Patents

Literature

105results about How to "Reduce splice loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

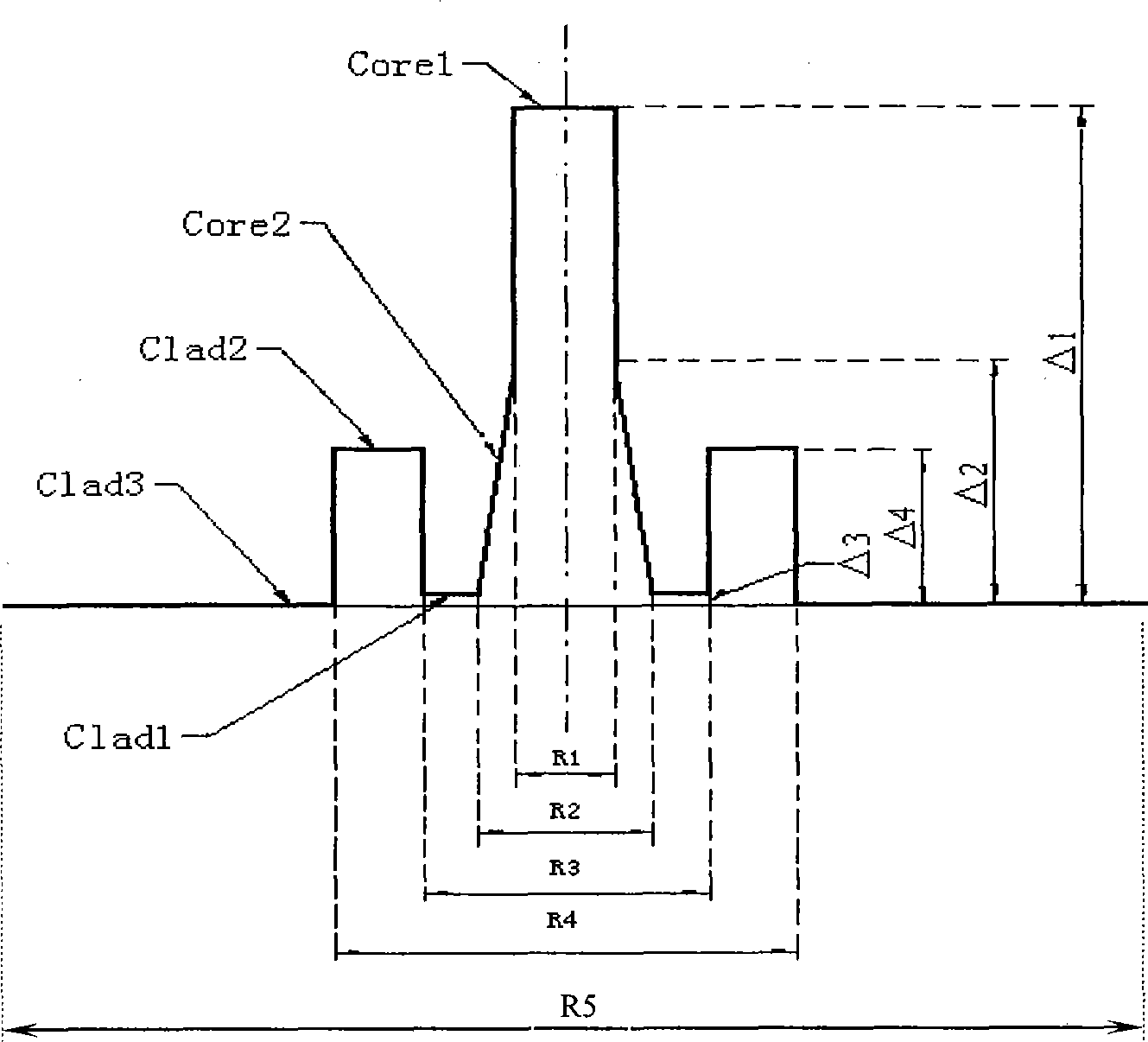

Low-attenuation bending insensitive single mode fiber

InactiveCN104316994AGood attenuation performanceDelay decayOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrometer

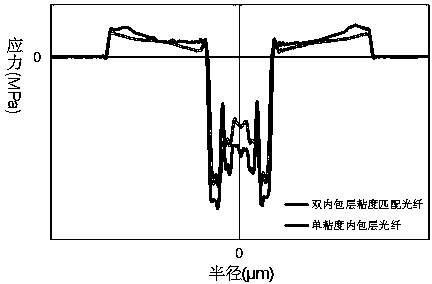

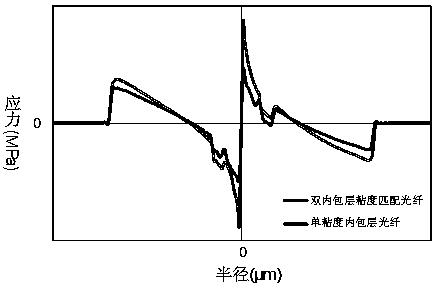

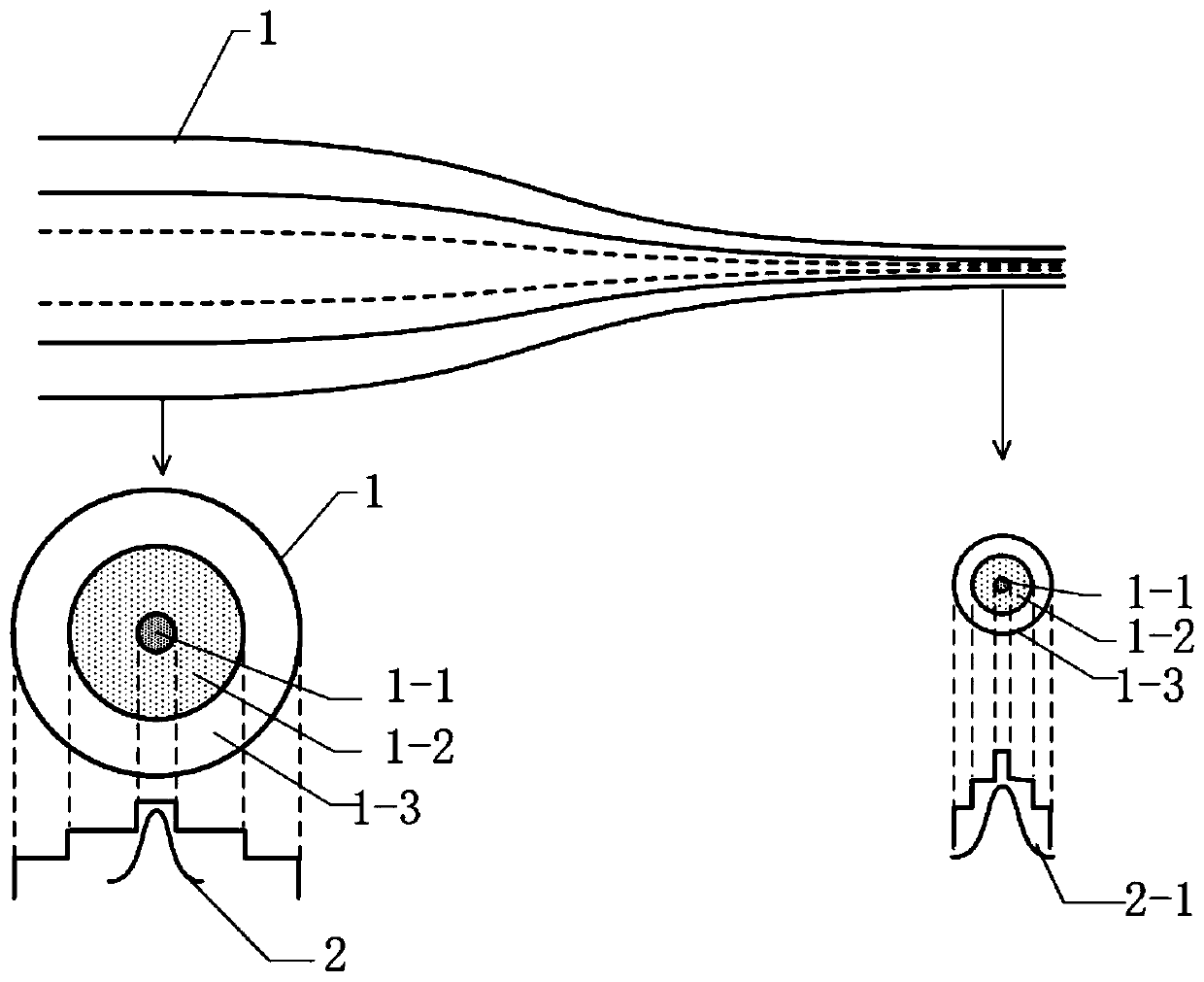

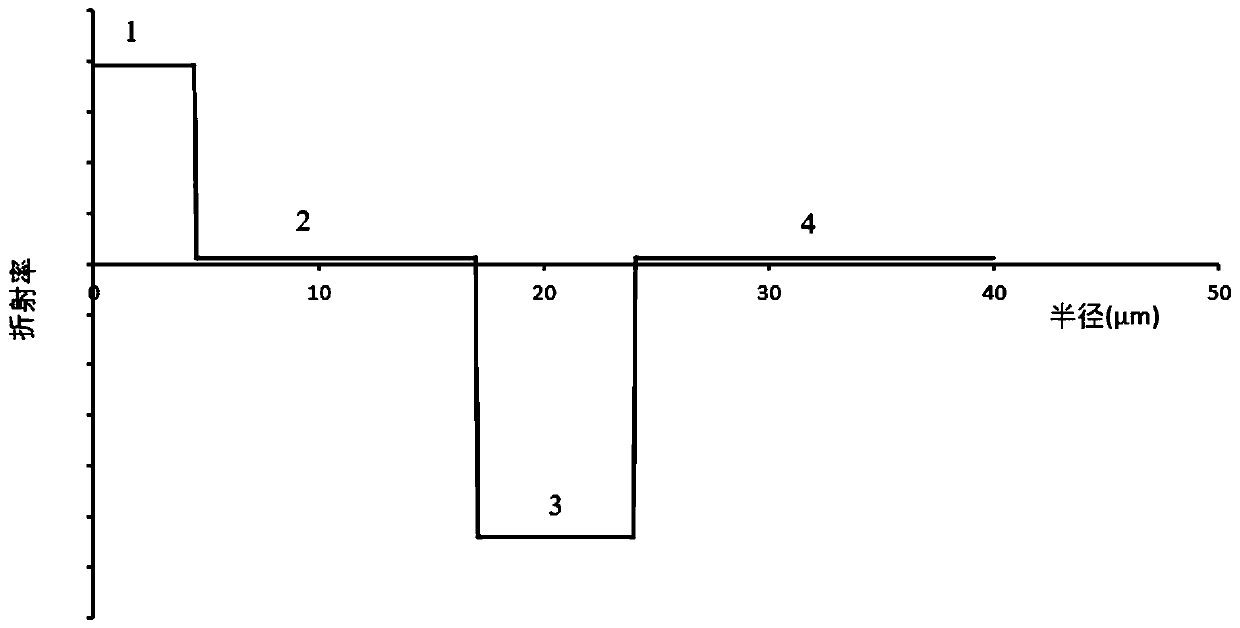

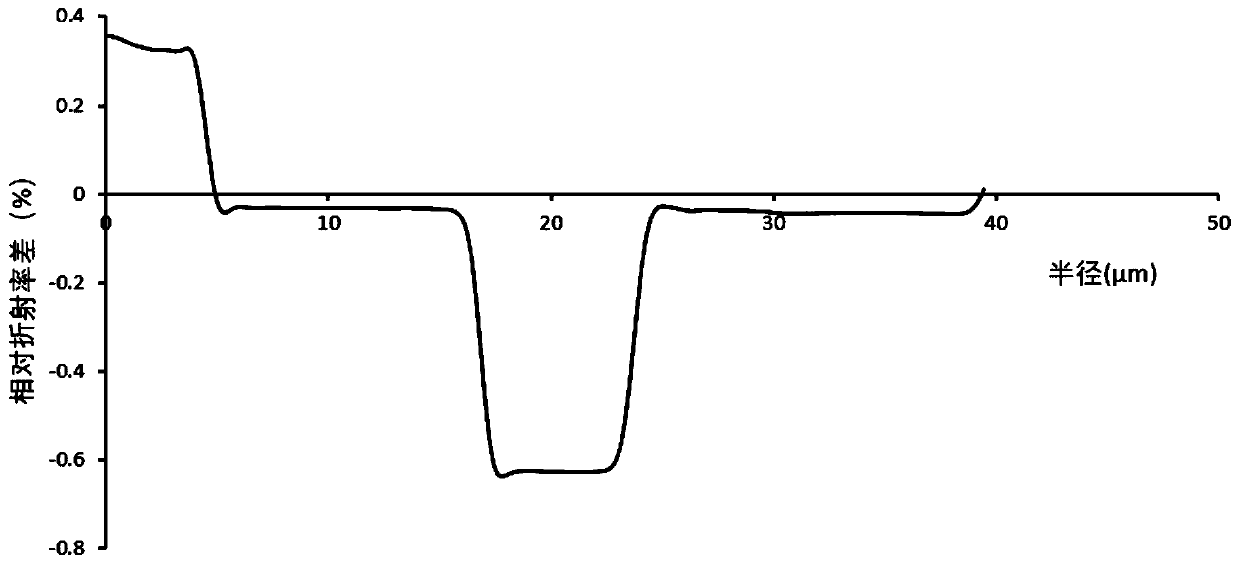

The invention relates to a low-attenuation bending insensitive single mode fiber which comprises a core layer and wrapping layers. The low-attenuation bending insensitive single mode fiber is characterized in that the relative refractive index difference delta1 of the core layer ranges from 0.30% to 0.38%, the radius R1 of the core layer ranges from 3.5 micrometers to 4.5 micrometers, the four wrapping layers are arranged outside the core layer, the first wrapping layer is a first inner wrapping layer tightly surrounding the core layer, the relative refractive index difference delta2 of the first wrapping layer ranges from -0.02% to 0.02%, the radius R2 of the first wrapping layer ranges from 6.5 micrometers to 8.5 micrometers, the second wrapping layer is a second inner wrapping layer tightly surrounding the first inner wrapping layer, the relative refractive index difference delta3 of the second wrapping layer ranges from -0.02% to 0.02%, the radius R3 of the second wrapping layer ranges from 8 micrometers to 11 micrometers, the third wrapping layer is a downwards-concave wrapping layer tightly surrounding the second inner wrapping layer, the relative refractive index difference delta4 of the third wrapping layer ranges from -0.5% to -0.2%, the radius R4 of the third wrapping layer ranges from 12 micrometers to 20 micrometers, and the fourth wrapping layer is an outer wrapping layer tightly surrounding the downwards-concave wrapping layer and is a pure quartz glass layer. The low-attenuation bending insensitive single mode fiber can be completely matched with a G.652.D optical fiber, and therefore the low attenuation, the large effective area and the bending resistance can be better unified.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

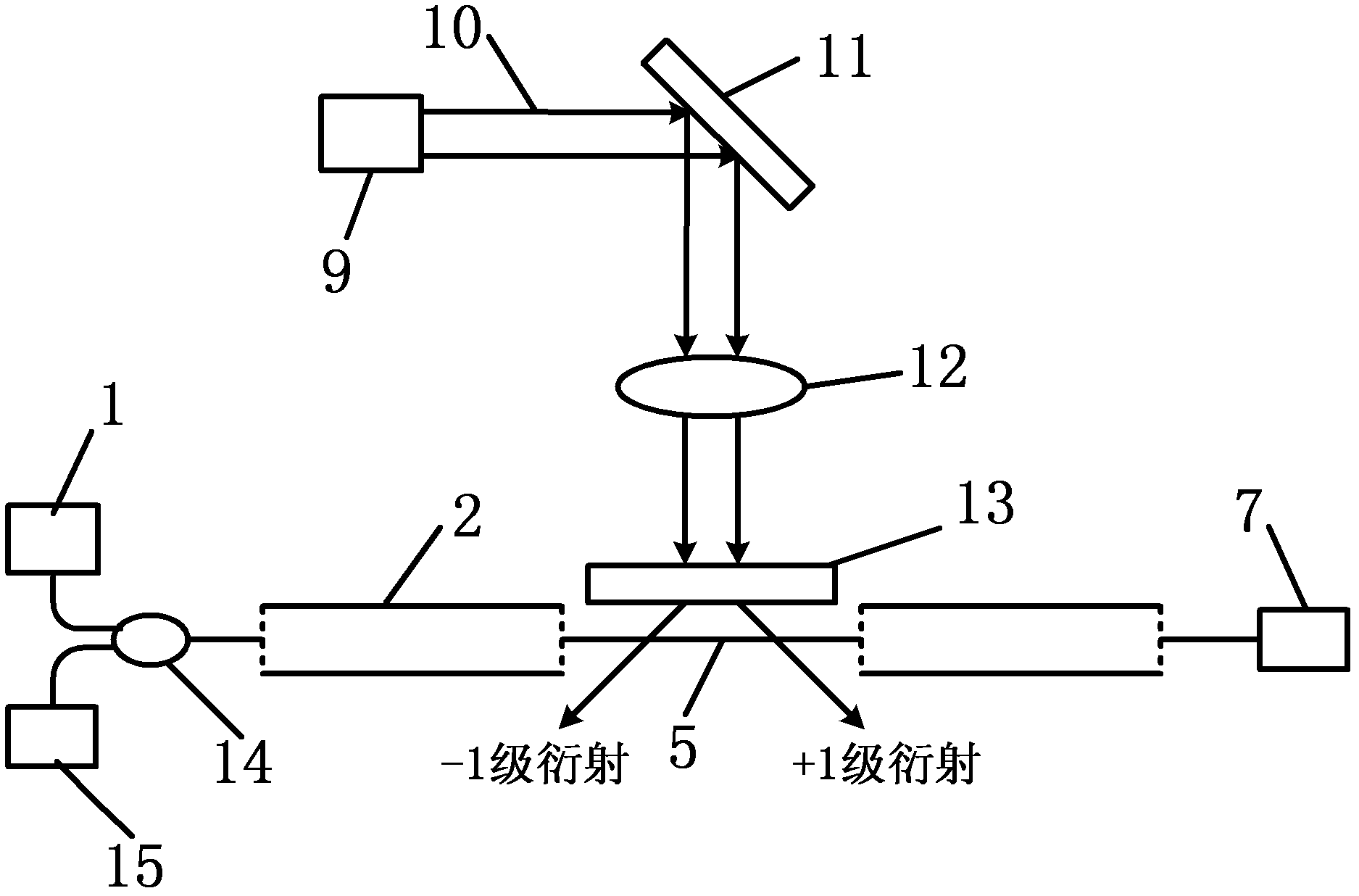

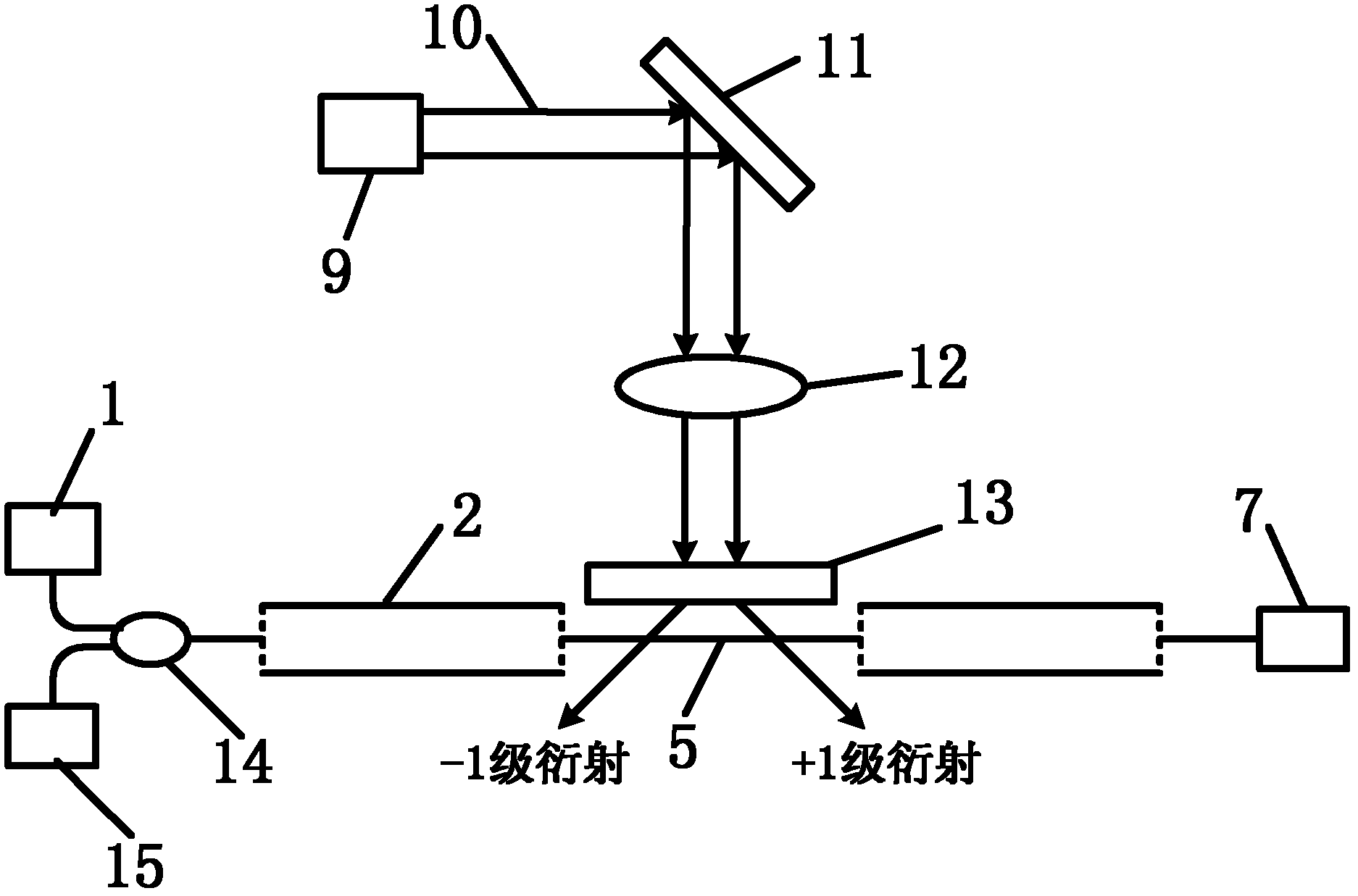

Micro-nano fiber grating laser writing method and device

InactiveCN102540322AReduce splice lossHigh core energyCladded optical fibrePhotomechanical exposure apparatusFiberMicro nano

The invention discloses a micro-nano fiber grating laser writing method and a micro-nano fiber grating laser writing device. The method comprises the following steps of: tapering normal multi-mode fibers; manufacturing micro-nano fibers; and then taking 193 nm ultraviolet laser as a scribing means. The device comprises a fiber clamp, and an ArF excimer laser, a 45-degree full power reflector, a cylindrical lens and a phase mask plate which are sequentially arranged, wherein the ArF excimer laser is used for emitting 193 nm ultraviolet laser; the tapered fiber is fixed on the fiber clamp; micro-nano fiber regions of the fibers are arranged in front of the phase mask plate in parallel; the 193 nm ultraviolet laser emitted by the ArF excimer laser is reflected through the 45-degree full power reflector and then vertically emitted to the cylindrical lens; and the phase mask plate is arranged in front of the cylindrical lens. According to the method and the device, extra processing for the fibers is not required, the mechanical strength and the toughness of the fibers are kept, the cost is low, the scribing efficiency is high, the bandwidth is narrow, the mode is controllable and the repeatability is high.

