Method for manufacturing bent insensitive optical fiber preformed rod

An optical fiber preform and bend-insensitive technology, which is applied in the field of optical communication, can solve the problems of low mechanical strength of optical fiber, insufficient bending performance, and large attenuation of optical fiber, and achieve good compatibility, improved mechanical strength, and small stress residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

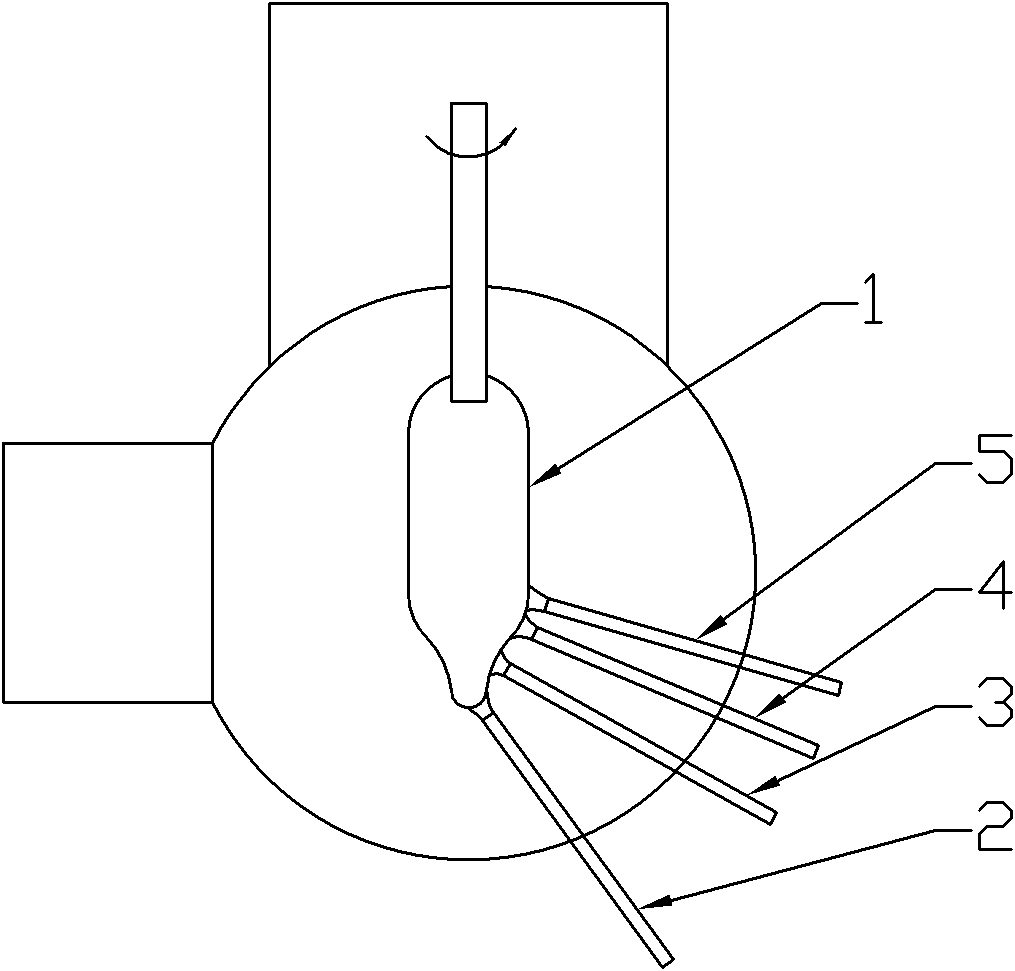

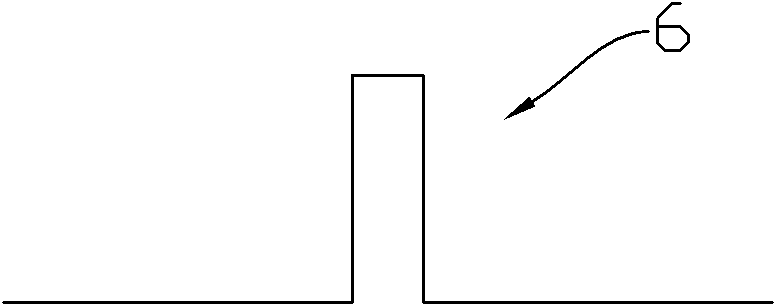

[0040] Use 1 doping blowtorch to make mandrel 1, see structure type Figure 2a The depressed-cladding fiber structure 7 in , and then the cladding is deposited by OVD.

