Patents

Literature

32results about How to "Improve economic level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charging station system of electric automobile and matched charging method thereof

ActiveCN101834455AReasonable layoutNovel structureBatteries circuit arrangementsElectric powerCharging stationHigh pressure

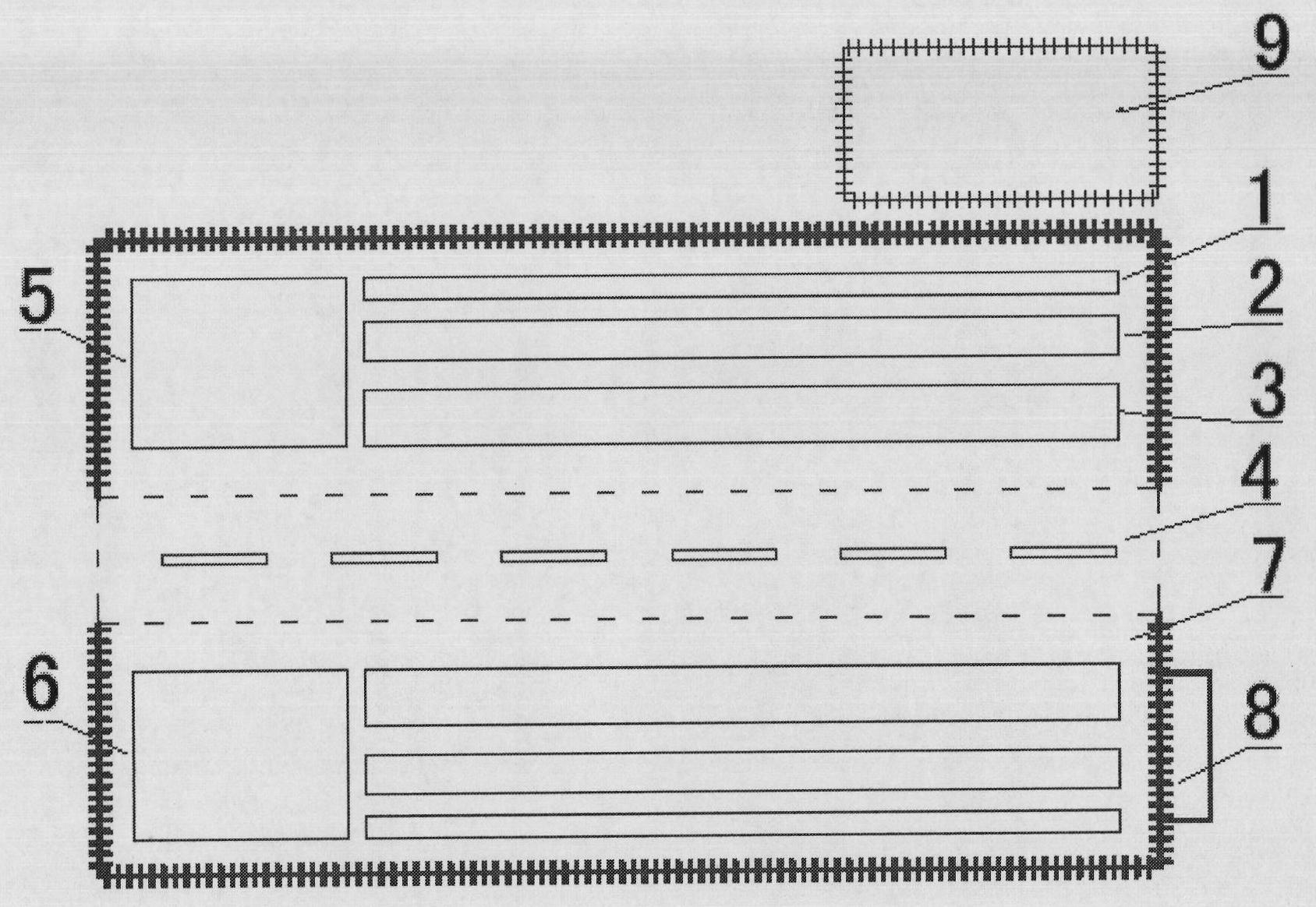

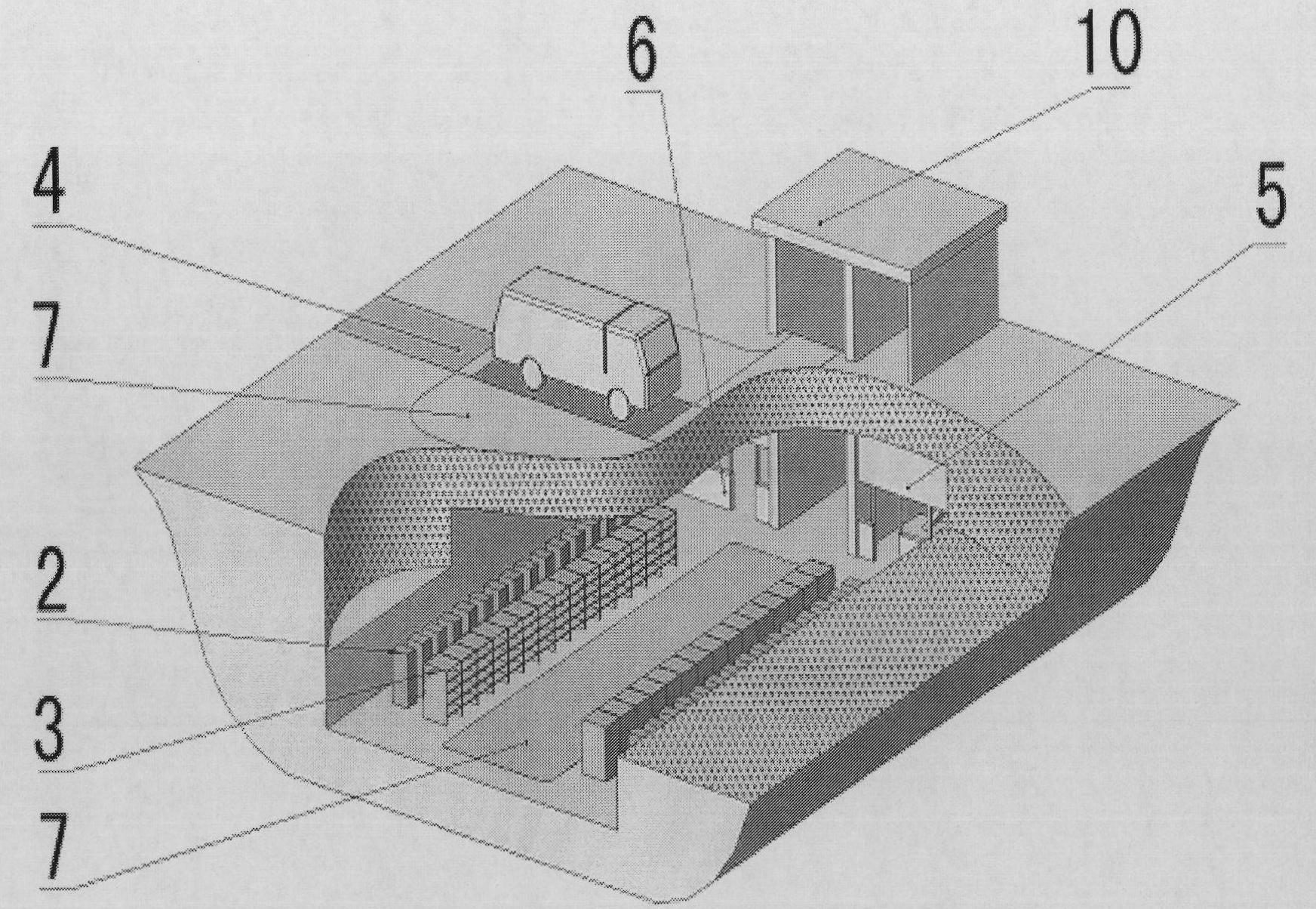

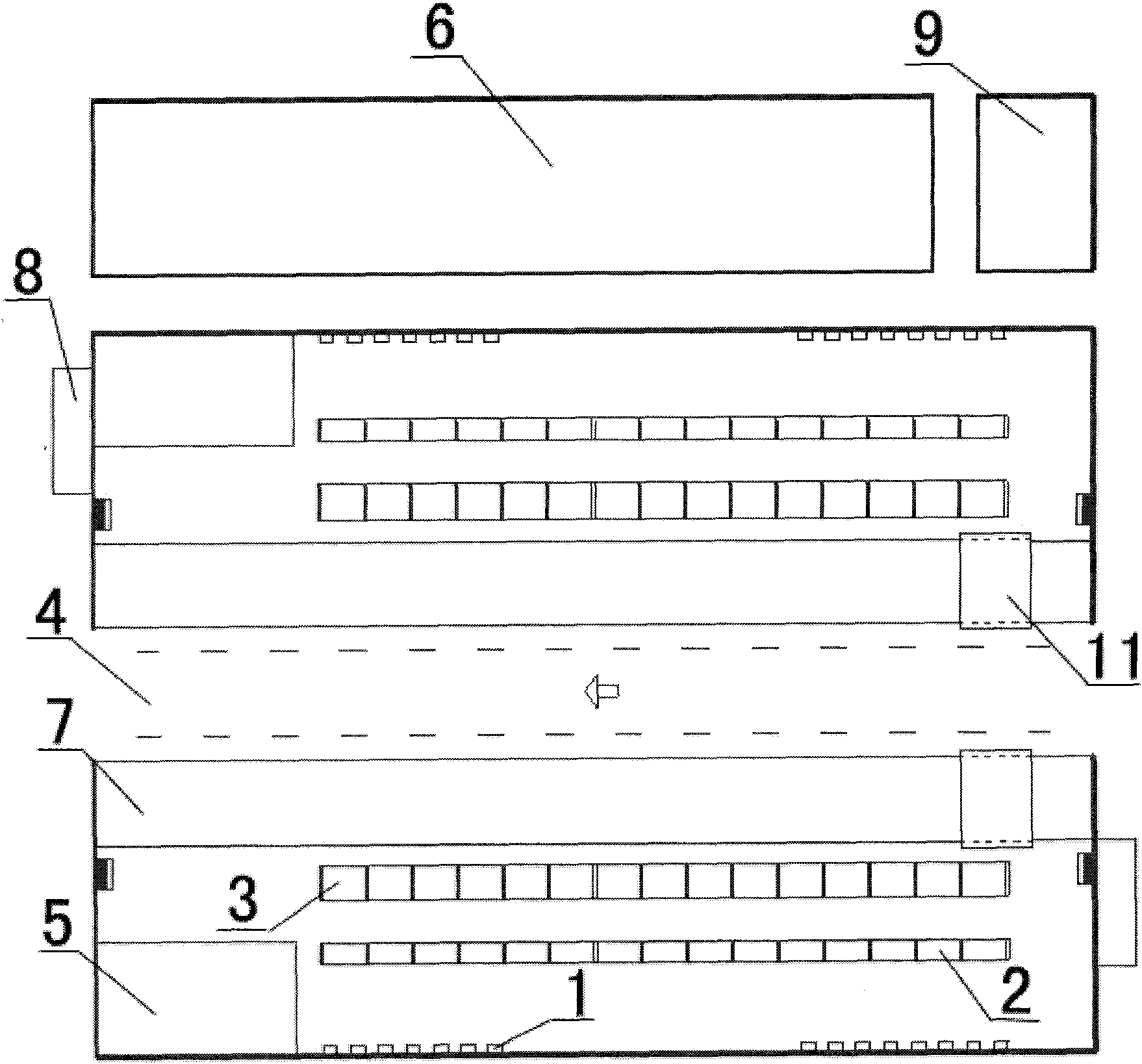

The invention provides a charging station system of an electric automobile and a matched charging method thereof. The charging station system comprises an automobile parking region, a battery replacement unit, a battery storage unit, a charging unit, a low-voltage distribution unit and a high-voltage distribution unit, wherein the automobile parking region is used for packing the electric automobile the batteries of which is to be replaced; the battery replacement unit is used for replacing the batteries of the electric automobile through battery replacement equipment; the battery storage unit is used for storing and charging the batteries; the charging unit is used for charging the batteries stored on the battery storage unit; the low-voltage distribution unit is used for supplying power to the charging unit; and the high-voltage distribution unit is used for converting inputted high-voltage power to low-voltage power. The charging station system of the electric automobile in the invention has the characteristics of reasonable layout and novel structure, can realize rapid charging, improve the charging efficiency and simultaneously replace and charge the batteries of multiple electric automobiles, and has the advantages of high economic level and stable running with lower cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

