Vertical roasting furnace roasting carbon block production method

A production method and a roasting furnace technology are applied to the production field of roasting carbon blocks in a vertical roasting furnace, which can solve the problems of high investment and high energy consumption, and achieve the effects of low dust content, reduced energy consumption, and reduced roasting production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the embodiments and drawings, but the protection scope of the present invention is not limited by the embodiments and drawings.

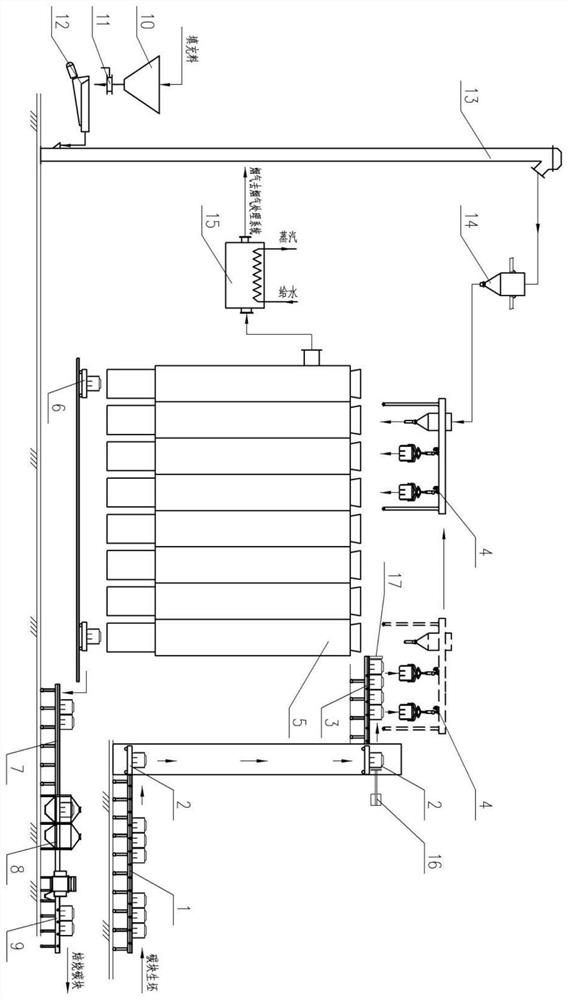

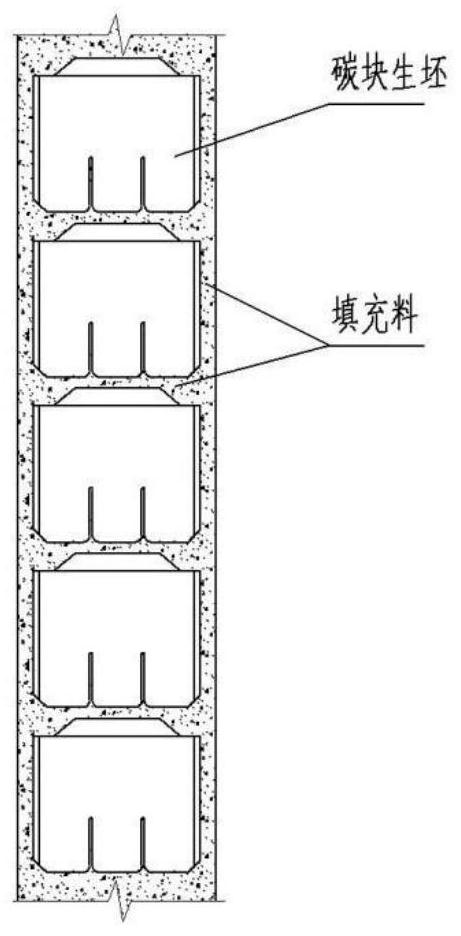

[0029] figure 1 It is a schematic diagram of the process flow of the present invention, as figure 1 As shown, the method for roasting and producing carbon blocks in a vertical roaster of the present invention includes a carbon block green body conveying system, a filling material feeding system, a furnace loading system, and a carbon block conveying and cleaning system; the green body conveying system includes a conveyor 1 , conveyor B 3, lifting equipment 2 pushing block mechanism 16 and block mechanism 17, and block mechanism 17 is the mechanical device installed on the end of conveyor B 3, and utilizes its own height to stop the carbon block from continuing to move; The system includes a hopper 10, a gate 11, a vibrating feeder 12, a bucket elevator 13, and a buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com