Elastic cement paste and preparation method thereof

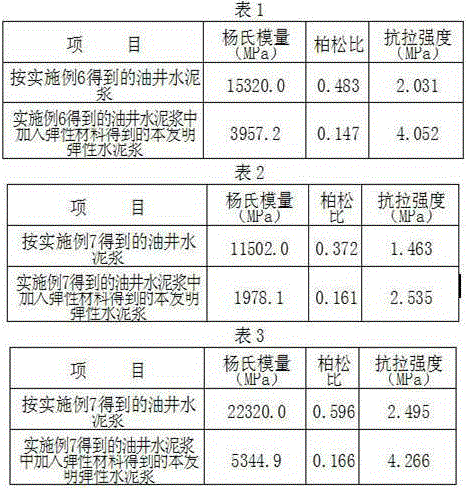

A technology of cement slurry and oil well cement slurry, which is applied in the field of oil well cement slurry, can solve the problems of cement stone breaking, affecting mining, microcracks, etc., and achieve the improvement of tensile strength, reduction of annular channeling, and reduction of Young's modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the raw material of the elastic cement slurry includes oil well cement slurry and elastic material; wherein: the elastic material is 3% to 40% of the cement mass in the oil well cement slurry.

Embodiment 2

[0022] Embodiment 2, the raw material of the elastic cement slurry includes oil well cement slurry and elastic material; wherein: the elastic material is 3% or 40% of the cement mass in the oil well cement slurry.

Embodiment 3

[0023] Example 3, the elastic cement slurry is obtained according to the following preparation method: add the required amount of elastic material to the oil well cement slurry and mix evenly to obtain the elastic cement slurry. The method of the present invention is simple, does not require additional equipment, is beneficial to on-site implementation, and has a wide source of raw materials and low cost. By adding an elastic material that reduces the Young's modulus of cement stone to the oil well cement slurry, the inherent brittleness of cement stone can be effectively solved. During the subsequent perforation and large-scale fracturing of oil and gas wells, micro-cracks appear inside the cement stone and / or micro-annular gaps appear on the cementing interface, and oil, gas and water flow through underground layers, seriously affecting Crude Oil Recovery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com