Process of preparing fiber preformrod

An optical fiber preform and preform technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve problems such as poor resistance to hydrogen damage, reduce hydroxyl content, eliminate network structure defects, and excellent resistance to environmental hydrogen influence Effect

Active Publication Date: 2007-11-07

JIANGSU FASTEN CO LTD

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This separate process is more advantageous than the process of one-time deposition and sintering into rods in the tube in terms of eliminating internal moisture; however, the resulting quartz rods contain hydroxyl groups, which have poor resistance to hydrogen damage, and the attenuation coefficient of 1383nm after hydrogen aging The increase is greater than 0.005dB / km

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0043] 1310nm

Embodiment 2

[0045] 1310nm

Embodiment 3

[0047] 1310nm

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

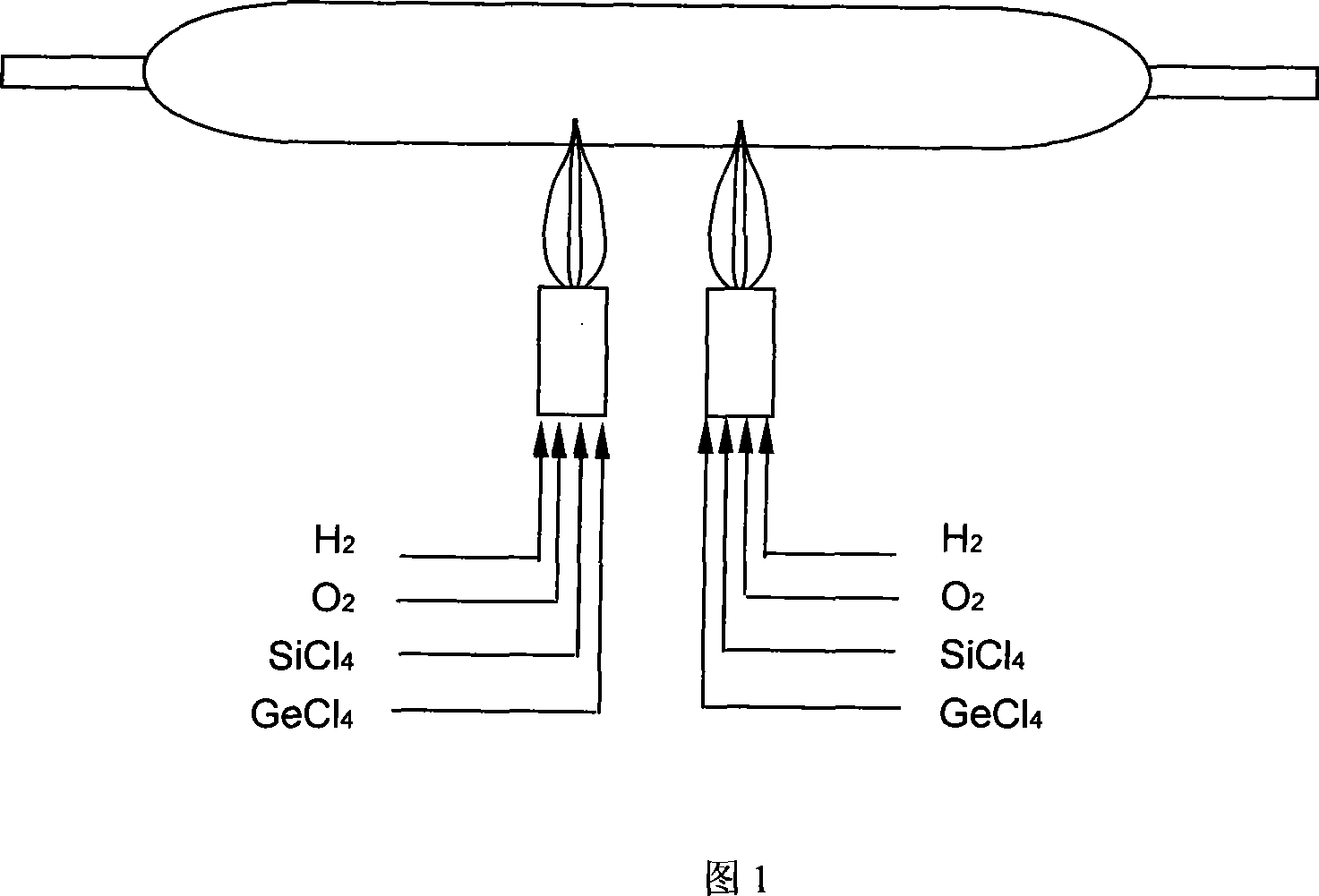

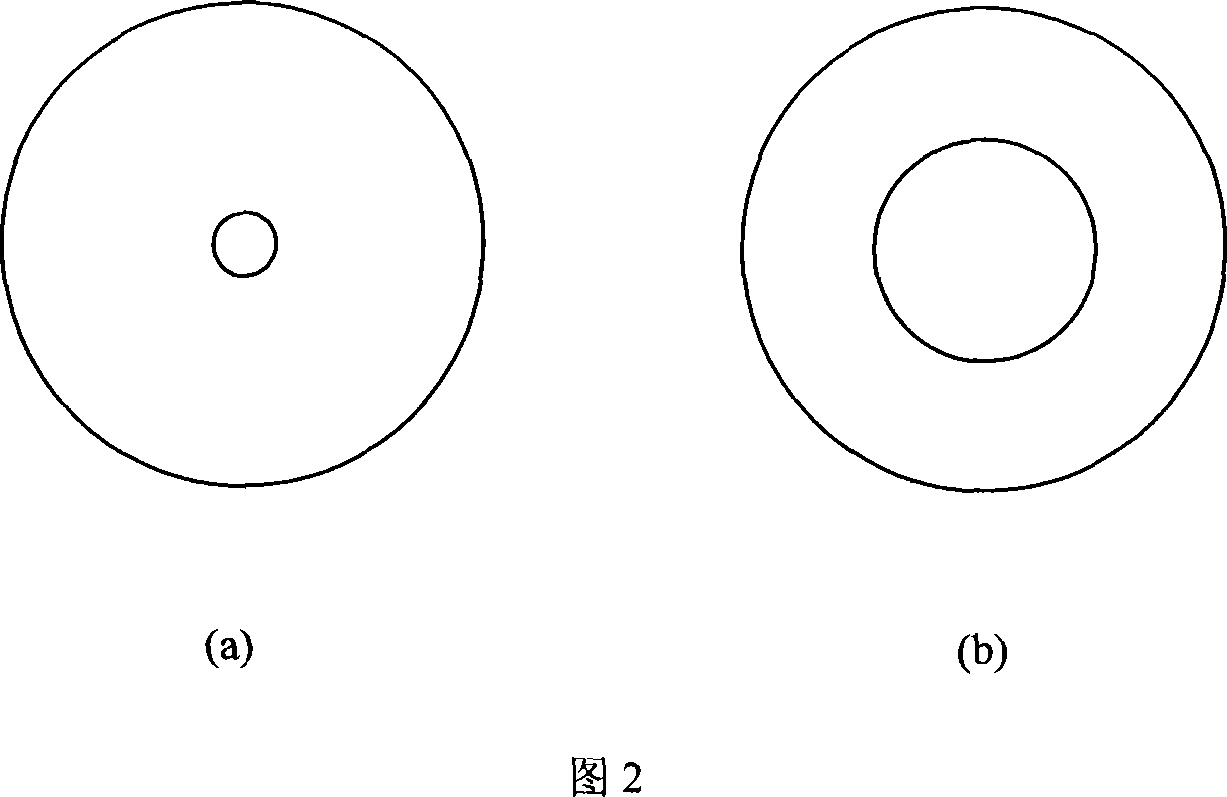

