Premixed feed for poultry, and preparation method thereof

A premixed feed and poultry technology, applied in animal feed, animal feed, applications, etc., can solve problems such as unscientific feed nutrition ratio, lack of minerals in feed, and influence on the development of aquaculture, so as to protect the environment and human health, Reduce the production of toxic and pathogenic metabolites and solve the effect of drug residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

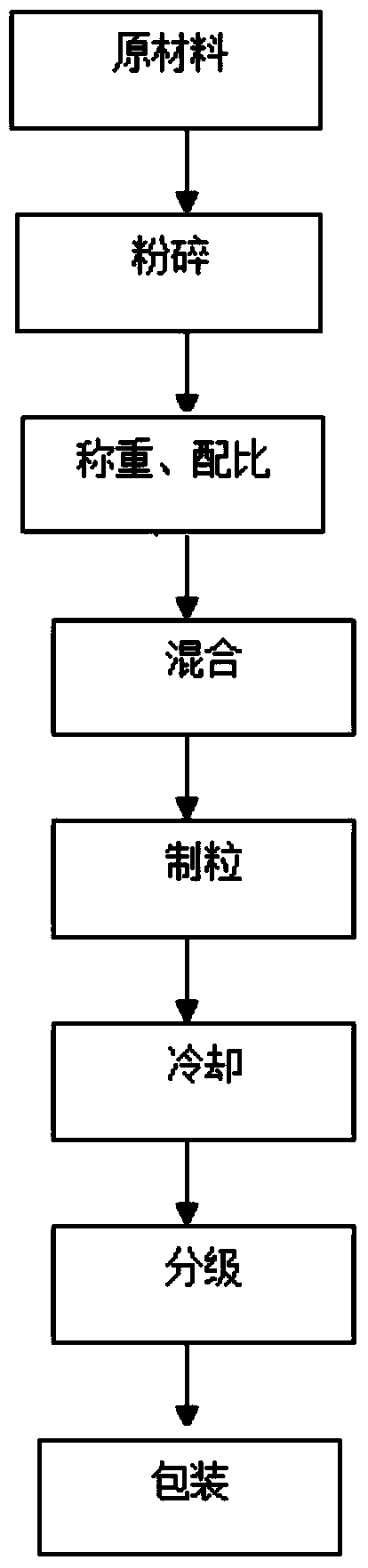

[0019] In the second aspect of the present invention, the preparation method of premixed feed for poultry includes the following steps: crushing various raw materials, passing through an 80-mesh sieve to obtain powdered feed; weighing and mixing the powdered feed according to the proportion; The mixed powder material is heated to 70-90°C by steam to obtain granules; the prepared granules are cooled, classified and packaged to obtain the final product.

[0020] Finally, examples and comparative examples of the premixed feed for poultry according to the present invention and its preparation method are described.