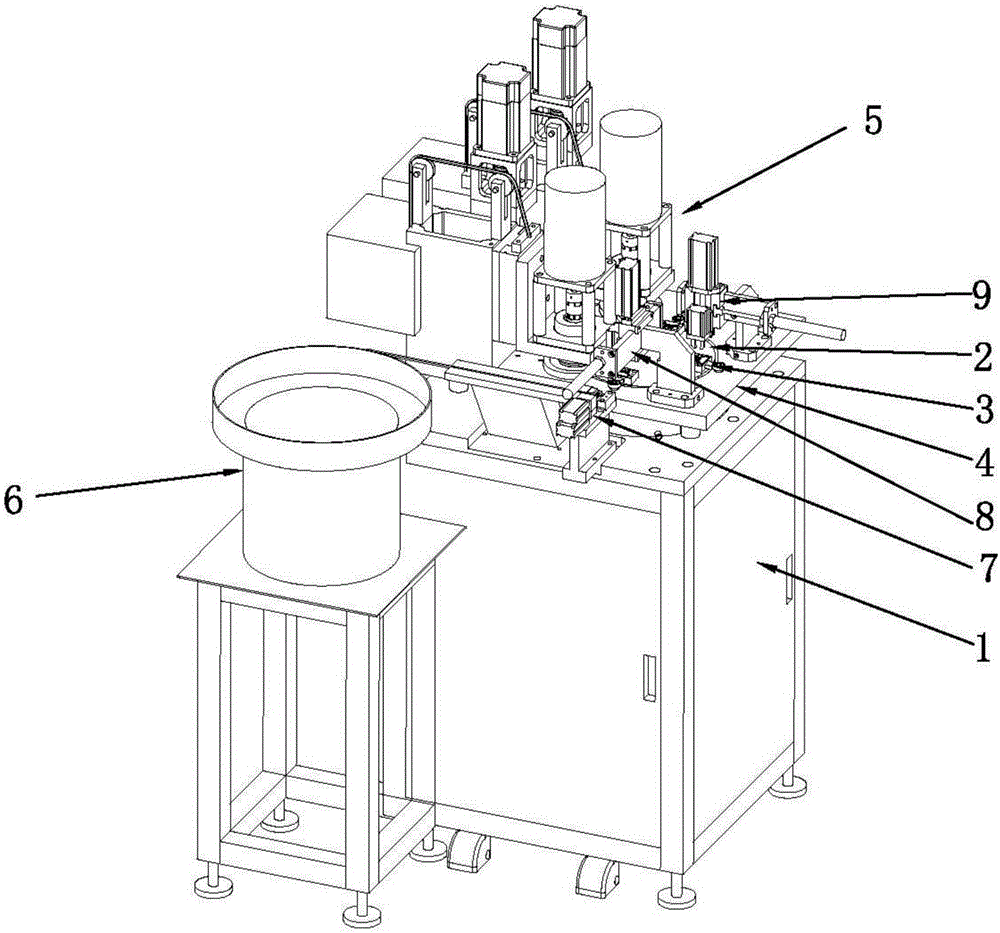

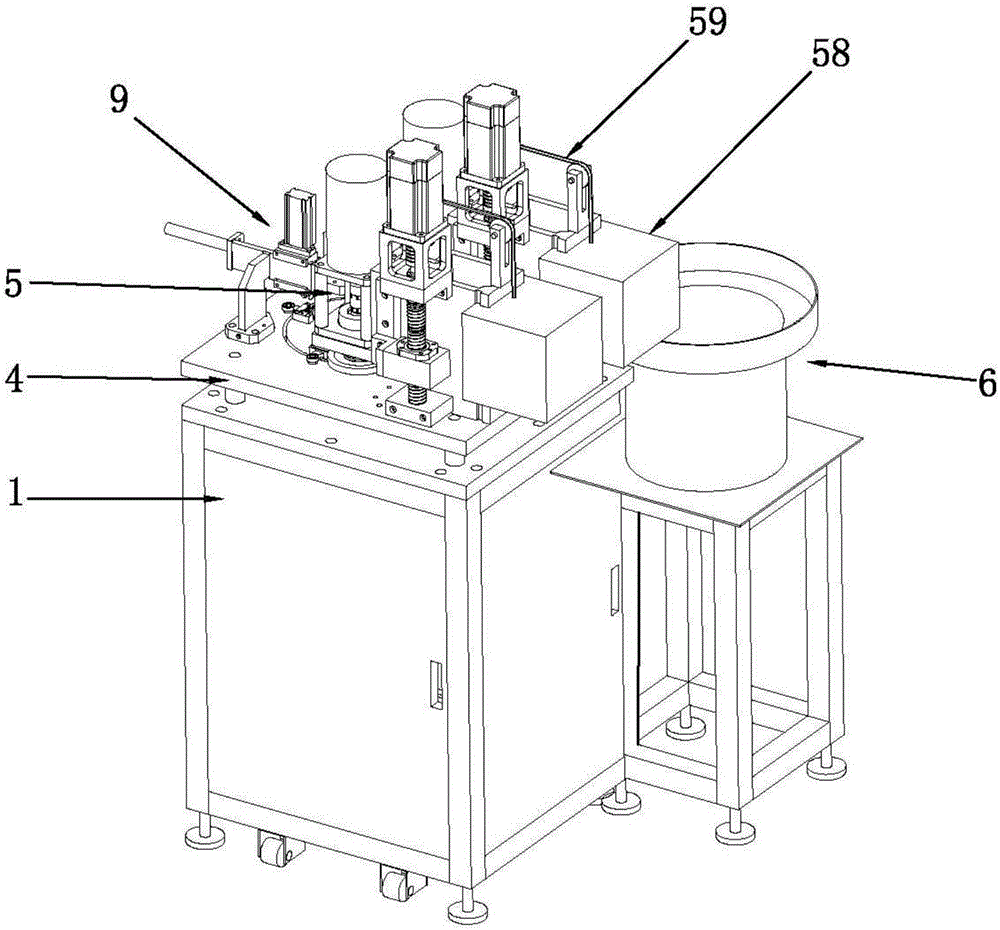

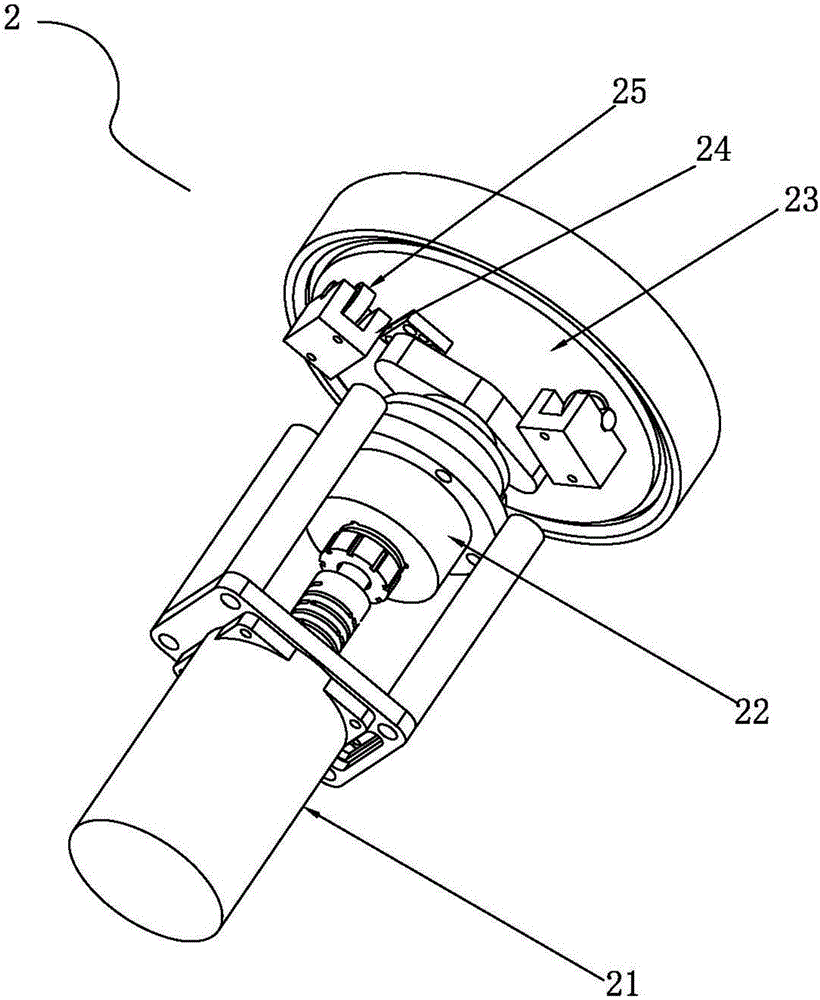

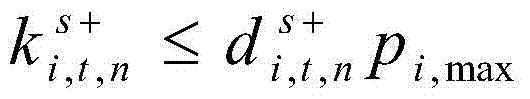

Automatic grinding machine used for grinding metal shell of USB interface

InactiveCN106737056AEasy clampingEasy to processGrinding machinesGrinding feedersAutomatic controlControl system

The invention provides an automatic grinding machine used for grinding a metal shell of a USB interface. The automatic grinding machine comprises a machine case which is internally equipped with a PLC automatic control system and a rotary workbench, wherein a supporting panel is mounted at the outer side of the rotary workbench in parallel; four product positioning devices, two perpendicular grinding devices and loading mechanical hands, which are arranged on the upper end surface of the rotary workbench, are fixedly mounted on the supporting panel; a vibrating disc used for automatically loading is arranged beside the machine case; and a quantitative feeding mechanism is arranged at one side of the discharge hole of the vibrating disc. The automatic grinding machine realizes automatic positioning and grinding for the metal shell of the USB interface, so that grinding auxiliary time is greatly reduced, heavy job of clamping workpieces during large-scale production is reduced, and clamping and processing for the workpieces can be improved, and therefore, the automatic grinding machine has the advantages of reducing labor intensity of workers, improving production efficiency, improving processing quality and the like; and moreover, the production period of the metal shell of the USB interface is shortened, so that production benefits of the enterprises are improved, and economic level of workers is improved.