Owner:JINAN UNIVERSITY

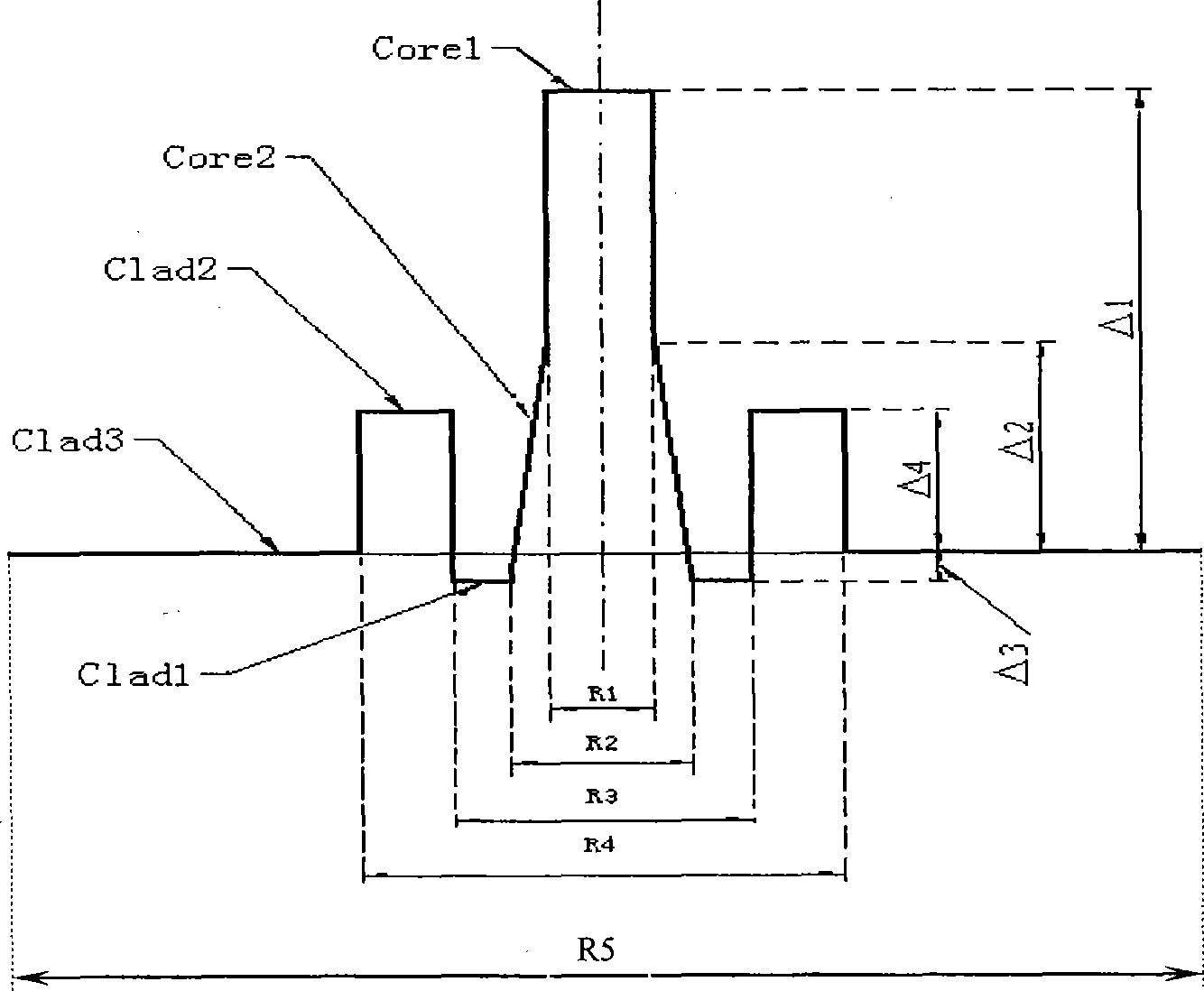

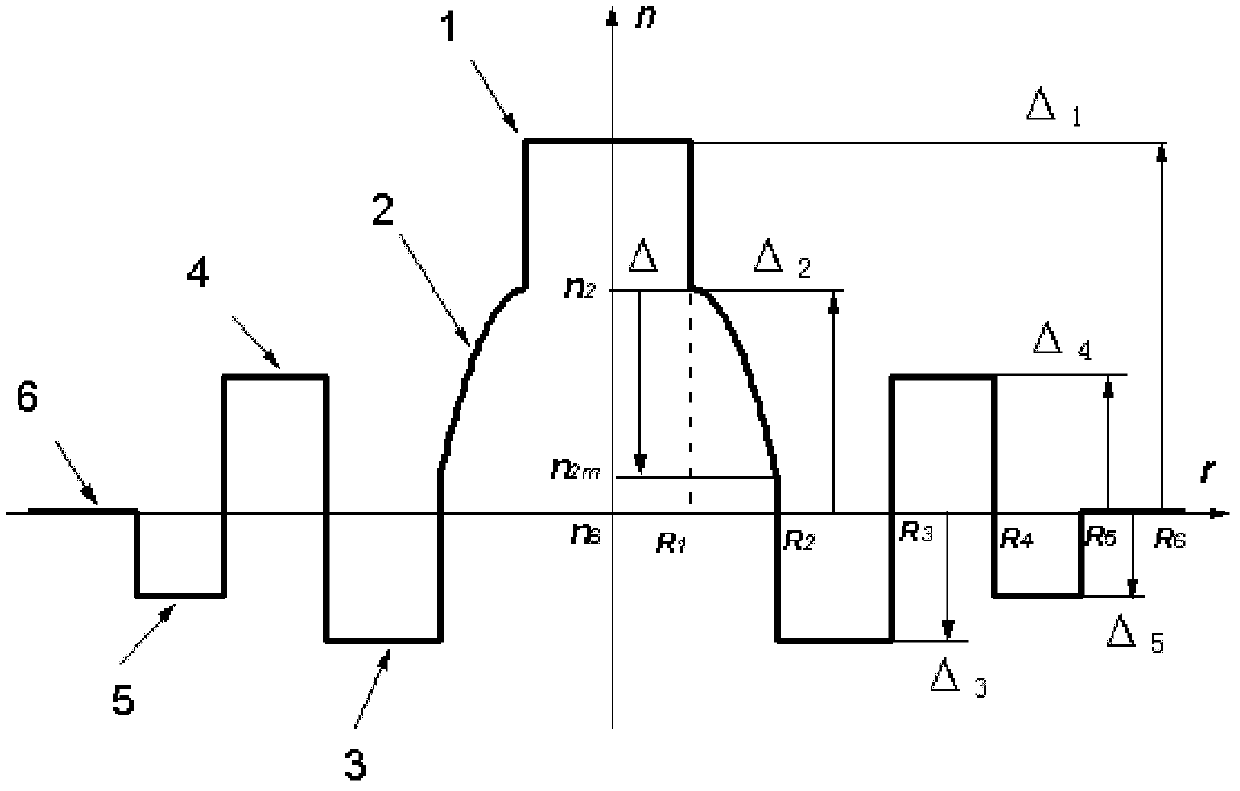

Improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution

ActiveCN101446663ASimple structureEasy to getOptical fibre with multilayer core/claddingOptical waveguide light guideColor effectPolarization mode dispersion

The invention provides an improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution, comprising an optical fiber core layer, and a cladding covered on the optical fiber core layer; wherein, the optical fiber core layer comprises an internal core layer and an external core layer enclosing the internal core, both of which have different refractive indexes; the refractive index of the external core layer is gradually distributed; the cladding comprises an internal cladding, a ring-core cladding and an external cladding which are sequentially arranged from interior to exterior and have different refractive indexes; the external cladding layer is a pure SiO2 glass layer; the refractive index distribution of the optical fiber core layer meets the formula that n1 is more than n2 which is more than nc; the refractive index distribution of the cladding meets the formula that n4 is more than n3 which is more than nc or n4 is more than nc which is more than n3. The improved nonzero dispersion-shifted single-mode optical fiber has low nonlinear color-effect characteristic (namely large effective area), optimum dispersion and low dispersion efficiency, effectively solves the nonlinearity problem and polarization mode dispersion problem of high-speed communication, reduces the dispersion management cost and has low fusing loss, thus being applicable to large-capacity high-speed long-distance transmission system.

Owner:HANGZHOU FUTONG COMM TECH CO LTD +1

Optical fiber large in effective area

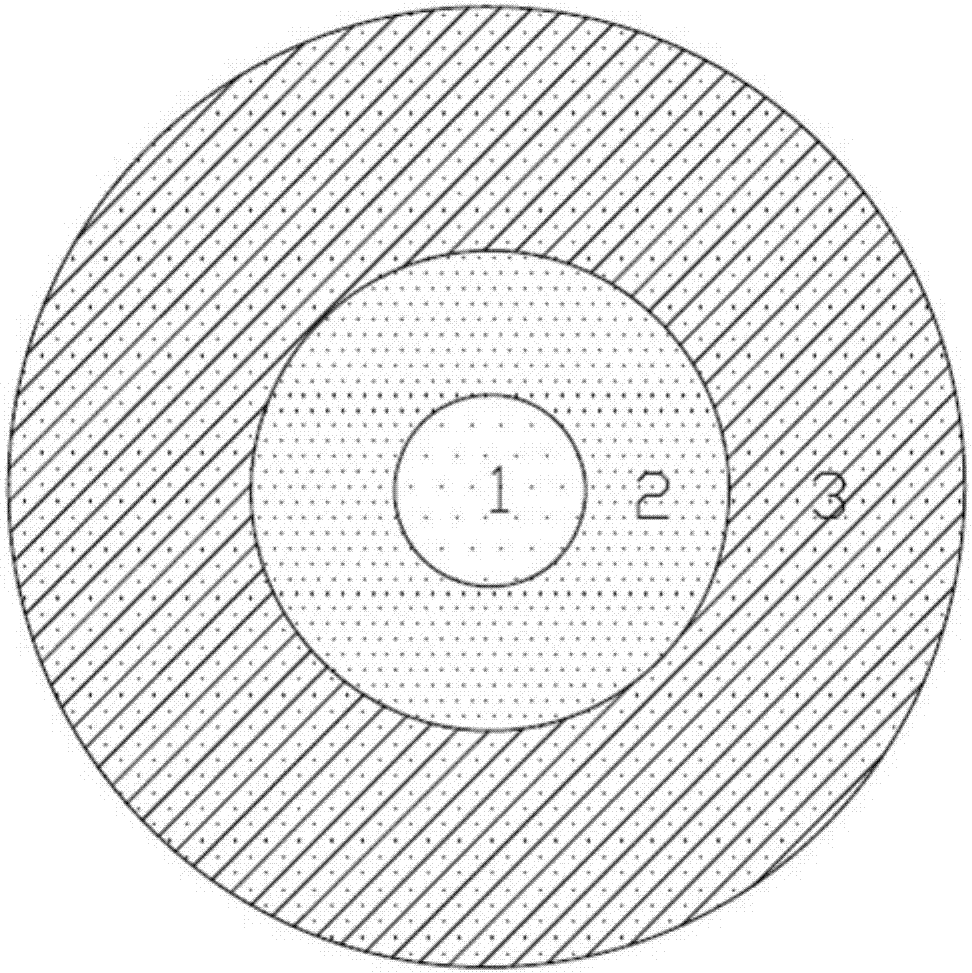

ActiveCN103257393AImprove bending characteristicsGood bending propertiesOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingCommunications systemRelative refractive index

The invention relates to an optical fiber large in effective area. The optical fiber large in the effective area comprises a fiber core layer and a covering layer. The optical fiber large in the effective area is characterized in that the fiber core layer comprises an inner core layer and an outer core layer, the radius r1 of the inner core layer is 1 to 4 microns, a relative refractive index difference delta 12 of the inner core layer to the outer core layer meets the condition that -0.2% <= delta 12 < 0%, the relative refractive index difference of the inner core layer to the outer core layer is invariant or gradually increased along with increasing of the radius, the radius r2 of the outer layer is 4 to 7 microns, and the relative refractive index difference delta 2 of the outer core layer is -0.15 % to 0.05 %; the covering layer comprises an inner covering layer, a sunk concave covering layer and an outer covering layer, the inner covering layer covers the fiber core layer, the radius r3 of the inner covering layer is 7 to 20 microns, the relative refractive index difference delta 3 is within the range of -0.5 % to -0.1 %, the radius r4 of the sunk concave covering layer is 12 to 40 microns, the relative refractive index difference delta 4 is within the range of -1.0 % to -0.3 %, and the relative refractive index difference delta 5 is within the range of -0.2% to -0.4%. The optical fiber large in the effective area has a large effective area, quite low transmission loss and good curve characteristics, and is particularly suitable for application of a long-distance high-speed large-volume communication system.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

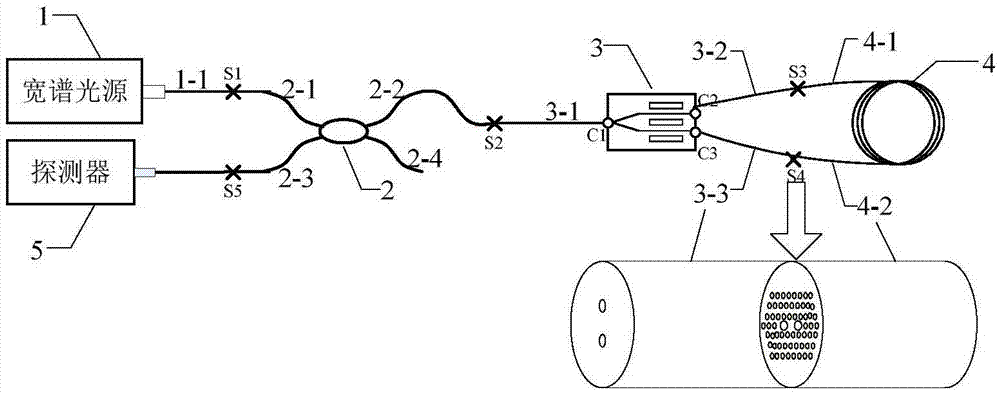

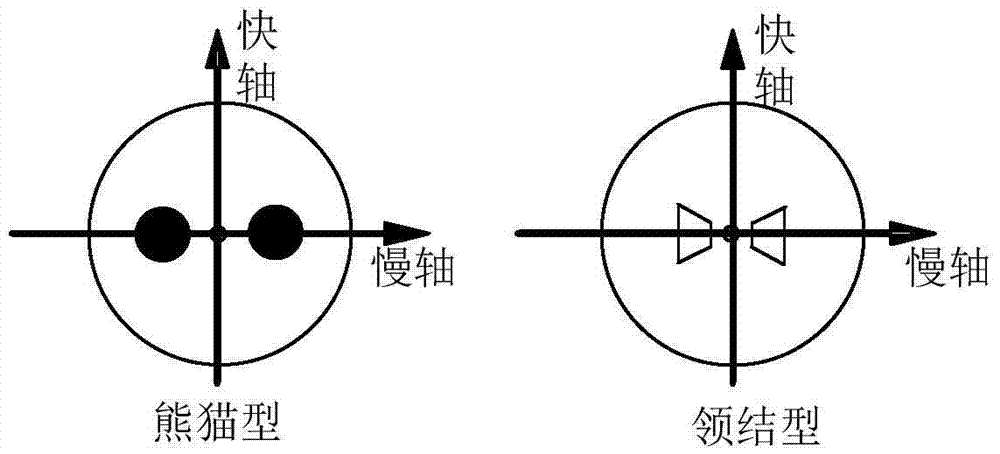

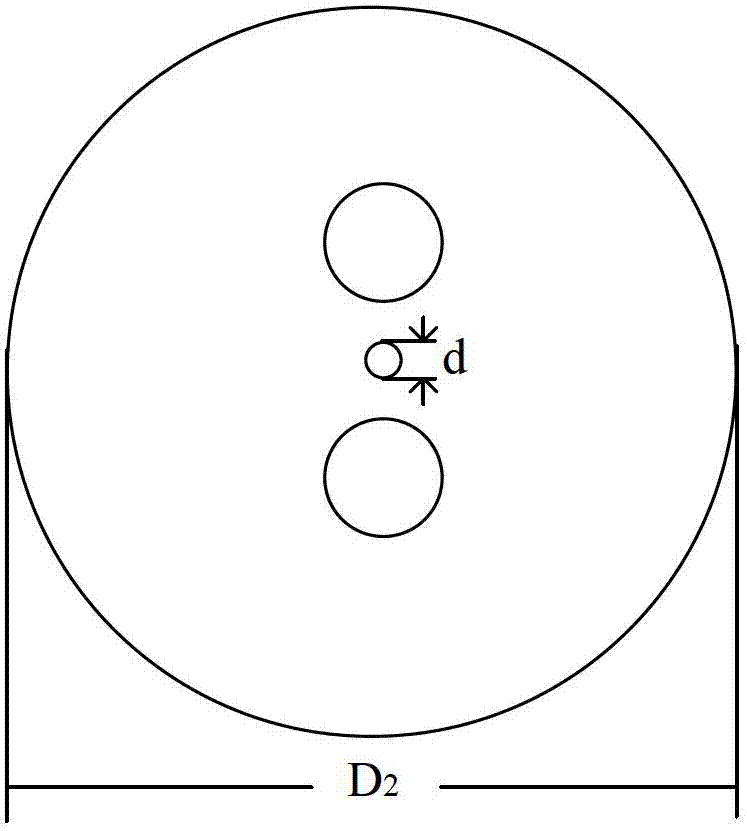

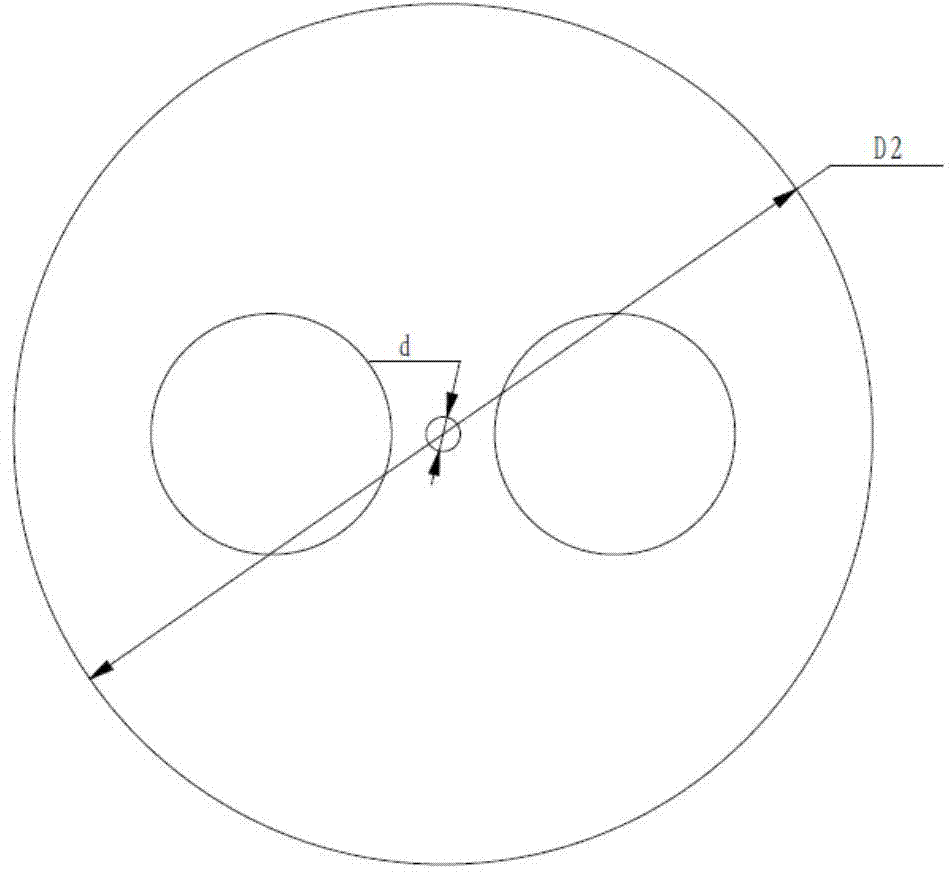

Polarization-maintaining photonic crystal fiber gyroscope and manufacturing method thereof

ActiveCN105444750AImprove bias stabilityReduce polarization errorSagnac effect gyrometersFiber couplerGyroscope

The invention discloses a polarization-maintaining photonic crystal fiber gyroscope light path. The polarization-maintaining photonic crystal fiber gyroscope light path comprises a polarization-maintaining fiber coupler, a broad band optical source, a Y waveguide, a polarization-maintaining photonic crystal fiber ring spliced with a Y waveguide output tail fiber and a detector and is characterized in that the polarization-maintaining fiber coupler acts on a polarization-maintaining fiber fast axis, a Y waveguide tail fiber is a stress birefringence polarization-maintaining fiber, 0-degree axis alignment splicing is performed between the fiber fast axis and the Y waveguide TE mode, the polarization-maintaining pohotonic crystal fiber ring is obtained by winding double macropore type polarization-maintaining photonic crystal fibers, 90-degree axis alignment splicing is performed between the axial direction of double macropore type polarization-maintaining photonic crystal fibers and the axial direction of the stress birefringence polarization-maintaining fiber, and useful signals in the gyroscope light path are all transmitted in the fast axis. The photonic crystal fiber gyroscope light path has the advantages of low temperature sensitiveness, radiation resistance and the like of a common photonic crystal fiber gyroscope, further effectively inhibits polarization errors of the gyroscope and facilitates improvement of zero-bias stability of the fiber gyroscope.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Intermediate/far infrared super-continuum spectrum fiber laser

InactiveCN102856783AIncrease powerLow costActive medium materialActive medium shape and constructionInfraredChalcogenide glass

The invention discloses an intermediate / far infrared super-continuum spectrum fiber laser which relates to the field of laser photoelectrons. The intermediate / far infrared super-continuum spectrum fiber laser comprises a pulse fiber laser, a quartz photonic crystal fiber, a passive intermediate infrared chalcogenide glass fiber, a passive intermediate / far infrared chalcogenide glass fiber, a filter, an excitation source and a rare earth ion doped chalcogenide glass fiber, wherein a super-continuum spectrum laser is generated by the pulse laser emitted by the pulse fiber laser through the quartz photonic crystal fiber to excite the passive intermediate infrared chalcogenide glass fiber so as to generate an intermediate infrared super-continuum spectrum laser; the intermediate infrared super-continuum spectrum laser is filtered by the filter; the filtered intermediate infrared super-continuum spectrum laser is used as a seed resource laser and amplified through the rare earth ion doped chalcogenide glass fiber; and the amplified intermediate laser is used for exciting the passive intermediate / far infrared chalcogenide glass fiber so as to generate an intermediate / far infrared super-continuum spectrum laser with a wavelength of 5-14 micrometers. According to the intermediate / far infrared super-continuum spectrum fiber laser, the shortage of light sources of intermediate / far infrared lasers is solved and the output of the intermediate / far infrared super-continuum spectrum laser is realized.

Owner:BEIJING UNIV OF TECH

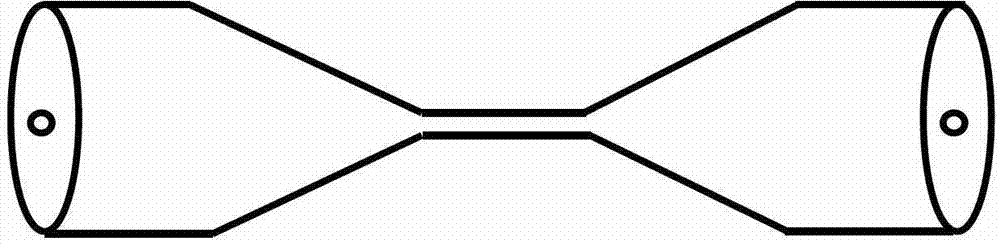

Polarization-maintaining fiber coupler, preparation method thereof and all-fiber optical current sensor

ActiveCN101515049AEliminate the disadvantages of unstable performanceImprove reliabilityCoupling light guidesMulti-mode optical fiberSingle-mode optical fiber

The invention discloses a polarization-maintaining fiber coupler. A coupling region of the polarization-maintaining fiber coupler is made of single-mode optical fibers, an input end of the polarization-maintaining fiber coupler at least contains a polarization-maintaining optical fiber, an output end which is directly communicated with the input end is one single-mode optical fiber, the input end of the polarization-maintaining fiber coupler at least contains one single-mode optical fiber, an output end which is directly communicated with the input end is the polarization-maintaining optical fiber, and the polarization-maintaining optical fibers of the input end and the output end are fused with the corresponding single-mode optical fibers in the coupling region respectively. A method for preparing the polarization-maintaining fiber coupler comprises the following steps that: firstly, a heat sealer is used to prepare two-node optical fibers; secondly, the optical fibers are arranged and axially positioned according to the design requirement; and finally, a plurality of the single-mode optical fibers in the middle are fused and drawn into the coupling region. In the polarization-maintaining fiber coupler, the coupling region is formed by drawing the single-mode optical fibers, so a device has the characteristics of no sensitivity to the polarization and temperature environment, and the stability and the reliability of the device are greatly improved. The invention also discloses an all-fiber optical current sensor.

