Automatic grinding machine used for grinding metal shell of USB interface

A technology of USB interface and metal shell, applied in the field of automatic grinding machines, can solve the problems of unsuitable grinding equipment for processing, unguaranteed CPK value, increase labor intensity of employees, etc., so as to shorten the auxiliary grinding time and reduce the burden of clamping workpieces. work, the effect of improving the quality of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

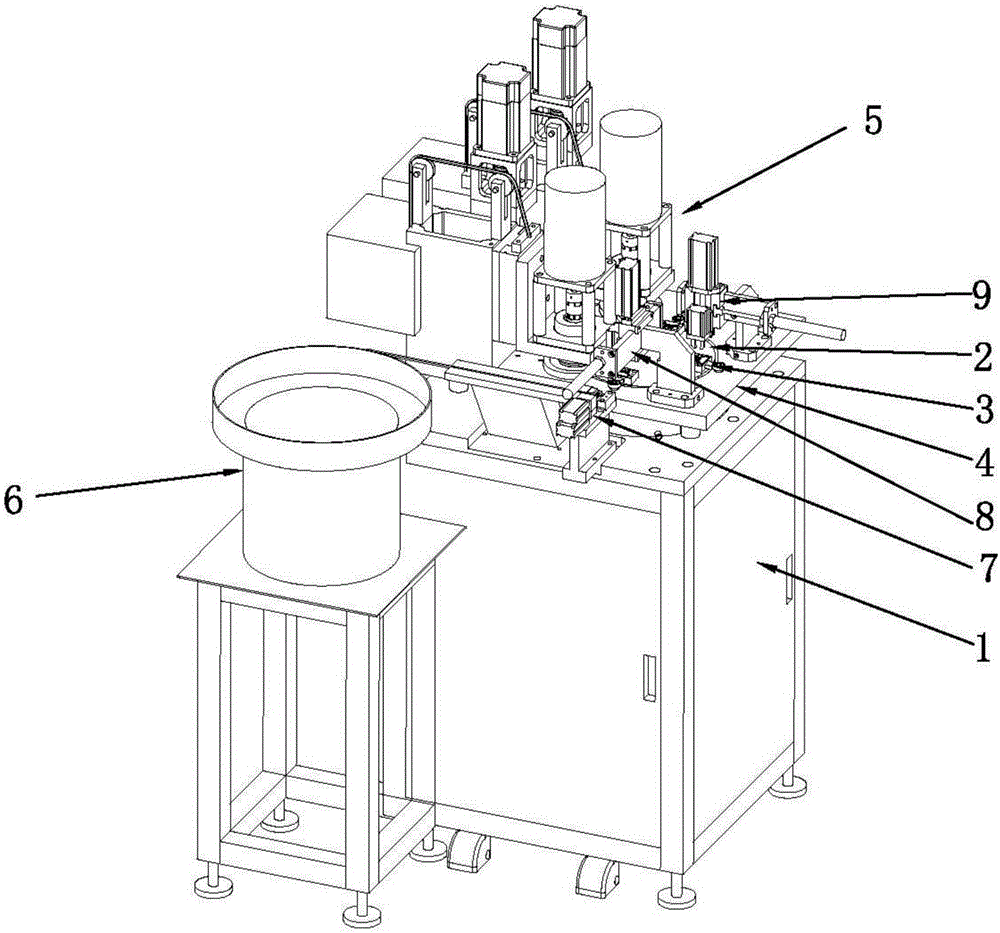

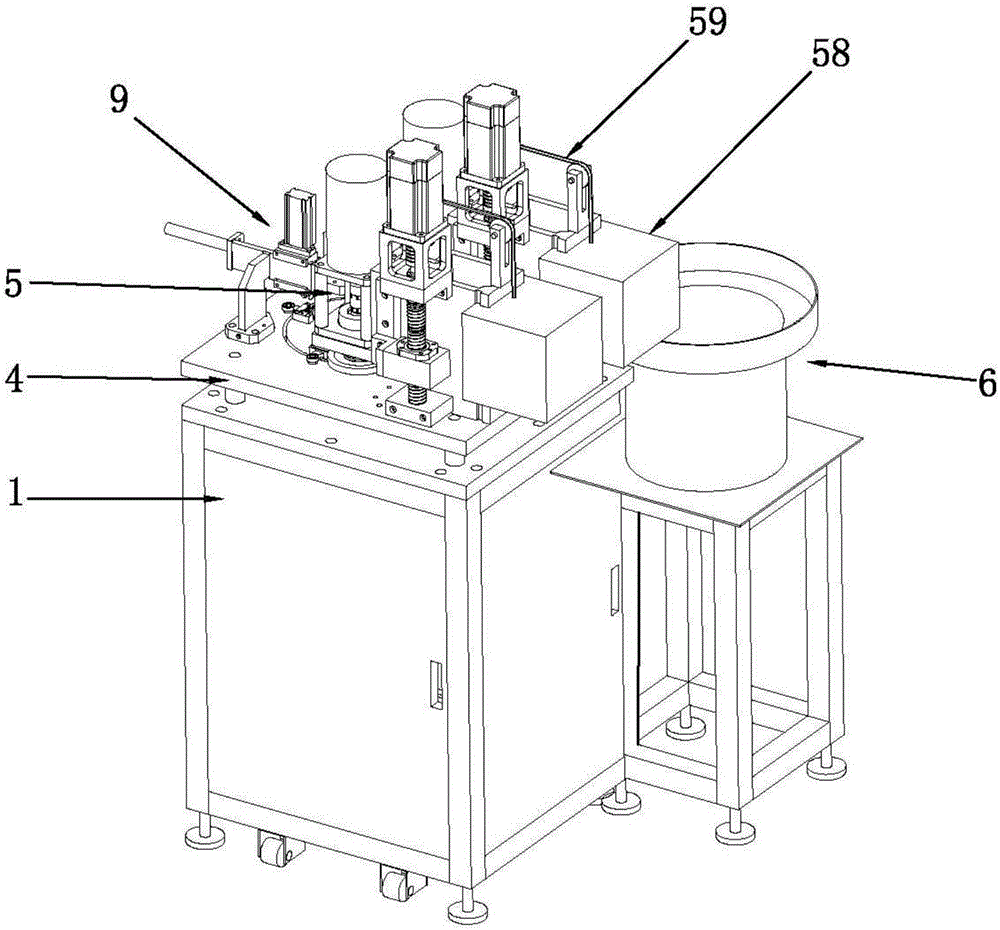

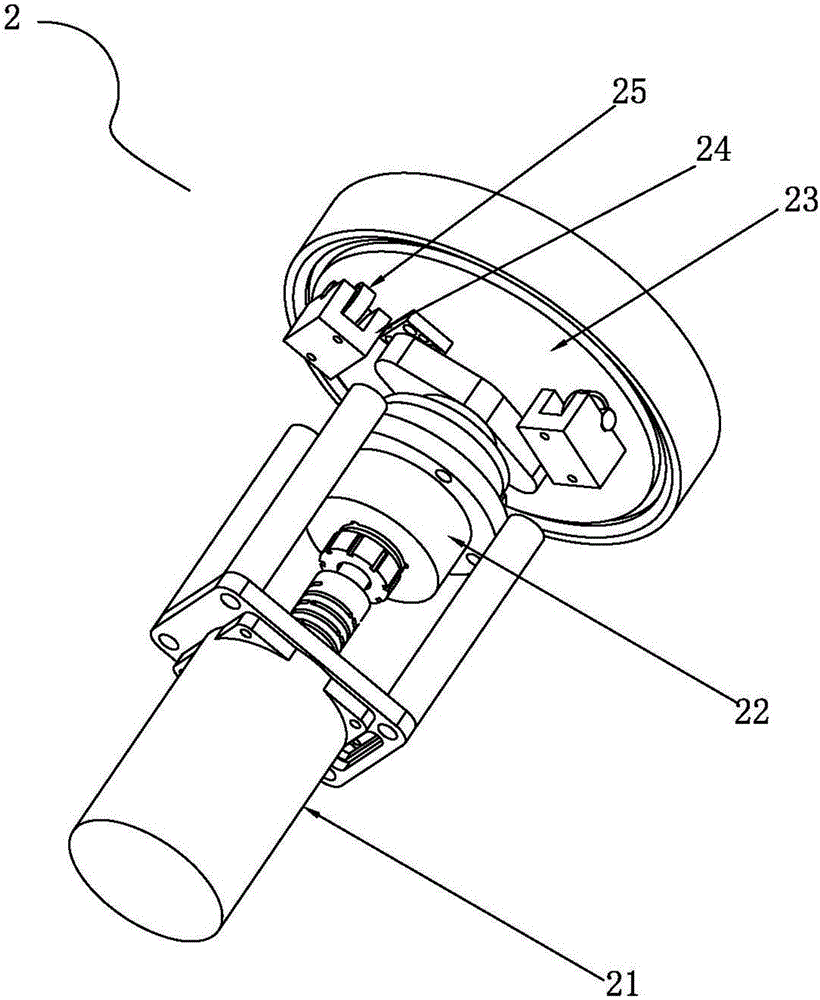

[0040]The present invention provides an automatic grinder for grinding metal casings with USB interfaces, comprising a cabinet 1 with a PLC automatic control system installed inside, a rotary table 2 is arranged in the middle of the top of the cabinet 1, and the top of the rotary table 2 is Four product positioning devices 3 are arranged on the end surface, and a support panel 4 is installed parallel to the outside of the rotary table 2. The support panel 4 is installed on the top of the chassis 1 through four support columns, so that the upper end surface of the support panel 4 and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com