Owner:XINGKE ELECTRONICS TECH

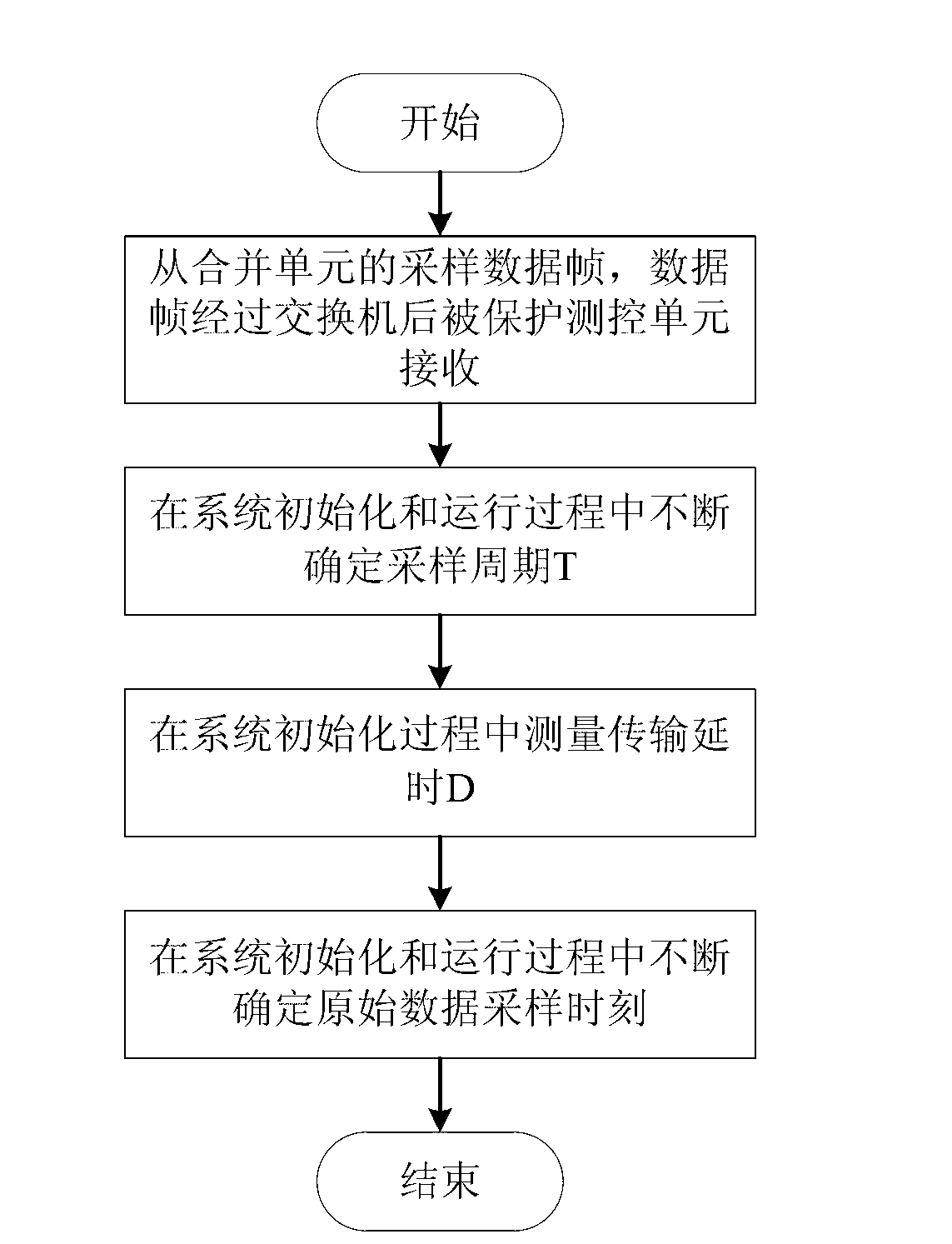

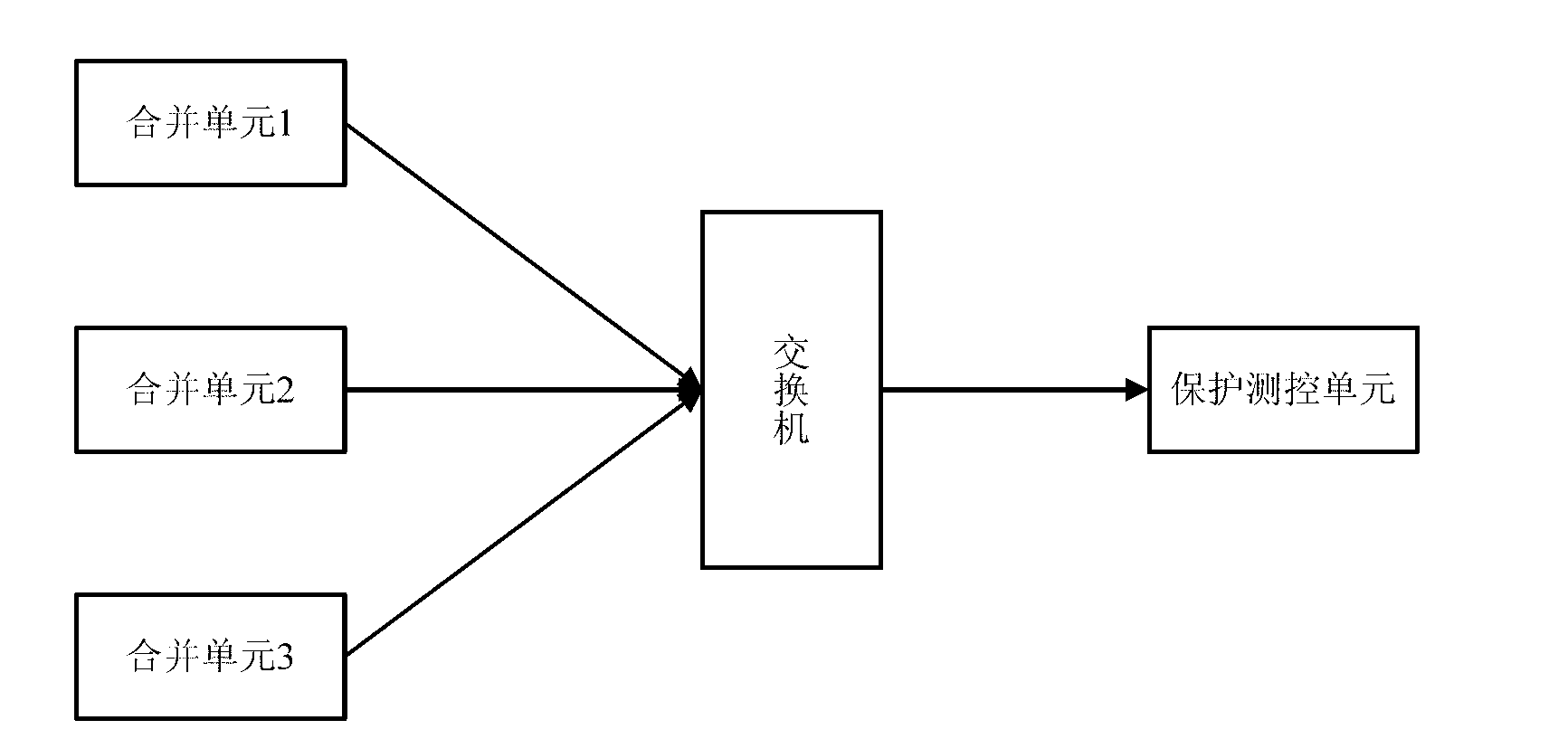

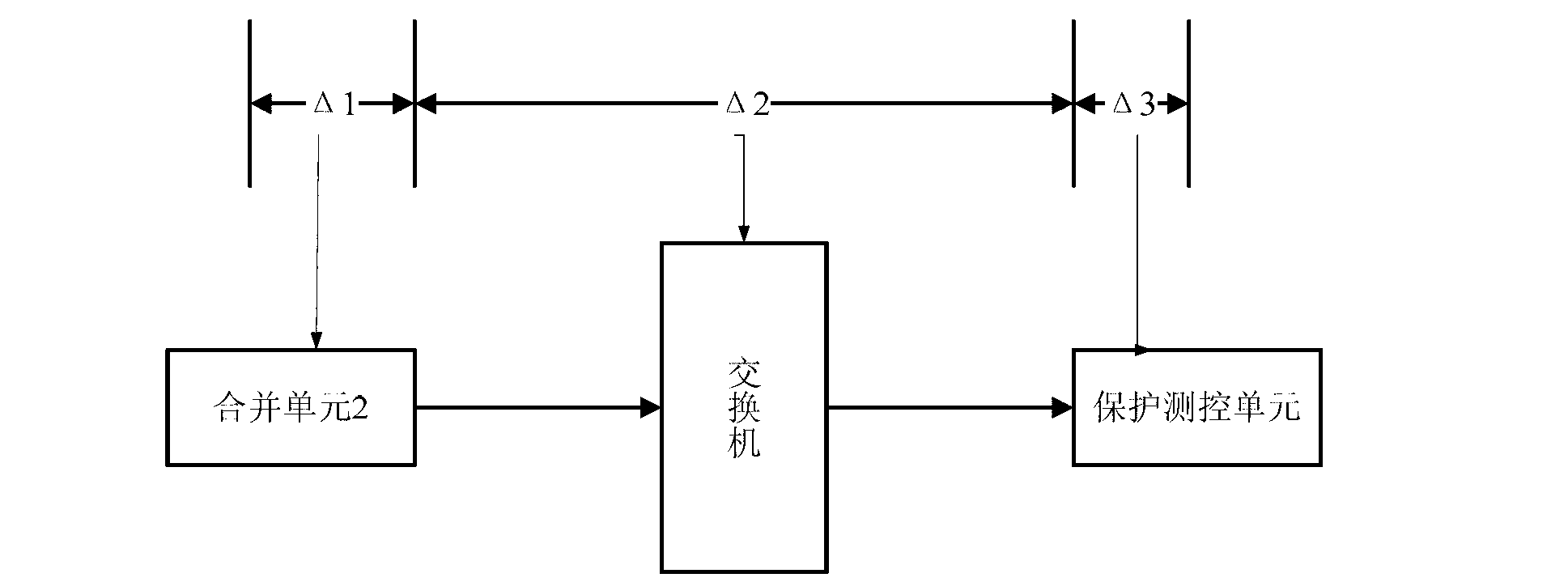

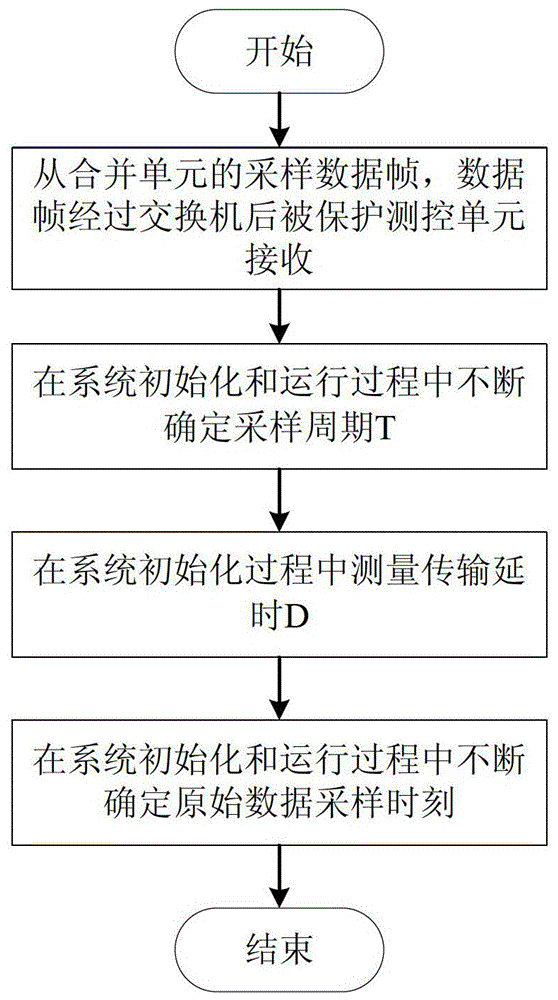

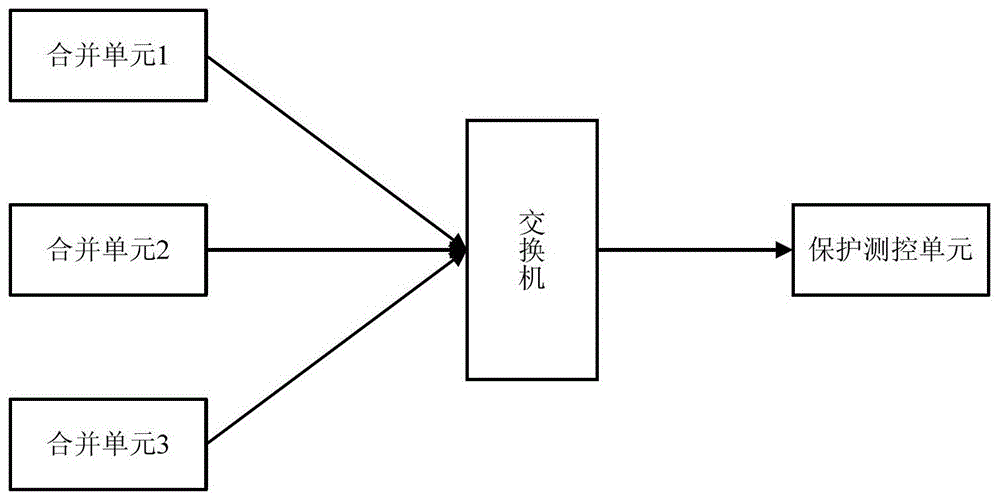

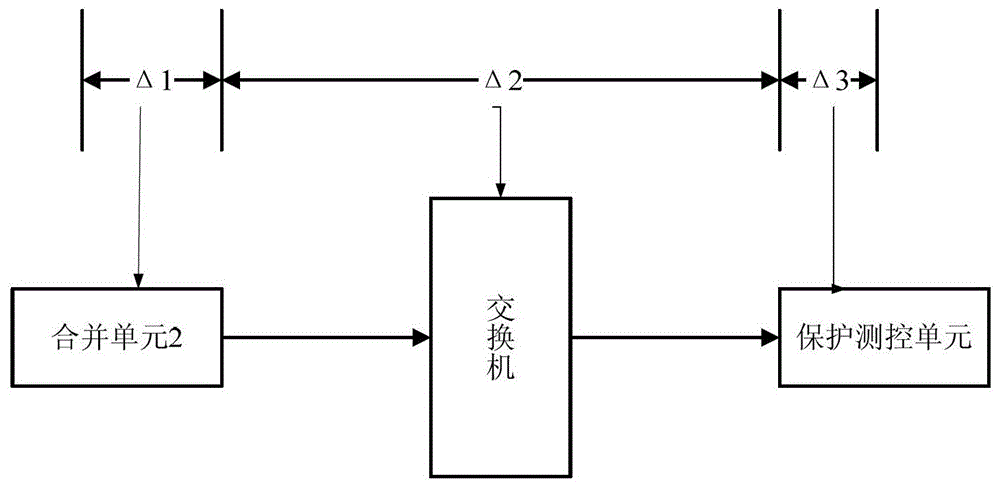

Method for determining sampling moment according to data receiving moment

ActiveCN103227643AReduce complexityLow costAnalogue/digital conversionElectric signal transmission systemsFiberTransmission time delay

The invention relates to a method for determining a sampling moment according to a data receiving moment. A device adopted by the method comprises a merging unit, a switch and a protection and measure-control unit which are sequentially connected through optical fibers. Data sampling for the method is performed uniformly, and the method comprises the following steps: (1), sampling data frames from the merging unit, receiving the data frames by the protection and measure-control unit after the data frames pass through the switch; (2),determining a sampling period T continuously in system initialization and operation processes; (3),measuring transmission time delay D in a system initialization process; and (4), determining a sampling moment of raw data continuously in the system initialization and operation processes. According to the method, uncertainty of time delay of data transmission is eliminated; and further, the switch is adopted in a data transmission process, therefore, the complexity for fiber-optic link can be reduced, and the calculation accuracy of the sampling moment is high.

Owner:CHINA ELECTRIC POWER RES INST +3

Safflower fruit vinegar beverage and method for preparing the same

ActiveCN101480263AImprove economic levelPromote the protection of the environmentWine preparationFood preparationOxideSecretion

The invention relates to safflower fruit vinegar which belongs to the drink field. Safflower, sea backthern and blackcurrant are special local products in the northwest of China, and have great economic value and medicine value, therefore, the invention provides novel safflower fruit vinegar which uses the safflower, the sea backthern, and the blackcurrant as main raw materials, sweetener and preservative are added, and the fruit vinegar is made by a series of processes of materials selection, zymohydrolysis, alcoholic fermentation, acetic acid fermentation, aging, preparation, fine filtering and filling, sterilization and cooling, and the like. The invention has multiple vitamins, amino acids, and biological active ingredients, can stimulate the cranial nerves, promotes the secretion of digestive juice, inhibits the forming of oxide, promotes the improvement of the area economic level, is favorable to environment protection, and has simple process, fast effect, and easy popularization.