Owner:上海康阔光智能技术有限公司

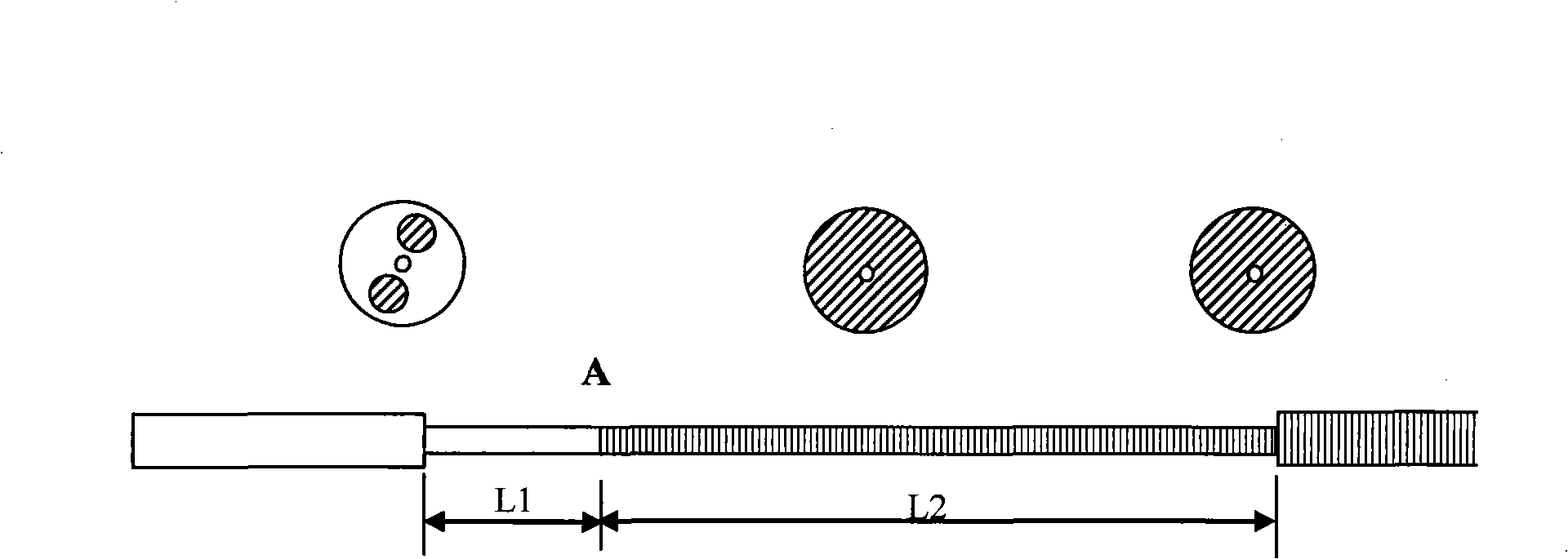

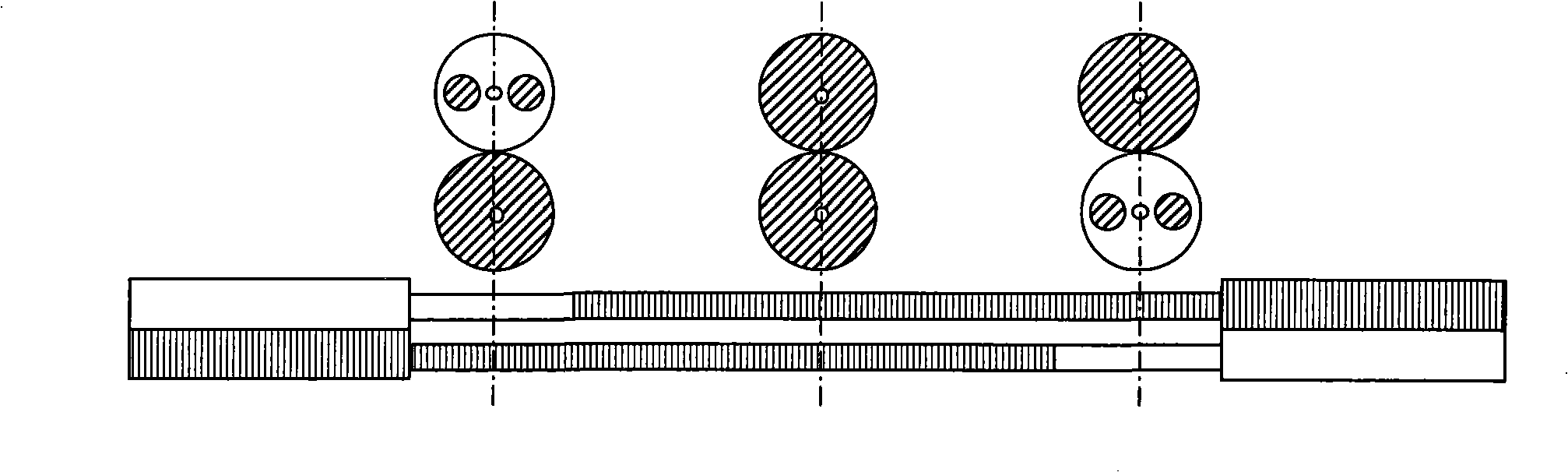

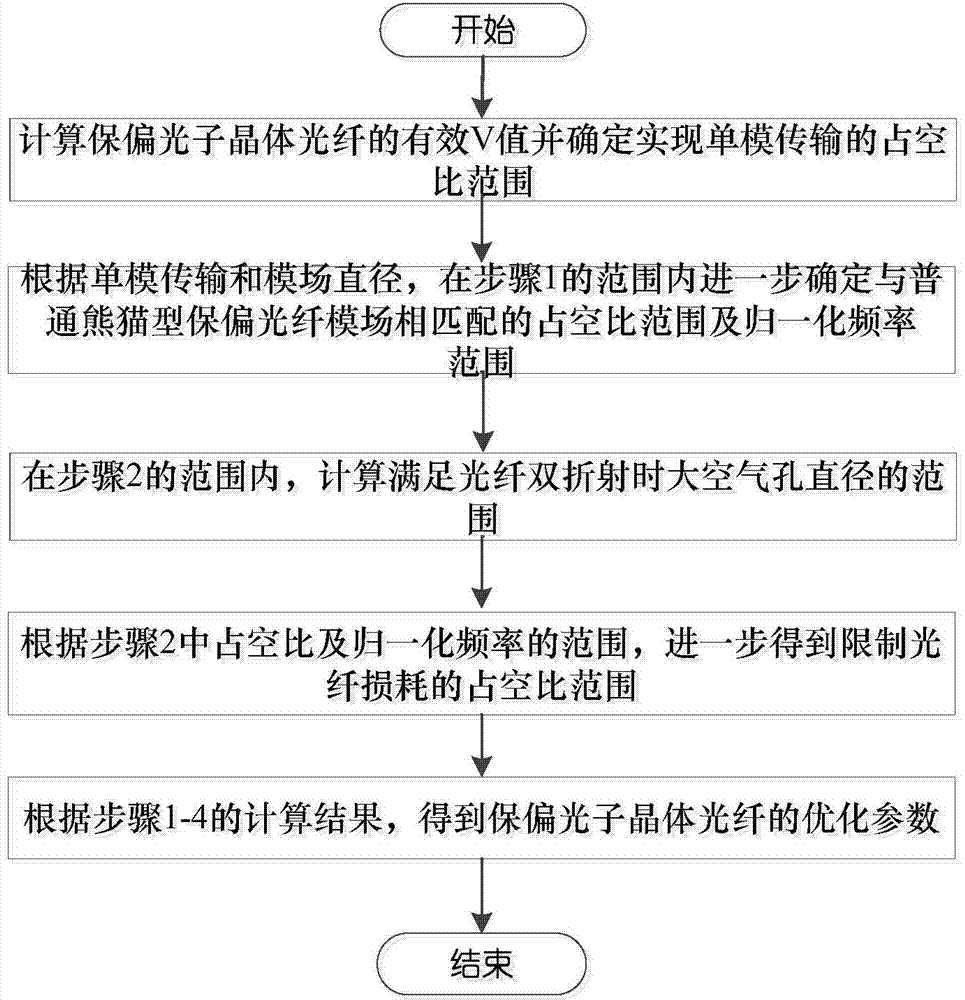

Polarization-maintaining photonic crystal fiber and panda fiber welding method

The invention discloses a polarization-maintaining photonic crystal fiber and panda fiber welding method. The polarization-maintaining photonic crystal fiber and panda fiber welding method is characterized by comprising a step 1 of selecting an initial position of a fiber, a step 2 of aligning a polarization shaft, and a step 3 of welding. The polarization-maintaining photonic crystal fiber and panda fiber welding method realizes better matching of two fiber mode fields and lowering welding consumption by controlling collapse of an air hole of a photonic crystal fiber and a diameter at the welding point of the panda fiber. The polarization-maintaining photonic crystal fiber and panda fiber welding method lowers welding consumption and improves welding intensity by adding a propelling distance in a fiber welding process appropriately. By adopting a novel welding machine and an end face imaging and shaft alignment technology, the polarization-maintaining photonic crystal fiber and panda fiber welding method can realize alignment of the polarization shafts of both the photonic crystal fiber and the panda fiber and improve shaft alignment precision. The polarization-maintaining photonic crystal fiber and panda fiber welding method, disclosed by the invention, has the advantages of being simple in technology, only needing once welding, and being easy to operate, good in repeatability and applicable for welding between photonic crystal fibers of the other types and traditional single-mode fibers.

Owner:BEIHANG UNIV

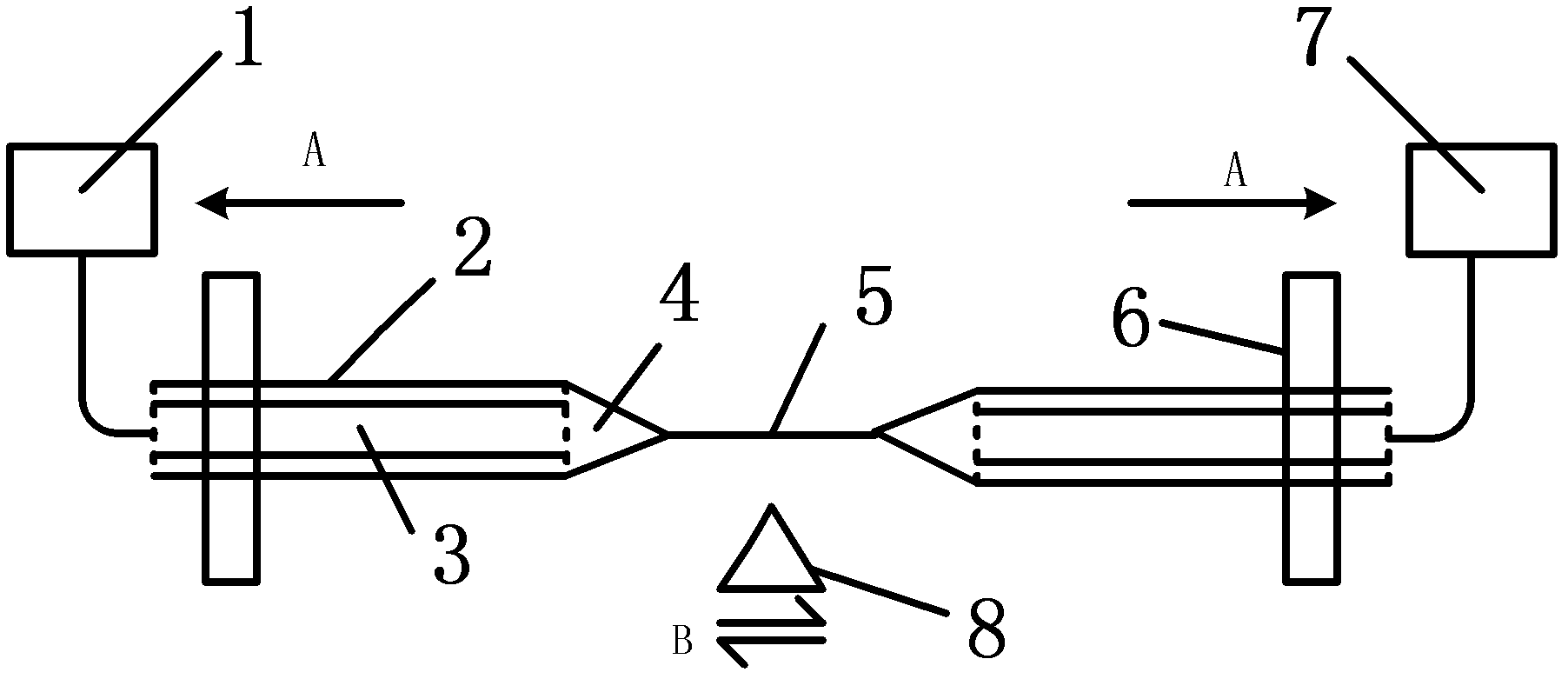

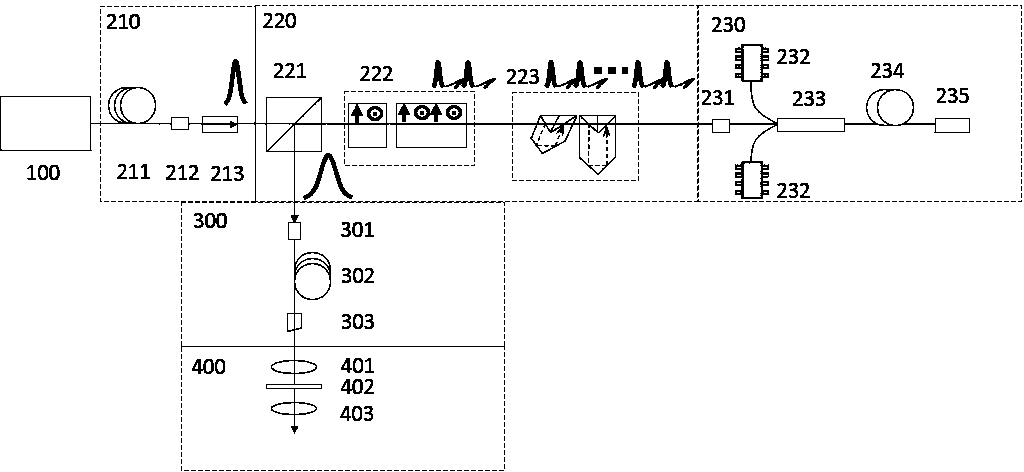

Crosstalk suppression type multi-core optical fiber beam splitter with low insertion loss

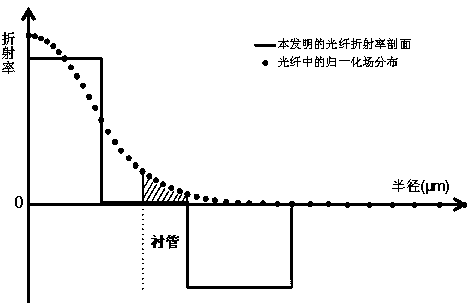

InactiveCN110441862ALow reflection return lossReduce splice lossCoupling light guidesSingle-mode optical fiberMulti-mode optical fiber

The invention provides a crosstalk suppression type multi-core optical fiber beam splitter with low insertion loss. The multi-core optical fiber beam splitter is characterized by being composed of aninput standard single-mode optical fiber, a multi-clad optical fiber, a porous quartz capillary sleeve and a multi-core optical fiber. Fiber cores of the single-mode optical fiber and the multi-clad optical fiber have the same single-mode field distribution; the multi-clad optical fiber is embedded into the porous quartz capillary sleeve; the diameter of the fused and tapered multi-clad optical fiber is reduced; optical fields in the fiber cores are converted in inner claddings; fundamental mode transmission is kept; and a mode field of an output end is matched with that of the multi-core optical fiber. The specially designed multi-clad optical fiber can effectively reduce the insertion loss of a device and effectively suppress the inter-core crosstalk of the device. The multi-core opticalfiber beam splitter can be used for low-loss and low-crosstalk beam splitting connection of the multi-core optical fiber, and is particularly suitable for beam splitting connection of the multi-coreoptical fiber with the large fiber core number and the high fiber core density.

Owner:GUILIN UNIV OF ELECTRONIC TECH

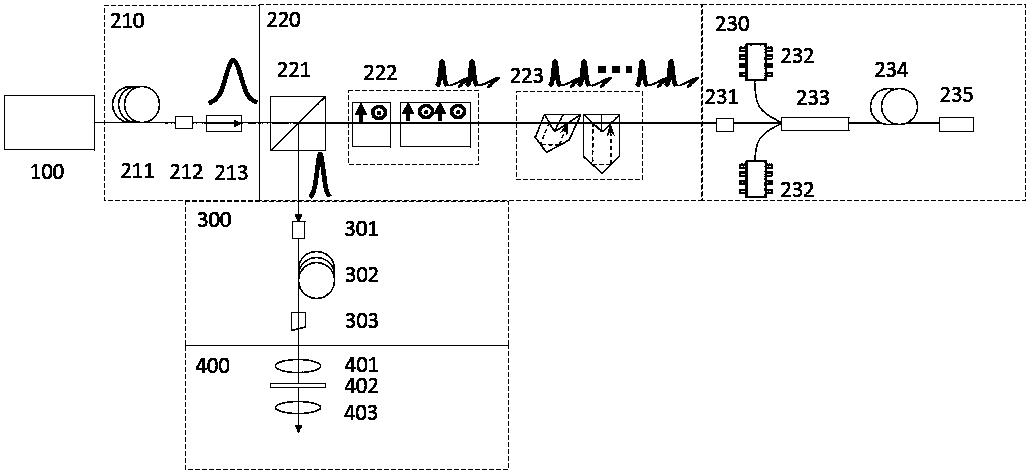

780 nm high-power optical-fiber femtosecond laser device

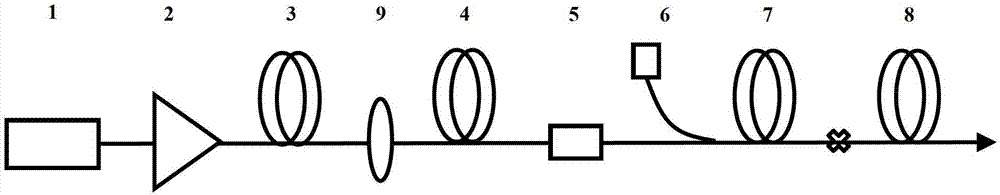

InactiveCN104283097ANot affected by dispersionReduce nonlinear effectsActive medium shape and constructionNon-linear opticsSeeds sourceComputer module

The invention discloses a 780 nm high-power optical-fiber femtosecond laser device. The laser device comprises a laser device seed source, a laser spreading and amplifying module, a laser compression module and a laser frequency doubling module, the laser device seed source and the preceding modules are sequentially connected, the laser spreading and amplifying module is composed of a chirped pulse spreading sub module, a pulse separation sub module and an optical fiber amplifying sub module, and the laser device seed source and the modules all work at the waveband of 1560 nm. A mixed pulse spreading mode is adopted, pulses are spread from 100 fs to 1ns in a small work space, the amplified pulses are compressed to below 100 fs through non-linear compression of a single-mode fiber, and ultimately the pulses reach 780 nm after frequency doubling of non-linear crystals. The laser device has the advantages of being high in stability, simple in structure, small and ingenious in size, low in cost and the like.

Owner:SHANGHAI LANGYAN OPTOELECTRONICS TECH

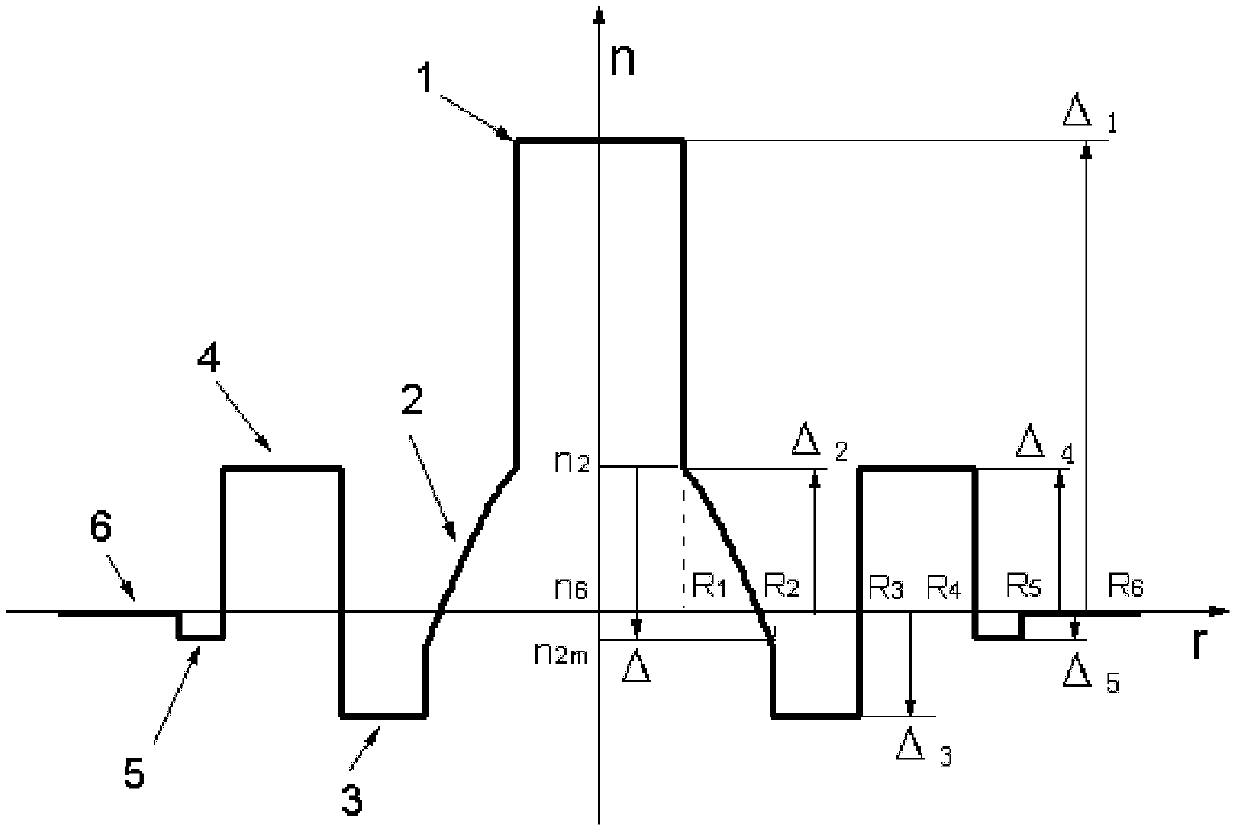

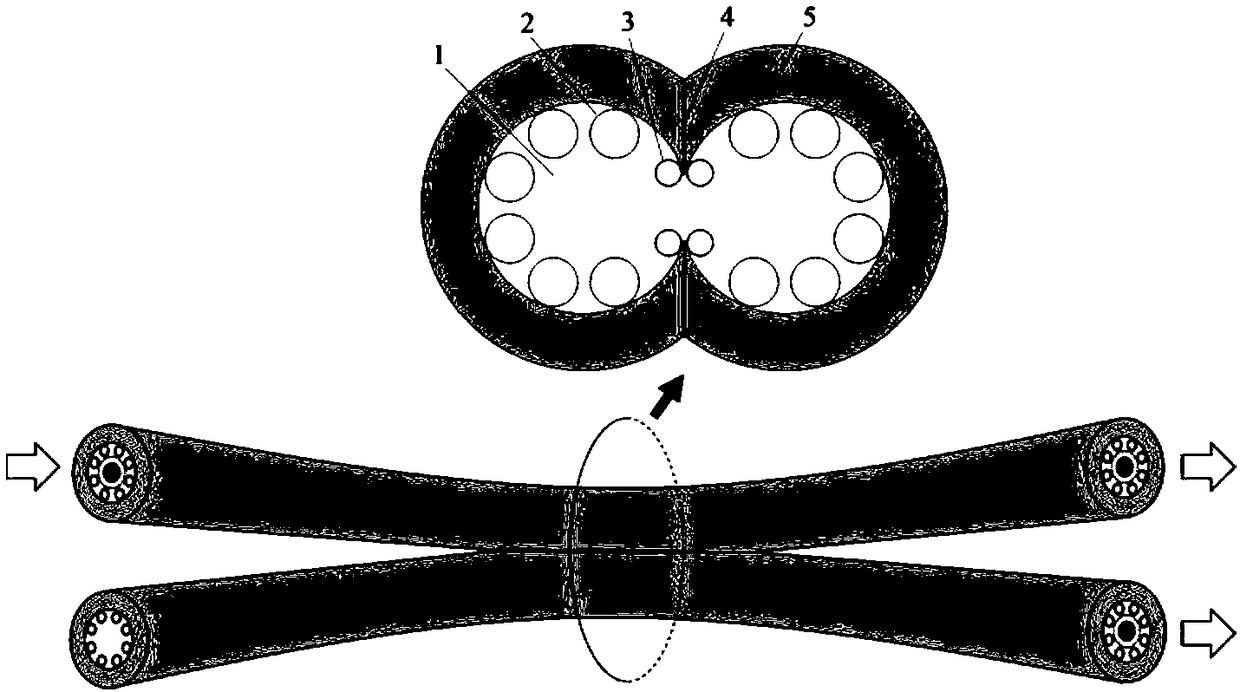

Multi-cladding optical fibre and multi-core optical fibre coupler

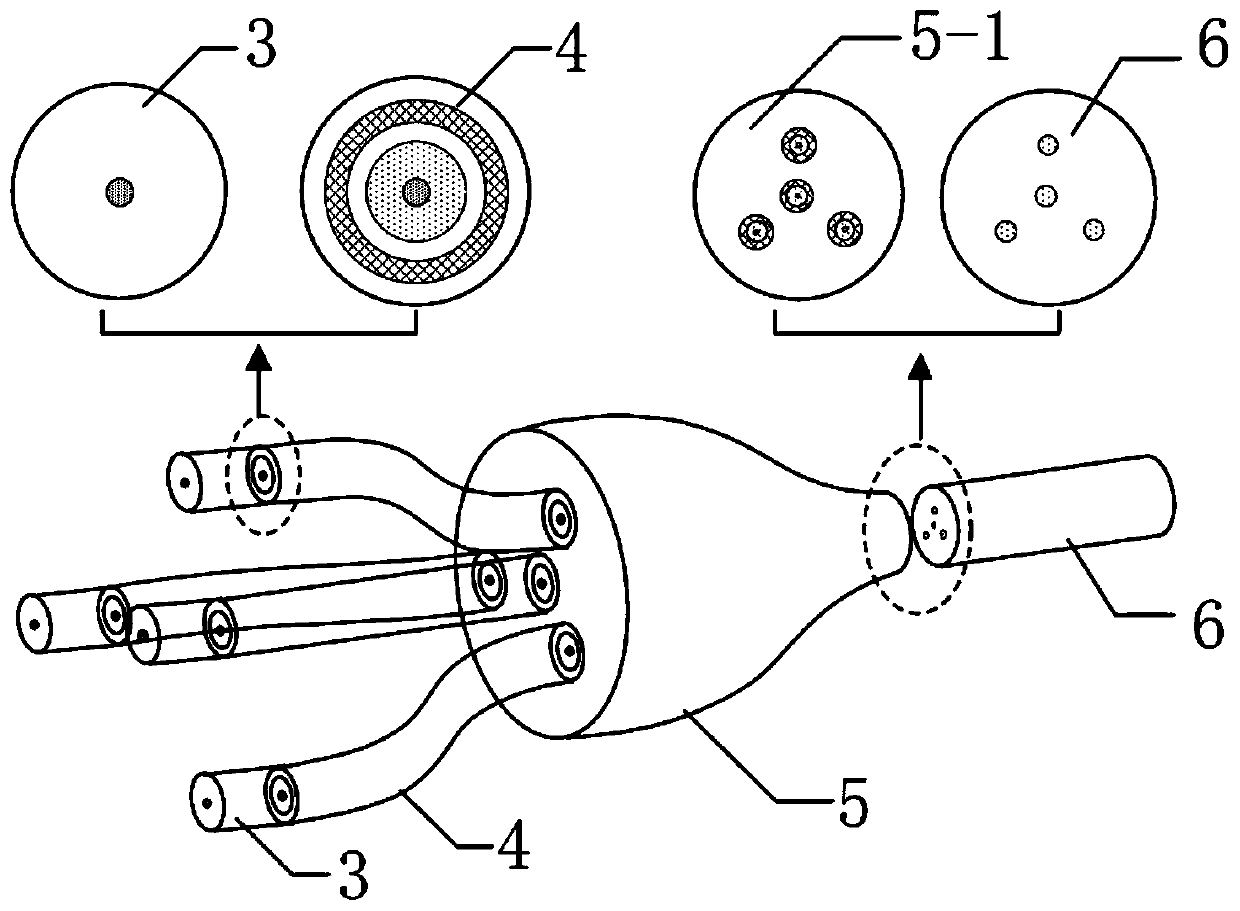

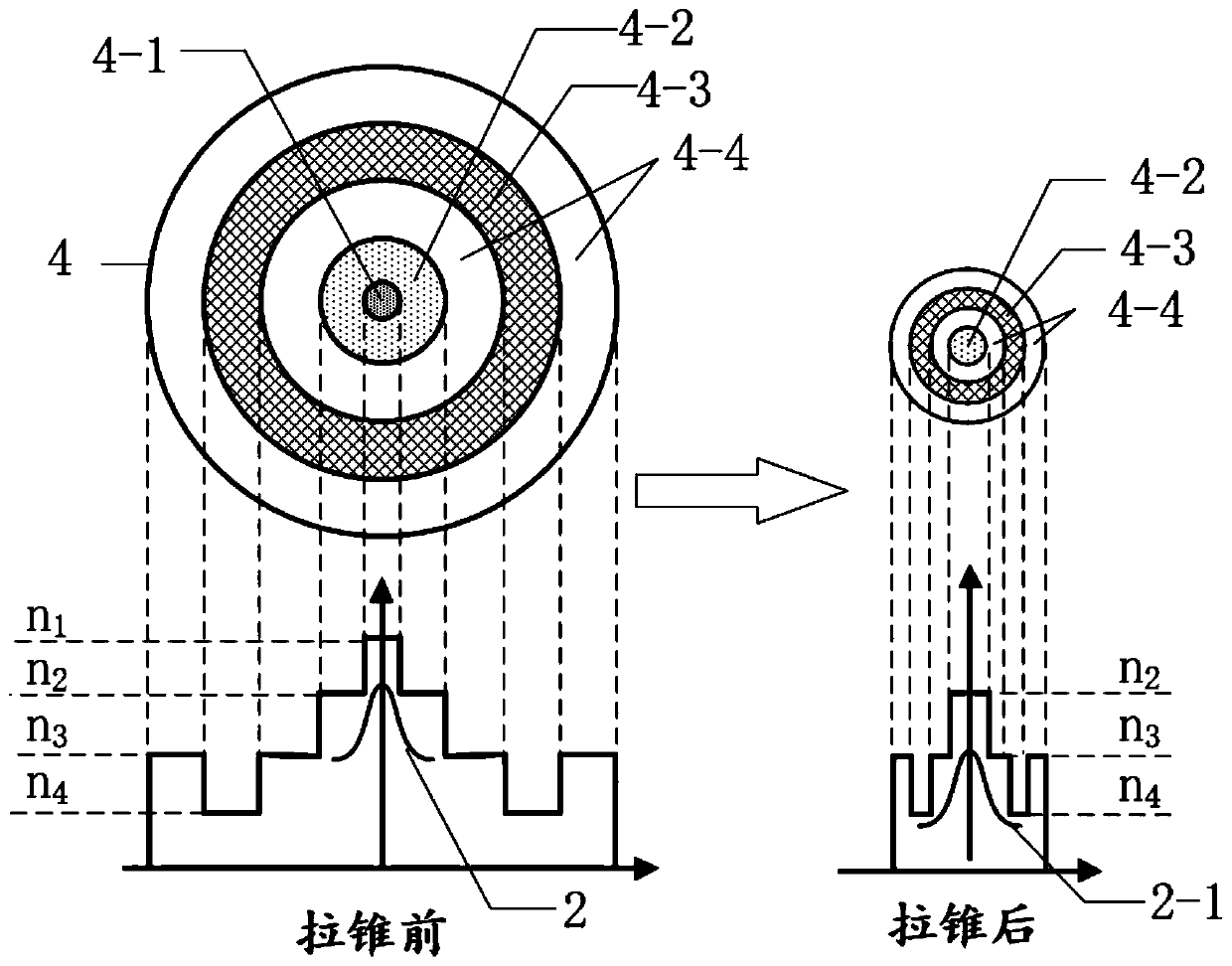

ActiveCN109581583AEasy to makeImprove scalabilityOptical fibre with multilayer core/claddingCoupling light guidesFiberOptoelectronics

The invention discloses a multi-cladding optical fibre and a multi-core optical fibre coupler. The multi-core optical fibre coupler comprises N multi-cladding optical fibres and a bushing; the multi-cladding optical fibre comprises a fibre core and multiple claddings encircling the fibre core; the multiple claddings sequentially comprise an inner cladding, a sunken inner cladding, an annular cladding, an outer cladding, a sunken outer cladding and a mechanical cladding from inside to outside; the multi-core optical fibre coupler is obtained by inserting the N multi-cladding optical fibres intothe bushing, tapering and cutting the bushing at one point in the middle of the bushing and welding a multi-core optical fibre; after the N multi-cladding optical fibres are inserted into the bushingand tapered, the fibre core, the inner cladding, the sunken inner cladding and the annular cladding of each multi-cladding optical fibre of the tapered end form a tapered fibre core; and the outer cladding, the sunken outer cladding and the mechanical cladding form a tapered cladding. According to the multi-core optical fibre coupler provided by the invention, after being tapered, the multi-cladding optical fibre can be in low-loss welding with the multi-core optical fibre, and also can be in low-loss welding with a standard single-mode optical fibre; and furthermore, the macrobend loss is relatively low.

