FRP-SMA steel bridge deck pavement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with the accompanying drawings, the present invention will be further described, the embodiments of the present invention are only used to illustrate the present invention rather than limit the present invention, without departing from the technical idea of the present invention, according to the common technical knowledge and conventional means in the art, made Various substitutions and changes should be included within the scope of the present invention.

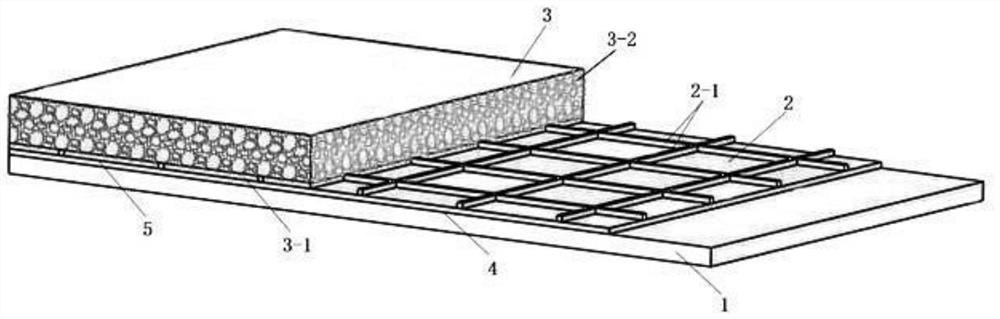

[0028]This application relates to a flexible steel bridge deck pavement system in bridge engineering, which uses FRP pavement protection layer 2 and SMA pavement wear layer 3 to form the pavement structure layer, and uses FRP pavement protection layer 2 as the pavement function layer New FRP-SMA steel bridge deck pavement structure.

[0029] The above-mentioned SMA pavement surface layer, after improvement, is called SMA pavement wear layer 3 in this application; the above-mentioned FRP paveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com