Owner:XINJIANG ZHUANGZI IND

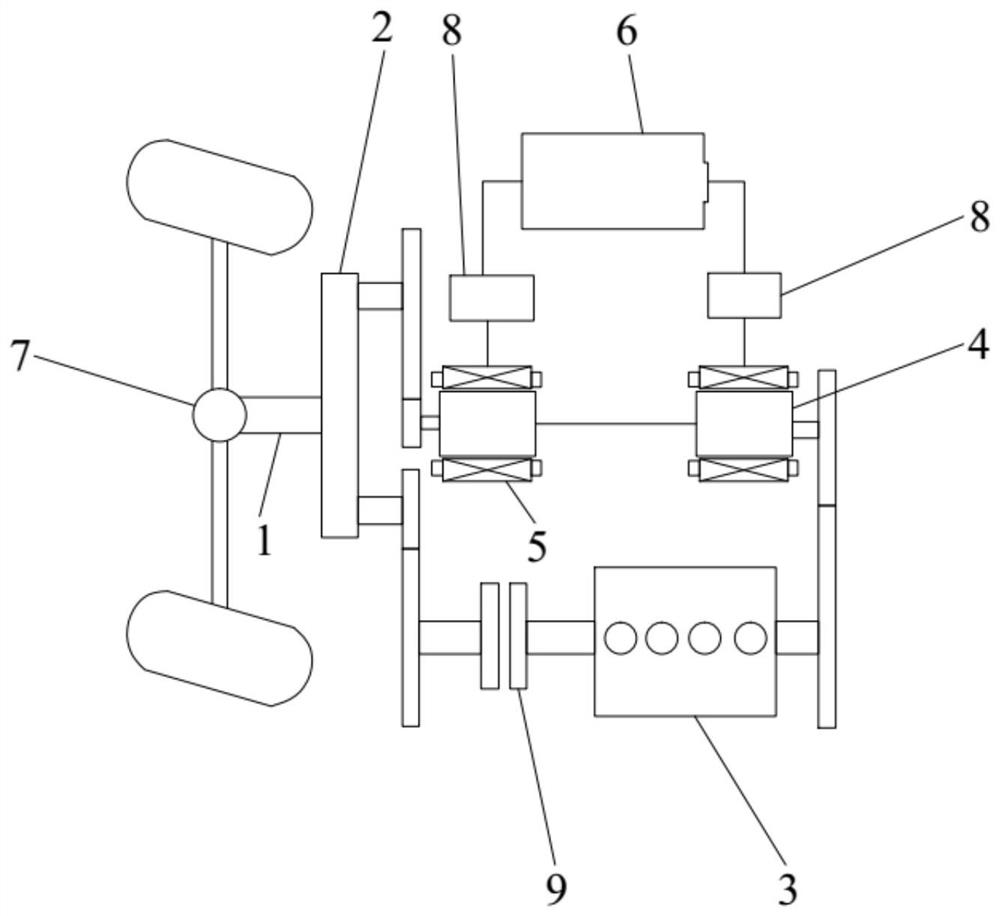

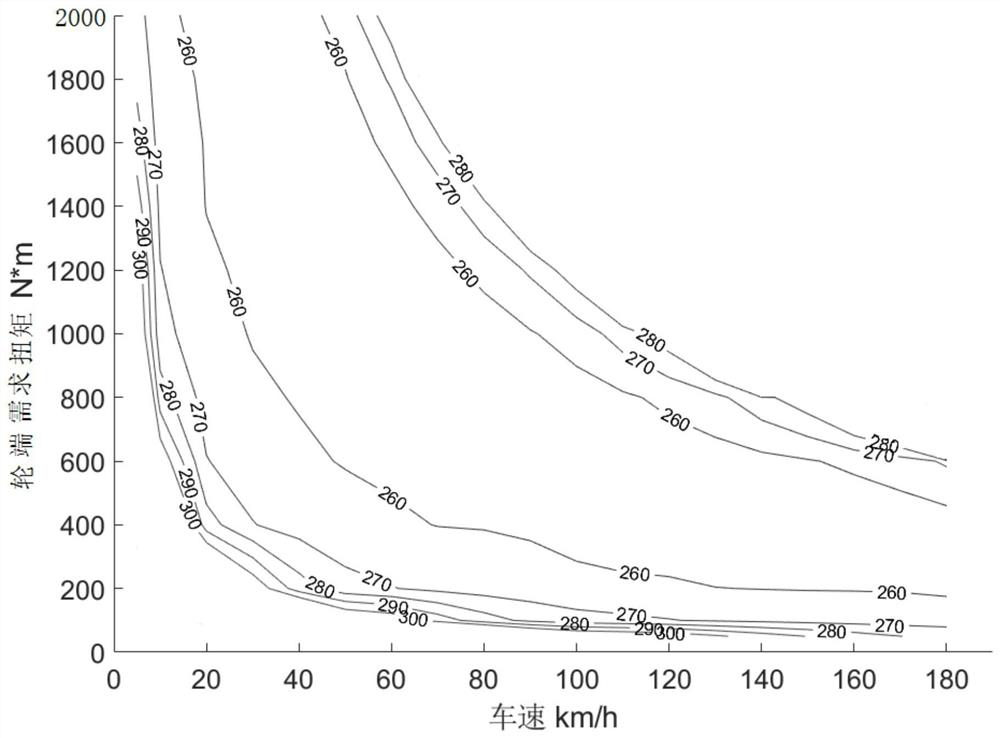

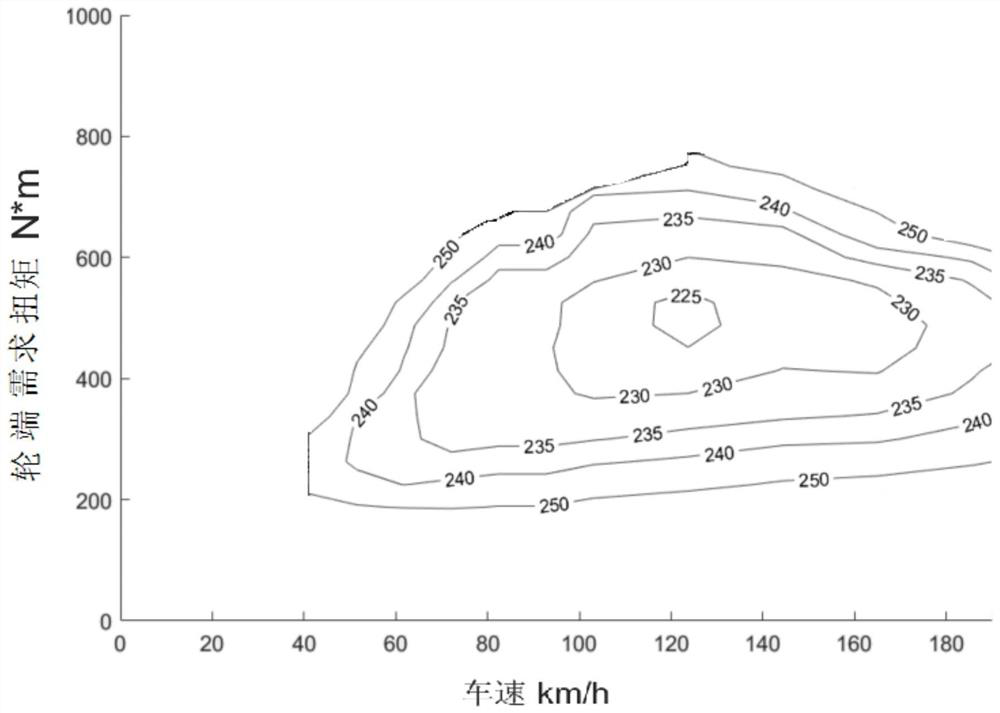

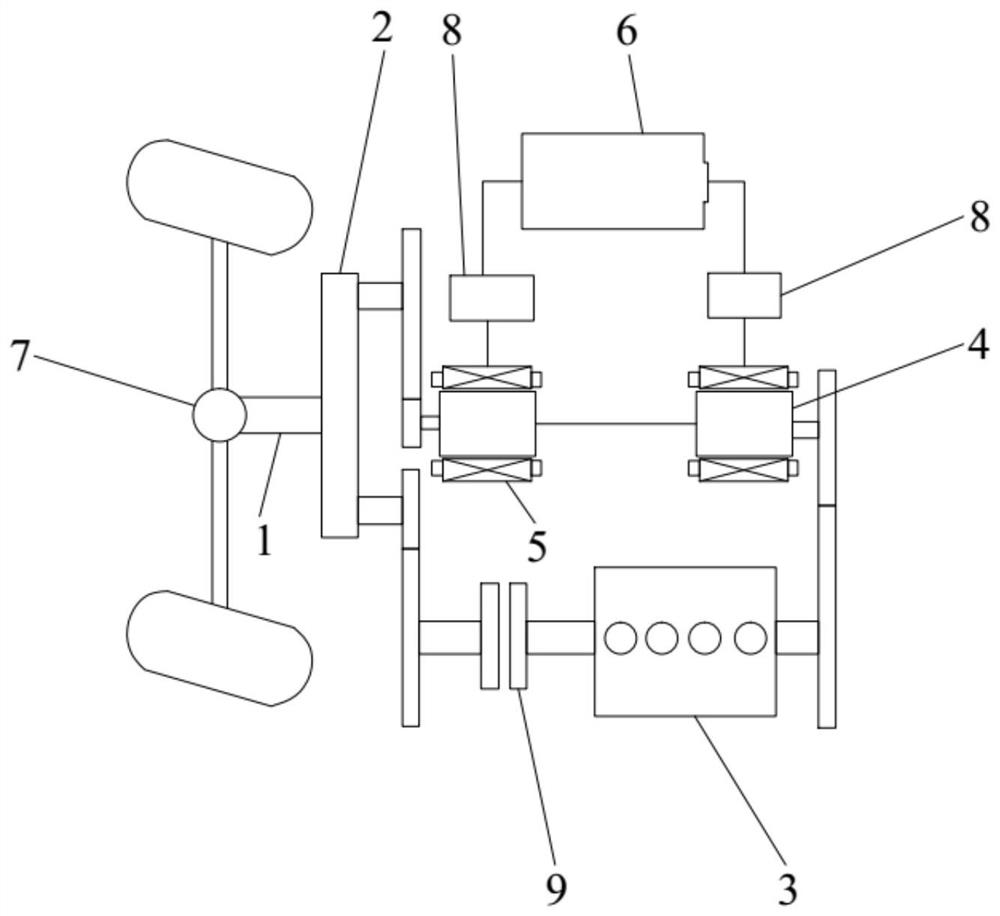

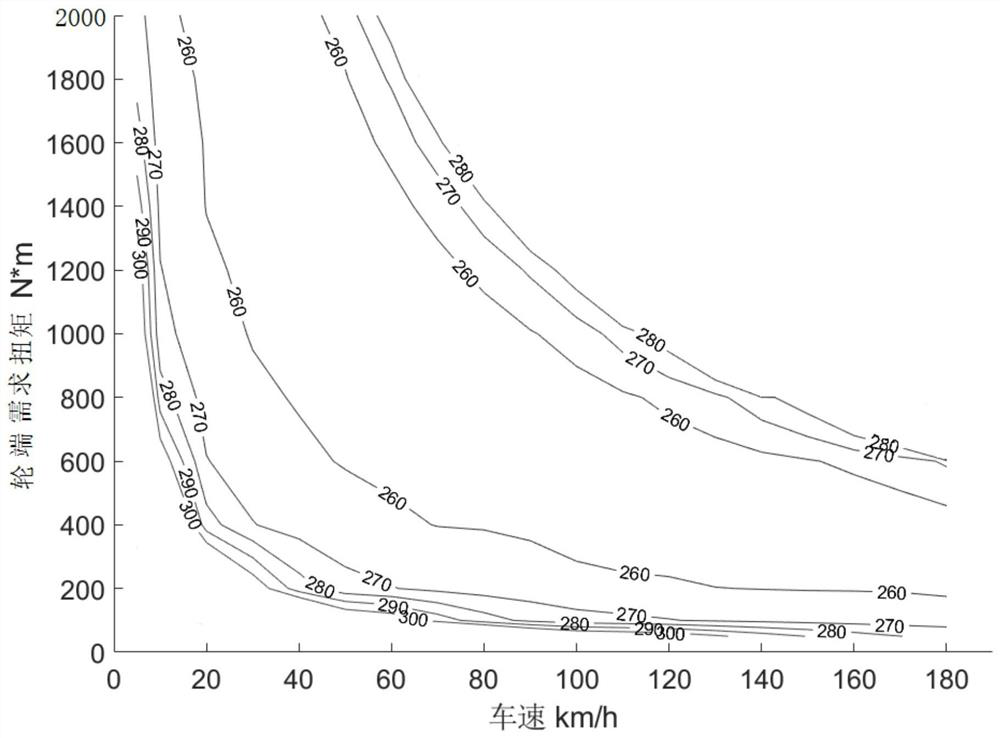

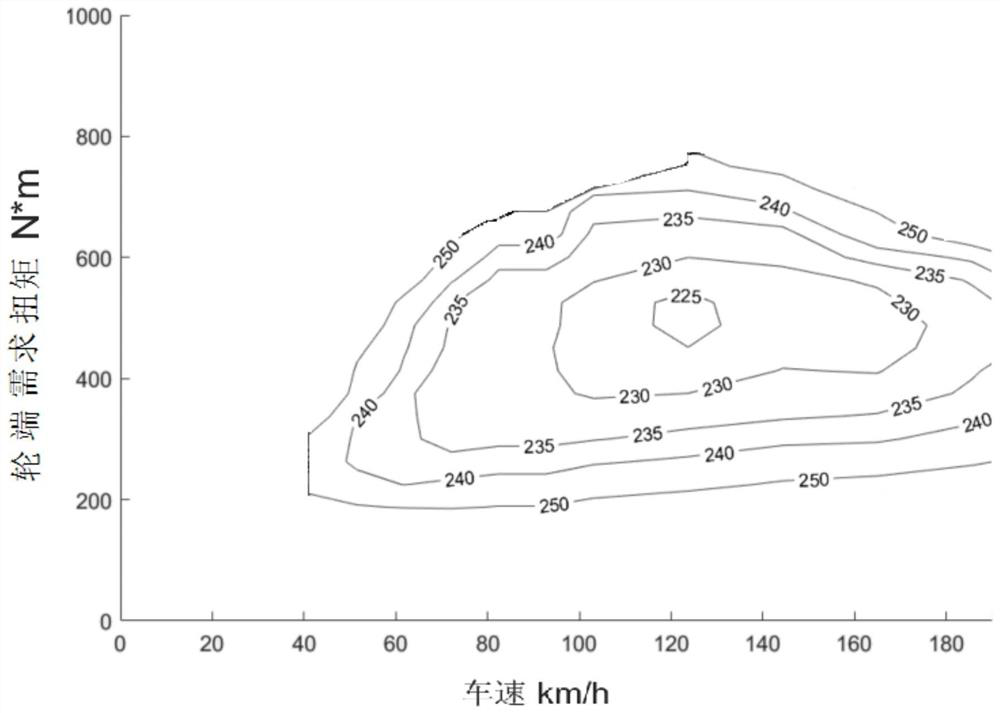

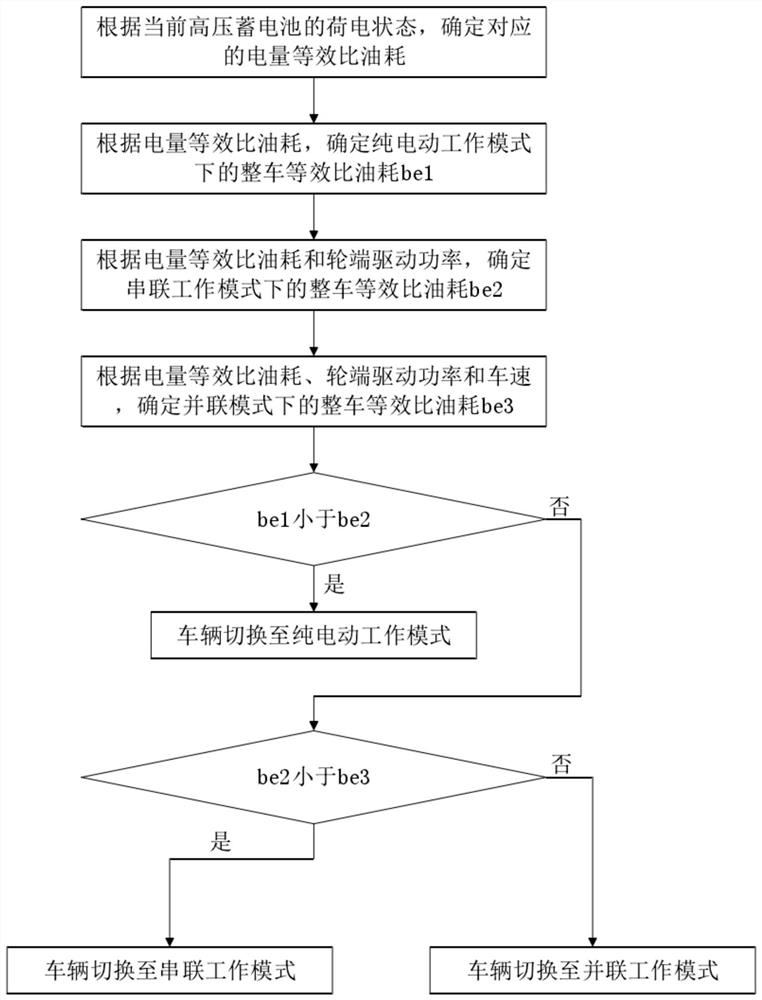

Hybrid vehicle working mode switching method and hybrid power vehicle

ActiveCN113320522AReduce fuel consumptionImprove economic levelHybrid vehiclesPower efficientEngineering

The invention relates to the technical field of vehicles, and particularly discloses a hybrid vehicle working mode switching method which comprises the following steps: respectively measuring the power of an engine in a series working mode and a parallel working mode based on the power of the whole vehicle; then testing the series minimum specific fuel consumption and the parallel specific fuel consumption based on the power of the engine, and drawing a series vehicle fuel consumption characteristic map and a parallel vehicle fuel consumption characteristic map according to different vehicle power test results, during actual running of the vehicle, determining the switching condition of the working modes of the hybrid power vehicle according to the series-connection whole vehicle fuel consumption characteristic atlas and the parallel-connection whole vehicle fuel consumption characteristic atlas. According to the method, starting from the angle of specific fuel consumption of an engine, the working mode with low fuel consumption of the engine in the parallel-connection working mode and the series-connection working mode can be selected, and maximum efficacy of the high efficiency zone of the egine is realized, and thus the fuel consumption of the whole vehicle is reduced, and the economical level of the whole vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