Owner:HUAZHONG UNIV OF SCI & TECH

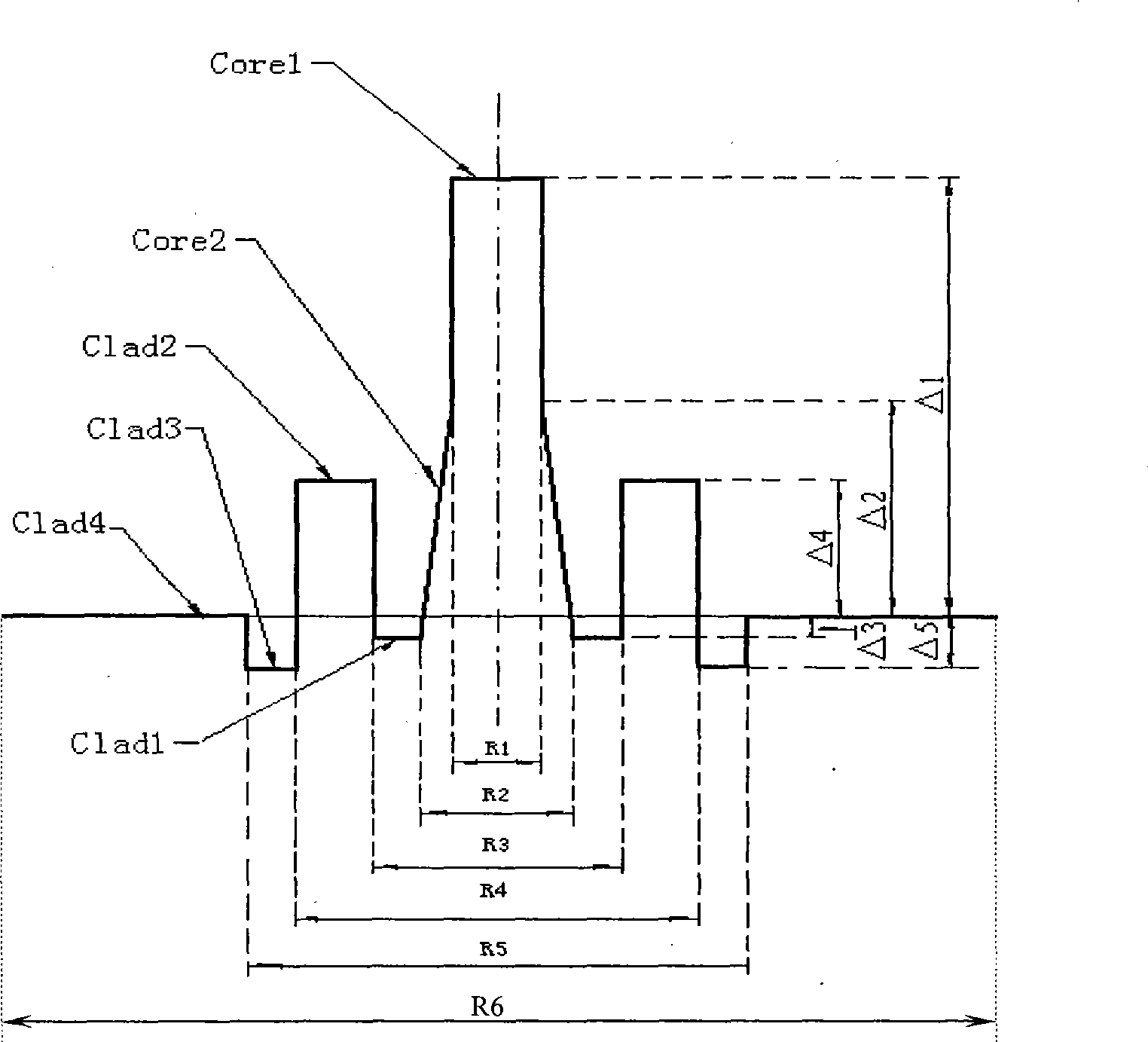

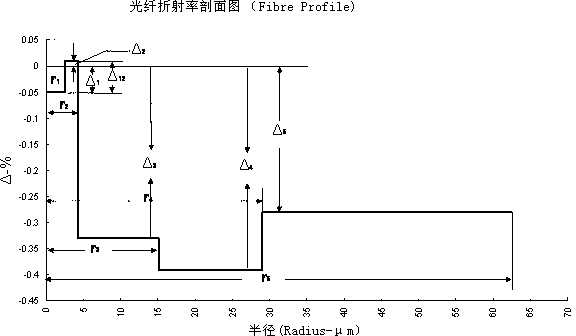

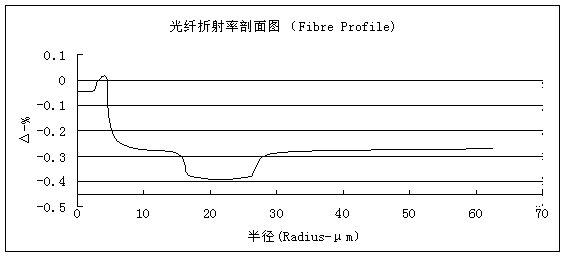

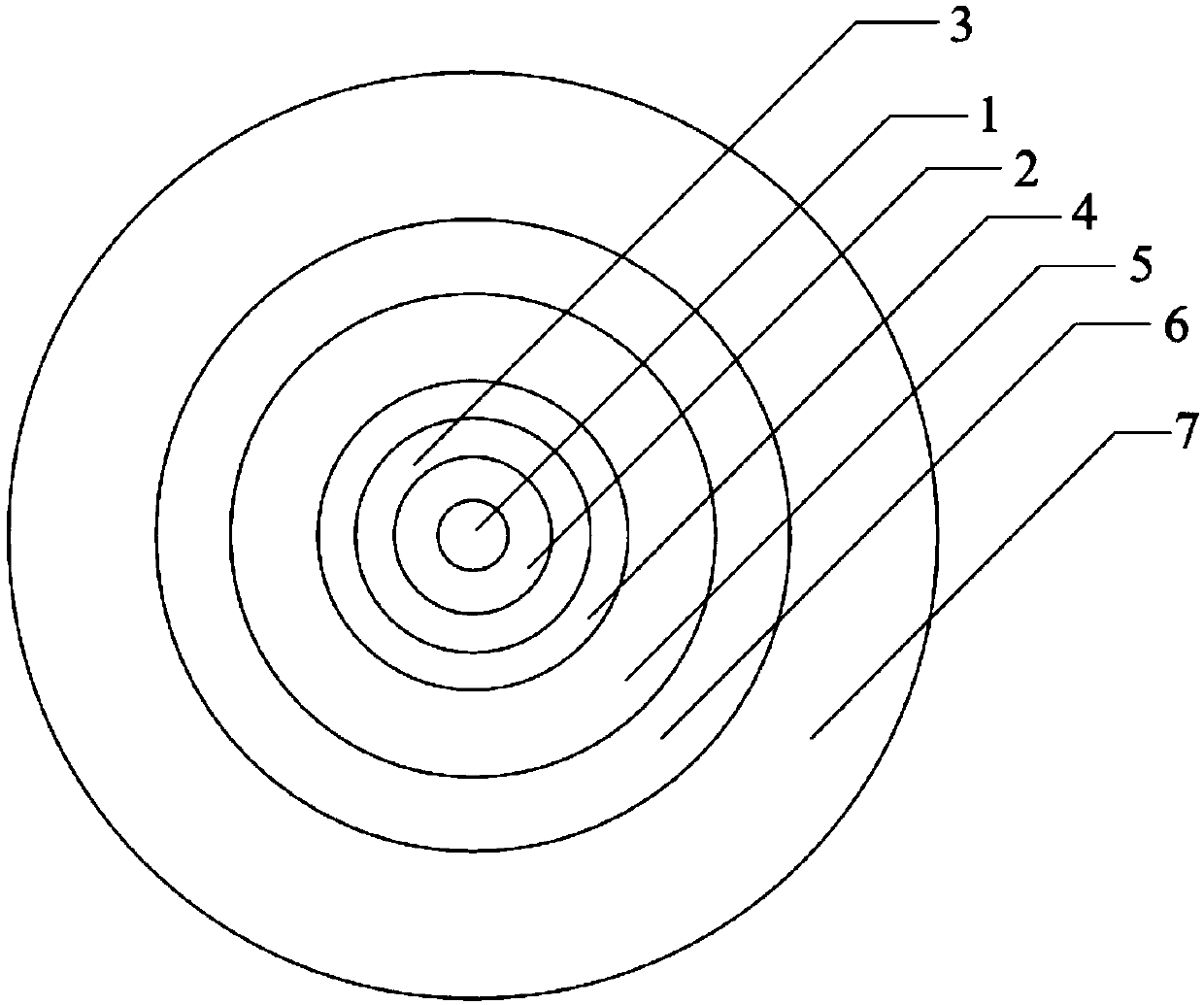

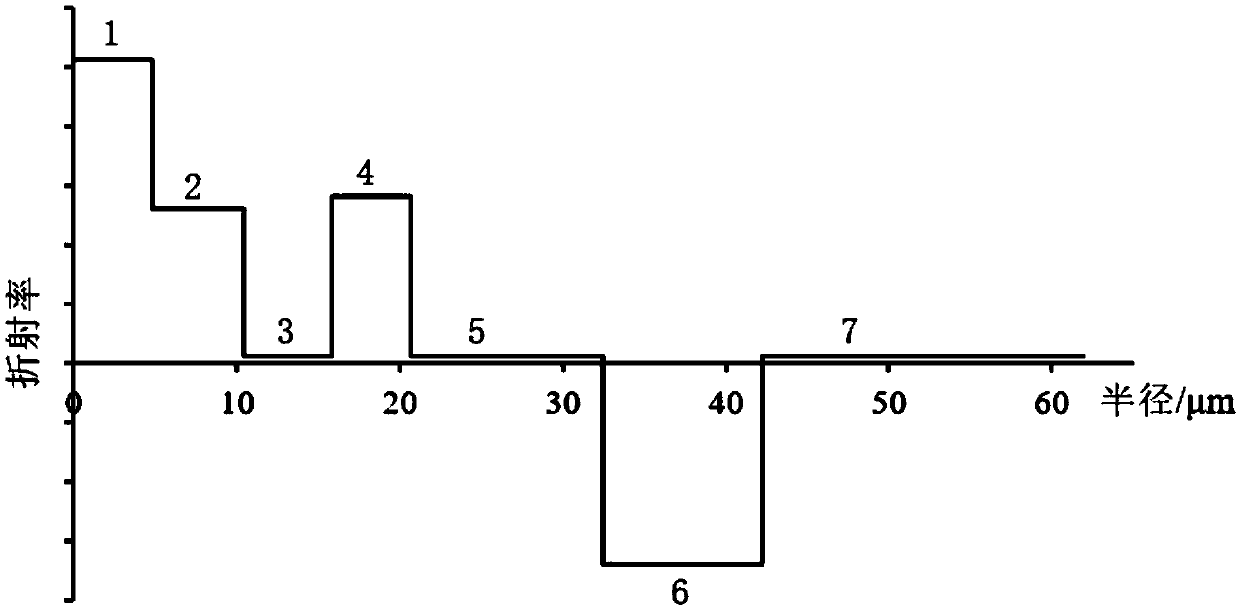

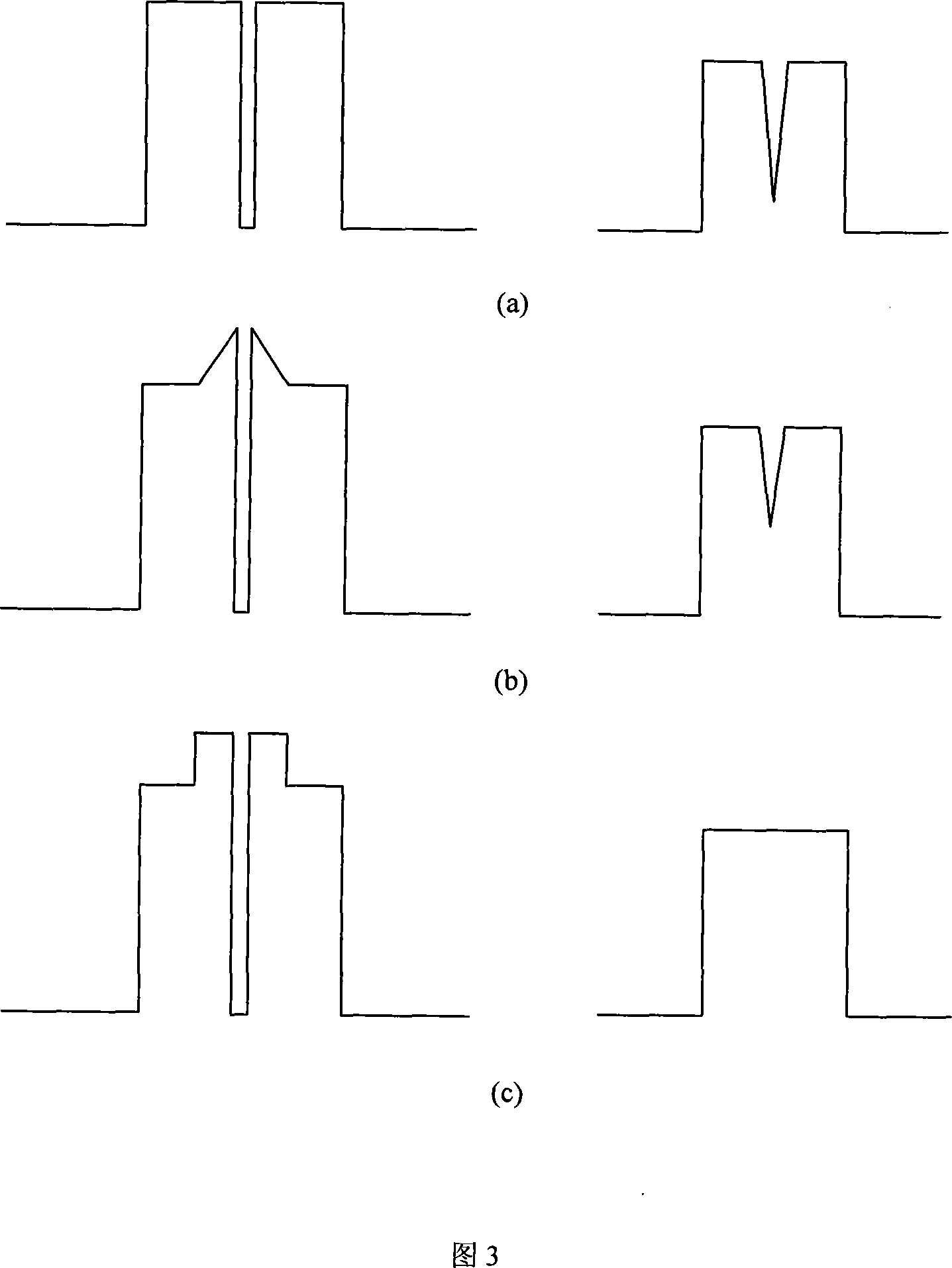

Dispersion optimization single-mode optical fibre for super-high-speed long-distance dense wave division multiplexing

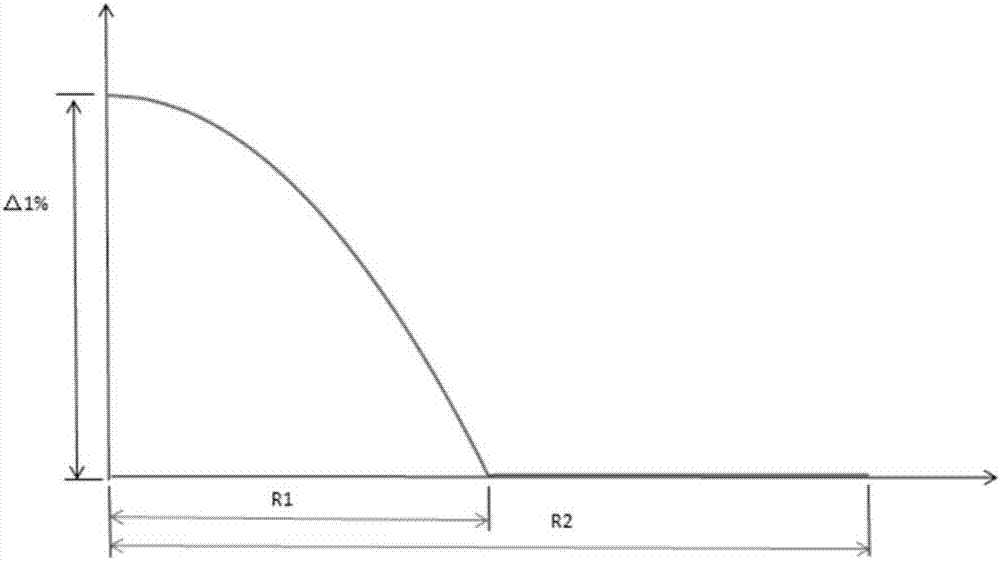

ActiveCN102200610AIncrease the dispersion valueReduce transmission lossOptical fibre with multilayer core/claddingOptical waveguide light guideUltra high speedMultiplexing

The invention discloses a dispersion optimization single-mode optical fibre for super-high-speed long-distance dense wave division multiplexing and belongs to an optical communication technology. A refractive index profile of the dispersion optimization single-mode optical fibre comprises six continuous structural layers with the distribution of different refractive indexes from the centre to the outside; and the distribution of the refractive indexes changes along with a radius. The refractive indexes are distributed sequentially from the centre to the outside like that: Delta 1, in which an absolute value of r is less than or equal to R1; Delta (r) = Delta ((r-R1) / (R2-R1)) <alpha>, in which the absolute value of r is more than R1 and less than or equal to R2; Delta 3, in which the absolute value of r is more than R2 and less than or equal to R3; Delta 4, in which the absolute value of r is more than R3 and less than or equal to R4; Delta 5, in which the absolute value of r is more than R4 and less than or equal to R5; and 0, in which the absolute value of r is more than R5 and less than or equal to R6, wherein r is the radius; Ri represents the maximum radius of the respective structural layers; i is equal to 1 to 6; Delta i is an increment of a maximum value of the refractive index of the i-th layer on the refractive index of the outermost layer; Delta (r) is a relative refractive index of the minimum refractive index of the radius r position of the second layer by reference of the maximum value of the refractive index of the second layer; Delta is the relative refractive index of a minimum value of the refractive index of the second layer by reference of the maximum value of the refractive index of the second layer; and alpha is a distribution factor and more than 0.

Owner:TIANJIN XINMAO SCI & TECH

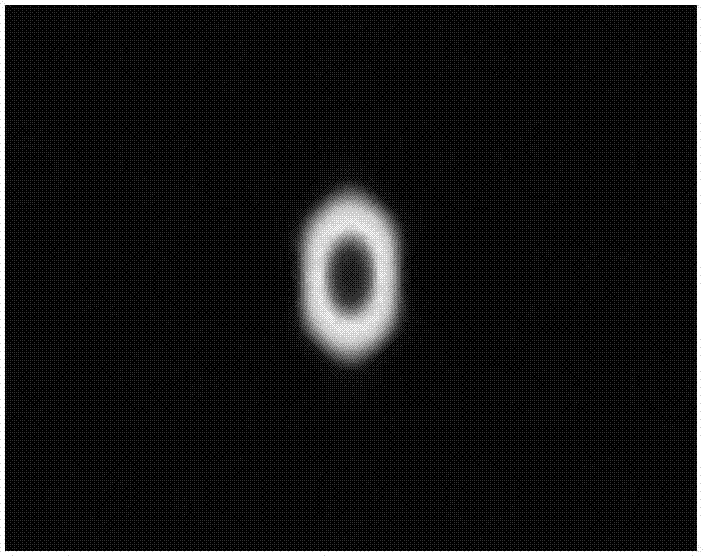

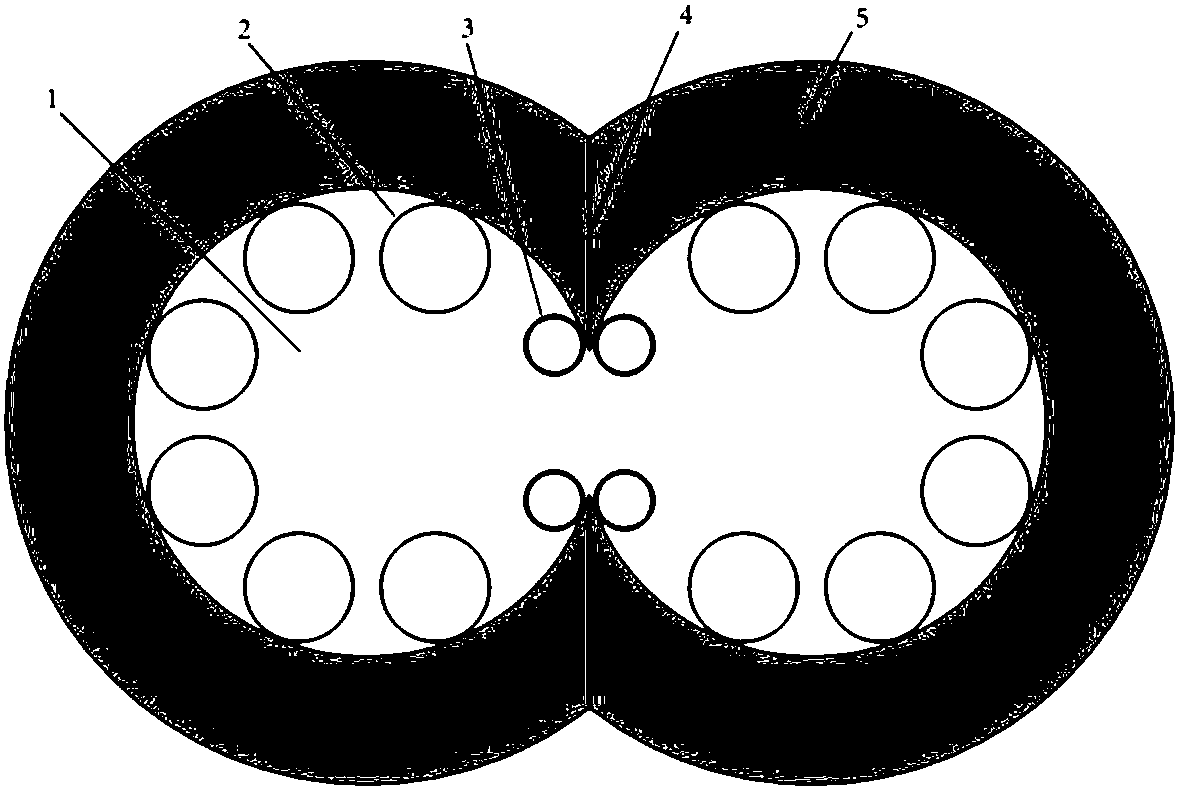

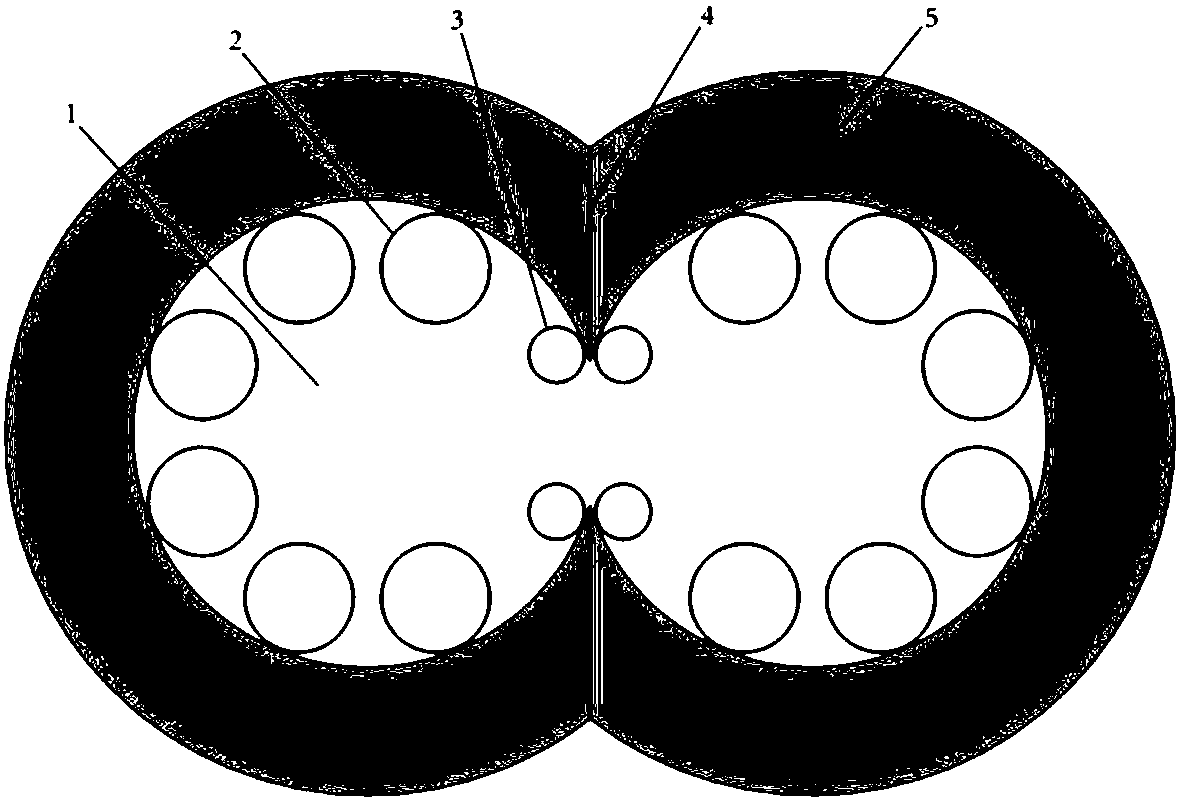

Hollow-core antiresonance photonic crystal fiber coupler and application thereof

ActiveCN108549128AReduce splice lossImplement inputOptical fibre with multilayer core/claddingCoupling light guidesFiber couplerEngineering

The invention belongs to the technical field of fiber couplers, and particularly relates to a hollow-core antiresonance photonic crystal fiber coupler and application thereof. The fiber coupler is formed by two hollow-core antiresonance fibers with polished side faces. The basic structure of each hollow-core antiresonance fiber comprises a fiber core, a circle of micro-capillary inner covering layer around the fiber core and an outer covering layer covering the exterior of the micro-capillary inner covering layer. The polished faces of the hollow-core antiresonance fibers are arranged on the outer covering layer and are attached to each other and subjected to fusion or tapering, so a fiber coupler is manufactured. Before the tapering or during the tapering, the ring distance of two rings near the attached faces is reduced or increased, so the mode coupling of the fiber core of the two hollow-core antiresonance fibers is optimized. The fiber coupler is simple in design and highly practical, can be used for pulse laser, especially, full-fiber coupling and laser beam splitting of femtosecond laser and can be applied in a hollow-core fiber gyroscope to replace a solid fiber coupling module.

