Low-modulus medical titanium alloy and preparation method thereof

A titanium alloy, low modulus technology, applied in the field of metallurgy, can solve the problems of low strength of titanium alloy, small superelastic recovery, difficult smelting and casting processing, etc., and achieves improved superelasticity, low Young's modulus, good The effect of cold workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

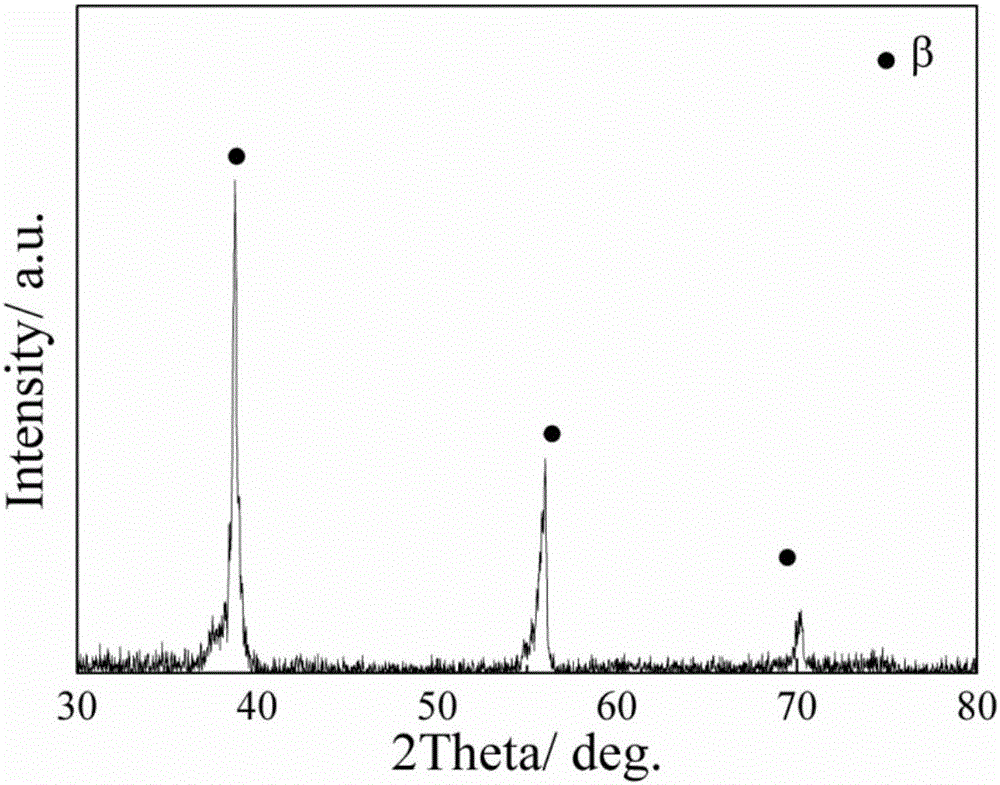

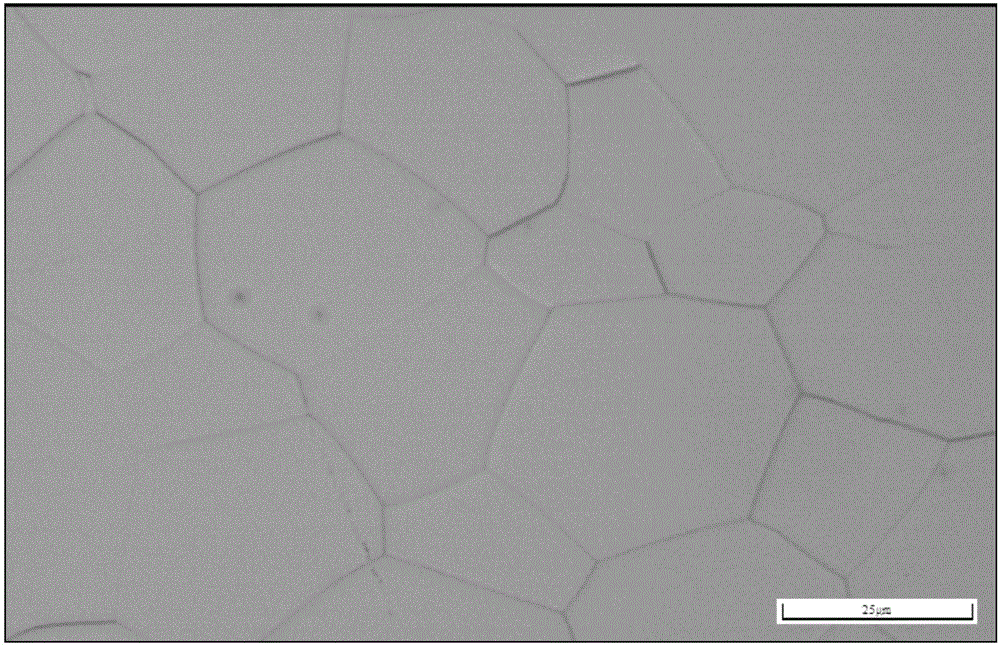

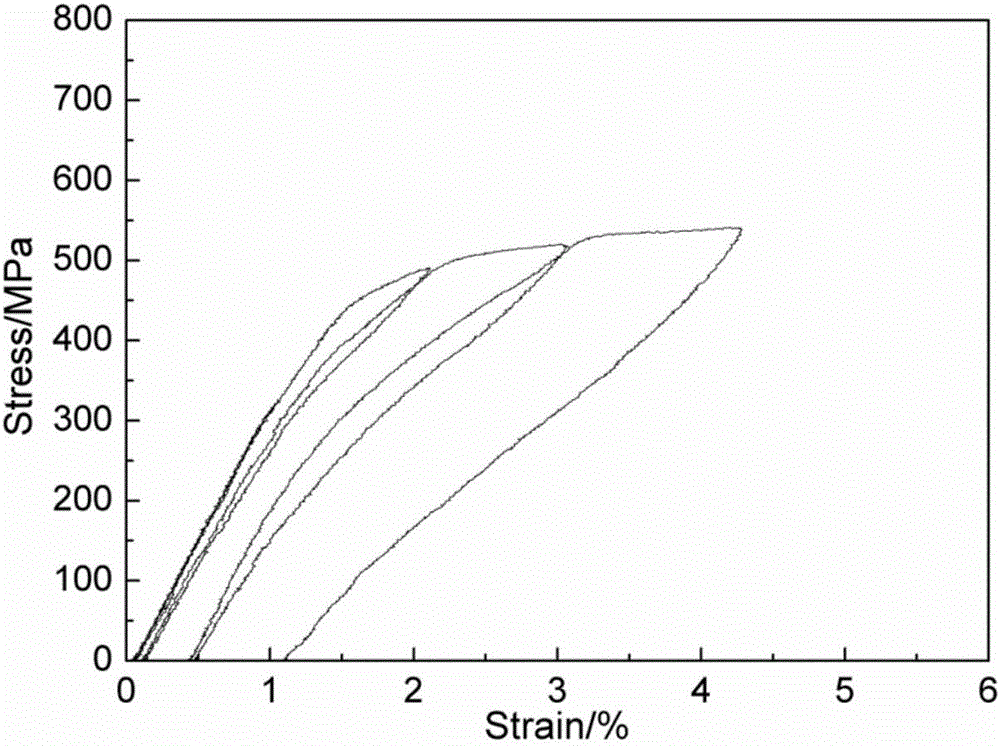

[0051] Ti with a purity of ≥99.95%, Cr with a purity of ≥99.95%, and Nb with a purity of ≥99.95% are used as raw materials, and an alloy ingot with a molar percentage of 22% Nb, 2% Cr, and the balance of Ti is prepared by high vacuum arc melting . The ingot was homogenized and annealed at 1000°C for 10 hours, followed by solid solution at 850°C for 1 hour, and cold rolled at room temperature by about 90%. The sheet obtained by cold rolling was annealed at 800°C for 1 hour and then quenched as the final test sample state. In this state, the alloy is a single β phase, the Young's modulus measured by nanoindentation is 56.4GPa, the tensile strength measured by static load tensile method is about 568MPa, and the superelastic recovery is about 2.8%.

Embodiment 2