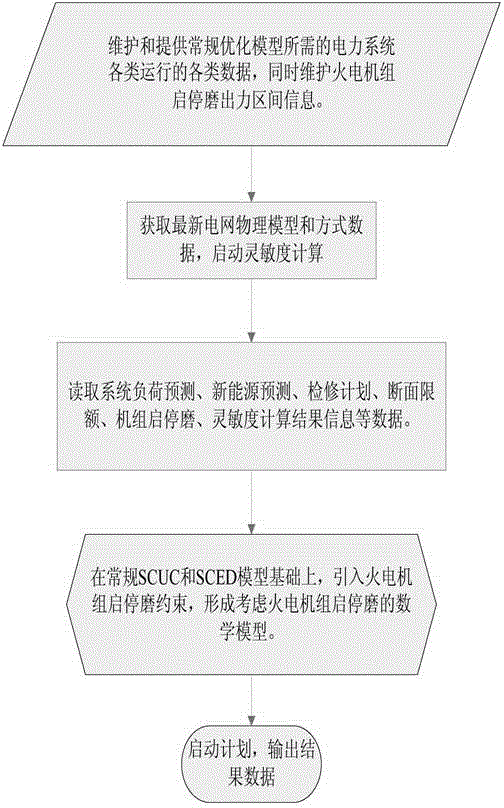

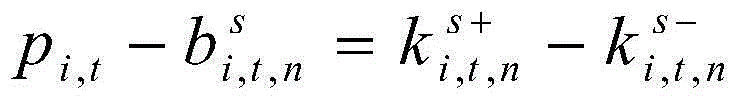

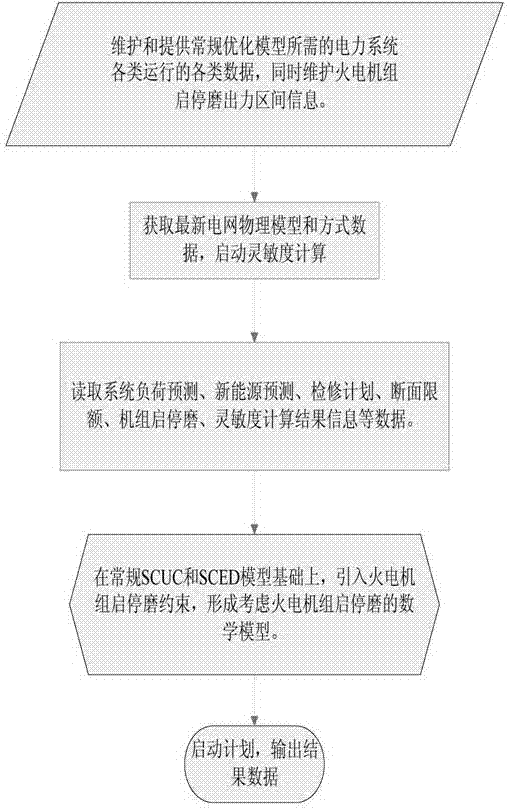

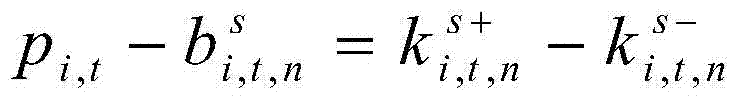

Generation schedule optimization method taking into consideration thermal power unit-driven coal mill start and stop

ActiveCN104156785AImprove economic levelEconomic stabilityForecastingSystems intergating technologiesMathematical modelPhysical model

The invention discloses a generation schedule optimization method taking into consideration thermal power unit-driven coal mill start and stop. The method comprises the following steps: (1) operation data of a generation schedule optimization model is acquired, and the thermal power unit-driven coal mill start and stop power output range is maintained; (2) the latest grid physical model and real-time manner data are acquired, and sensitivity calculation is started to obtain sensitivity result information; (3) the generation schedule optimization model reads system basic data, the thermal power unit-driven coal mill start and stop power output range, and the sensitivity result information; and (4) according to all the input data read in step (3) and based on the generation schedule optimization model, a thermal power unit-driven coal mill start and stop constraint is introduced and modeled into an optimization model taking into consideration thermal power unit-driven coal mill start and stop, and result information is output. By introducing the mathematical model of the thermal power unit-driven coal mill start and stop constraint, frequent coal mill start and stop caused by continuous up-and-down fluctuation of output power of a thermal power unit is avoided, a designed unit schedule is more economic and more reliable, and the cost of power generation is reduced.

Owner:NARI TECH CO LTD

Natural animal feed

The invention discloses natural animal feed which consists of the following components in part by weight: 60 parts of soybean cake, 10 parts of wheat, 10 parts of fish meal, 3 parts of shell powder, 4 parts of vitamin complex, 20 parts of bone meal, 5 parts of lysine and 10 parts of couch grass root. The natural animal feed disclosed by the invention has the advantages that the raw materials are cheap, the production technology is simple, and the production cost is relatively low; and since natural components are proportioned, the raw materials do not have toxic and side effect, the proportioning is reasonable and the nutrition is balanced, therefore, the growth of poultry and livestock is greatly promoted, the economic level of the breeding industry is improved, and the natural animal feed is easy to popularize and use.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

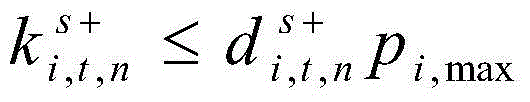

Internal combustion engine gas exhaust and temperature exhaust management system and control method

InactiveCN111608824AEmission reductionMeet the needs of rapid heatingElectrical controlInternal combustion piston enginesPhysicsIntercooler

The invention belongs to the technical field of vehicle engines, and particularly relates to an internal combustion engine gas exhaust and temperature exhaust management system and a control method. The internal combustion engine gas exhaust and temperature exhaust management system comprises an internal combustion engine, an air filter, an inlet gas intercooler and an aftertreatment system. Whenengine exhaust gas recirculation (EGR) is introduced into management, according to different engine load requirements, by controlling the open degree of a second exhaust managing valve and a first exhaust managing valve which are integrated on a first runner and a second runner respectively as well as the combined effect of a low-temperature EGR one-way valve, the backpressure of the engine is improved, then EGR is driven to enter a gas inlet system, the introduction proportion of EGR can be controlled flexibly, and the control requirement that the exhaust recirculation proportion in a cylinder is 0-100% can be achieved. The system and the control method can also be used for engine exhaust temperature management and can assist in engine braking.

Owner:FAW JIEFANG AUTOMOTIVE CO

Outdoor breeding method for scorpions

InactiveCN106070076APrevention and treatment of black rotReduce mortalityAnimal husbandryMortality rateOrder Scorpiones

The invention belongs to the technical field of animal breeding, and particularly relates to an outdoor breeding method for scorpions. The method aims at increasing the yield of the scorpions and improving the quality of the scorpions. A glass enclosure is erected outdoors, and the scorpions grow in the glass enclosure; rubble stacks are erected in the glass enclosure, the scorpions are fed with yellow mealworms, one catty of yellow mealworms is put into each catty of scorpions, a lamp source is arranged in the glass enclosure at night, and various insects are attracted to feed the scorpions; the humidity in the glass enclosure is kept between 45% and 65%, the temperature is kept between 23 DEG C to 35 DEG C, when the humidity is lower than 45%, grass is placed in the glass enclosure, and then water is sprayed to the grass to keep the humidity so that the scorpions can be in contact with the water. According to the method, the natural growing environment is fully simulated, the survival rate of larvae of the scorpions is increased, and the growth death rate of the larvae of the scorpions is reduced.

Owner:靳良明

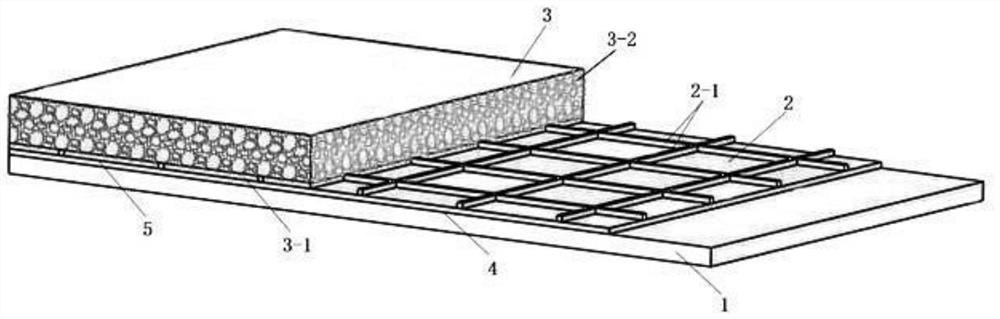

FRP-SMA steel bridge deck pavement structure

PendingCN113186816ALow costImprove economic levelBridge structural detailsArchitectural engineeringBridge deck

The invention discloses an FRP-SMA steel bridge deck pavement structure. The structure is composed of an FRP pavement protection layer and an SMA pavement wearing layer which are laid from bottom to top. The top face, facing the SMA pavement wearing layer, of the FRP pavement protection layer is provided with convex-edge matts-shaped shear keys; and the thickness of the SMA pavement wearing layer embedded into the matts of the FRP pavement protection layer is a thermosetting SMA thin layer, and the rest thickness is a thermoplastic SMA thin layer. According to the present invention, the convex-edge matts-shaped shear keys of the FRP pavement protection layer can restrain the SMA mixture to drive the interface bonding resin to slide during the SMA pavement wearing layer construction so as to ensure the interface connection quality, and can provide the synergistic effect with the thermosetting SMA thin layer of the SMA pavement wearing layer so as to enhance interface shear connection in the transverse bridge direction and the longitudinal bridge direction after the SMA wearing layer molding, so that the structure form is more reasonable, structural stress is safer, design and construction quality is more controllable, engineering cost is more economical, the two technical problems which are difficult to solve in the asphalt concrete steel bridge deck pavement structure can be solved, and the technical and economic levels of flexible steel bridge deck pavement are remarkably improved.

Owner:张锡祥

Animal feed

The invention discloses an animal feed, comprising the following ingredients in parts by weight: 60 parts of bean cake, 10 parts of wheat, 10 parts of fish meal, 5 parts of ferrous sulfate, 3 parts of pepper powder, 4 parts of compound vitamine, 20 parts of bone meal, and 5 parts of lysine. The animal feed is low in material price, simple in production process, low in production cost, free of toxic and side effects in materials, reasonable in proportion, balanced in nutrition, and easy to popularize and use, greatly promotes growth of poultry and livestock, and improves the economic level of breeding industry.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

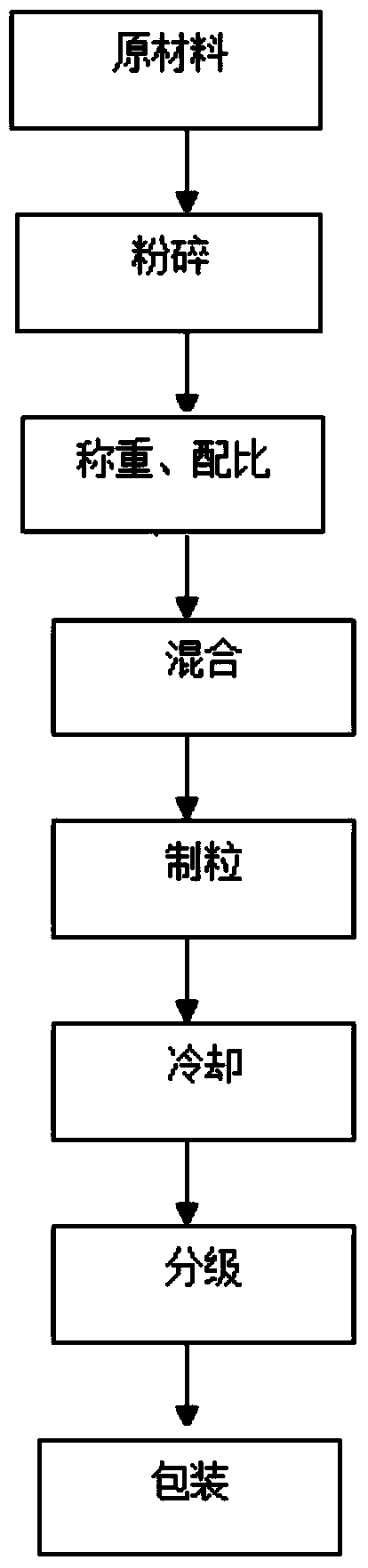

Premixed feed for poultry, and preparation method thereof

The invention provides a premixed feed for poultry, and a preparation method thereof. The premixed feed for the poultry comprises compound mineral elements, compound vitamins, compound enzyme and a carrier. The preparation method of the premixed feed for the poultry comprises the steps of smashing various raw materials; screening with a 80-mesh sieve to obtain powdery materials; weighing the powdery materials according to proportions; mixing; heating the mixed powdery material with steam to a temperature of 70-90 DEG C to obtain particles; cooling the prepared particles; grading and packaging to obtain a final product. The raw materials for the premixed feed for the poultry have no side or toxic effect and are cheap; the production technology is simple; and raw materials are reasonable in proportions and balanced in nutrition, thereby promoting growth of the poultry, increasing economic level of breeding industries and being convenient for popularization and application.