Owner:深圳市同昇光电有限公司

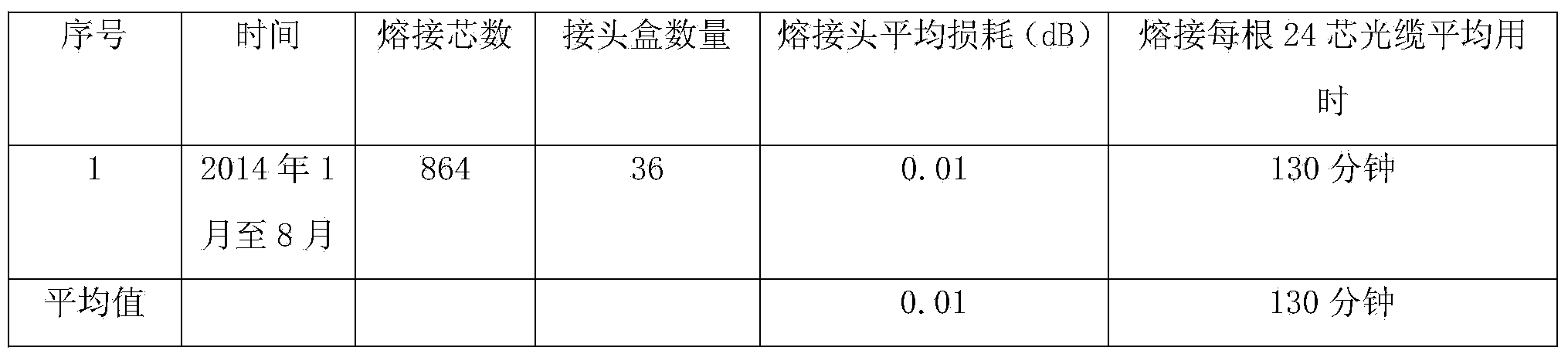

Optical cable splicing method

InactiveCN104297880AReasonable continuation processReduce splice lossFibre mechanical structuresFiberCommunication quality

The invention discloses an optical cable splicing method. The optical cable splicing method includes the following steps: (1) selecting an optical cable with the appropriate length and winding the end face of the optical cable with adhesive tape; (2) peeling the optical cable, wherein another person makes the preparation work for tools and materials needed by an optical cable splice closure, an optical cable fusing device and fusing while one person peels the optical cable; (3) conducting the fiber core splicing working procedure; (4) in the optical cable splicing process, conducting real-time measurement at the other end of an optical fiber while fusing is carried out by another worker, and instantly notifying the worker to conduct fusing again when it is found that fusing losses exceed the standard. By means of the method, the optical cable splicing process is reasonable, the optical cable fusing losses are small, time is saved, the process is good, the optical cable splicing quality is improved, the communication quality is better improved, and the better communication guarantee is provided for other relevant departments; meanwhile, the attractive appearance is guaranteed, and the optical cable operation quality is guaranteed.

Owner:STATE GRID CORP OF CHINA +3

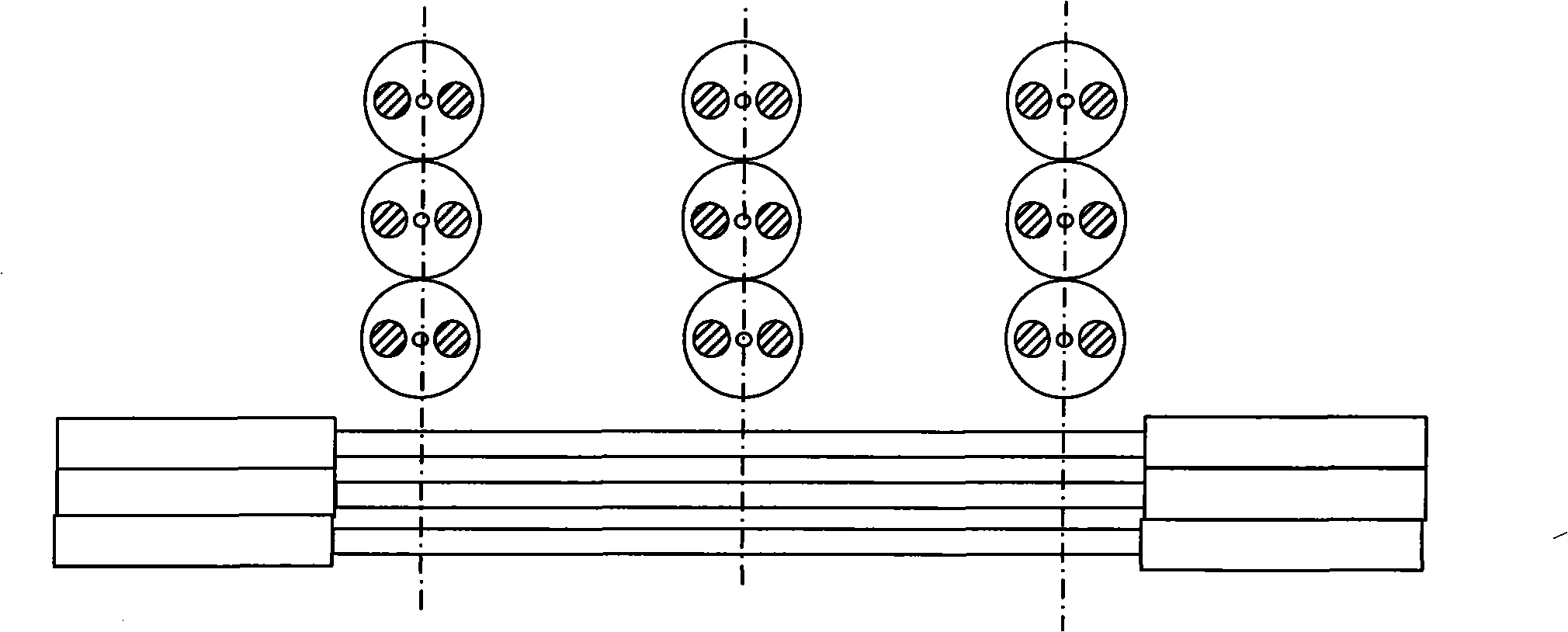

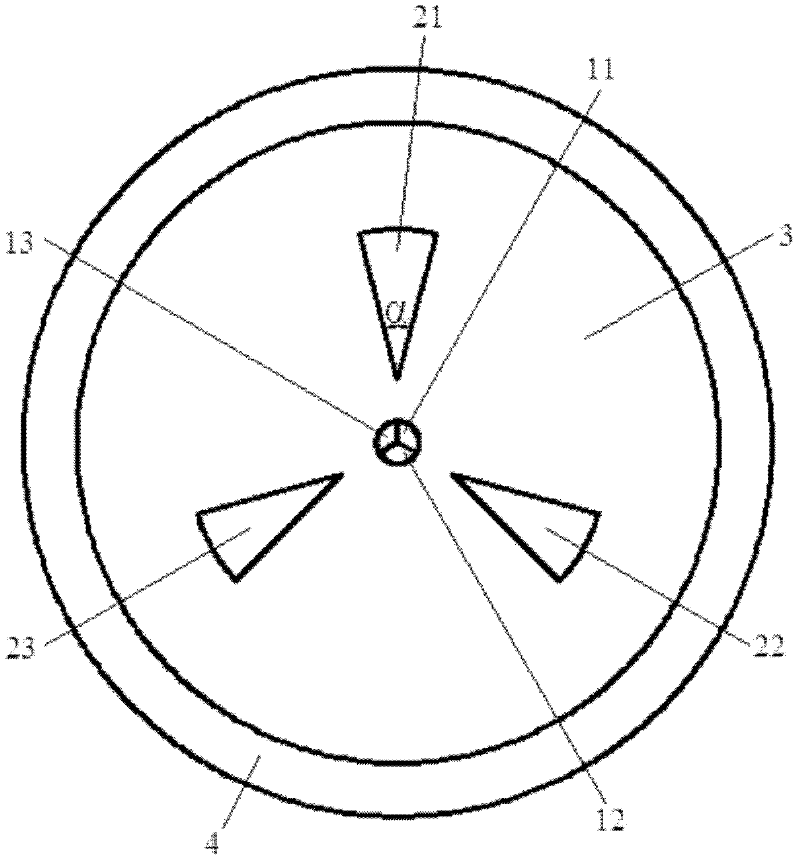

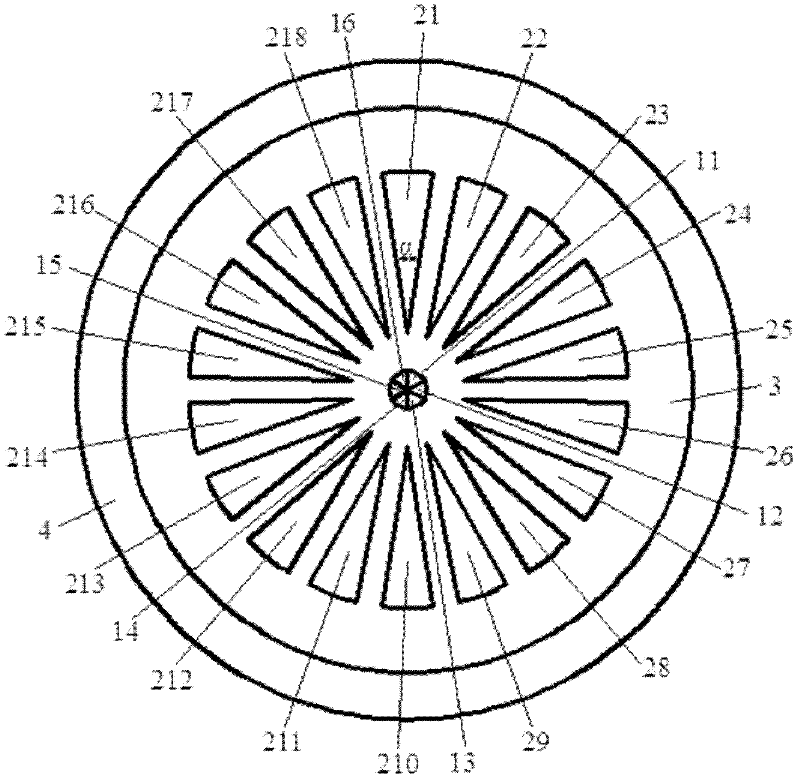

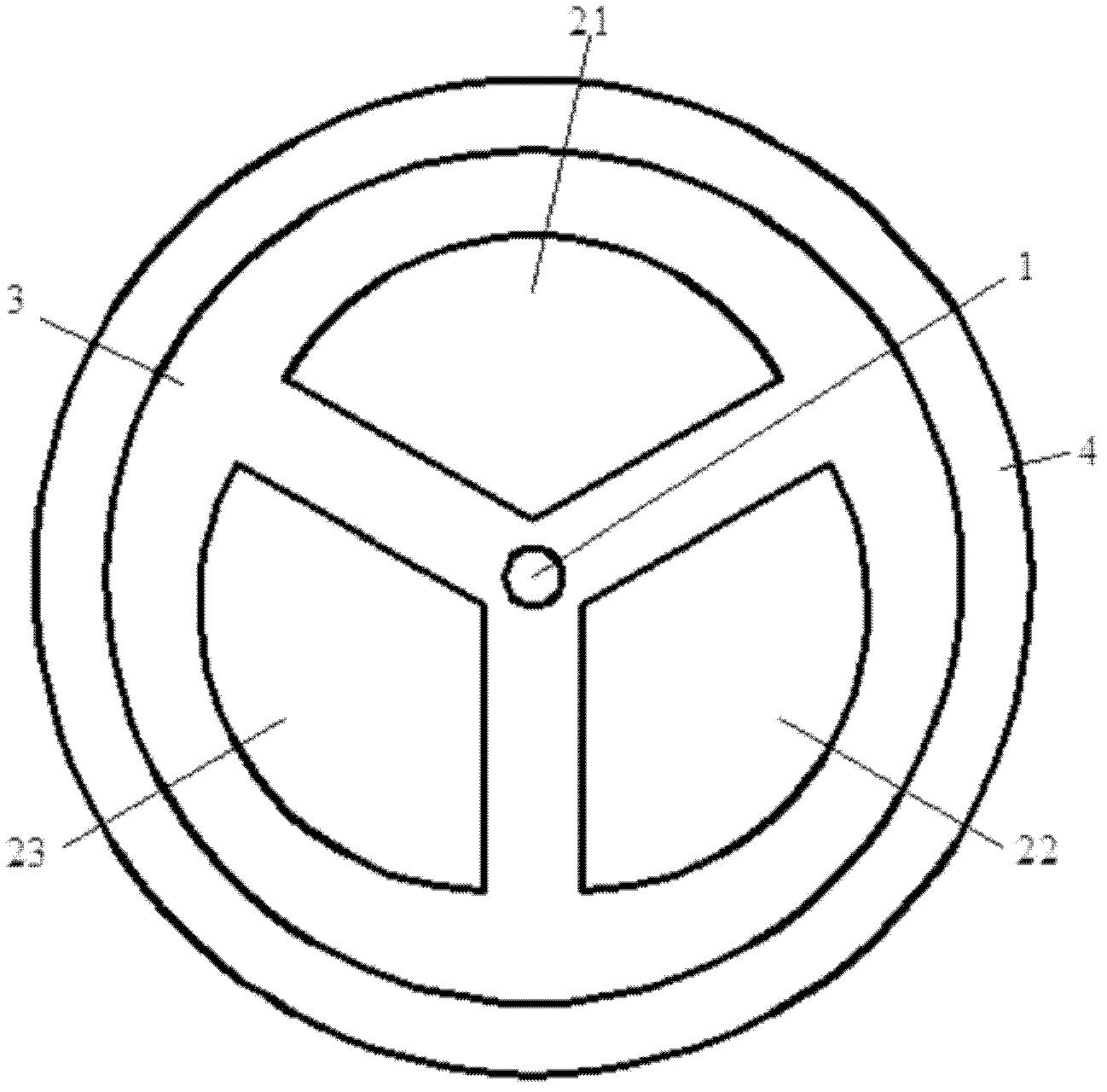

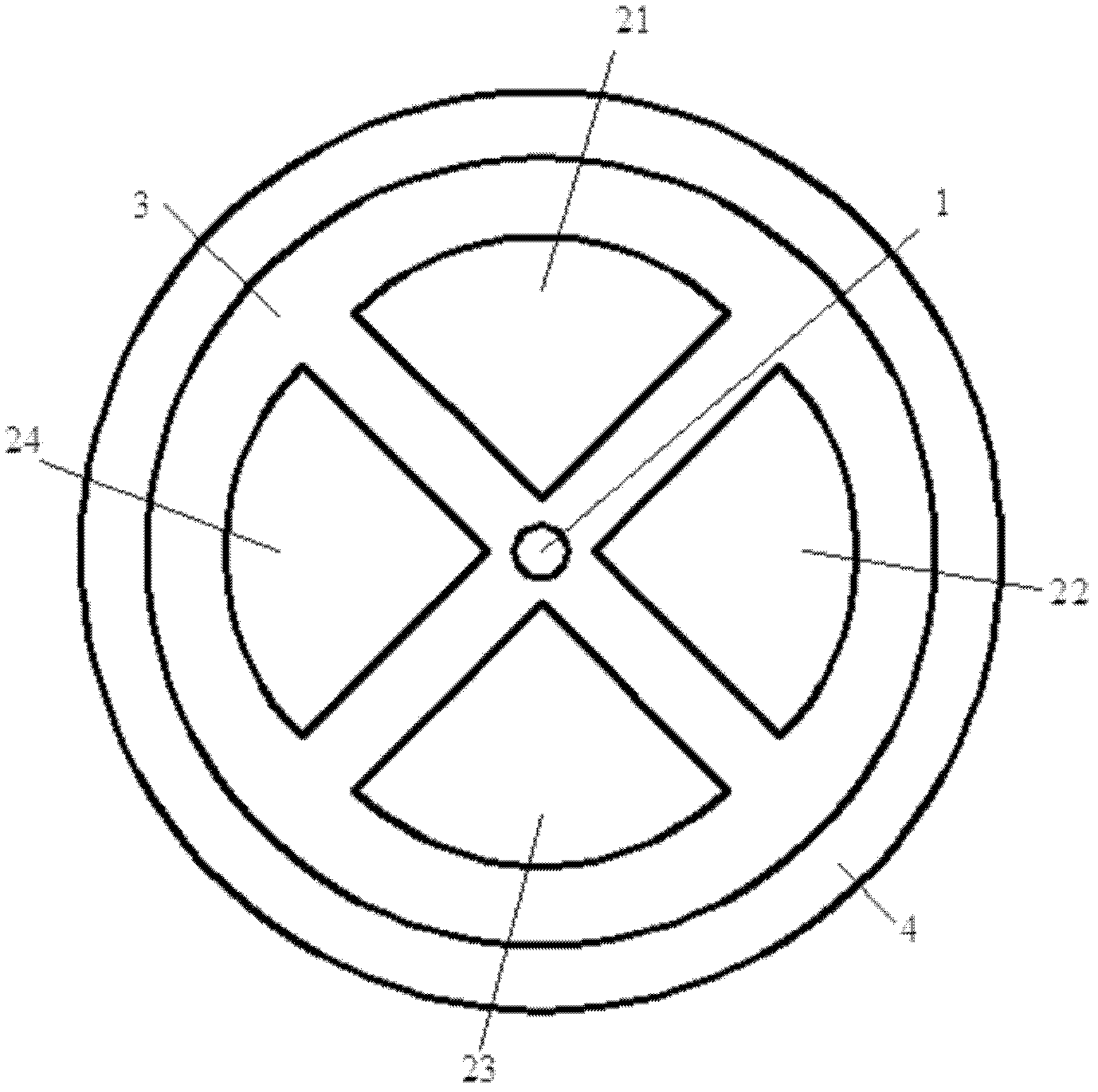

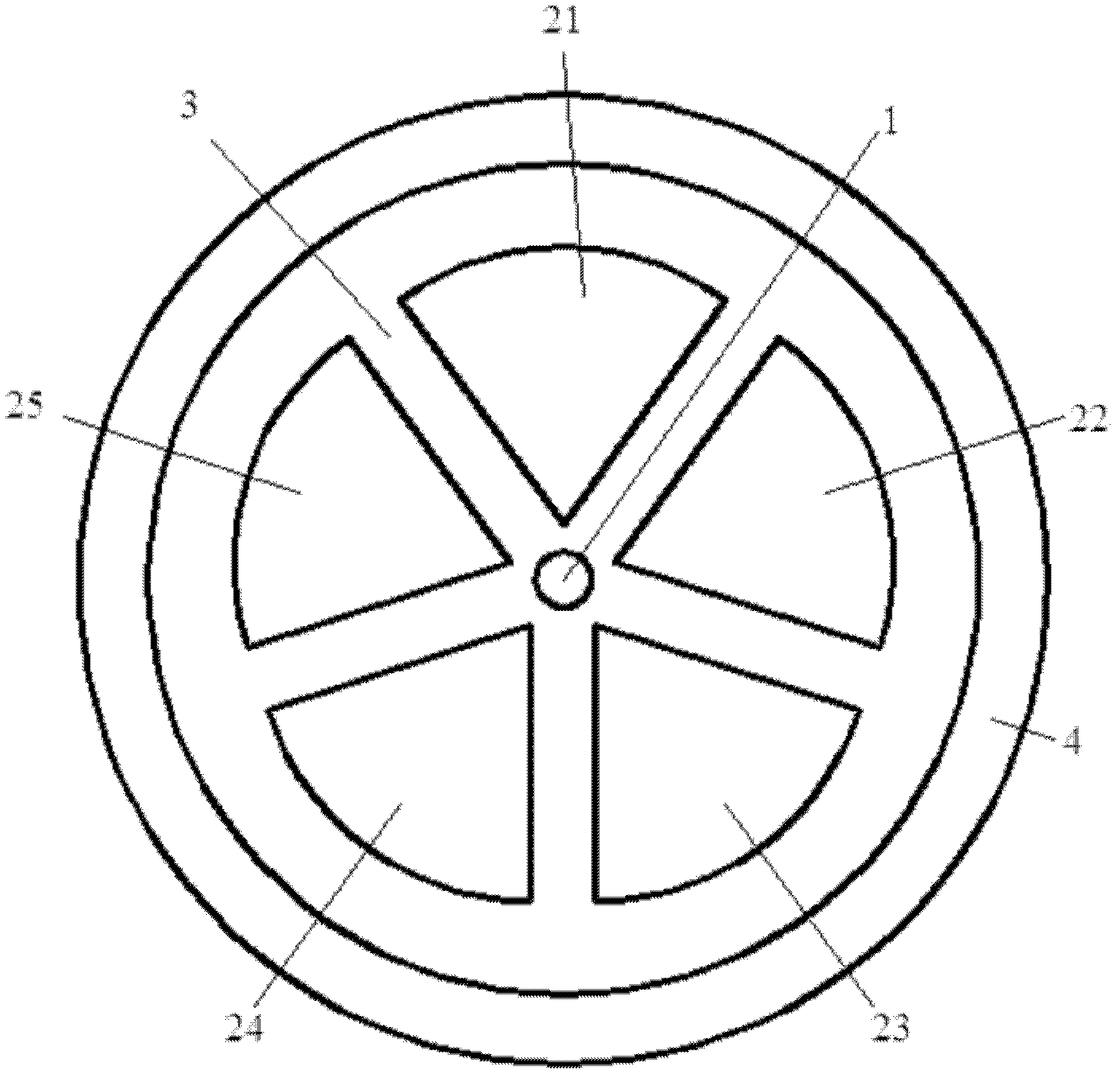

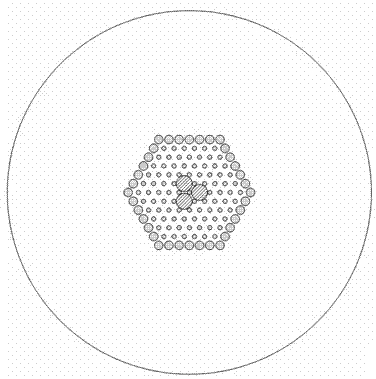

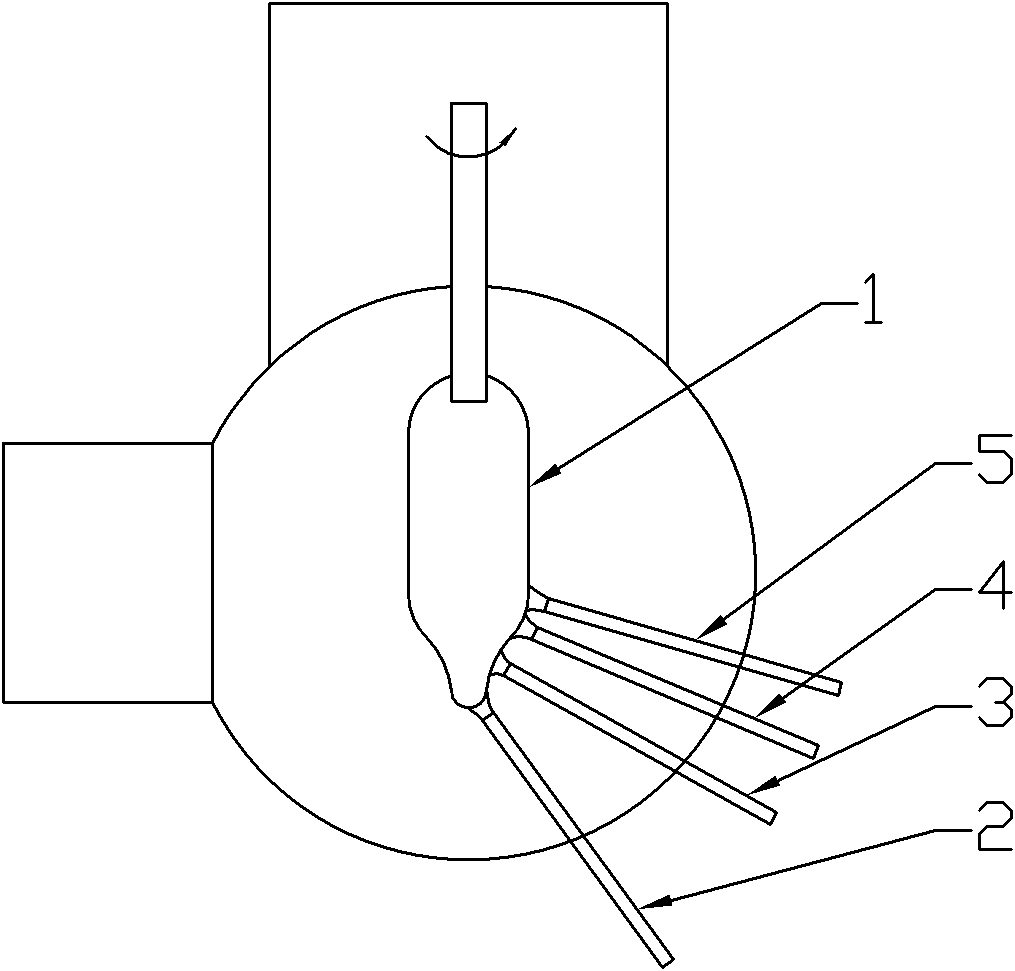

Peripheral multi-sector core optical fiber of circular core multi-sector area and manufacturing method thereof

InactiveCN102262263AImprove yieldReduce splice lossGlass making apparatusOptical fibre with multilayer core/claddingOptical powerBroadband

An optical fibre with a multiple-sector fiber core at the periphery of a multiple-sector area of the circular fiber core, and a fabrication method thereof belong to the fields of the high-power broadband fiber laser and the special optical fibre, which overcome the problem that a single-core doubly-clad optical fibre with multiple rare-earth ion doped regions is limited to bear optical power and the problem that a block clad optical fibre core layer has a limited diameter. Sector rare-earth ion doped regions 1 to N are all the same in optical refractive index, radius and radian, and form a complete circular fibre core, wherein N is an integer greater than or equal to 3 and less than or equal to 9; sector fibre cores 1 to M having the same radius and the same radian a are evenly distributed around the circular fibre core in an inner cladding layer, wherein M is an integer greater than or equal to N or less than or equal to 32 and a is greater than or equal to pi / 2M and less than or equal to 2pi / M; distances between the vertexes of the sector fibre cores 1 to M and the outer circle of the circular fibre core are equal; and the circular fibre core is equal to the sector fibre cores 1to M in rare-earth ion doping type set. The fabrication method comprises fabricating circular fibre core fine rods and sector fibre core fine rods and organizing the fine rods into the optical fibre.The yield of the optical fibre is high and the welding loss of the optical fiber with a single-mode optical fibre is low; and single-mode operation in large-mode area is realized.

