and anti-channeling technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of poor cementation of the cementing interface, high brittleness of cement stone, failure to meet the requirements of perforation and large-scale fracturing, etc. problems, to achieve the effect of improving the quality of cementation, high tensile strength, and avoiding oil, gas and water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

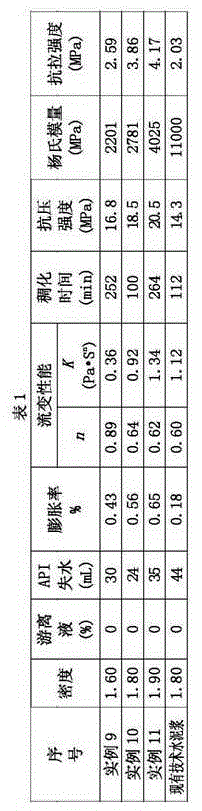

Examples

Embodiment 1

[0018] Embodiment 1, the elastic anti-channeling cement slurry raw material contains 100 parts by weight of cement, 15 to 40 parts of elastic material, 40 to 65 parts of coarse silica sand, 20 to 30 parts of silicon powder, and 5 to 10 parts of fine silica sand. 3 to 6 parts of expansion agent, 17.7 to 40.5 parts of additives, 30 to 45 parts of water. The liquid-cement ratio in the elastic anti-channeling cement slurry obtained by the invention is 45% to 75%, and the liquid-cement ratio is the percentage of additive and mixing water in the cement mass.

Embodiment 2

[0019] Embodiment 2, the elastic anti-channeling cement slurry raw material contains 100 parts by weight of cement, 15 parts or 40 parts of elastic material, 40 parts or 65 parts of coarse silica sand, 20 parts or 30 parts of silicon powder, and 5 parts or 10 parts of fine silica sand. 3 or 6 parts of expansion agent, 17.7 or 40.5 parts of additives, 30 or 45 parts of water.

Embodiment 3

[0020] Example 3, the elastic anti-channeling cement slurry is obtained according to the following preparation method: the required amount of cement, elastic material, coarse silica sand, silicon powder, fine silica sand, additives and water are uniformly mixed to obtain the elastic anti-channeling cement slurry. In the present invention, by adding latex elastic material, expansion agent and silica sand and silica powder of different particle sizes, reasonable particle gradation is achieved by using close packing theory; close packing improves cement density, corrosion resistance, perforation impact resistance and Reduce the permeability; the expansion agent causes the volume expansion of the cement to produce chemical prestress, enhances the cementation force between the annulus and the casing and the formation, and effectively closes the micro-annulus; works together with the latex to achieve better anti-channeling ability, and at the same time improves the cementing second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com