Owner:仙桃市仙发饲料有限公司

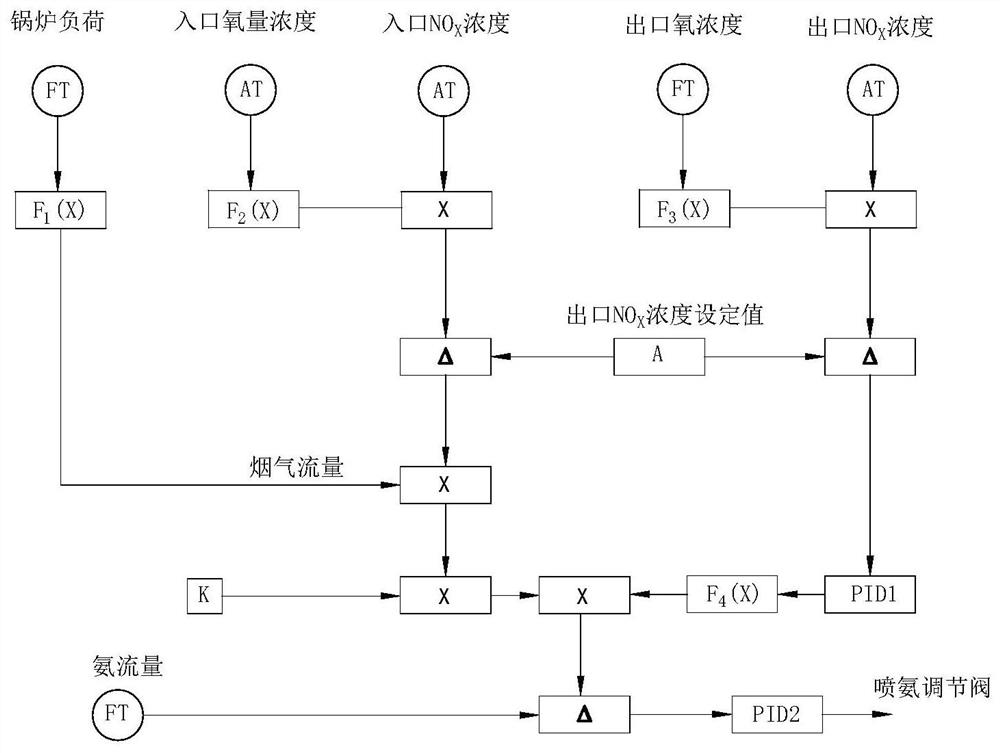

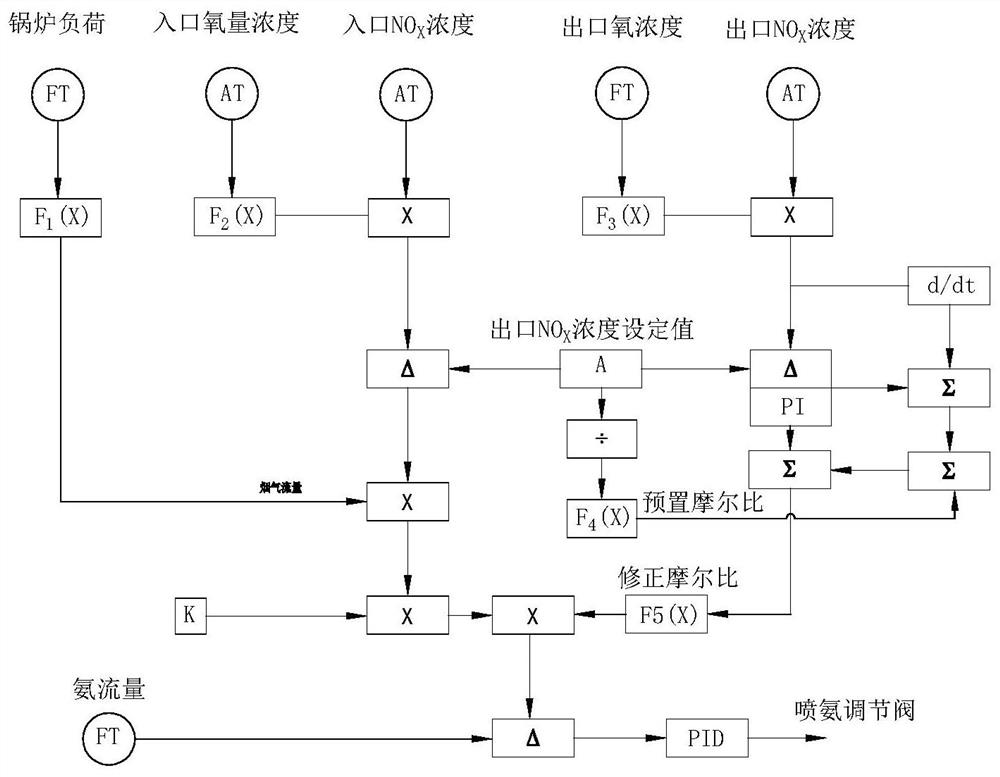

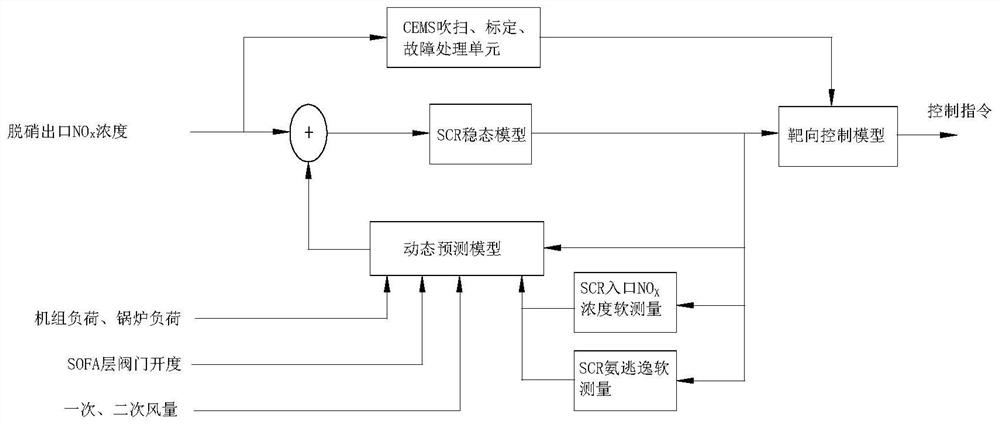

And driving SCR denitration ammonia spraying targeted control loop based on model

PendingCN111931358AImprove operating economyImprove the level of economic operationDesign optimisation/simulationSpecial data processing applicationsTarget controlEngineering

The invention relates to an SCR denitration ammonia spraying targeted control loop based on model driving. The system comprises an SCR steady-state model, a dynamic prediction model, a targeting control model, an SCR inlet NOx concentration soft measurement model and an SCR ammonia escape soft measurement model. Adding the NOx concentration at the outlet of the SCR denitration system to the outputvalue of the dynamic prediction model; wherein the signal is used as an input signal of the SCR steady-state model; the SCR steady-state model gives a reference instruction according to the directionand the size of an input signal and the deviation degree in a front period and a rear period so as to be adjusted by the targeting control model; and meanwhile, the reference instruction also servesas signal input values of the dynamic prediction model, the SCR inlet NOx concentration soft measurement model and the SCR ammonia escape soft measurement model, and signal outputs of the SCR inlet NOx concentration soft measurement model and the SCR ammonia escape soft measurement model are fed back to the dynamic prediction model. The ammonia spraying amount can be effectively reduced, and the operation economy of the unit is improved.

Owner:INNER MONGOLIA JINGNENG KANGBASHI THERMAL POWER CO LTD

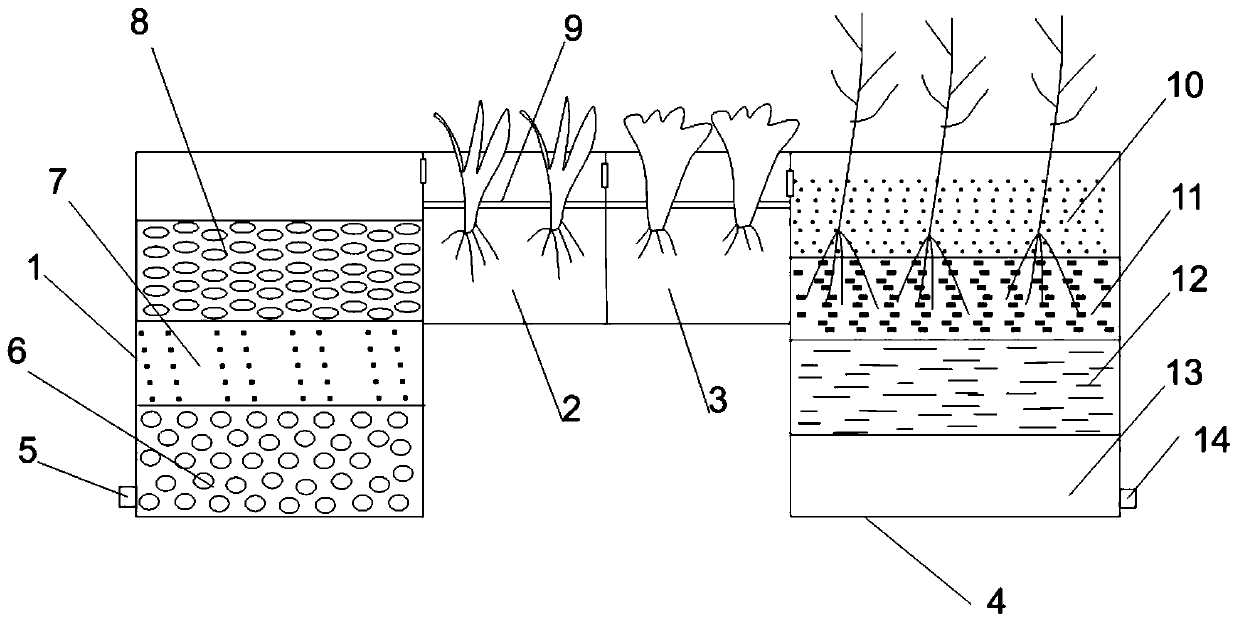

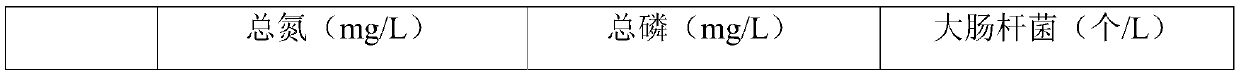

System and method for efficiently intercepting and purifying nitrogen and phosphorus in rural domestic sewage

InactiveCN111333267AAchieve purificationImprove economic levelTreatment involving filtrationMultistage water/sewage treatmentActivated carbonPurification methods

The invention discloses a system and a method for efficiently intercepting nitrogen and phosphorus in rural domestic sewage and purifying water. The system comprises a primary filter tank, a primary ecological tank, a secondary ecological tank and an interception tank which are sequentially communicated from the upper part, wherein a water inlet pipe is arranged at the lower part of the primary filter tank, a coarse sand layer, a fine sand layer and an active particle layer are sequentially arranged in the primary filter tank from bottom to top, pore plates are arranged in the primary ecological tank and the secondary ecological tank, and different types of economic plants are planted in the primary ecological tank and the secondary ecological tank; a soil layer, an interception layer, a quartz sand layer and an activated carbon layer are sequentially arranged in the interception pond from top to bottom, aquatic plants are planted in the soil layer, and a drainage pipe is arranged on the lower portion of the interception pond. By adopting the water purification system and the water purification method, total nitrogen and total phosphorus in the sewage can be effectively removed, sothat the purified water body meets the discharge standard.

Owner:CHENGDU TECH UNIV

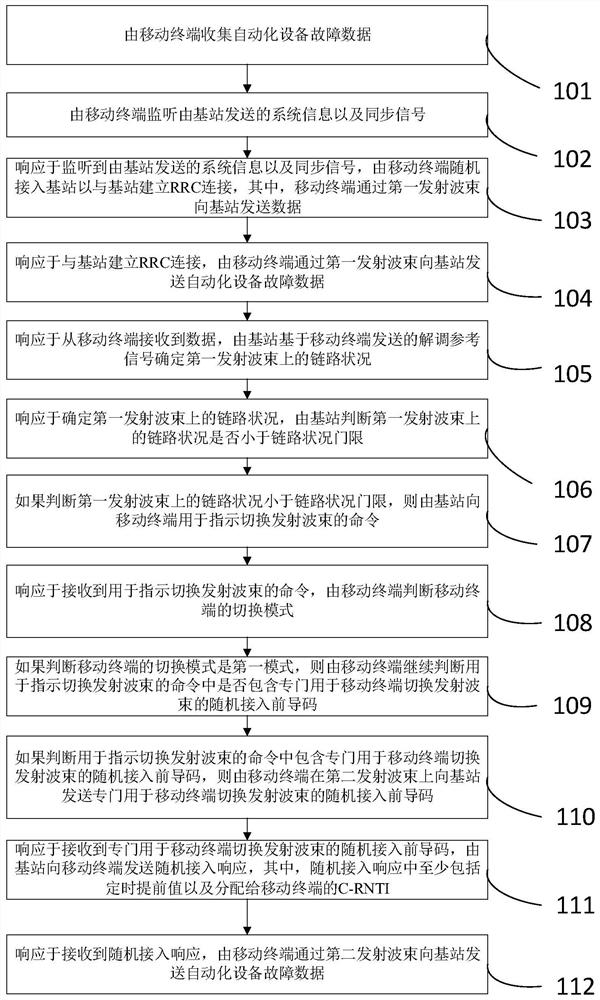

Method and system for transmitting fault data of automatic equipment of intelligent factory in real time

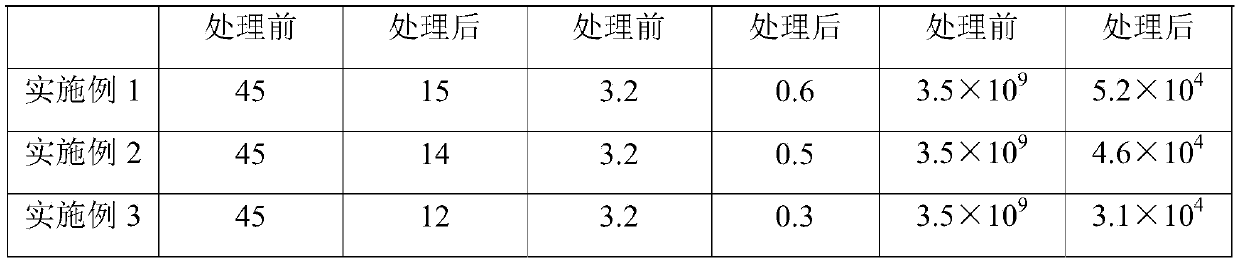

ActiveCN111736560ALow priceThe global economy has improvedElectric testing/monitoringPilot signal allocationDemodulationReal time transmission

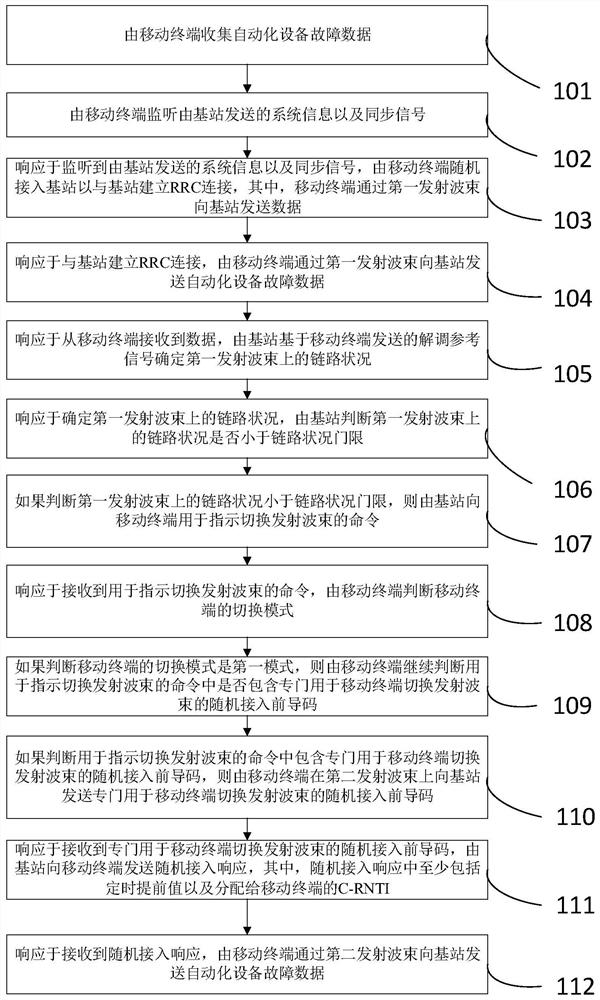

The invention discloses a method for transmitting fault data of automatic equipment of an intelligent factory in real time. The method comprises the following steps that a mobile terminal collects thefault data of automatic equipment; the mobile terminal monitors system information and a synchronization signal sent by a base station; in response to the monitored system information and synchronization signal sent by the base station, the mobile terminal randomly accesses the base station to establish an RRC connection with the base station; in response to the establishment of the RRC connection with the base station, the mobile terminal sends the fault data of the automatic equipment to the base station through a first transmitting beam; in response to the receiving of the data from the mobile terminal, the base station determines the link condition on the first transmitting beam based on a demodulation reference signal sent by the mobile terminal; in response to the determining of thelink condition on the first transmitting beam, the base station determines whether the link condition on the first transmitting beam is less than a link condition threshold; and if judging that the link condition on the first transmitting beam is smaller than the link condition threshold, the base station sends a command for indicating switching of the transmitting beam to the mobile terminal.