Owner:BEIJING JIAOTONG UNIV

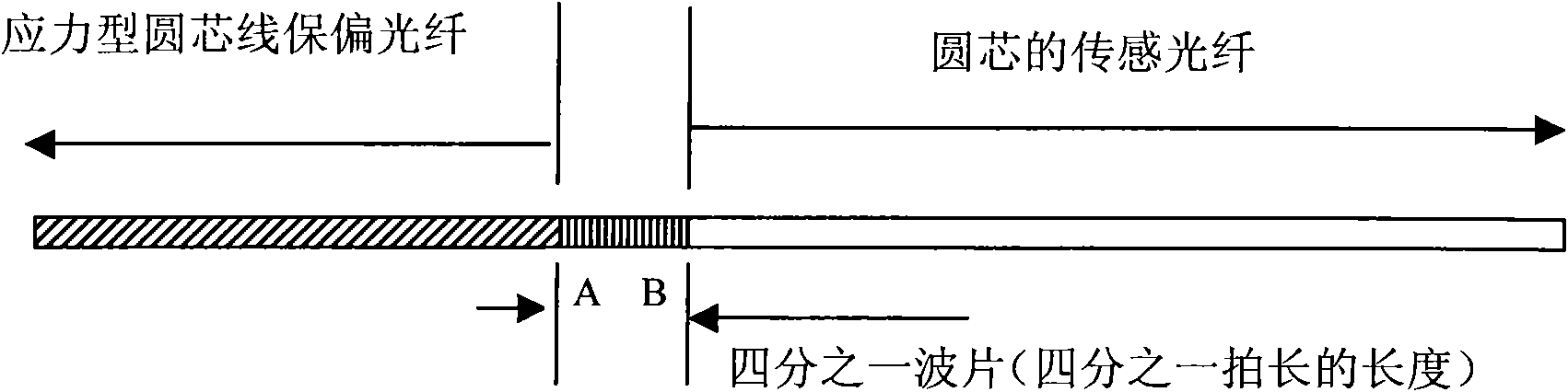

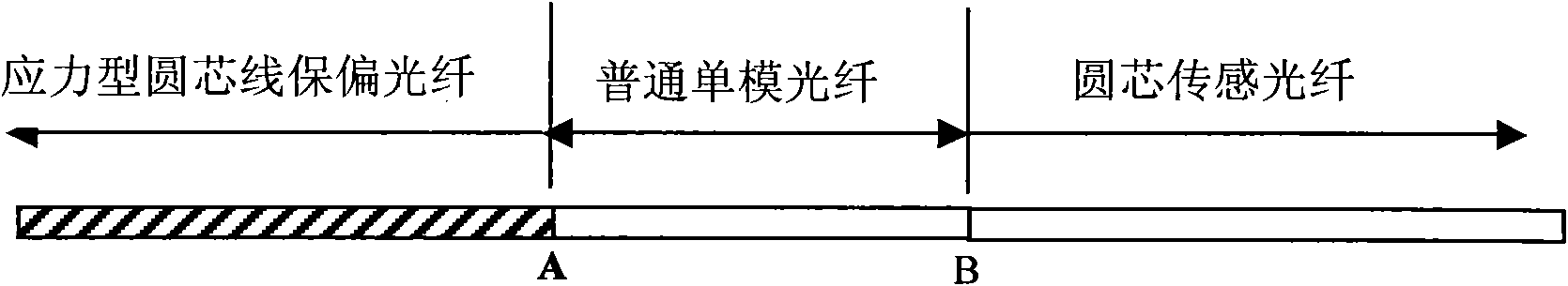

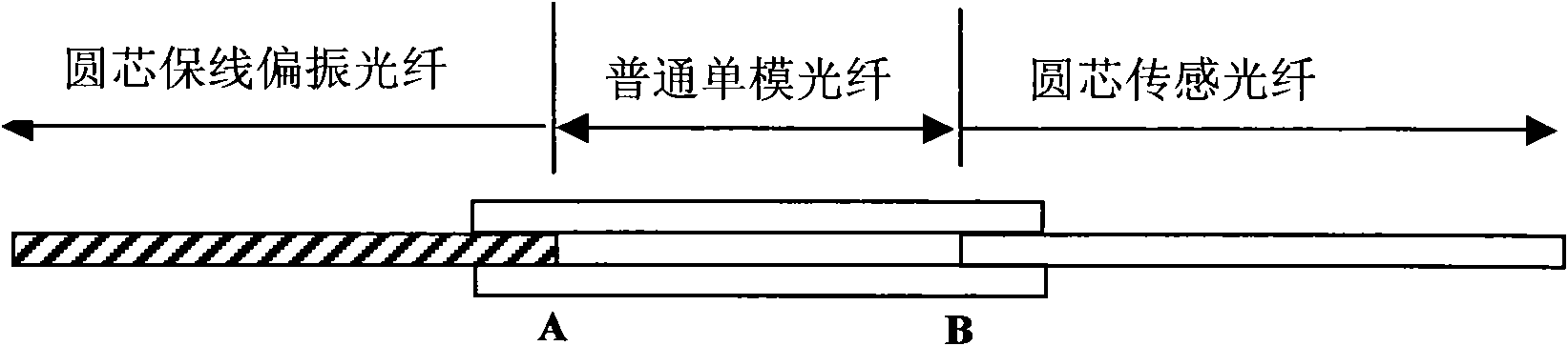

Full optical fibre quarter-wave plate and preparation method thereof

InactiveCN101587201AReduce splice lossCladded optical fibrePolarising elementsPolarization-maintaining optical fiberMaterials science

The invention discloses a preparation method of a full optical fibre quarter-wave plate, which comprises the following steps: step1, splicing one end of a circular core wire polarization-preserving optical fibre used for transmission and one end of a section of single mode optical fibre in a fusion mode, and splicing one end of a circular core sensing optical fibre with the other end of the single mode optical fibre in a fusion mode; step 2, taking at least a section of the optical fibre as an auxiliary optical fibre, placing the auxiliary optical fibre to be parallel and abutting against one side or both sides of the single mode optical fibre of the spliced fibre structure in the step 1, and making a main shaft of the circular core wire polarization-preserving optical fibre form an angle of 45 DEG with a placed plane; and step 3, heating and melting concatenated single mode optical fibre areas with high temperature, making the single mode optical fibre of the heating area and the auxiliary fibre achieve a melting state and be melted together, continuously heating and making the single mode optical fibre of a circular core gradually be elliptical, and controlling the heating and welding time to prepare and form the quarter-wave plate. The preparation method utilizes common single mode optical fibres to prepare the quarter-wave plate with tiny loss, and also can be used for preparing other set wave plates.

Owner:COMCORE OPTICAL TECH

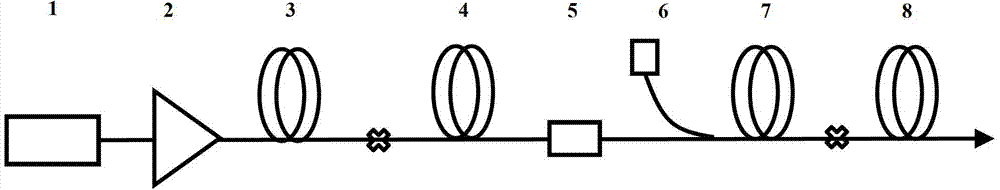

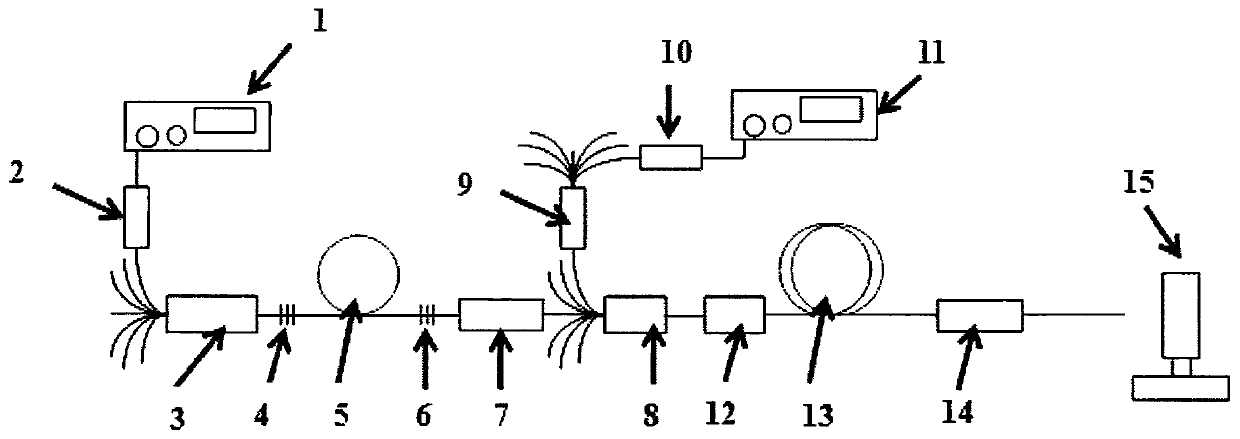

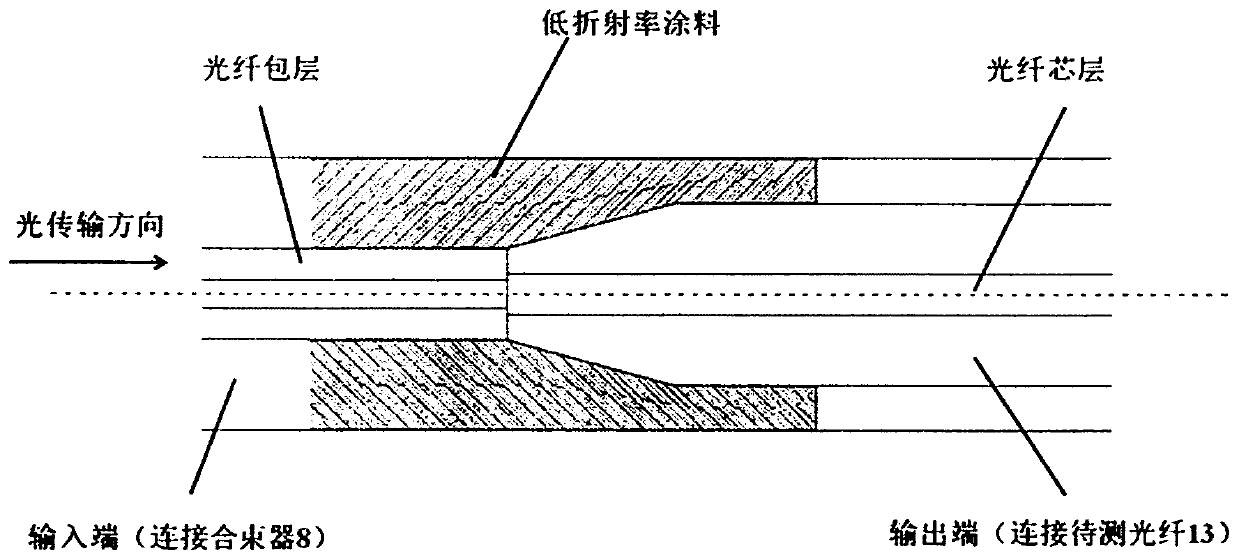

Erbium-doped active fiber all-fiber laser test system for high power and testing method thereof

InactiveCN110779682AIncrease the maximum withstand powerGuaranteed normal transmissionTesting fibre optics/optical waveguide devicesOptical power meterGrating

The invention relates to an erbium-doped active fiber all-fiber laser test system for high power and a testing method thereof. 915nm laser is produced through laser pumping; the laser is combined to afiber through a forward beam combiner; the 915nm pumping laser converts 915nm pumping light input previously into 1080nm laser through a resonance cavity structure comprising a high reflective grating, an active fiber and a low reflective grating; the converted 1080nm laser filters all pumping light in a cladding layer through a cladding light stripper; 976nm pumping light produced through laserpumping and the 1080nm laser passing the cladding light stripper are combined in a fiber through a beam combiner; the 976nm pumping light and the 1080nm laser pass a cladding light adapter at the sametime, then 976nm pumping light in the cladding layer in the fiber is converted into 1080nm laser in a core layer through a to-be-tested active fiber; and finally, remaining pumping light in the cladding layer is stripped through the cladding light stripper, and all 1080nm laser is output to an optical power meter.

Owner:JIANGSU FASTEN OPTOELECTRONICS TECH

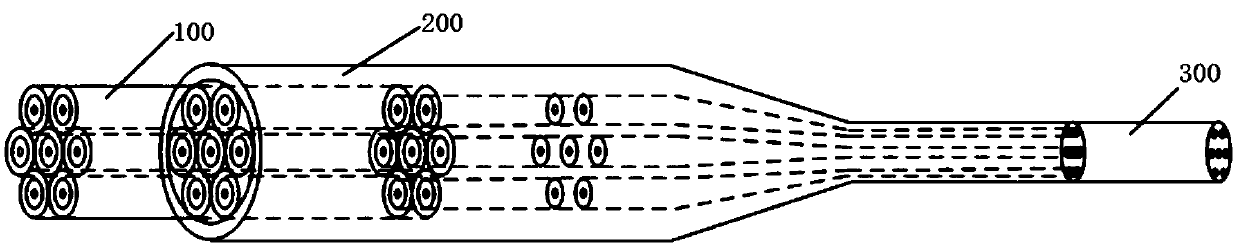

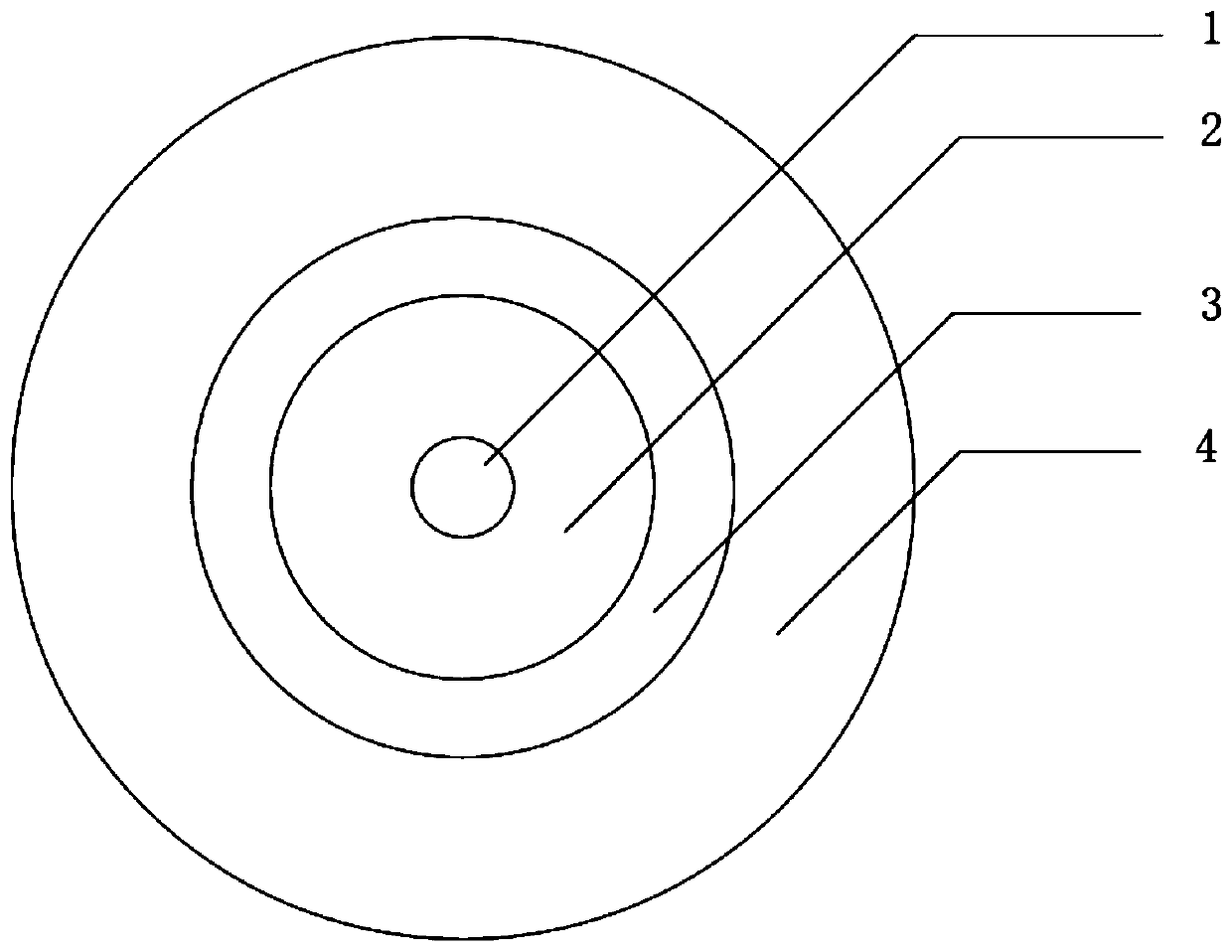

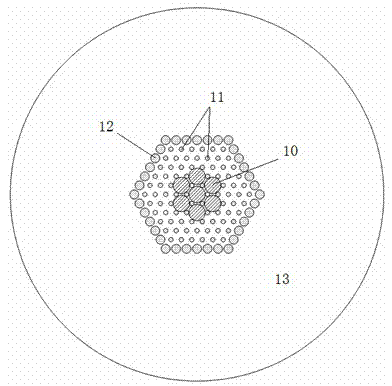

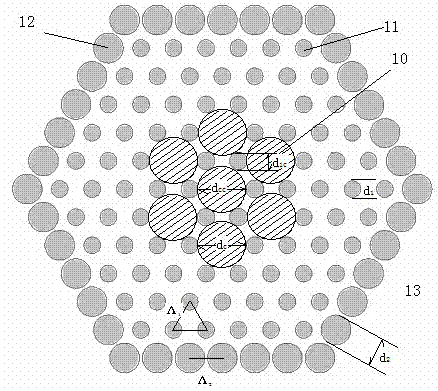

Multi-core fiber with low crosstalk between cores

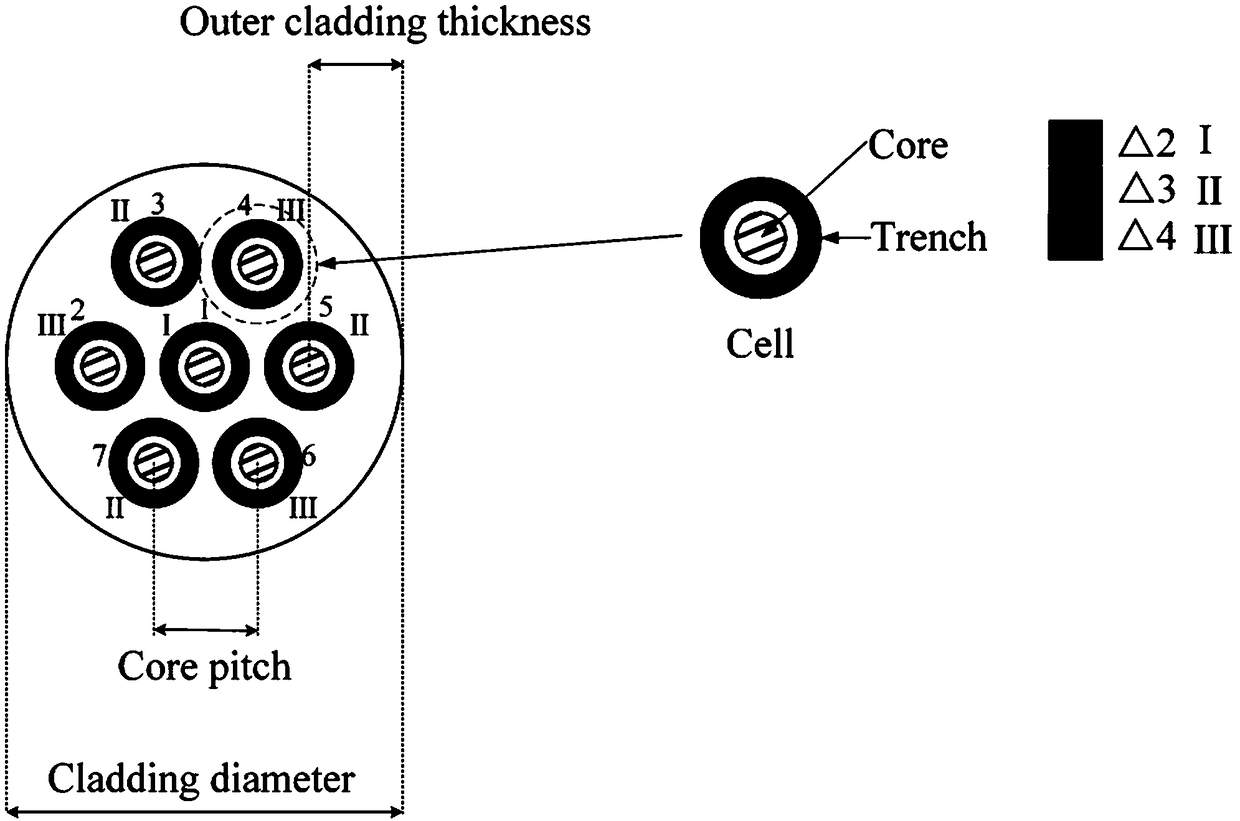

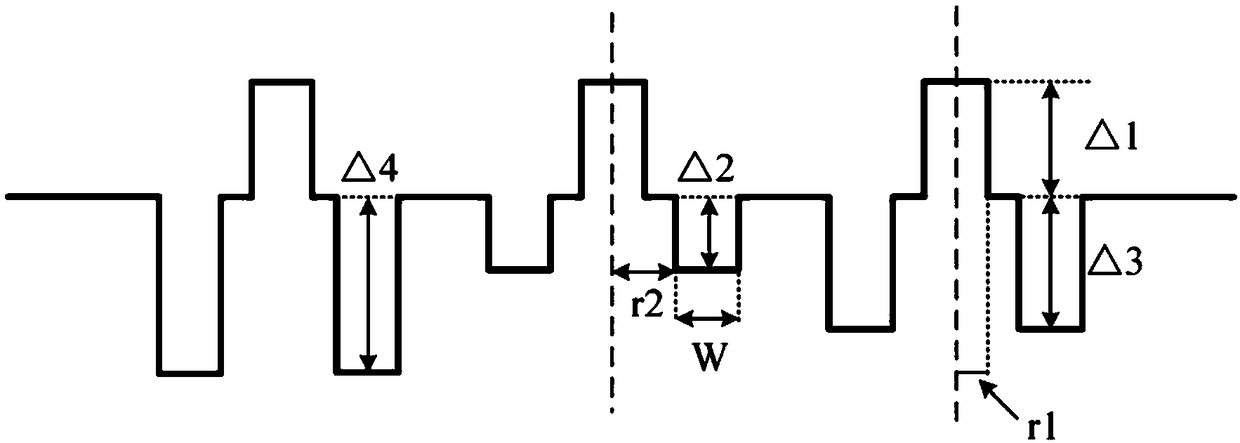

PendingCN109283613ALow crosstalk between coresLarge mode field areaMulticore optical fibreOptical waveguide light guideMultiplexingTransport system

The invention relates to a multi-core fiber with low crosstalk between cores, and belongs to the field of optical fiber communication. The multi-core fiber with low crosstalk between the cores is characterized by comprising a middle core (1), an annular groove structure (I) around the periphery of the middle core, six outer cores (2)-(7) extending along the fiber axis and arranged in a regular hexagon shape, annular groove structures (II) and annular groove structures (III) around the peripheries of the six outer cores correspondingly, and wrapping layers covering the middle core, the six outer cores and the groove structures (I), (II) and (III). Different refractive indexes are arranged in the adjacent groove structures (I), (II) and (III) correspondingly, and the refractive index difference among the adjacent groove structures (I) and (II), (II) and (III) is no less than 0.001, and thus the purpose of suppressing crosstalk between the cores is achieved. Meanwhile, since the core structures are the same, the multi-core fiber with low crosstalk between the cores has smaller melting loss than ordinary single mode fibers, is facilitated to being drawn into the fiber, can be widely applied to air-division multiplexing optical fiber transmission system and other fields, and has broad application prospects.

