Multi-core nonlinear optical fiber

A technology of nonlinear optical fiber and optical fiber, applied in the direction of nonlinear optics, multi-layer core/clad optical fiber, cladding optical fiber, etc. core and other issues, to achieve the effects of reducing pump light leakage, reducing splice loss, and increasing fiber core diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiment.

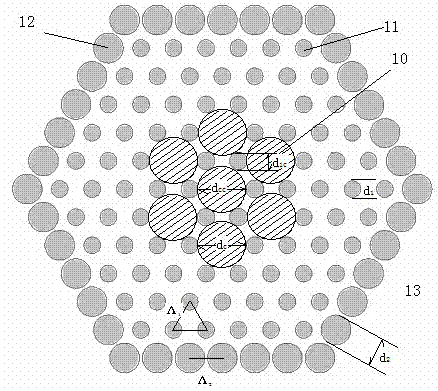

[0052] Generally, for a single-core microstructured fiber, the air filling rate of the air cladding is usually 0.42, which is critical for single-mode and multi-mode (d is the diameter of the air hole, and Λ is the pitch of the air hole). When the filling rate is less than 0.42, the microstructured fiber Single-mode output, when d / Λ>0.42, micro-structured fiber multi-mode output. When combined with bending, because bending can effectively suppress high-order modes, leaving only the fundamental mode in the core, the air filling rate can be appropriately increased.

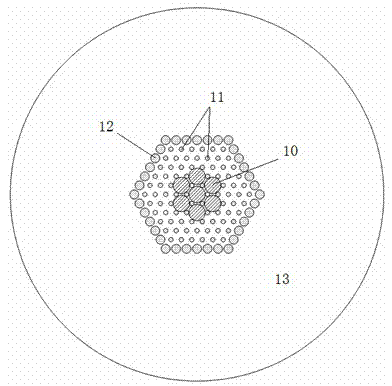

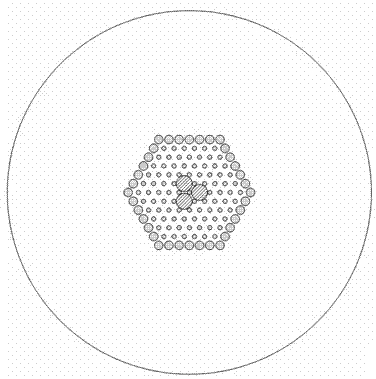

[0053] The radial section structure of the first embodiment of the present invention is as follows: figure 1 , 2 Shown, comprise fiber core 10, air cladding and pure silica glass total cladding 13, described fiber core is 7, and described air cladding divides and comprises inner air cladding and outer air cladding, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com