Charging station system of electric automobile and matched charging method thereof

A technology for electric vehicles and charging stations, applied to electric vehicles, battery circuit devices, collectors, etc., can solve the problems of undeveloped layout methods, design specifications and standards, and achieve the effects of providing charging efficiency, novel structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable your examiners to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail as follows. The described preferred embodiments are only used to illustrate the technical solutions of the present invention, not to limit the present invention. invention.

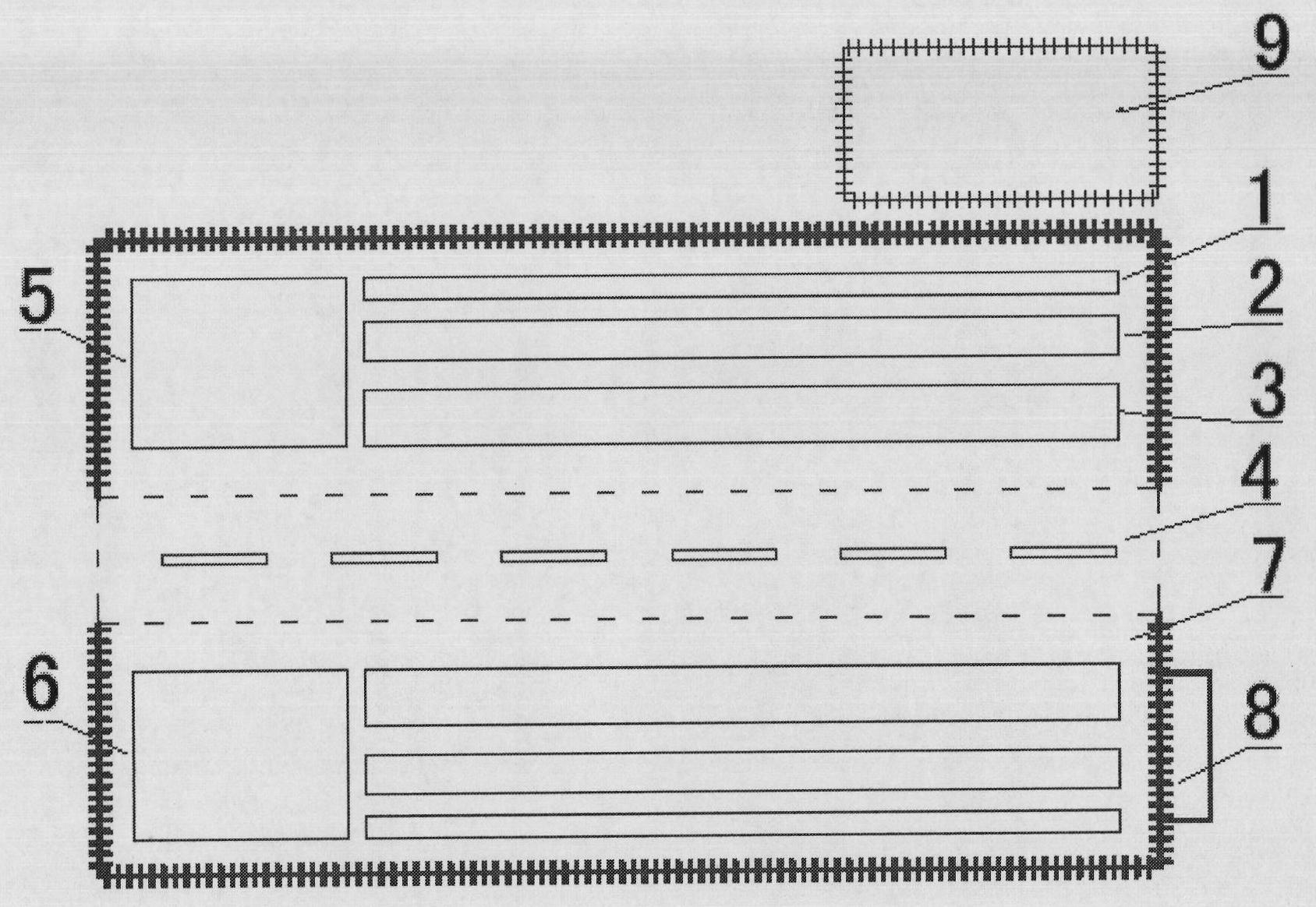

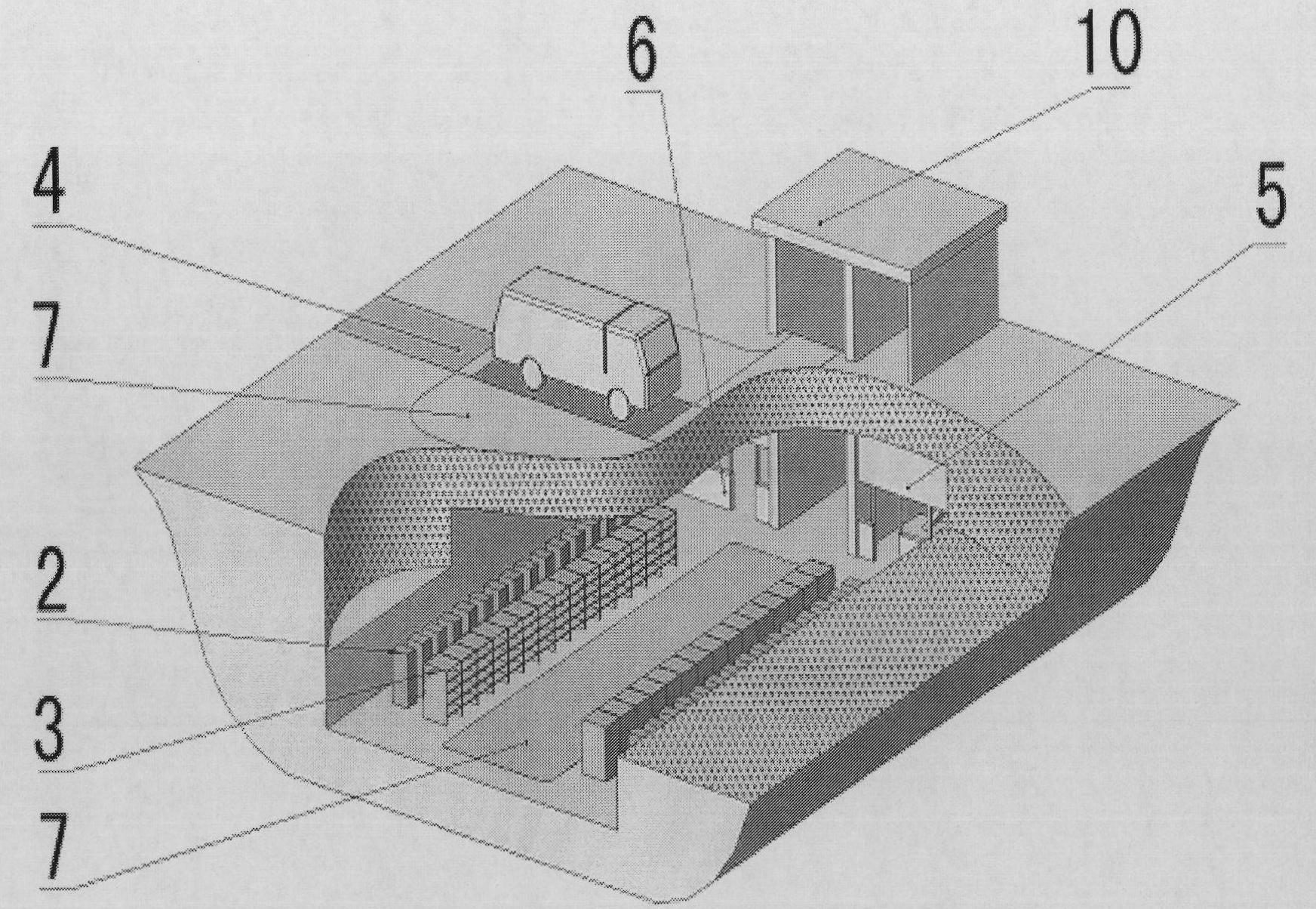

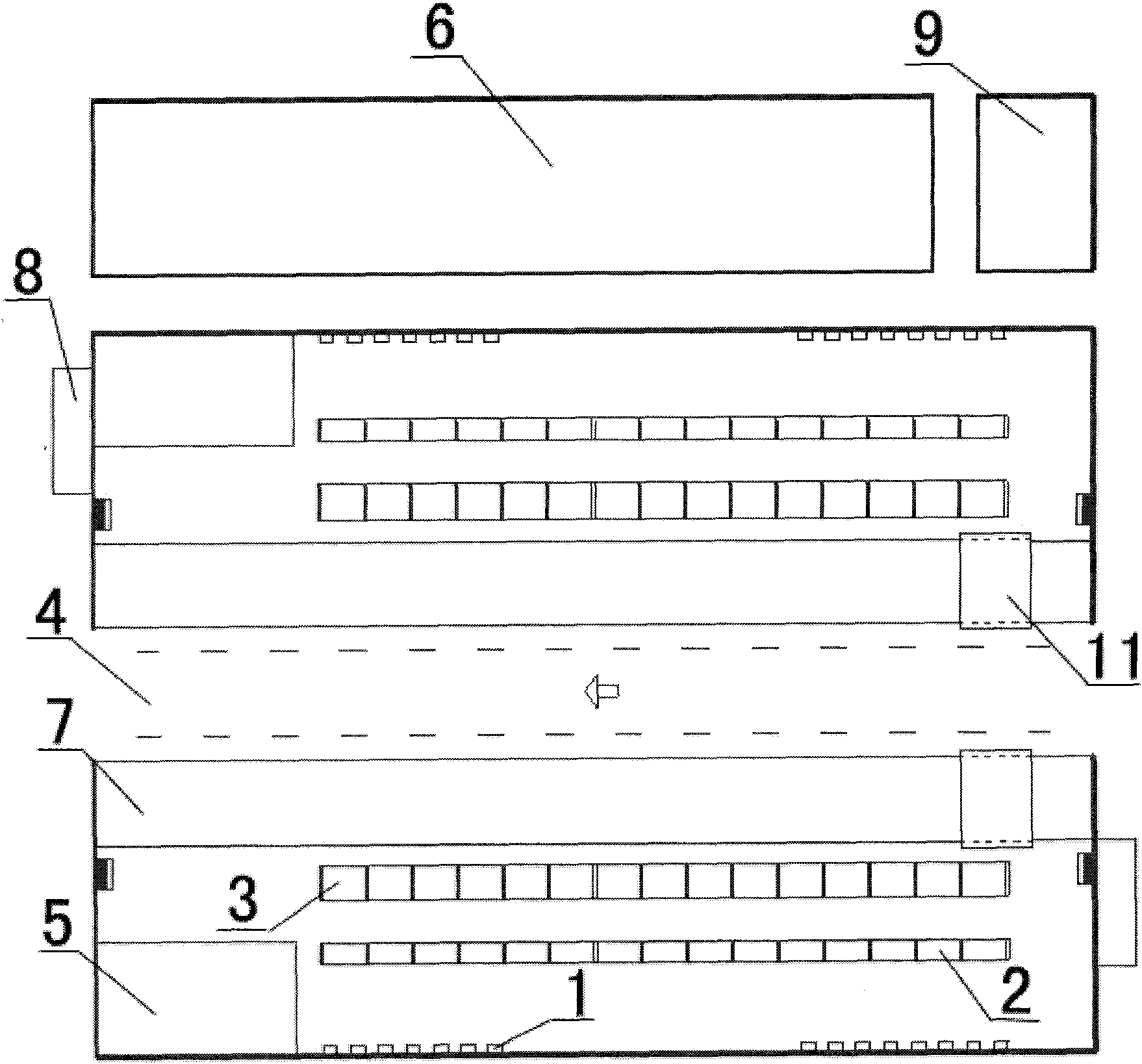

[0040] Such as figure 1 with figure 2 as shown, figure 1 It is a schematic structural diagram of a planar charging station system according to the present invention, figure 2 It is a structural schematic diagram of the three-dimensional charging station system according to the present invention. Depend on figure 1 with figure 2 It can be seen that the electric vehicle charging station system of the present invention takes the workshop for replacing the battery of the electric vehicle and charging the replaced battery as the core, and the internal layout adopts a symmetrical arrangement to make full use of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com