Preparation method for polystyrene/polyvinylidene fluoride cation exchange membrane

A kind of polyvinylidene fluoride, cation exchange technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

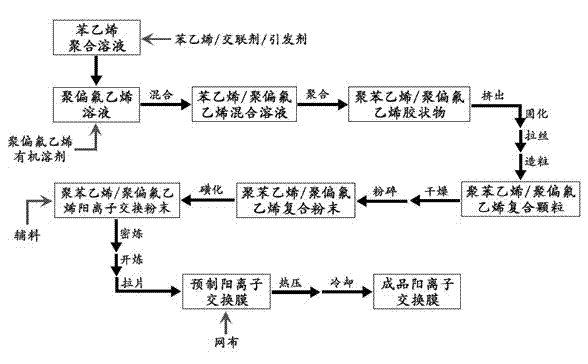

Method used

Image

Examples

Embodiment 1

[0029]In a 500ml three-neck flask, add 50g of polyvinylidene fluoride powder (brand DF-1), add 180ml of dimethylacetamide, heat to 85°C, and stir for 90 minutes to form a transparent polyvinylidene fluoride solution. Take a 250 ml Erlenmeyer flask, add 36.5 g of styrene, 3.5 g of divinylbenzene (80.5% content) and 1.8 g of benzoyl peroxide, and stir magnetically at room temperature until the solid is completely dissolved to obtain a styrene polymerization solution. Slowly add the styrene polymerization solution dropwise into the high-speed stirred polyvinylidene fluoride solution, control the addition within 20 minutes, and then continue stirring for 30 minutes to obtain a homogeneous mixed solution.

[0030] Subsequently, the above mixed solution was poured into clean watch glasses in batches, wrapped and sealed with plastic wrap, placed in an oven, pre-polymerized at 75°C for 2 hours, and polymerized at 85°C for 12 hours. Take out the watch glass, take out the polymerized po...

Embodiment 2

[0035] 45.5 grams of styrene, 4.5 grams of divinylbenzene (80.5%) and 2.0 grams of benzoyl peroxide were used to prepare a styrene polymerization solution to replace the styrene polymerization solution in Example 1, and the remaining proportions remained unchanged. According to the same method as in Example 1, a finished polystyrene / polyvinylidene fluoride cation exchange membrane was prepared.

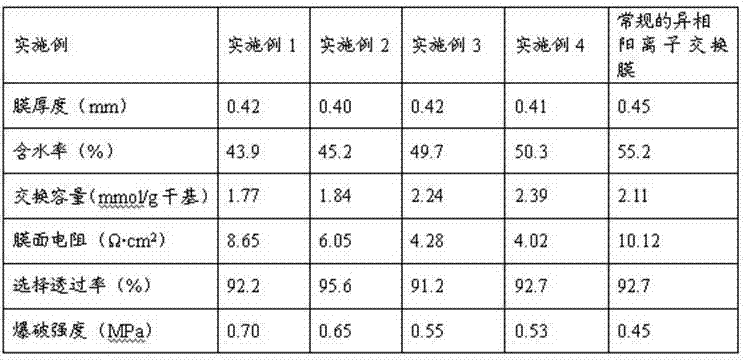

[0036] According to the determination method described in the national standard (HY / T 034.2-1994), the performance of the prepared cation exchange alloy membrane was measured, and the results are shown in Table 1. Membrane resistance is 40% lower than conventional polystyrene-based cation exchange heterogeneous membranes, and membrane strength is increased by 44%.

Embodiment 3

[0038] 55.2 grams of styrene, 4.8 grams of divinylbenzene (80.5%) and 2.0 grams of benzoyl peroxide were used to prepare a styrene polymerization solution to replace the styrene polymerization solution in Example 1, and the remaining proportions remained unchanged. According to the same method as in Example 1, a finished polystyrene / polyvinylidene fluoride cation exchange membrane was prepared.

[0039] According to the determination method described in the national standard (HY / T 034.2-1994), the performance of the prepared cation exchange alloy membrane was measured, and the results are shown in Table 1. The membrane resistance is 58% lower than that of conventional polystyrene-based cation exchange heterogeneous membranes, which is very close to that of cation exchange homogeneous membranes (generally, the membrane resistance of cation exchange homogeneous membranes is 2~4 Ω·cm 2 ); the membrane strength is 22% higher than that of conventional heterogeneous membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com