Owner:BEIJING JIAOTONG UNIV

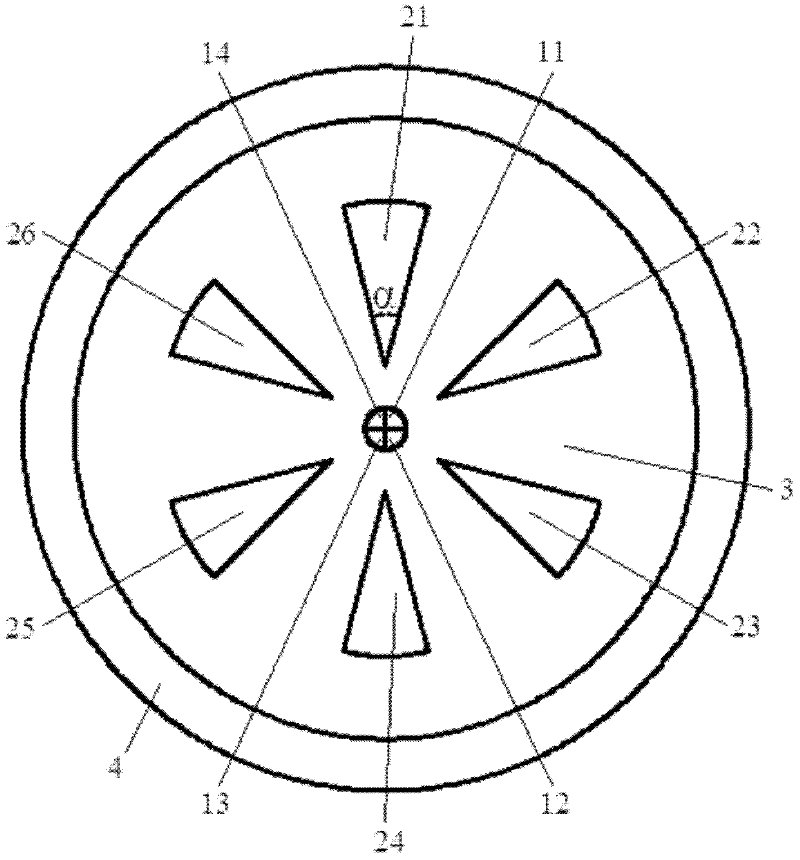

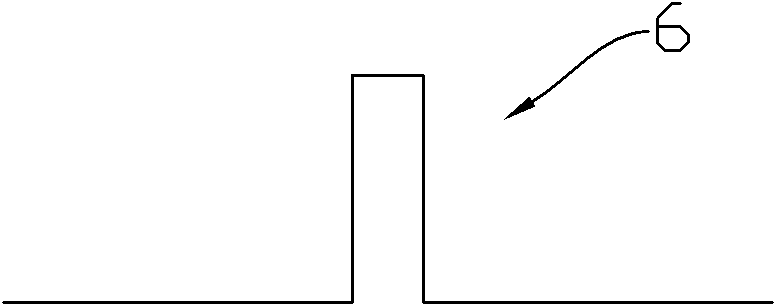

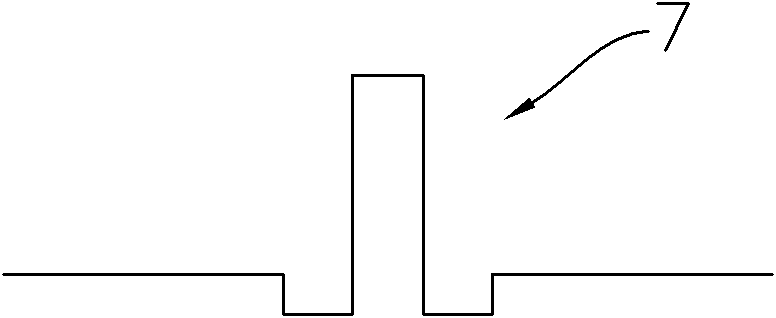

Large mode field area single-mode chrysanthemum fiber core distribution fiber and manufacturing method thereof

InactiveCN102305958AImprove yieldReduce manufacturing costGlass making apparatusOptical fibre with multilayer core/claddingRare earth ionsBroadband

The invention discloses a large mode area single-mode chrysanthemum fiber core distribution fiber and a manufacturing method thereof, and belongs to the field of high-power broadband fiber amplifiers, lasers and special fibers. The large mode field area single-mode chrysanthemum fiber core distribution fiber overcomes the defects of low bulk production yield of the existing large mode field single-mode fiber, limited core layer diameter of partitioning cladded-fiber and the like. N fan-shaped fiber cores with same diameters and radians are uniformly distributed around a circular core in an inner cladding of the fiber, and are recorded as the first fan-shaped fiber core to the Nth fan-shaped fiber core, wherein N is an integer more than or equal to 3 and less than or equal to 32. The manufacturing method comprises the following steps of: selecting two same rare earth ion-doped type fiber preforms; removing claddings of the two fiber preforms by only leaving core areas; drawing one of the fiber preforms into a round thin rod; processing the other one of the fiber preforms into N fan-shaped thin rods with same semi-diameters and radians; constituting the round thin rod and the N fan-shaped thin rods, sleeving a quartz tube on the thin rods, and filling the gap with thin quartz rods; and drawing the large mode field area single-mode chrysanthemum fiber core distribution fiber.

Owner:BEIJING JIAOTONG UNIV

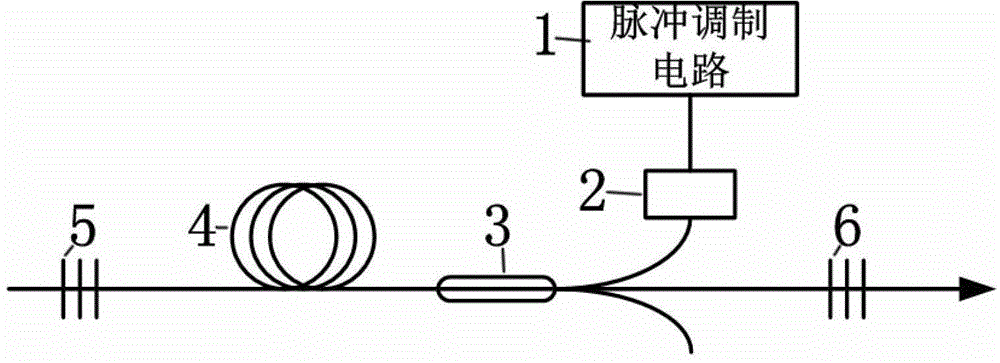

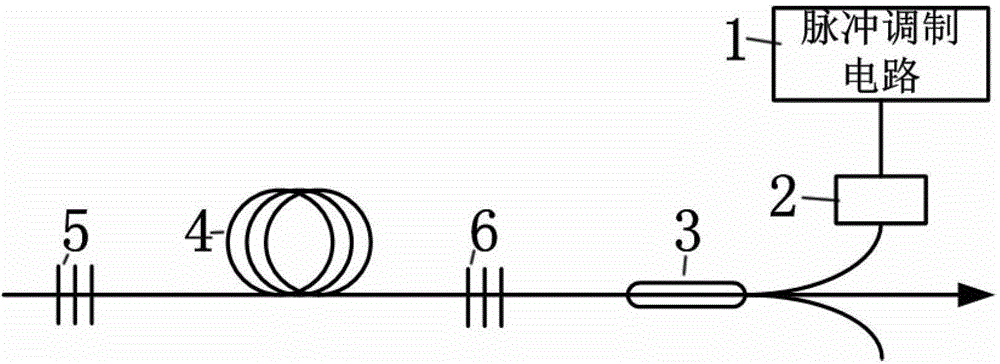

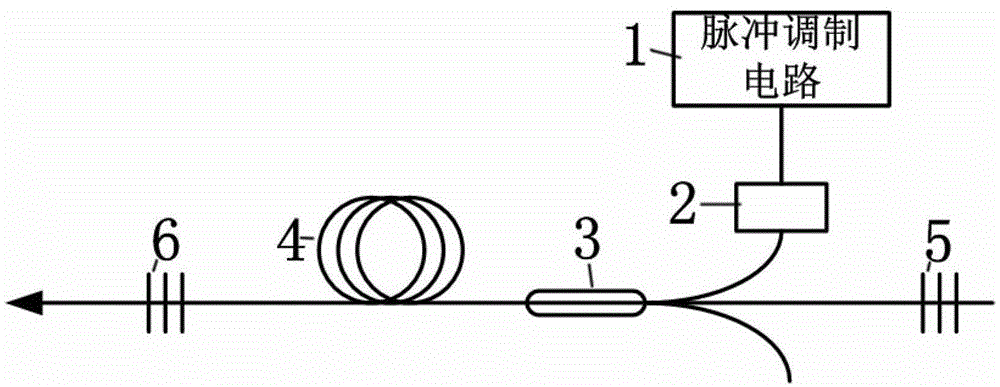

Pulse pump type standing wave resonant cavity nanosecond pulse laser

InactiveCN103151684AReduce splice lossOvercome the disadvantage of high insertion lossOptical resonator shape and constructionActive medium shape and constructionTime domainFiber

The invention discloses a pulse pump type standing wave resonant cavity nanosecond pulse laser which comprises a pulse modulation circuit, a pump laser, a beam combiner, a gain fiber, an isolator and an output coupler; a doped fiber in a resonant cavity not only can play a role in gaining a medium under the pulse pump condition, but also can be taken as a saturable switch for quick response to generate a laser pulse of which the time domain width is within the nanosecond order of magnitude; the repetition frequency of the pulse depends on that of pump light; and the pulse width depends on the combined action of energy in the cavity and the length of the resonant cavity. The pulse pump type standing wave resonant cavity nanosecond pulse laser has the advantages of simple structure, tunable pulse width, tunable repetition frequency, high optical to optical conversion efficiency and the like, has good stability and is suitable for various application occasions for industrial processing.

Owner:广东华快光子科技有限公司

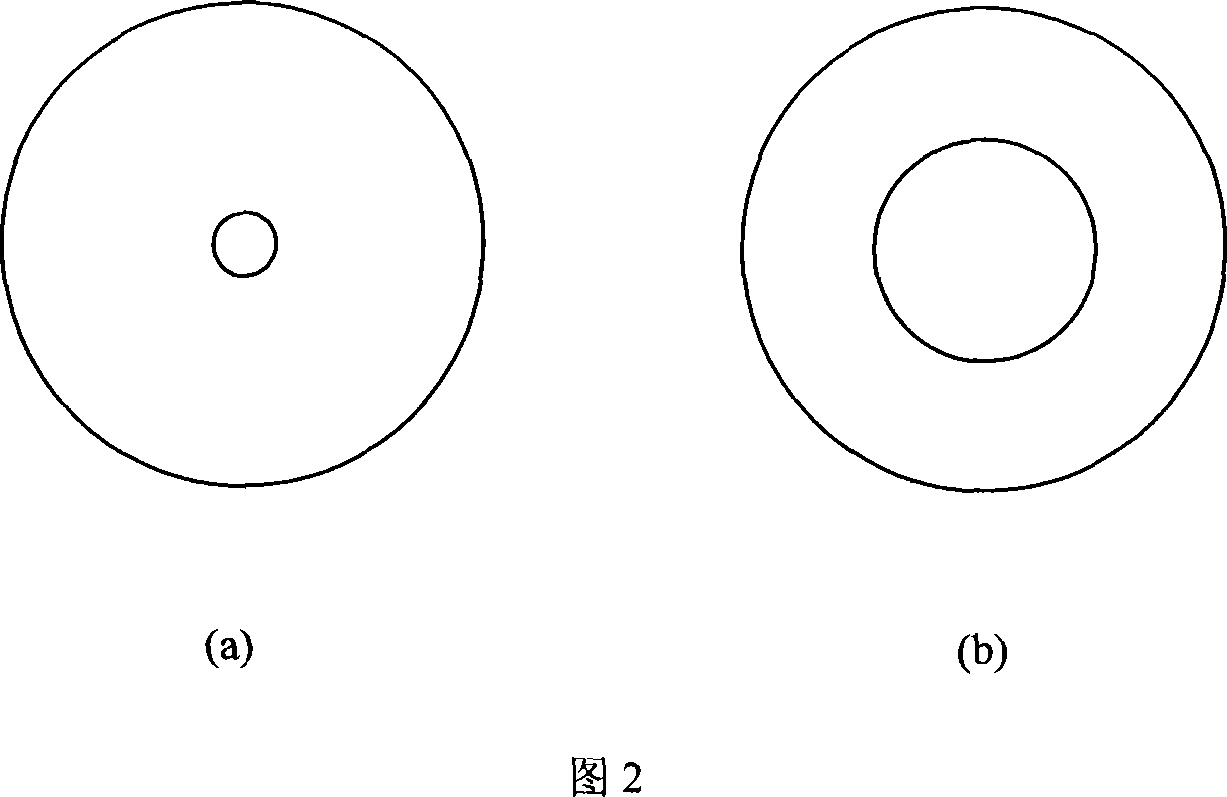

Process of preparing fiber preformrod

ActiveCN101066834AEliminate network structure flawsExcellent anti-hydrogen aging propertiesGlass making apparatusGlass productionChemistryBridging oxygen

The process of preparing fiber preformed rod includes deuterium-hydrogen displacement reaction on quartz rod with low hydroxyl radical content and high purity for deuterium atom to occupy the non-bridge oxygen bond in quartz glass so as to reduce the probability of hydroxyl radical to diffuse, plasma flame etching to eliminate surface adsorbed hydroxyl radical of the quartz rod completely, depositing GeO2 and SiO2 onto the surface of the quartz rod, combined loose perform rod with central quartz rod, and dewatering and sintering in a sintering furnace to obtain transparent fiber preformed rod. The present invention is suitable for large- scale production and has low production cost, and the fiber preformed rod may be drawn into mono-mode fiber with low attenuation at 1383 nm wavelength, high hydrogen ageing resistance and very low PMD.

Owner:JIANGSU FASTEN CO LTD

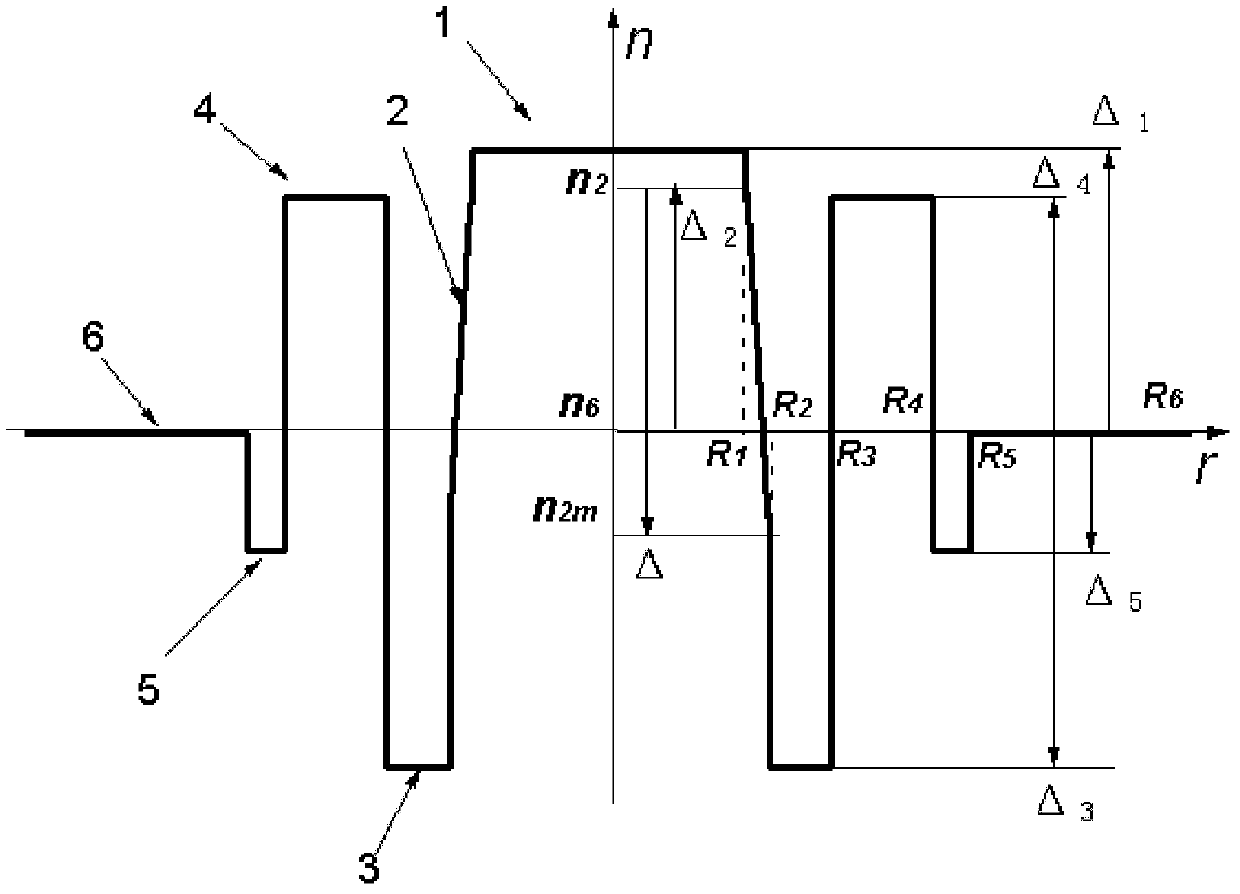

Single-mode optical fiber and multi-core optical fiber coupler

ActiveCN111290075AReduce splice lossEasy to prepareOptical fibre with multilayer core/claddingCoupling light guidesSingle-mode optical fiberCore (optical fiber)

The invention discloses a single-mode optical fiber and a multi-core optical fiber coupler, which belong to the technical field of optical fibers. The single-mode optical fiber comprises a fiber core,a first outer cladding layer, a sunken outer cladding layer and a mechanical cladding layer which are sequentially arranged from inside to outside, wherein refractive indexes in the fiber core, the first outer cladding layer, the sunken outer cladding layer and the mechanical cladding layer are uniformly distributed; the refractive index of the interface of the fiber core and the first outer cladding changes suddenly, the refractive index of the interface of the sunken outer cladding and the mechanical cladding changes suddenly, and the refractive index of the sunken outer cladding is smallerthan that of the mechanical cladding. The optical fiber coupler comprises a sleeve and a single-mode optical fiber, the single-mode optical fiber is nested in the sleeve, and one end of the sleeve istapered; one end of the sleeve tapering is used for being welded with the multi-core optical fiber; and each single-mode optical fiber in the non-tapering end is respectively welded with the corresponding standard single-mode optical fiber. The problem of large loss of the existing multi-core optical fiber coupler is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-core nonlinear optical fiber

ActiveCN103698840ASolve the problem of low loss connectionReduce leakageOptical fibre with multilayer core/claddingOptical waveguide light guideMicrostructure fiberErbium lasers

The invention relates to a multi-core nonlinear optical fiber. The multi-core nonlinear optical fiber comprises three or more fiber cores, an air cladding layer and a pure quartz glass cladding layer, wherein the air cladding layer includes an inner air cladding layer and an outer air cladding layer; the inner air cladding layer is composed of inner air holes in an inter lattice; the outer air cladding layer is composed of outer air holes in an outer lattice; the inner lattice is a regular hexagonal lattice including a center point; the outer lattice is a regular hexagonal lattice surrounding the inner lattice; the center distances between any two neighboring points in both the inner lattice and the outer lattice are equal to each other; the inner air holes are distributed in all points of the inner lattice except for the points for distributing the fiber cores; the fiber cores are symmetrically distributed around the center point; the center distances between any two neighboring fiber cores are equal to each other; the outer air holes are distributed in all points of the outer lattice. The multi-core nonlinear optical fiber provided by the invention solves the problem of low-loss connection between a large-core-diameter tail fiber of a high-power fiber laser and a nonlinear microstructure fiber, can bear higher pumping power and can realize dispersion characteristics of optical fibers more effectively.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

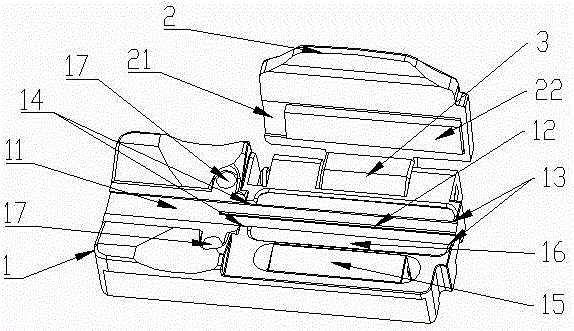

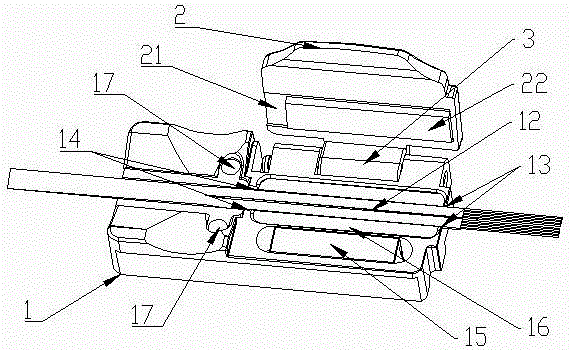

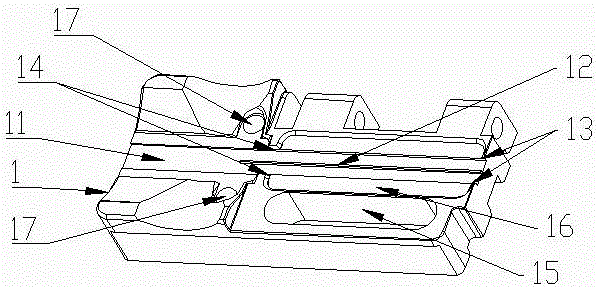

Optical fiber clamping tool for optical fiber fusion splicer

PendingCN106842427AAchieve clampingGuarantee welding qualityCoupling light guidesEngineeringFusion splicing

The invention discloses an optical fiber clamping tool for an optical fiber fusion splicer. The optical fiber clamping tool comprises a body and a cover body, wherein the body is pivotally connected with the cover body through a rotating shaft, an optical fiber placement groove, optical fiber confinement front parts and optical fiber confinement rear parts are arranged on the body, a rib is arranged in the optical fiber placement groove, an optical fiber fixing part for fixing an optical fiber is arranged on the cover body, and an elastic body is arranged in the optical fiber fixing part. According to the optical fiber clamping tool, a 12-core ribbon optical fiber with a diameter of 200mu m can be accommodated and clamped; in addition, the original optical fiber fusion splicer can be used for a new optical fiber, so that the fusion splicing quality is ensured, and meanwhile, the cost is reduced.

Owner:INNO INSTR (CHINA) INC

Multimode optical fiber, application thereof and temperature measuring system

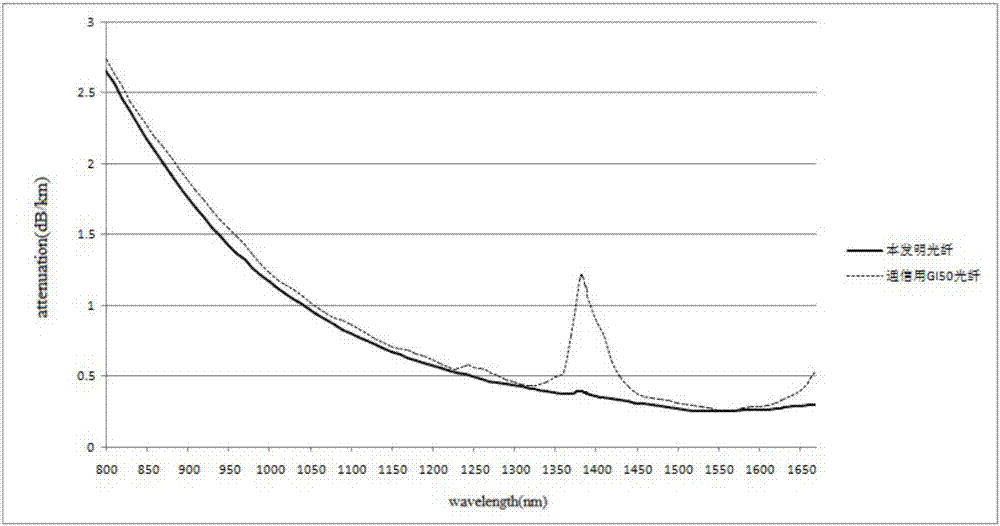

ActiveCN107132615AImprove spatial resolutionHigh bandwidthOptical fibre with graded refractive index core/claddingThermometers using physical/chemical changesSignal-to-noise ratio (imaging)Relative refractive index

The invention discloses a multimode optical fiber, application thereof and a temperature measuring system. The multimode optical fiber comprises a core layer and a cladding layer covering the core layer; the radius of the core layer is 23.75-26.25 micrometers, the refractive index profile of the core layer is in gradient refractive index distribution, the index distribution index alpha is 1.80-1.89, the relative refractive index difference delta1% of the core layer is 1.0-1.15%, and the fusion loss is smaller than or equal to 0.08 dB. The optical fiber is applied to the middle-long-distance distributed temperature measuring system, and the temperature measuring distance of the system reaches 10-27 km. The system comprises a pulse light source, a wavelength division multiplexer, an avalanche diode, a data acquisition device, an upper computer and the temperature measuring multimode optical fiber. The multimode optical fiber is high in temperature measuring space resolution, high in temperature measuring precision and long in measuring distance. The temperature measuring system is simple in structure, high in signal-to-noise ratio and accurate in result.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Optical cable joint method based on cable holder

InactiveCN103033893AOptimize the connection processReduce splice lossCoupling light guidesFibre mechanical structuresMode field diameterOptical fiber cable

The invention relates to an optical cable joint method based on a cable holder. The optical cable joint method comprises the following steps of (1) selecting a plurality of cable bare fibers with same mode field diameter; (2) paving the cable bare fibers; (3) fixing a joint between the two cable bare fibers by using the cable holder; (4) cutting a fiber end face of each cable bare fiber through a fiber end face cutter; and (5) welding the joint through a welding machine, testing continuing loss of a welding point through an optical time domain reflectometer (OTDR) while welding in a welding process, and welding the position which does not meet requirements again. Compared with the prior art, the optical cable joint method has the advantages of optimizing cable joint procedures, reducing optical fiber welding loss and the like.

