Method and system for real-time transmission of automation equipment fault data in smart factories

A technology of automation equipment and fault data, applied in the direction of transmission system, digital transmission system, comprehensive factory control, etc., can solve problems such as prediction and operation status of difficult industrial gluing robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT OF THE INVENTION The specific embodiments of the present invention will be described in detail below, but it should be understood that the scope of the invention is not limited by the specific embodiments.

[0019]Unless otherwise clear, otherwise, in the entire specification and claims, the term "comprising" or "comprising" or "comprising" or the like will be understood to include the states or components or components, and Other components or other components are not excluded.

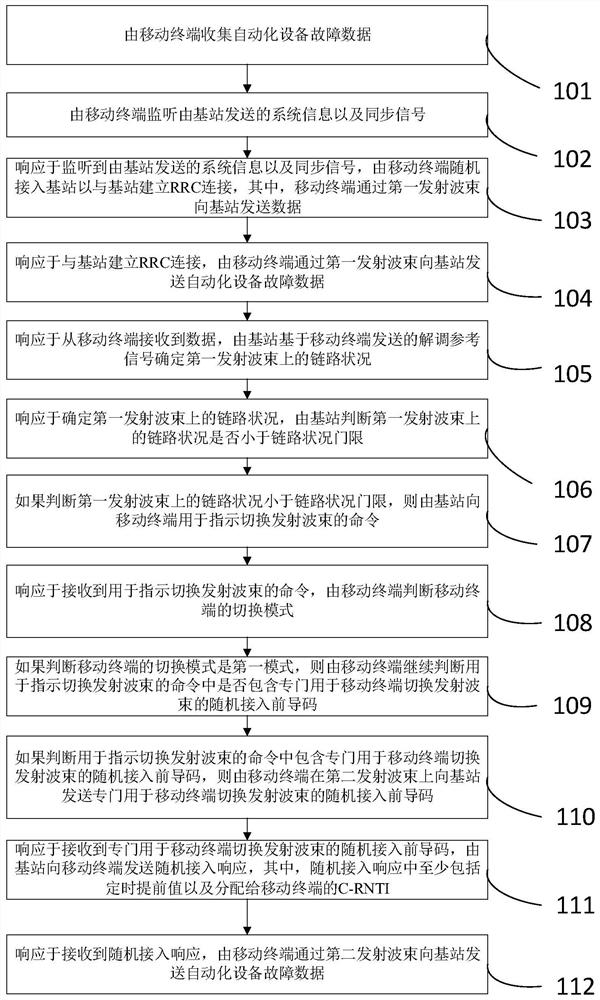

[0020]figure 1It is a flow chart of a method according to an embodiment of the present invention. As shown, the method of automated device fault data for the real-time transmission of the intelligent factory of the present invention includes the following steps:

[0021]Step 101: Collect automation device fault data by the mobile terminal;

[0022]Step 102: System information and synchronization signal transmitted by the base station by the mobile terminal;

[0023]S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com