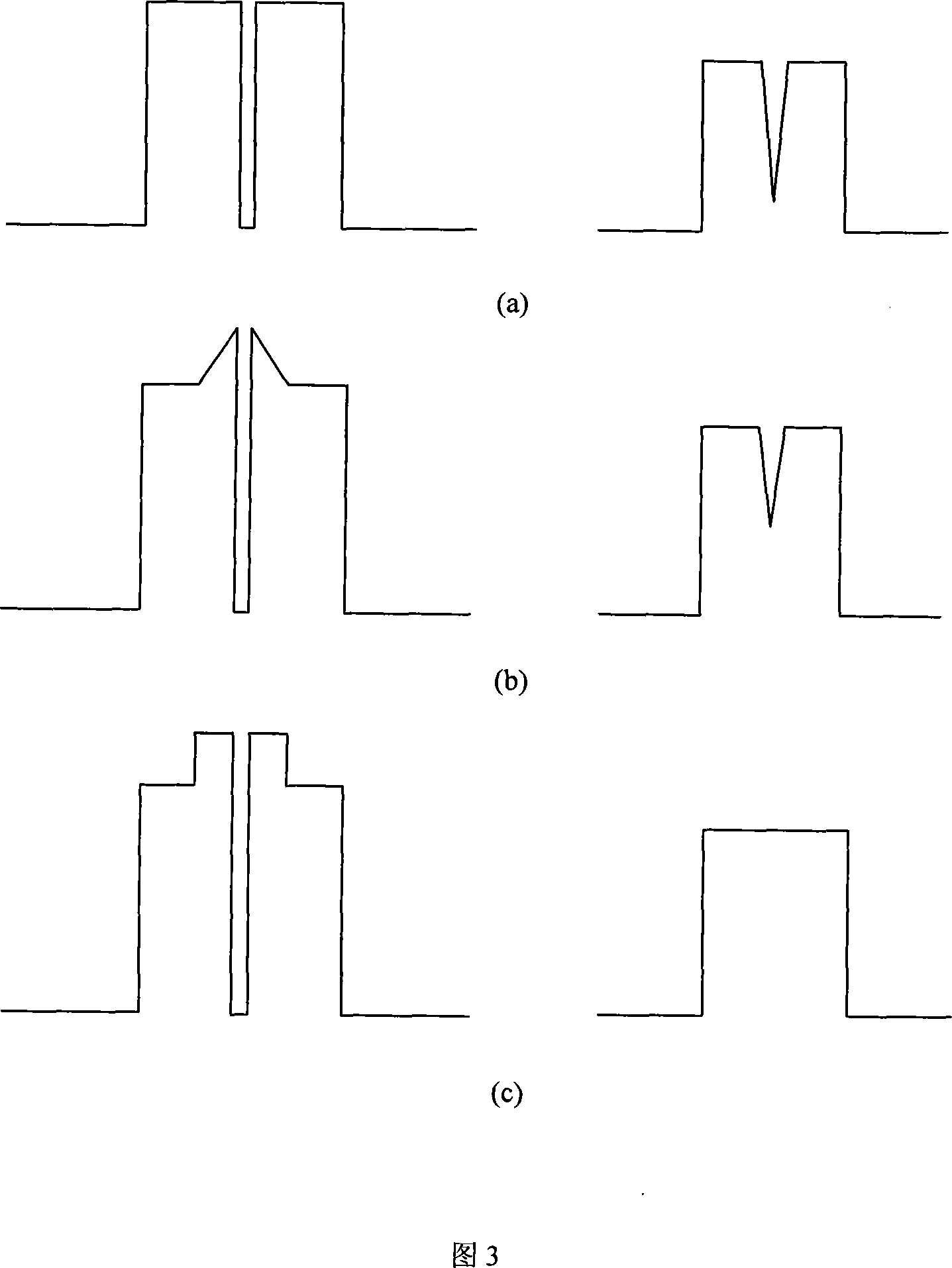

The process of preparing fiber preformed rod includes deuterium-hydrogen displacement reaction on quartz rod with low hydroxyl radical content and high purity for deuterium atom to occupy the non-bridge oxygen bond in quartz glass so as to reduce the probability of hydroxyl radical to diffuse, plasma flame etching to eliminate surface adsorbed hydroxyl radical of the quartz rod completely, depositing GeO2 and SiO2 onto the surface of the quartz rod, combined loose perform rod with central quartz rod, and dewatering and sintering in a sintering furnace to obtain transparent fiber preformed rod. The present invention is suitable for large- scale production and has low production cost, and the fiber preformed rod may be drawn into mono-mode fiber with low attenuation at 1383 nm wavelength, high hydrogen ageing resistance and very low PMD.

Description

1. Technical field [0001] The invention relates to a preparation method of an optical fiber preform, in particular to a preparation method of an optical fiber preform for producing a low water peak optical fiber by reducing the hydroxyl content in the optical fiber preform by an external deposition (OVD) process. 2. Background technology [0002] The transmission loss of conventional single-mode fiber (G.652B) is relatively high in the wavelength range of 1360-1460nm, which affects the application of optical communication systems in this band. Increased internal loss. Since the main vibrational absorption peak of OH is around 1383nm, the absorption peak at 1383±3nm is customarily called the water peak. ITU-T stipulates that the G652C specification requires that after the optical fiber undergoes hydrogen damage, its maximum attenuation coefficient of 1383±3nm must be less than or equal to the attenuation coefficient specified at 1310nm, and this kind of optical fiber is gene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B37/018

CPCC03B37/0148C03B37/01466C03B2201/22C03B37/01413C03B37/01446C03B2201/31Y02P40/57

Inventor 查健江冯术娟严薇曲风西李兴元江锋尤茂勇陆剑锋吴江卞进良梁乐天

Owner JIANGSU FASTEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com