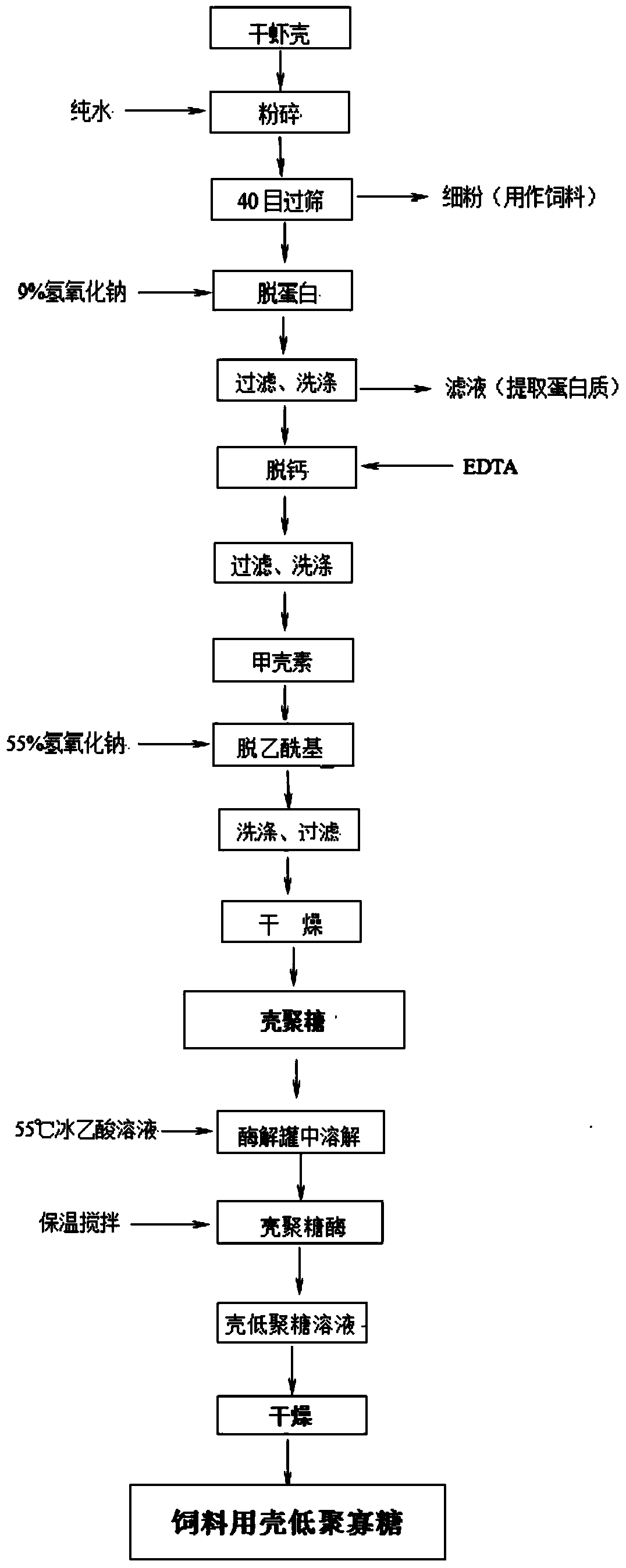

[0021] First prepare chitooligosaccharides:

[0022] Use dried shrimp shells as raw materials, crush them into pieces about 4×4mm2 in size, pass through a 50-mesh sieve, put the sieved shrimp shells into a 50-mesh nylon mesh bag, soak in 9% NaOH solution for 20 hours at room temperature, filter, Dry it, then rinse it with clean water until neutral, and then dry it to ...

Embodiment 1

[0027] Compound minerals: copper sulfate 3.00g, ferrous sulfate 27.00g, zinc sulfate 25.00g, manganese sulfate 20.00g, sodium selenite 10.00g, calcium iodate 15.00g;

[0028] Multivitamins: Antioxidant A20.00g, Chitooligosaccharides12.00g, Vitamin B11.00g, Vitamin B24.00g, Antioxidant B20.00g, Calcium Cold Acid 5.00g, Niacinamide 20.00g, Vitamin A9.00g, Vitamin A D3 2.50g, folic acid 2.00g, esterified VC 1.50g, vitamin E 2.00g, vitamin K 2.00g, biotin 1.00g, threonine 5.00g, lysine 200.00g, methionine 100.00g, choline chloride 100.00 g;

[0029] Wheatgrass powder 80.00g;

[0030] Compound enzyme 1.50g, phytase 1.50g;

[0031] Carrier 310.00 g.

[0032] Grind the above-mentioned various raw materials and pass through a 80-mesh sieve to obtain powdered materials; weigh and mix the powdered materials according to the proportion; heat the mixed powdered materials to 80°C by steam to obtain granules; Cooling, grading, packaging, to obtain the final product.

Embodiment 2

[0034] Compound minerals: copper sulfate 4.00g, ferrous sulfate 26.00g, zinc sulfate 26.00g, manganese sulfate 19.00g, sodium selenite 11.00g, calcium iodate 14.00g;

[0035] Multivitamins: antioxidant A21.00g, chitooligosaccharides11.00g, vitamin B12.00g, vitamin B23.00g, antioxidant B21.00g, calcium cold acid 4.00g, niacinamide 21.00g, vitamin A8.00g, vitamin D33.50g, folic acid 1.00g, esterified VC2.50g, vitamin E1.00g, vitamin K2.50g, biotin 0.5g, threonine 6.00g, lysine 199.00g, methionine 101.00g, choline chloride 99.00 g;

[0036] Wheatgrass powder 81.00g;

[0037] Compound enzyme 0.50g, phytase 2.50g;

[0038] Carrier 309.00 g.

[0039] Preparation method is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com