Manufacturing method for soft-magnetic Fe-Si-Al-Ni alloy powder

A kind of alloy powder, manufacturing method technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

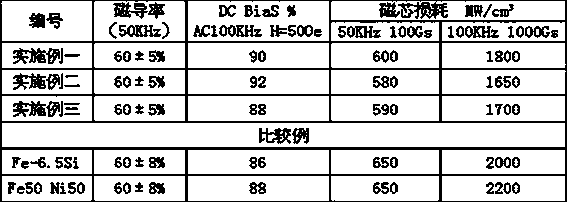

Examples

Embodiment 1

[0016] 1) The alloy is smelted in a nominal 500kg induction heating vacuum quick-setting furnace. Industrial pure iron, polysilicon, pure aluminum, pure nickel, manganese metal, ferrophosphorus alloy and sponge titanium are put into the furnace for smelting in a certain proportion, and they are quickly solidified into flakes under vacuum protection. The mass percentage content of its chemical composition is: Si4.50%, Al4.0%, Ni1.50%, P0.30%, Mn0.20%, Ti0.40%, C0.012%, O280PPm, N230PPm, the rest is Fe ;

[0017] 2) Break the above-mentioned alloy flakes into 3-10mm granular flakes by mechanical crushing method;

[0018] 3) Carry out hydrogen protection heat treatment on the obtained granular flakes at a temperature of 1050°C for 3 hours;

[0019] 4) Put the heat-treated pellets into a ball mill to grind them into a fine powder of -100 mesh (<150μm);

[0020] 5) Carry out nitrogen protection heat treatment on the above-mentioned fine powder, the temperature is 800 ℃, keep war...

Embodiment 2

[0025] 1) The smelting of the alloy and the preparation of thin flakes are the same as in Example 1. The mass percentage content of the chemical composition of the alloy is: Si5.0%, Al3.0%, Ni1.50%, P0.50%, Mn0. 40%, Ti0.10%, C0.010%, O 2BOPPm, N235ppm, the rest is Fe;

[0026] 2) The thin flakes are mechanically crushed into 3-10mm granular flakes;

[0027] 3) The heat treatment of the sheet material is the same as that of Example 1-3, the heat treatment temperature is 1150°C, and the holding time is 2 hours;

[0028] 4) Ball milling of pellets and flakes is the same as that of Example 1-4;

[0029] 5) The heat treatment of the fine powder is the same as that of Example 1-5, the heat treatment temperature under nitrogen protection is 880°C, and the temperature is kept for 4 hours;

[0030] 6) Electromagnetic properties of the alloy: μo is 2350Gs / oe, μm is 19500Gs / Oe, Hc is 0.16Oe, ρ is 68μΩ . ,cm.

Embodiment 3

[0032] 1) Alloy smelting and thin flakes are the same as in Example 1-1. The chemical composition of the alloy is as follows: Si4.0%, Al3.5%, Ni1.50%, P0.10%, Mn0.10 %, Ti0.25%, C0.008%, O 2 80ppm, N 2 30ppm, the rest is Fe;

[0033] 2) The thin flakes are mechanically broken into 3-10mm granular flakes;

[0034] 3) The heat treatment of the granular flakes is protected by hydrogen, the temperature is 950 ° C, and the temperature is kept for 2 hours;

[0035] 4) Put the processed pellets into a ball mill and grind them into a fine powder of -100 mesh;

[0036] 5) The fine powder will be subjected to nitrogen protection heat treatment at a temperature of 900°C for 4 hours;

[0037] 6) Electromagnetic properties of the alloy; μ 0 It is 2400Gs / Oe, μm is 19000Gs / Oe, Hc is 0.15Oe, and ρ is 70μΩ·cm.

[0038] Magnetic properties of alloy powder: jHc 1.14Oe, Ms 190.0emu / g, Mr 0.12 emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com