Owner:SHANGHAI GONGLIAN COMM INFORMATION DEV

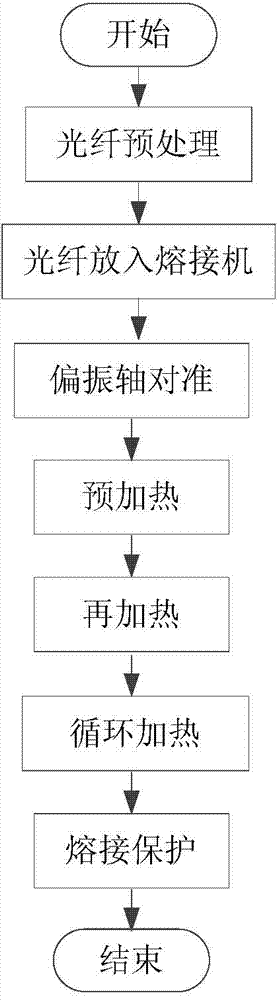

Welding method of polarization-maintaining photonic crystal fiber

ActiveCN103676003AImprove alignment accuracyReduce splice lossCoupling light guidesPhotonic crystalEngineering

The invention discloses a welding method of a polarization-maintaining photonic crystal fiber, and relates to fiber welding. The welding method comprises pretreating two fibers to be welded, wherein the pretreatment comprises heating, cleaning and cutting; putting the two fibers into a welding chamber of a welding machine, and aligning with a polarization shaft; preheating, reheating and cyclically heating welding parts, and strengthening and protecting welding points. According to the welding method of the polarization-maintaining photonic crystal fiber, the alignment accuracy of the polarization shaft is effectively improved, excessive welding loss caused by mismatching of fiber and mode field is avoided, and meanwhile the welding strength is high.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

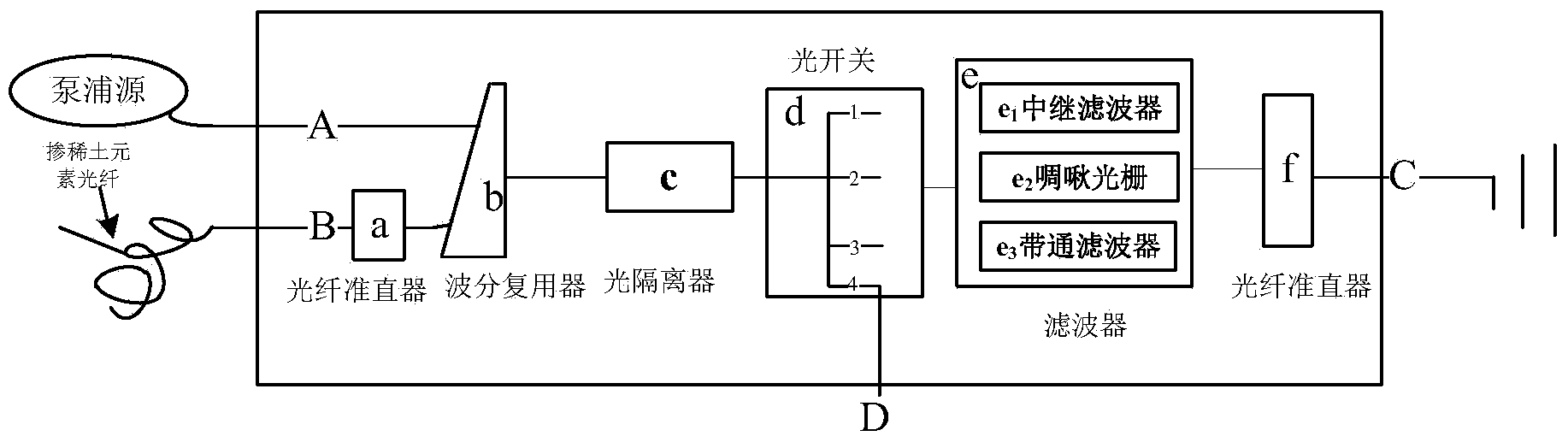

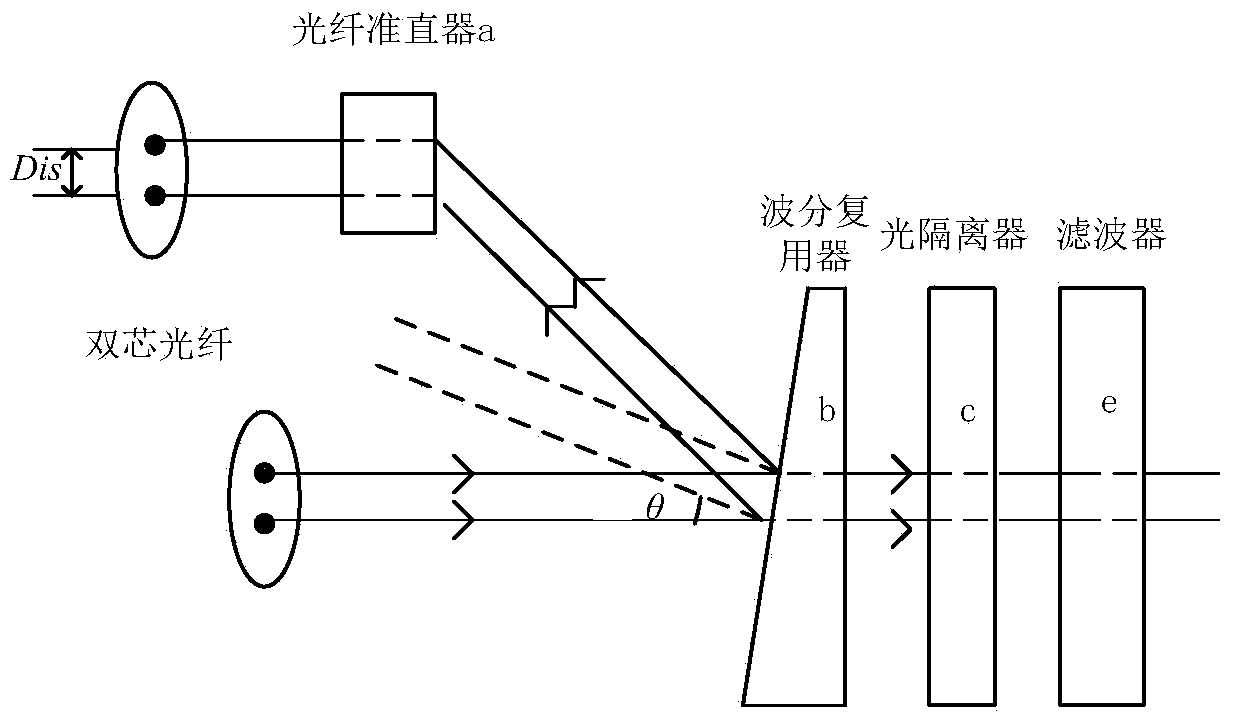

Multifunctional integrated device for ASE optical fiber source

ActiveCN103731210AGuaranteed reflection efficiencyGuaranteed Coupling EfficiencyWavelength-division multiplex systemsFibre transmissionRare-earth elementGrating

The invention provides a multifunctional integrated device for an ASE optical fiber source and belongs to the field of optical fiber communication. According to the multifunctional integrated device, an optical fiber collimator, a wavelength division multiplexer, an optical isolator, an optical switch and filters are integrated on a semiconductor chip. 980nm pump light is collimated and coupled through the wavelength division multiplexer and enters a rare-earth-doped optical fiber, and light generated by the rare-earth-doped optical fiber is collimated and coupled through the wavelength division multiplexer, the optical isolator and the filters and enters an output optical fiber. Based on the spectral signature of the light generated by the rare-earth-doped optical fiber, the filters are selected; specifically, when the spectrum of the light generated by the rare-earth-doped optical fiber is a 1560nm Gaussian spectrum, a chirp grating is selected; when the spectrum of the light generated by the rare-earth-doped optical fiber is a 1530nm Gaussian spectrum, the relay filter is selected, and when the spectrum of the light generated by the rare-earth-doped optical fiber is a flat spectrum, the band-pass filter is selected. The angle of the wavelength division multiplexer is 3.5 degrees. The multifunctional integrated device for the ASE optical fiber source guarantees the reflection efficiency and the coupling efficiency, reduces splice loss between devices and is small in size, good in stability and convenient to use.

Owner:BEIHANG UNIV

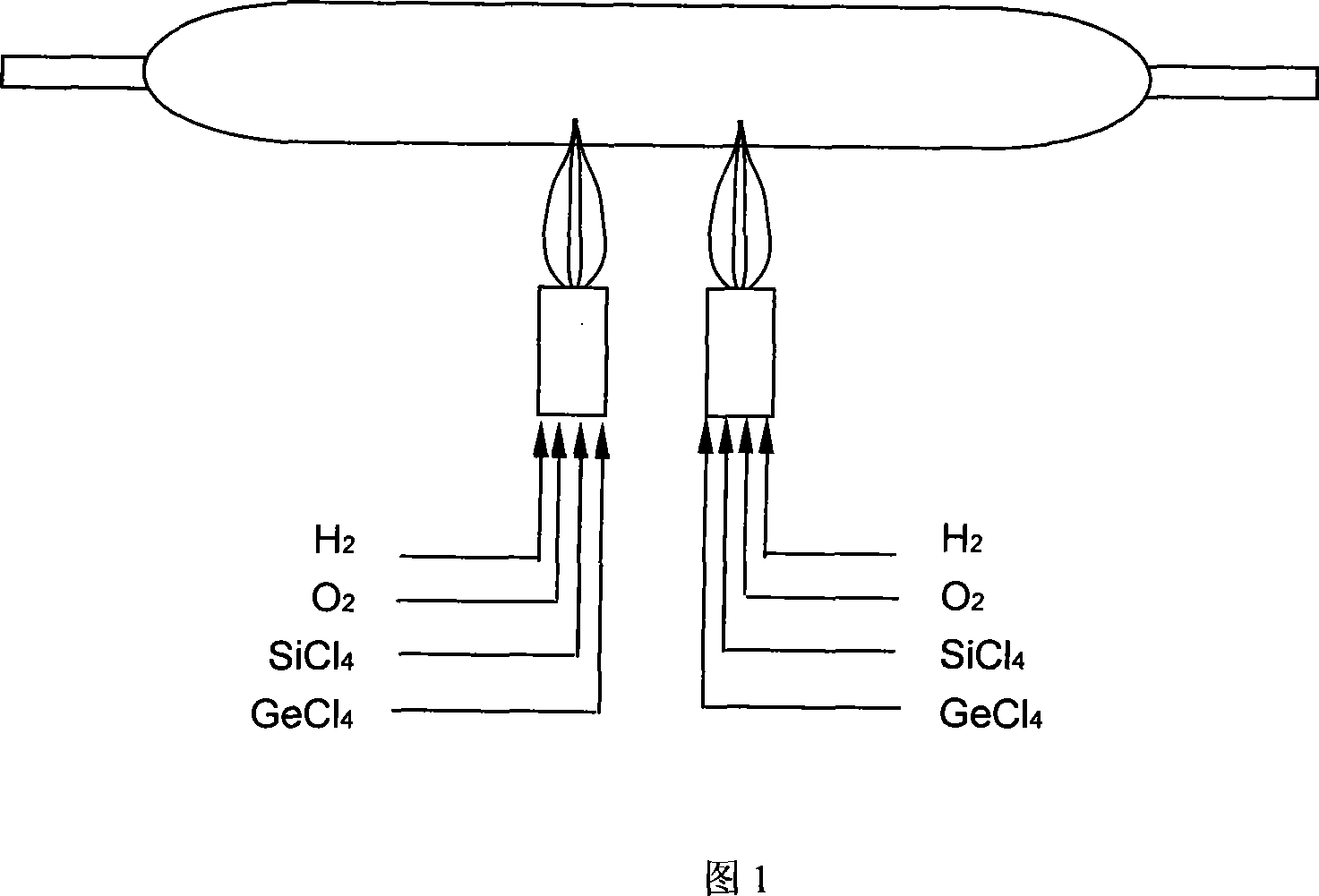

Method for manufacturing bent insensitive optical fiber preformed rod

ActiveCN102153275AImprove production efficiencySimple processGlass deposition burnersGlass fibre productsFiberOptical communication

The invention discloses a method for manufacturing a bent insensitive optical fiber preformed rod, and belongs to an optical communication technology. The bent insensitive optical fiber preformed rod prepared by the prior art has the defects of insufficient bending performance, high optical fiber attenuation, high OH- content, low optical fiber mechanical strength, complex process and the like. When a core rod is manufactured by using a vapor axial deposition (VAD) process, 1 to 2 paths of blast lamps for synchronously depositing a doped layer are increased according to the profile of the designed optical fiber preformed rod, a coating is manufactured on the vitrified core rod by using an outside vapor deposition (OVD) process or a sleeve process, and finally the bent insensitive optical fiber preformed rod is obtained. The optical fiber preformed rod prepared by the method has the advantages of low optical fiber attenuation, low OH- content, high mechanical strength and the like; themethod can manufacture the required structure model according to the requirement; the optical fiber drawn by using the manufactured optical fiber preformed rod has excellent bending performance, and is suitable for the application occasions of fiber to the home (FTTH) access, small optical devices, optical cables with small bending radius requirements and the like.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

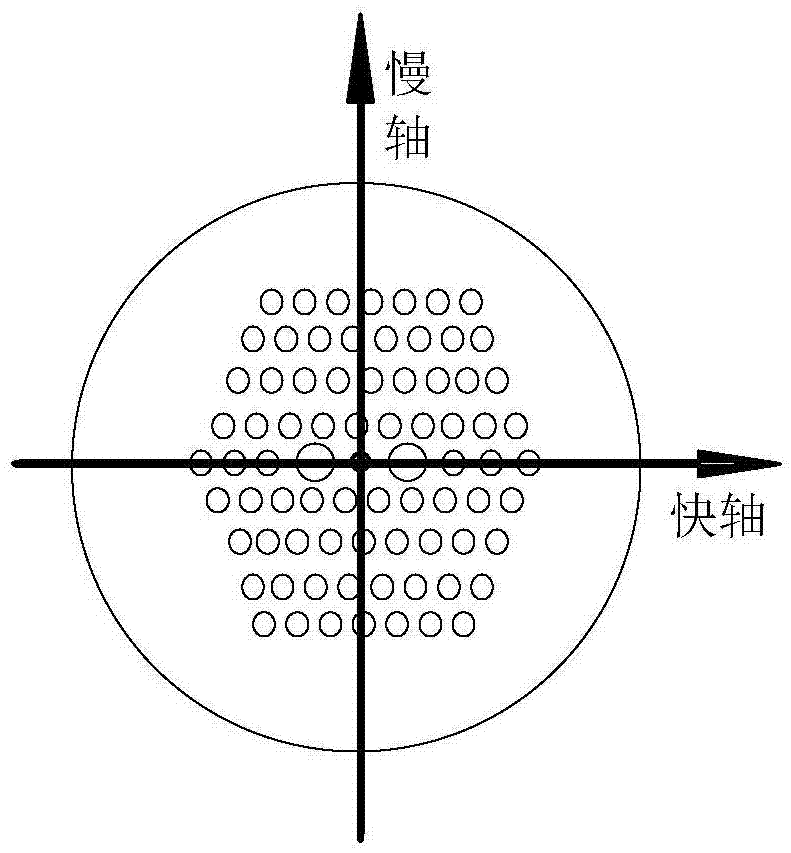

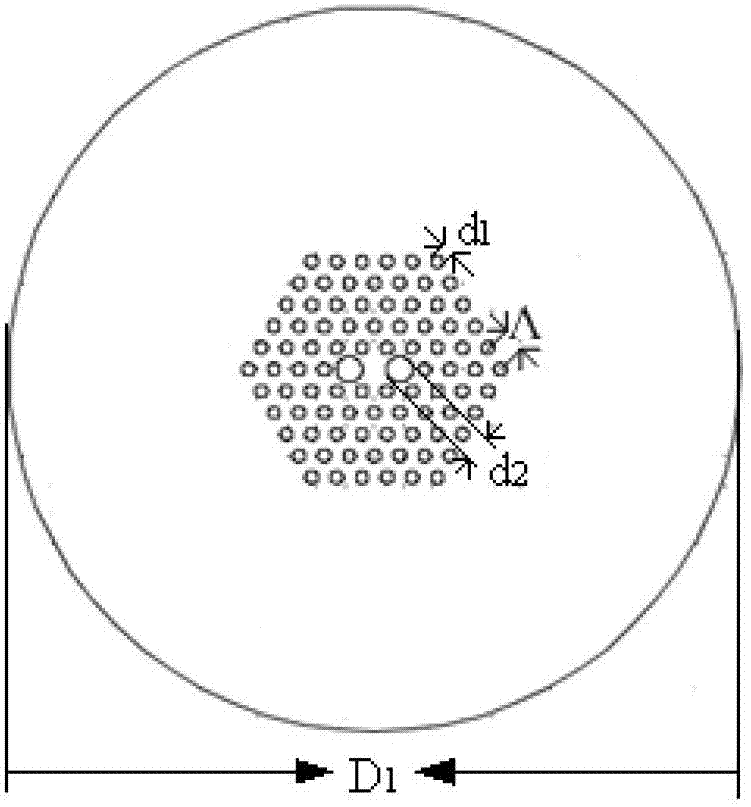

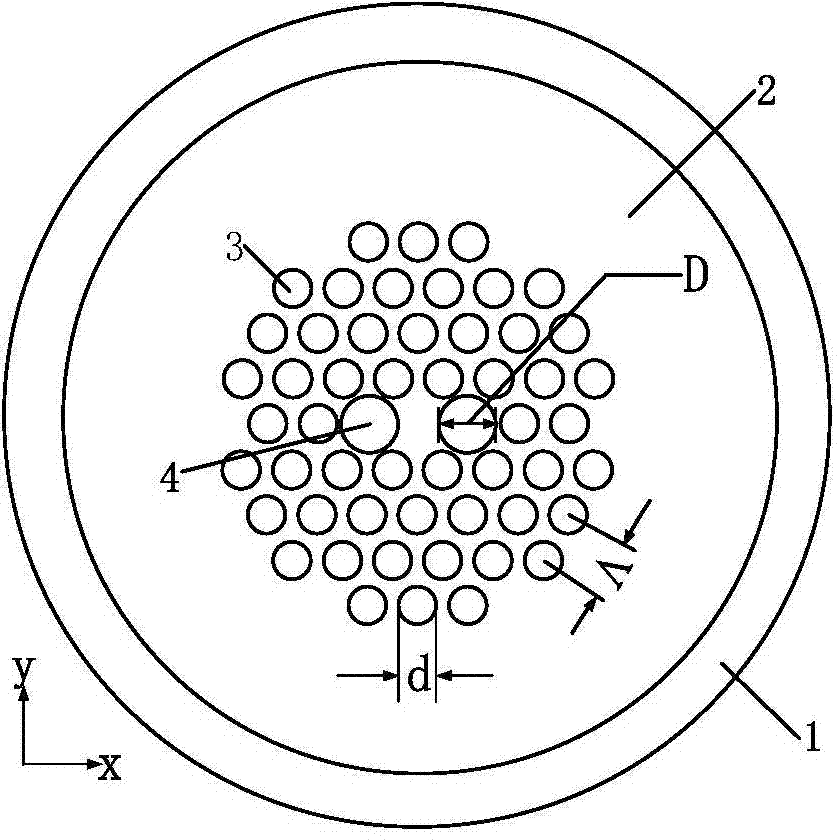

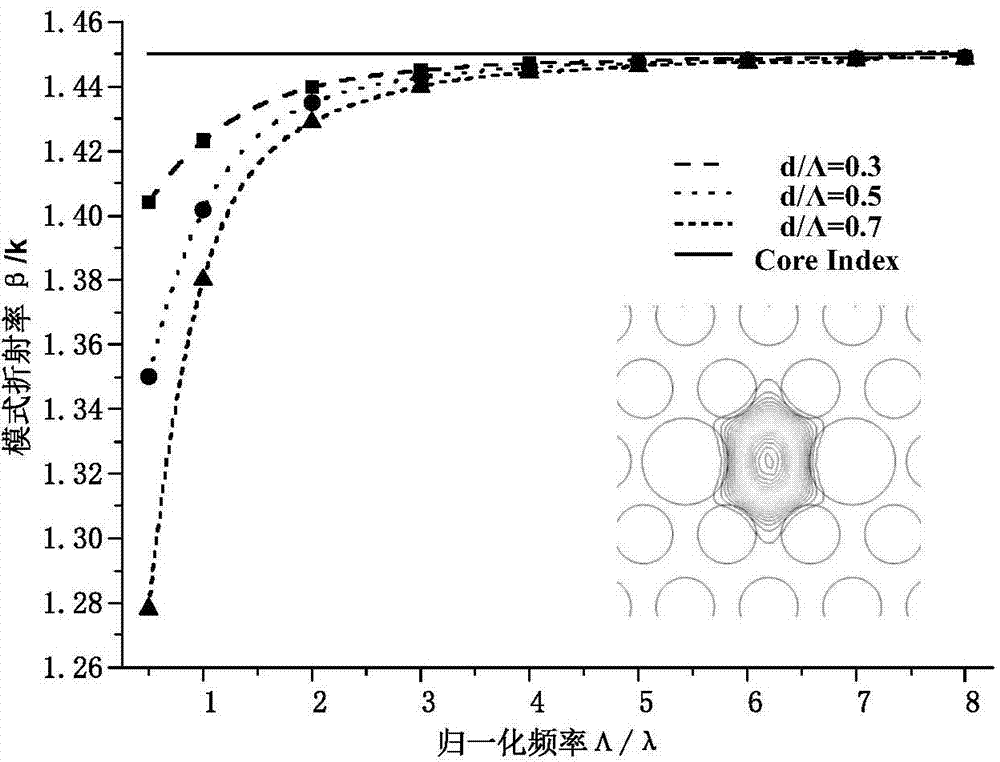

Small-diameter solid core polarization-maintaining photonic crystal fiber of four-layer structure

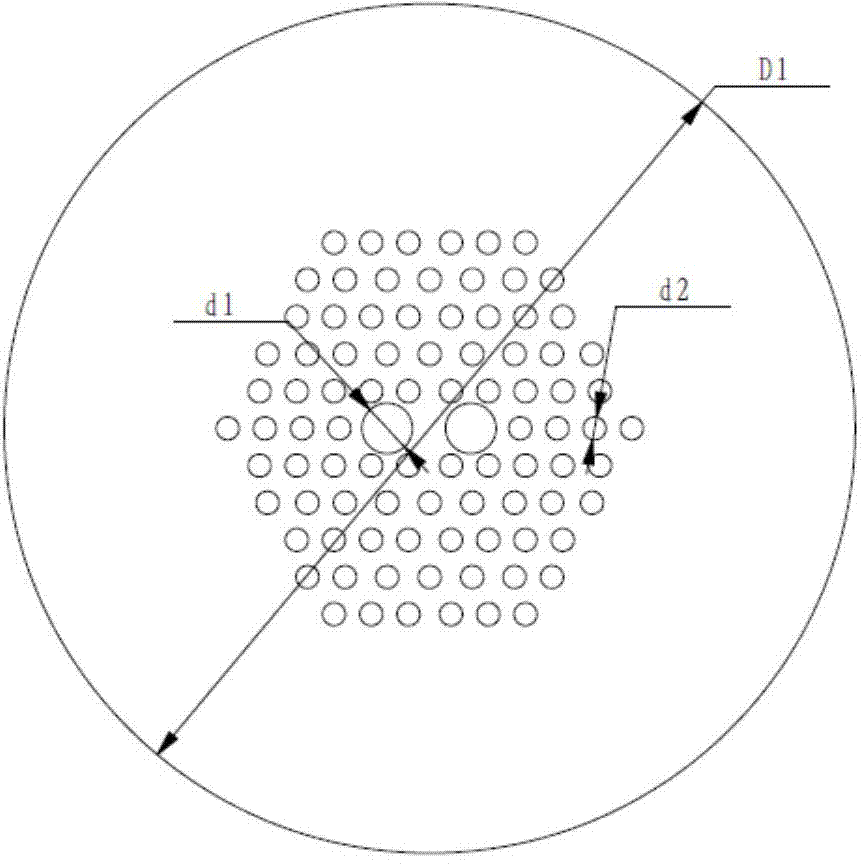

ActiveCN104765100AHigh precisionIncrease temperatureOptical fibre with multilayer core/claddingMode field diameterPhoton

The invention discloses a small-diameter solid core polarization-maintaining photonic crystal fiber of a four-layer structure and belongs to the technical field of microstructure fibers. The concrete structure refers to that a section is round, and the fiber sequentially comprises a coating layer, a cladding and cladding air pores from outside to inside. The cladding air pores are of a four-layer symmetric structure and are arrayed in a hexagon. The centers of the cladding air pores are concave parts, two large air pores are formed in the centers in the x-axis direction to form shape birefringence of the fiber. The diameter d of each cladding air pore is 3.0-3.8 micrometers; the distance A between every two adjacent cladding air pores is 5.4-6.2 micrometers; the diameter D of each large air pore is 5.5-6.4 micrometers, the duty ratio d / Lambada is 0.55-0.65, and the range of the normalized frequency Lambada / Lambada is 3.5-4. The fiber has the advantages that gyro precision is substantially improved within a certain size limit, the temperature performance of an fiber gyro and the temperature stability of fiber birefringence are improved, and the temperature sensitivity of the fiber gyro is reduced; an fiber mode field diameter is closer to that of a common polarization-maintaining fiber, so the welding loss is smaller; the diameters of the cladding and the coating layer are smaller than those of a current fiber, so gyro miniaturization is facilitated.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com