[0053] Ti with a purity of ≥99.95%, Cr with a purity of ≥99.95%, and Nb with a purity of ≥99.95% are used as raw materials, and an alloy ingot with a molar percentage of 10% Nb and 8% Cr with a balance of Ti is prepared by high vacuum arc melting. The ingot was homogenized and annealed at 950°C for 10 hours, then solidified at 850°C for 1 hour, and pulled out at room temperature to obtain a titanium alloy wire with a final diameter of about 1.0mm. After the wire was annealed at 800°C for 1 hour, the final test sample was taken state. The tensile strength obtained by tensile test of the alloy in this state is about 761MPa, the elongation is about 18%, and the Young's modulus is 56.4GPa.

Embodiment 3

[0055] Ti with a purity ≥99.95%, Cr with a purity ≥99.95%, Nb with a purity ≥99.95% and Sn with a purity ≥99.95% are used as raw materials, and the mole percentage is 12% Nb, 2% Cr, 1% Sn prepared by high vacuum arc melting , Alloy ingot with the balance being Ti. The ingot was homogenized and annealed at 1000°C for 10 hours, followed by solid solution at 900°C for 1 hour, and cold-rolled 90% at room temperature. After annealing the thin sheet obtained by cold rolling at 800°C for 1 hour, it was aged at 200°C for 1 hour as the final test sample state. The alloy in this state has a Young's modulus of 65.3GPa measured by nanoindentation, a tensile strength of about 710MPa, and an elongation of about 14%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com