High capacity multilayer ceramic dielectric capacitor composed of chips and provided with leads

A capacitor and high-capacity technology, applied in multiple fixed capacitors, fixed capacitor casings/packages, and fixed capacitor components, etc., can solve problems such as easy stress generation, chip contact with each other, affecting product installation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

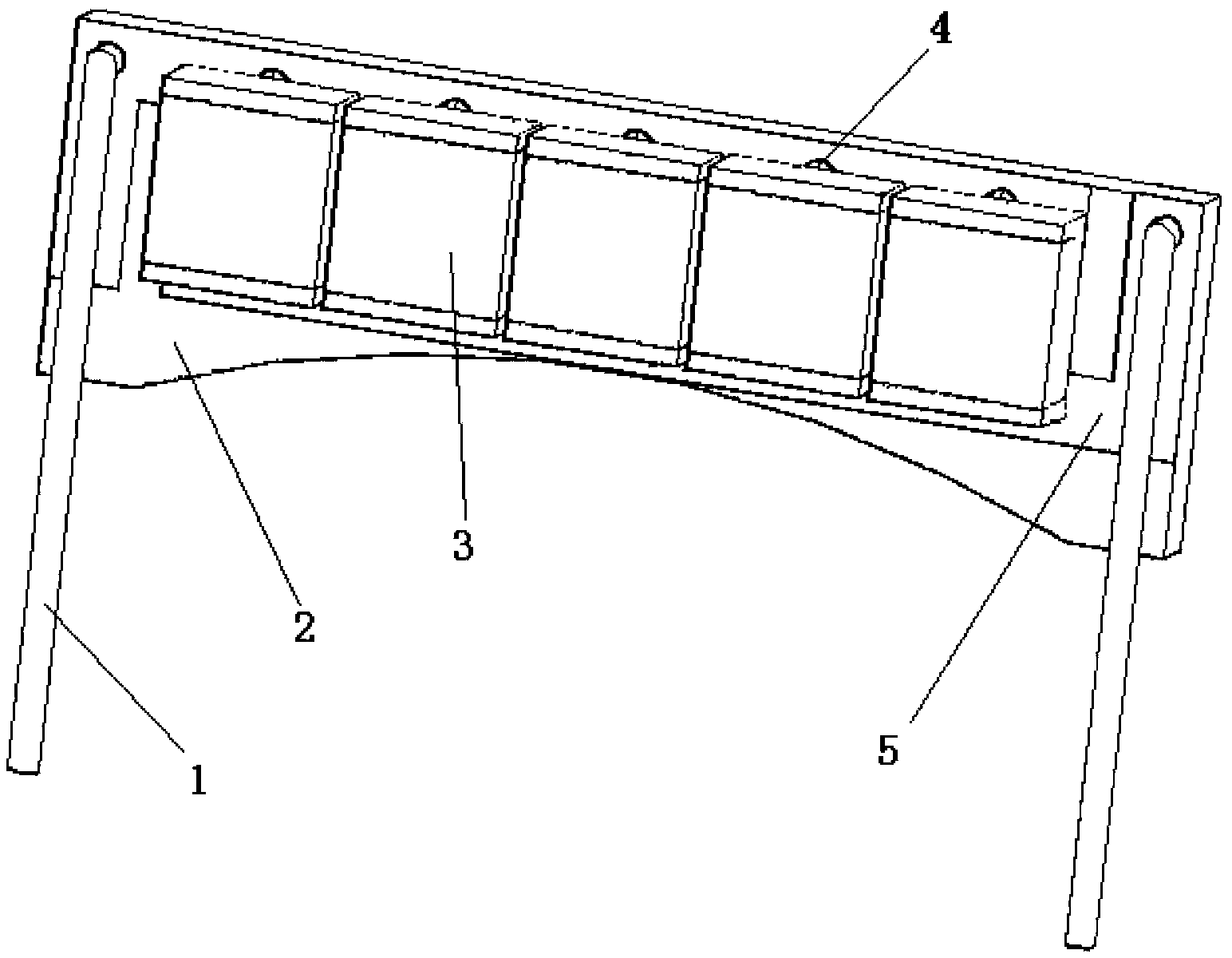

[0018] Such as figure 1 As shown, the present invention provides a schematic flow chart of a leaded large-capacity multilayer ceramic capacitor composed of multiple chips, including lead wires (1), substrate (2), ceramic capacitor chip (3), metal on the substrate via holes (4) and copper foil (5), wherein the ceramic capacitor chip (3) includes multiple chips, and two parallel copper foils (5) are coated on the substrate (2) in parallel, so The ceramic capacitor chips (3) are vertically arranged on the substrate (2) at equidistant distances, and the capacitor chips (3) on both sides of the substrate (2) are connected through metallized via holes (4). One section of the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com