An optimization method of power generation plan considering the start-stop grinding of thermal power units

A technology for thermal power units and power generation planning, which is applied in computing, instrumentation, data processing applications, etc., can solve problems such as increasing power generation costs, non-compliance with energy-saving dispatching and economical operation, frequent starting and stopping of coal mills, etc. Low intensity, economical level improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

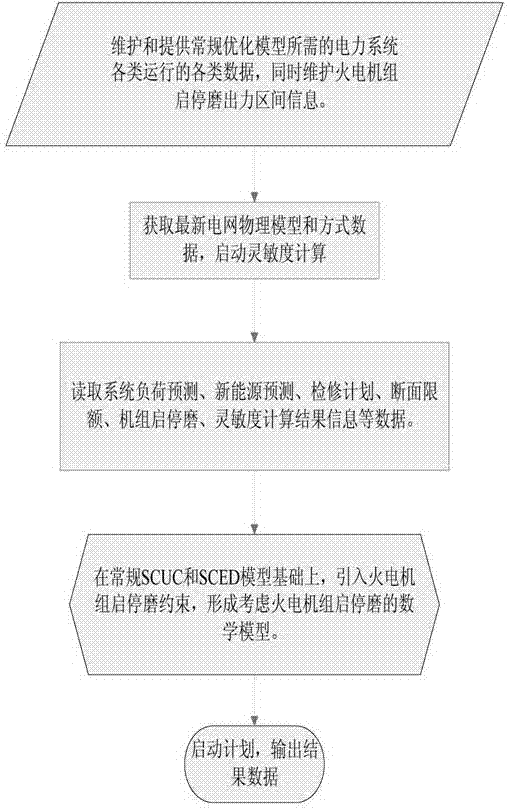

[0048]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0049] In order to achieve better cooperation between day-ahead and real-time planning and AGC, improve the output plan of thermal power units, and avoid frequent start-up and stop of coal mills caused by continuous fluctuations in output of thermal power units, the optimization model of day-ahead and real-time planning is introduced into the thermal power unit start-stop mill Constraints make the instructions issued by AGC closer to the requirements of economic dispatch.

[0050] By introducing the mathematical model of thermal power unit start-stop grinding constraints, a more reliable and effective economic unit output plan can be compiled, power generation costs can be reduced, and the closed-loop level of day-ahead and real-time planning and AG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com