Owner:合肥名龙电子科技有限公司

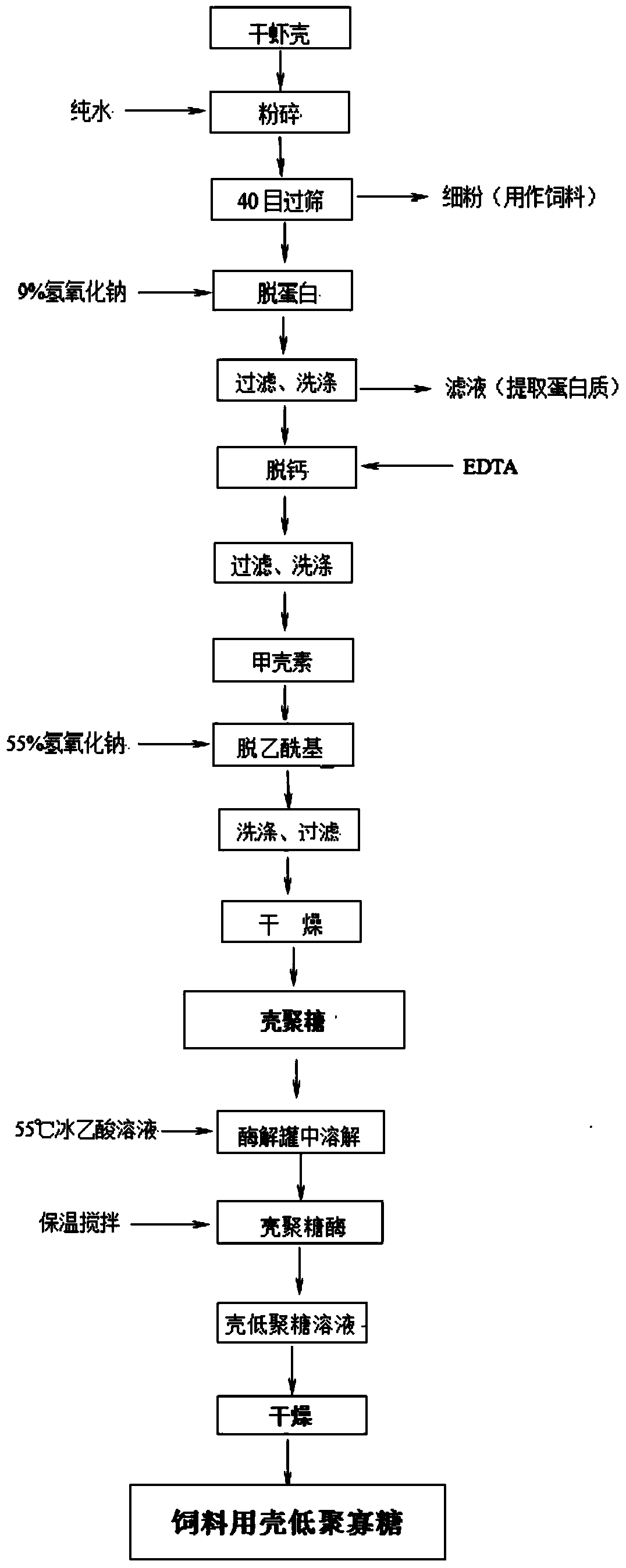

Feed and preparation method thereof

The invention discloses feed. The feed is prepared from the following components in parts by weight: 20-30 parts of copper sulfate, 35-60 parts of magnesium sulfate, 10-15 parts of ferrous sulfate, 30-40 parts of zinc sulfate, 25-30 parts of manganese sulfate, 3-5 parts of sodium selenite, 5-10 parts of calcium iodate, 10-15 parts of an antioxidant A, 50-80 parts of chitooligosaccharides, 10-15 parts of an antioxidant B, 10-15 parts of D-calcium pantothenate, 25-30 parts of niacinaminde, 1-5 parts of vitamin A, 5-10 parts of esterifiable VC, 5-10 parts of vitamin E, 10-15 parts of threonine, 5-8 parts of compound enzymes, 35-50 parts of potamogeton crispus powder, 50-80 parts of methionine, 50-80 parts of choline chloride, 100-200 parts of carrier defatted rice bran, 10-15 parts of cobalt chloride, 10-20 parts of potassium iodide and 20-30 parts of potassium chloride.

Owner:WUHAN ZHIFU ENTERPRISE MANAGEMENT CONSULTING CO LTD

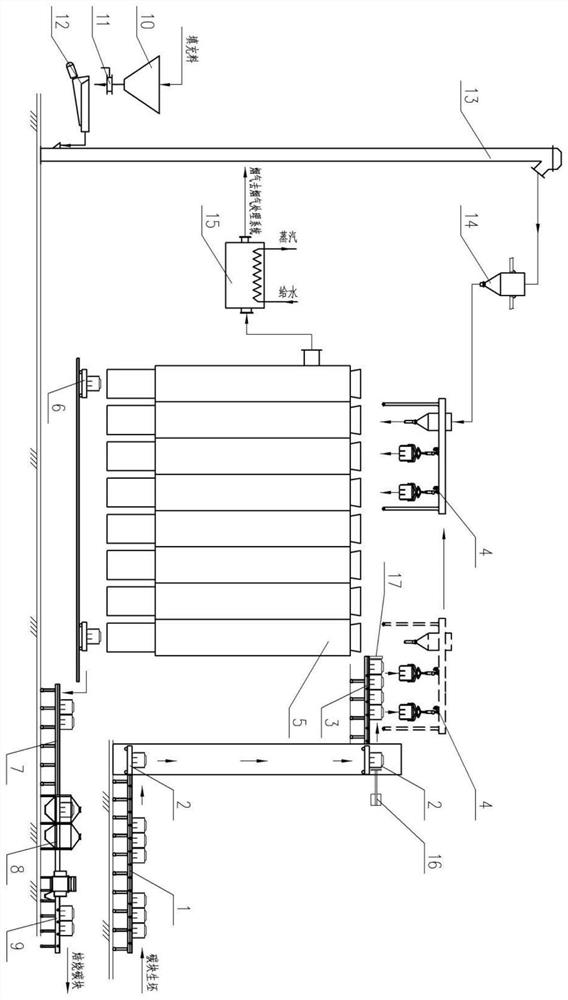

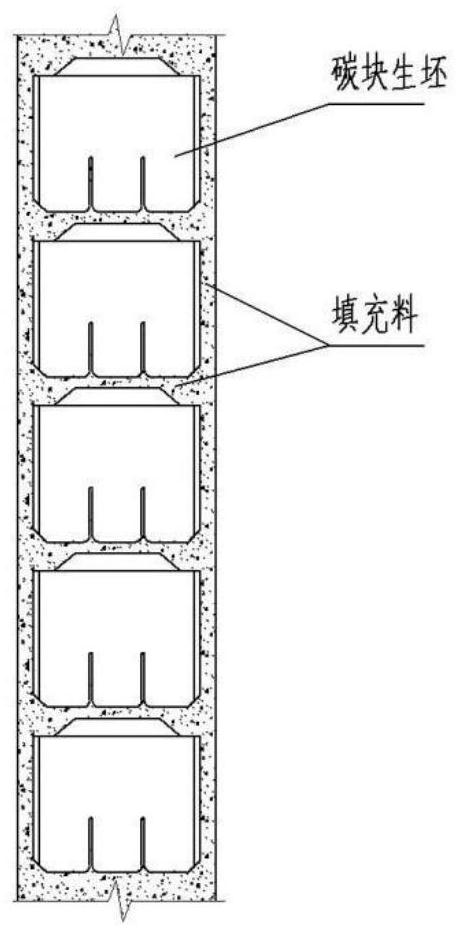

Vertical roasting furnace roasting carbon block production method

ActiveCN111620693AReduce energy consumptionReduce roasting production costsEnergy inputCarbon preparation/purificationChemistryProcess engineering

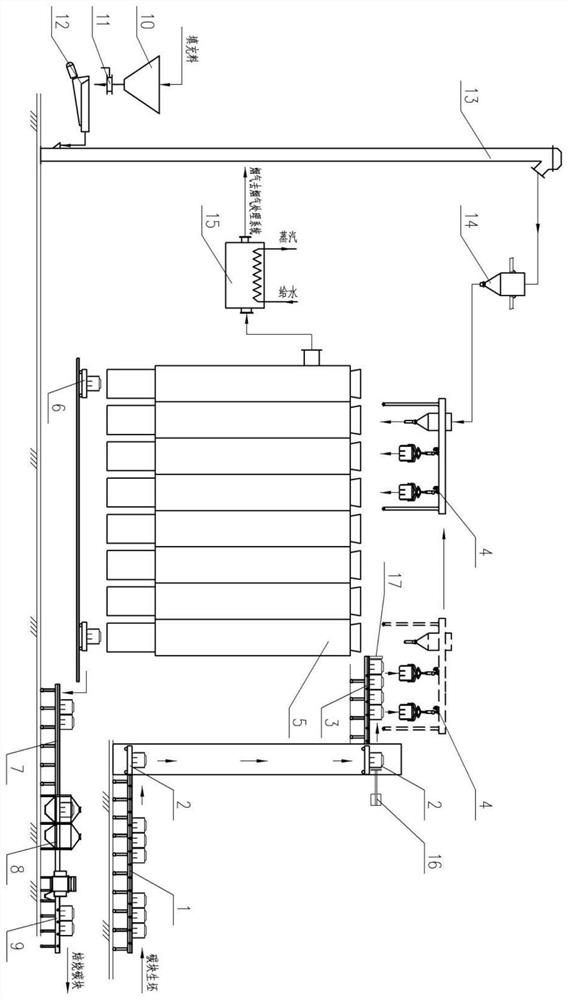

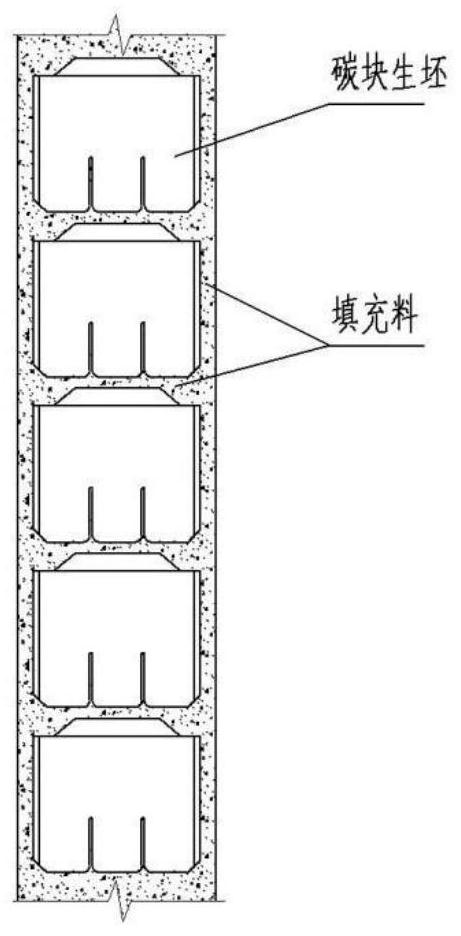

The invention relates to the technical field of carbon product roasting methods in the carbon industry, in particular to a vertical roasting furnace roasted carbon block production method which comprises a carbon block green body conveying system, a filler feeding system, a charging system and a carbon block conveying and cleaning system. The green body conveying system comprises a first conveyor,a second conveyor, lifting equipment, a pushing block mechanism and a stopping block mechanism. The filler feeding system comprises a feeding hopper, a gate, a vibrating feeder, a bucket elevator anda buffer bin. The charging system comprises a multifunctional charging vehicle; the carbon block conveying and cleaning system comprises a third conveyor and a cleaning machine and is used for transferring and cleaning carbon blocks. A vertical roasting furnace is adopted for roasting the carbon blocks, the problem that repeated heat storage needs to be conducted on refractory materials and fillers when a traditional annular roasting furnace conducts periodic heating is avoided, energy consumption of roasted products is reduced, and the roasting production cost is reduced; and meanwhile, thevertical roasting furnace is continuously operated, so that the problems of vacancy of a furnace chamber and high investment cost of refractory materials of the traditional ring type roasting furnaceare solved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

An optimization method of power generation plan considering the start-stop grinding of thermal power units

ActiveCN104156785BImprove economic levelEconomic stabilityForecastingSystems intergating technologiesPower gridPhysical model

The invention discloses a generation schedule optimization method taking into consideration thermal power unit-driven coal mill start and stop. The method comprises the following steps: (1) operation data of a generation schedule optimization model is acquired, and the thermal power unit-driven coal mill start and stop power output range is maintained; (2) the latest grid physical model and real-time manner data are acquired, and sensitivity calculation is started to obtain sensitivity result information; (3) the generation schedule optimization model reads system basic data, the thermal power unit-driven coal mill start and stop power output range, and the sensitivity result information; and (4) according to all the input data read in step (3) and based on the generation schedule optimization model, a thermal power unit-driven coal mill start and stop constraint is introduced and modeled into an optimization model taking into consideration thermal power unit-driven coal mill start and stop, and result information is output. By introducing the mathematical model of the thermal power unit-driven coal mill start and stop constraint, frequent coal mill start and stop caused by continuous up-and-down fluctuation of output power of a thermal power unit is avoided, a designed unit schedule is more economic and more reliable, and the cost of power generation is reduced.

Owner:NARI TECH CO LTD

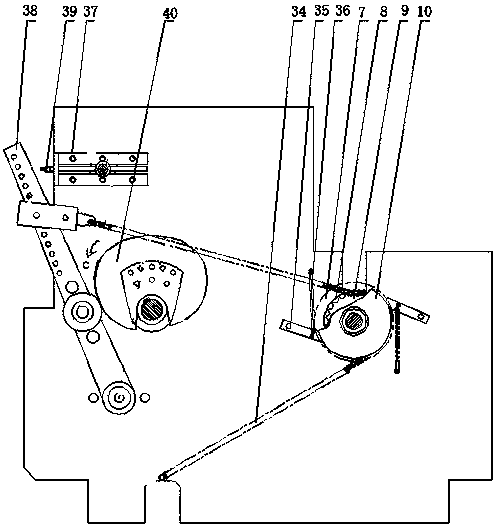

A large mesh device for a textile machine

The invention discloses a large-mesh device of a spinning machine. The large-mesh device comprises a warp-feeding swing arm, a main warp-feeding roller and a switching off cam, wherein the switching off cam is arranged nearby the warp-feeding swing arm; a switching off cam base is arranged on the bottom of the switching off cam; the main warp-feeding roller is arranged above the switching off cam; a switching off wedge block is arranged nearby the main warp-feeding roller; a main net-rolling roller is arranged on the other side of the warp-feeding swing arm; a check grooved pulley is arranged on the main net-rolling roller; a chain wheel is arranged in the check grooved pulley; a net-rolling clutch is arranged outside the main net-rolling roller. Due to the fact that the main warp-feeding roller and the net-rolling clutch are arranged, the using efficiency of the spinning machine is higher, the machining error of the spinning machine can be overcome, the machining precision of the spinning machine is guaranteed, the net-rolling number can be increased, the machining action of the spinning machine is precise, and the yield is well improved.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Safflower fruit vinegar beverage and method for preparing the same

ActiveCN101480263BResource optimizationImprove economic levelWine preparationFood preparationAdditive ingredientCranial nerves

The invention relates to safflower fruit vinegar which belongs to the drink field. Safflower, sea backthern and blackcurrant are special local products in the northwest of China, and have great economic value and medicine value, therefore, the invention provides novel safflower fruit vinegar which uses the safflower, the sea backthern, and the blackcurrant as main raw materials, sweetener and preservative are added, and the fruit vinegar is made by a series of processes of materials selection, zymohydrolysis, alcoholic fermentation, acetic acid fermentation, aging, preparation, fine filteringand filling, sterilization and cooling, and the like. The invention has multiple vitamins, amino acids, and biological active ingredients, can stimulate the cranial nerves, promotes the secretion of digestive juice, inhibits the forming of oxide, promotes the improvement of the area economic level, is favorable to environment protection, and has simple process, fast effect, and easy popularization.

