Preparation method of metal-carbon composite

A technology of carbon composite materials and carbon materials, which is applied in the field of metal matrix composite materials, can solve the problems of unsatisfactory performance and poor compactness, and achieve the effects of low cost, improved sintered compactness, and improved sintered diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

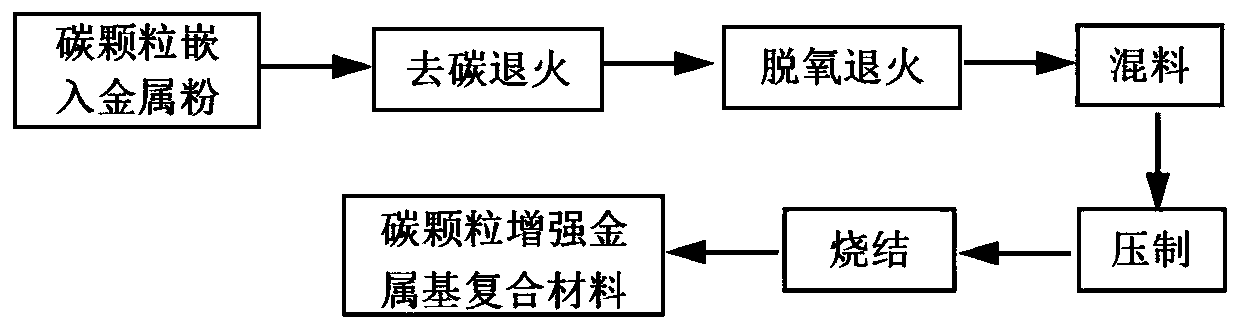

Method used

Image

Examples

preparation example 1

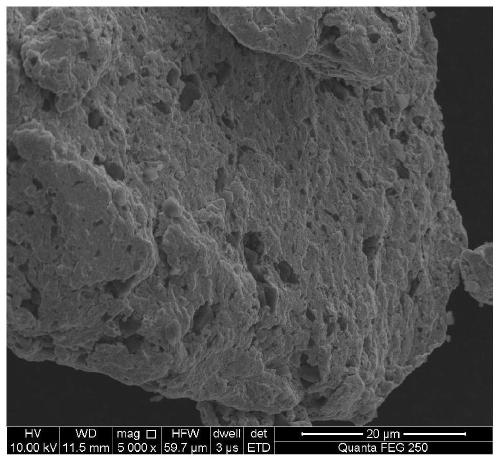

[0083] The preparation method of carbon particle embedding copper powder among the present invention is:

[0084] The short carbon fiber bundles are obtained by heat treatment at 700° C. for 50 minutes under an inert atmosphere or vacuum condition; the short carbon fiber bundles have a diameter of 6-8 μm and a length of 1-4 mm.

[0085] The short carbon fiber bundles and copper powder are mixed according to the volume ratio of 1:3 and then ball milled; the mixed powder is obtained; the condition parameters of the ball mill are: the rotating speed is 280r / min, the ball milling time is 6h, and the ball milling balls are stainless steel balls and cemented carbide Balls with a diameter of 3mm to 10mm (the mass ratio of ball milling balls with diameters of 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, and 9mm is 4:8:11:20:12:8:6:1). Then sieve 400 mesh sieves, get undersieve, as standby material;

[0086] The spare material was placed in the air, and pre-oxidized at 280°C for 15 minutes; then hyd...

preparation example 2

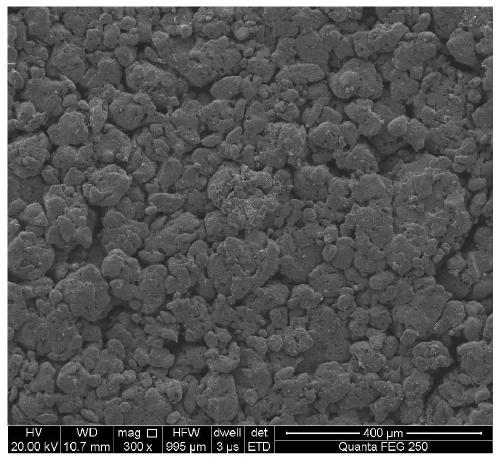

[0088] The preparation method of carbon fiber embedding nickel powder among the present invention is:

[0089] Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution; then impregnate the short carbon fibers in an 80°C phenolic resin alcohol saturated solution for 2 hours; then dry at 120°C for 2 hours; the short carbon fiber bundle The diameter is 6-8 μm, and the length is 1-4 mm.

[0090] Mix short carbon fiber bundles and electrolytic nickel powder (particle size 150 μm) according to the volume ratio of 2:3 and then perform ball milling; obtain mixed powder; the condition parameters of the ball milling are: the rotating speed is 250r / min, the ball milling time is 4h, and the ball milling balls are Stainless steel balls and hard alloy balls, the ball diameter is 3mm ~ 10mm (the mass ratio of ball milling ball diameters 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1 ); Finally, annealing heat treatment is carr...

preparation example 3

[0093] The preparation method of carbon particle embedding iron powder among the present invention is:

[0094] The short carbon fiber bundles are obtained by heat treatment at 700° C. for 60 minutes under an inert atmosphere or vacuum condition; the short carbon fiber bundles have a diameter of 6-8 μm and a length of 1-4 mm.

[0095]Mix short carbon fiber bundles and reduced iron powder (particle size 120 μm) according to the volume ratio of 1:10 and then perform ball milling; the mixed powder is obtained; the condition parameters of the ball milling are: the rotating speed is 250r / min, the ball milling time is 6h, and the ball milling balls are Stainless steel balls and hard alloy balls, the ball diameter is 3mm ~ 10mm (the mass ratio of ball milling ball diameters 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1 ). Then sieve 400 mesh sieves, get undersieve, as standby material;

[0096] The spare material was placed in the air, and pre-oxidized at 350°C for 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com