Vibration pick-up structure on basis of flexible main beam for vibration energy harvester

A vibration energy harvesting, main beam technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Small Young's modulus and wide band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

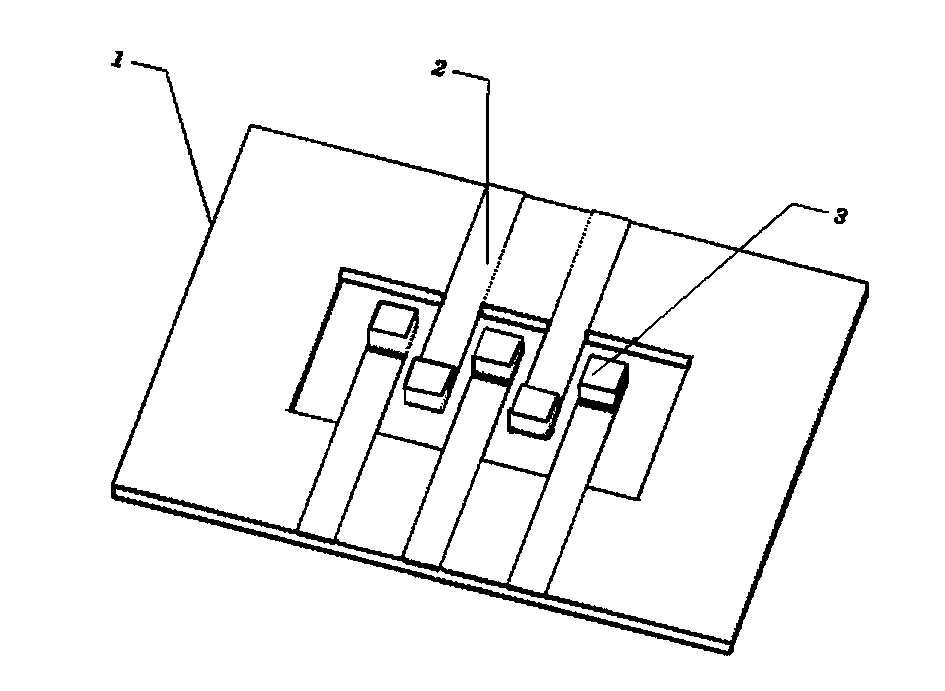

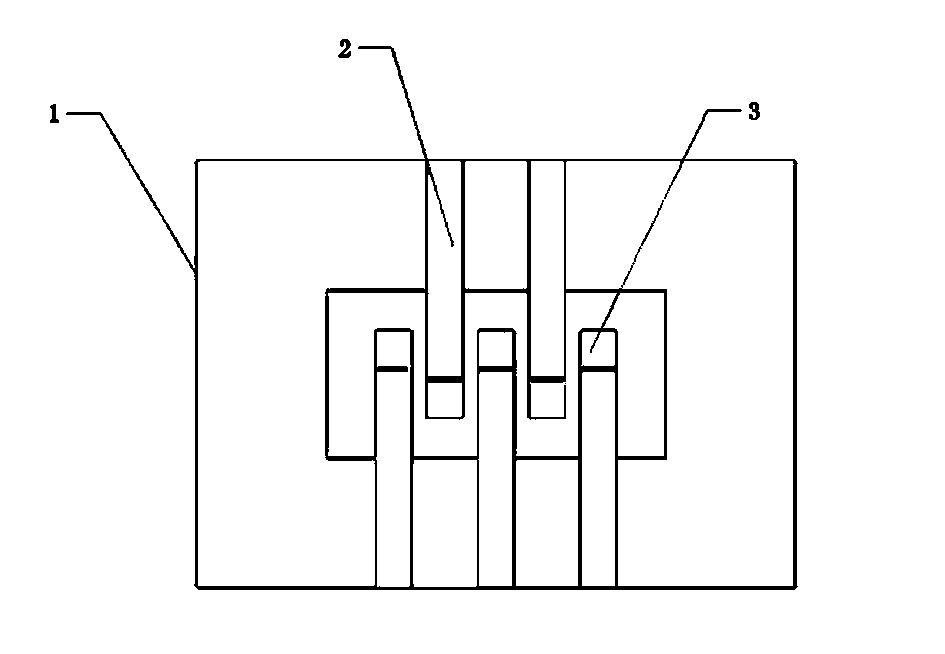

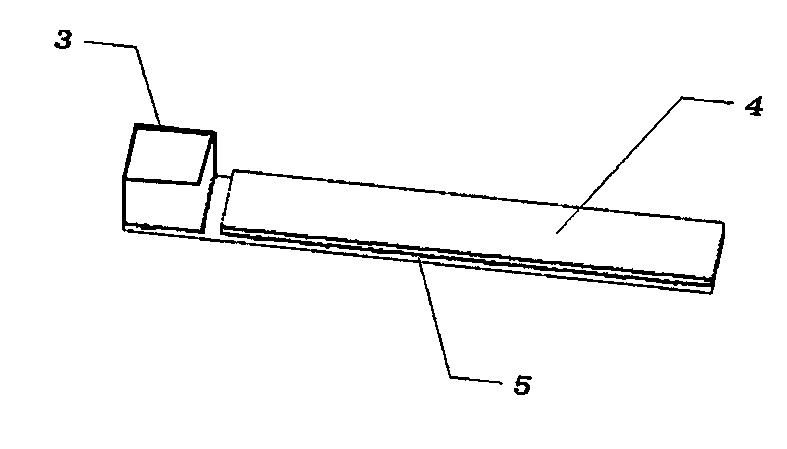

[0026] Such as figure 1 As shown, the present invention includes a flexible main beam 1, a piezoelectric cantilever beam 2 and a mass block 3. The flexible main beam 1 is a rectangular frame structure with a rectangular hole in the middle; one end of the piezoelectric cantilever beam 2 is bonded and fixed on the flexible main beam 1, the other end is suspended above the rectangular hole, the suspended length of the piezoelectric cantilever 2 is less than the width of the rectangular hole, and the mass block 3 is attached to the suspended end of the piezoelectric cantilever 2; several piezoelectric cantilever beams 2 are respectively in The two sides of the rectangular hole are interdigitated and arranged at equal intervals parallel to the short side of the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com