Owner:XINJIANG ZHUANGZI IND

A working mode switching method of a hybrid electric vehicle and the hybrid electric vehicle

ActiveCN113320522BReduce fuel consumptionImprove economic levelHybrid vehiclesPower efficientElectric vehicle

The invention relates to the technical field of vehicles, and specifically discloses a method for switching working modes of a hybrid vehicle. The method for switching working modes of a hybrid vehicle measures the power of the engine in the series working mode and the parallel working mode based on the vehicle power, and then measures the power of the engine in the The power test series minimum specific fuel consumption and parallel specific fuel consumption, and then according to the test results of different vehicle power draw series vehicle fuel consumption characteristic map and parallel vehicle fuel consumption characteristic map, when the vehicle is actually running, according to the series vehicle fuel consumption characteristic map From the perspective of specific fuel consumption of the engine, this method can maximize the efficiency by selecting the working mode with lower fuel consumption in the parallel working mode and the series working mode. Use the high-efficiency zone of the engine to reduce the fuel consumption of the vehicle and improve the economic level of the vehicle.

Owner:CHINA FIRST AUTOMOBILE

A Method of Determining Sampling Time According to Data Receiving Time

ActiveCN103227643BReduce complexityLow costAnalogue/digital conversionElectric signal transmission systemsFiberTransmission time delay

The invention relates to a method for determining a sampling moment according to a data receiving moment. A device adopted by the method comprises a merging unit, a switch and a protection and measure-control unit which are sequentially connected through optical fibers. Data sampling for the method is performed uniformly, and the method comprises the following steps: (1), sampling data frames from the merging unit, receiving the data frames by the protection and measure-control unit after the data frames pass through the switch; (2),determining a sampling period T continuously in system initialization and operation processes; (3),measuring transmission time delay D in a system initialization process; and (4), determining a sampling moment of raw data continuously in the system initialization and operation processes. According to the method, uncertainty of time delay of data transmission is eliminated; and further, the switch is adopted in a data transmission process, therefore, the complexity for fiber-optic link can be reduced, and the calculation accuracy of the sampling moment is high.

Owner:CHINA ELECTRIC POWER RES INST +3

Switching method for working modes of unplugged hybrid vehicle

ActiveCN113386732AReduce fuel consumptionImprove the level of economyHybrid vehiclesMotronicHybrid vehicle

The invention belongs to the technical field of power control of hybrid vehicles, and discloses a switching method for working modes of a non-plug-in hybrid vehicle. The method comprises the following steps: determining corresponding electric quantity equivalent specific fuel consumption according to the current charge state of a high-voltage storage battery; according to the current electric quantity equivalent specific fuel consumption, determining the whole vehicle equivalent specific fuel consumption in the pure electric working mode; according to the current electric quantity equivalent specific fuel consumption and the wheel end driving power, determining the whole vehicle equivalent specific fuel consumption in the series working mode; according to the current electric quantity equivalent specific fuel consumption, determining the wheel end driving power and the vehicle speed, the whole vehicle equivalent specific fuel consumption in the parallel connection mode; and according to the vehicle equivalent specific fuel consumption in the pure electric working mode, the series-connection working mode and the parallel-connection working mode, switching the vehicle to a working mode with the minimum vehicle equivalent specific fuel consumption. According to the method, the economical efficiency of the vehicle in the pure electric, series and parallel working modes is measured from the angle of the equivalent specific fuel consumption of the whole vehicle, the vehicle is controlled to switch the working modes, the fuel consumption of the vehicle is reduced, and the economical efficiency level of the vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

Agricultural mechanized production method

InactiveCN106613183ASave farming energyReduce planting labor costsSeed and root treatmentPlant cultivationAgricultural engineeringEngineering

The invention discloses an agricultural mechanized production method. The agricultural mechanized production method comprises the following steps: a) selecting the loosening permeable soil; b) fertilizing, seeding, earthing and rolling the loosening soil after the strip tillage; c) distributing the seeds to be strip-shaped along the length direction of the strip tillage during the seeding, wherein the width of the strip tillage is 1 / 3-1 / 8 of the seeding line spacing, and the depth of the strip tillage is 8-15 cm. The agricultural mechanized production method is capable of greatly saving the energy consumption of the tillage, reducing the labor cost of the planting, and directly improving the economic level, and the planting success rate is high.

Owner:HECHI TECH DEV CENT

Method and system for real-time transmission of automation equipment fault data in smart factories

ActiveCN111736560BLow priceThe global economy has improvedElectric testing/monitoringPilot signal allocationSmart factoryMonitoring system

The invention discloses a method for real-time transmission of automation equipment failure data of an intelligent factory, comprising the following steps: collecting automation equipment failure data by a mobile terminal; monitoring system information and synchronization signals sent by a base station; system information and synchronization signal, the mobile terminal randomly accesses the base station to establish an RRC connection with the base station; in response to establishing an RRC connection with the base station, the mobile terminal sends automation equipment failure data to the base station through the first transmission beam; in response to the mobile terminal After receiving the data, the base station determines the link status on the first transmit beam based on the demodulation reference signal sent by the mobile terminal; in response to determining the link status on the first transmit beam, the base station determines the link status on the first transmit beam Whether the condition is less than the link condition threshold; if it is judged that the link condition on the first transmit beam is less than the link condition threshold, the base station sends the mobile terminal a command to switch the transmit beam.

Owner:山东优迈信息科技有限公司

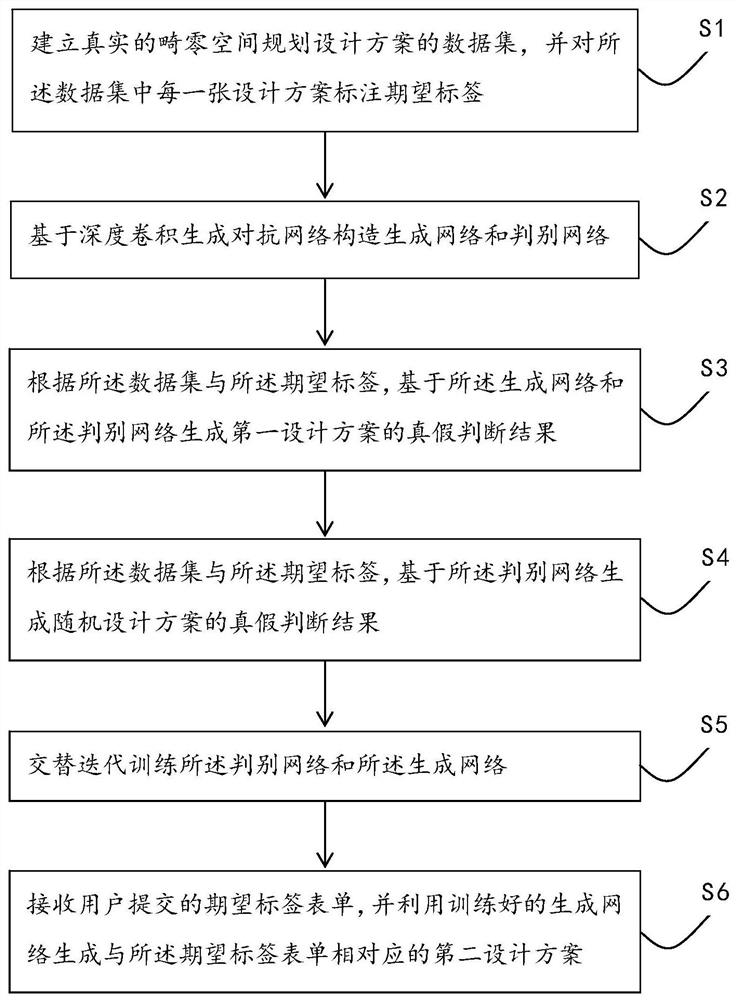

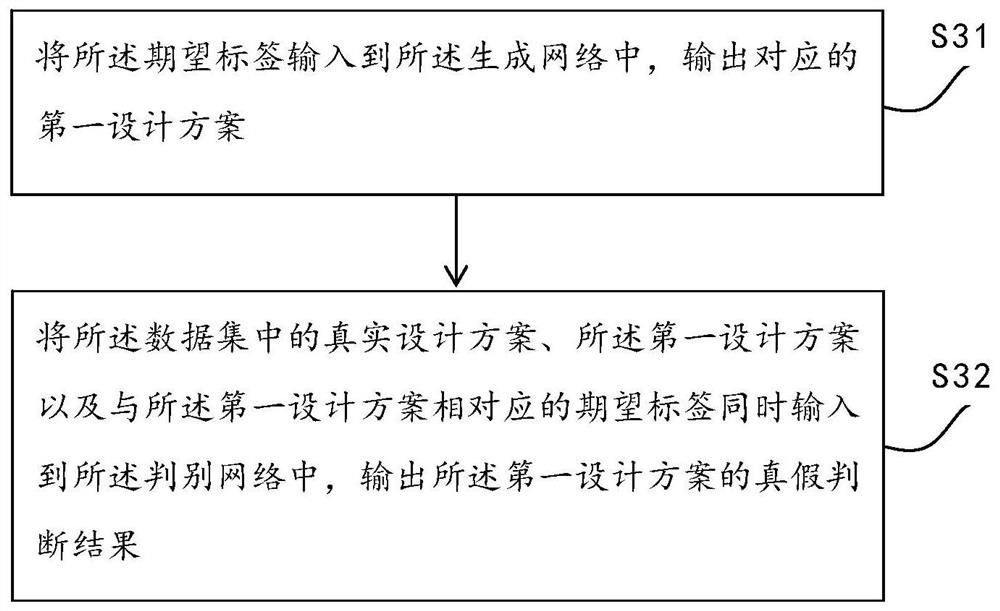

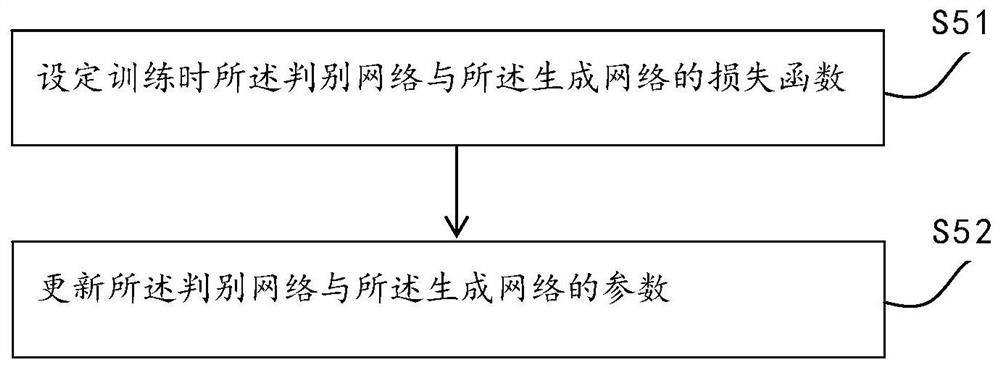

Generative adversarial network-based gorgeous null space planning design generation method and system

PendingCN112329116AReduce labor costsSave time and costGeometric CADDesign optimisation/simulationData setNetwork generation

The invention discloses a generative adversarial network-based gorgeous null space planning design generation method and system, and the method comprises the steps: building a data set of a real gorgeous null space planning design scheme, and marking an expected label for each design scheme in the data set; constructing a generative network and a discrimination network based on the deep convolution generative adversarial network; generating a true and false judgment result of the first design scheme based on the generation network and the judgment network according to the data set and the expected label; according to the data set and the expected label, generating a true and false judgment result of the random design scheme based on a judgment network; alternately iteratively training a discrimination network and a generation network; and receiving an expected label form submitted by the user, and generating a second design scheme corresponding to the expected label form by utilizing the trained generation network.

Owner:恩亿科(北京)数据科技有限公司

A kind of vertical roasting furnace roasting carbon block production method

ActiveCN111620693BLow investment costReduce consumptionEnergy inputCarbon preparation/purificationCarbon productProcess engineering

The present invention relates to the technical field of roasting methods for carbon products in the carbon industry, in particular to a production method for roasting carbon blocks in a vertical roasting furnace, including a carbon block green body conveying system, a filling material feeding system, a furnace charging system, and a carbon block conveying and cleaning system; The green body conveying system includes conveyor A, conveyor B, lifting equipment, pusher mechanism and stopper mechanism; the filling material feeding system includes hopper, gate, vibrating feeder, bucket elevator and buffer silo; The furnace system includes a multi-functional charging car; the carbon block conveying and cleaning system includes a conveyor C and a cleaning machine for the transfer and cleaning of carbon blocks. The present invention uses a vertical roaster to roast carbon blocks, avoiding the problem of repeated heat storage of refractory materials and filling materials due to periodic heating in traditional ring roasters, reducing energy consumption of roasted products, and reducing roasting production costs; at the same time, the vertical The roasting furnace is operated continuously, which avoids the problems of vacant furnace chamber and high investment cost of refractory materials in traditional ring roasting furnaces.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Feed additive

The invention discloses a feed additive which is prepared by mixing the following components in parts by weight: 60 parts of bean cake, 10 parts of oxytetracycline, 3 parts of zinc sulfate, 2 parts of ferrous sulfate, 3 parts of shellfish powder, 4 parts of complex vitamin, 20 parts of wheat, 20 parts of bone powder and 1 part of yeast. According to the invention, the raw materials are low in price and have no toxic or side effect; and the feed additive is simple in production process, low in production cost, reasonable in mixture ratio and balanced in nutrition, greatly accelerates the growth of poultry and livestock and improves the economic level of farming industry, and is easy to implement popularization and application.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com