[0041] The resulting bend-insensitive optical fiber preform properties are as follows:

[0042] Mode field diameter: 8.8~9.0μm;

[0043] Zero dispersion wavelength: 1300~1324nm;

[0044] Fiber cut-off wavelength: 1320±10nm;

[0045] Water peak absorption attenuation: 0.30~0.32dB / Km / km;

[0046] Macro bend φ30mm around 10 turns:

[0047] Additional loss value at 1550nm: 0.005~0.01dB / Km,

[0048] Additional loss value at 1625nm: 0.05~0.1dB / Km;

[0049] Macro bend φ20mm around 1 turn:

[0050] Additional loss value at 1550nm: 0.05~0.08dB / Km,

[0051] Additional loss value at 1625nm: 0.1~0.2dB / Km;

[0052] Macro bend φ15mm around 1 turn:

[0053] Additional loss value at 1550nm: 0.3~0.5dB / Km,

[0054] Additional loss value at 1625nm: 0.5~1.0dB / Km.

[0055] The mode field diameter of the optical fiber d...

Embodiment 2

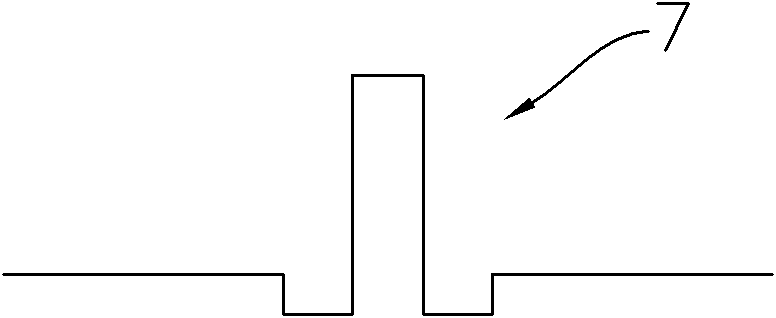

[0057] Use 1 doping blowtorch to make mandrel 1, see structure type Figure 2b The cladding-sag-type optical fiber structure 8 in , and then the cladding is deposited by OVD.

[0058] The resulting bend-insensitive optical fiber preform properties are as follows:

[0059] Mode field diameter: 8.4~8.8μm;

[0060] Zero dispersion wavelength: 1300~1324nm;

[0061] Fiber cut-off wavelength: 1300~1350nm;

[0062] Water peak absorption attenuation: 0.31~0.33dB / Km / km;

[0063] Macro bend φ30mm around 10 turns:

[0064] Additional loss value at 1550nm: 0.01~0.02dB / Km,

[0065] Additional loss value at 1625nm: 0.05~0.1dB / Km;

[0066] Macro bend φ20mm around 1 turn:

[0067] Additional loss value at 1550nm: 0.01~0.02dB / Km,

[0068] Additional loss value at 1625nm: 0.05~0.1dB / Km;

[0069] Macro bend φ15mm around 1 turn:

[0070] Additional loss value at 1550nm: 0.1~0.2dB / Km,

[0071] Additional loss value at 1625nm: 0.3~0.6dB / Km.

Embodiment 3

[0073] Use 1 or 2 doping torches to make mandrel 1, see structure type Figure 2c The double-clad depressed fiber structure 9 in , and then the cladding is deposited by OVD.

[0074] The resulting bend-insensitive optical fiber preform properties are as follows:

[0075] Mode field diameter: 8.4~8.8μm;

[0076] Zero dispersion wavelength: 1300~1324nm;

[0077] Fiber cut-off wavelength: 1300~1350nm;

[0078] Water peak absorption attenuation: 0.31~0.33dB / Km / km;

[0079] Macro bend φ30mm around 10 turns:

[0080] Additional loss value at 1550nm: 0.001~0.005dB / Km,

[0081] Additional loss value at 1625nm: 0.003~0.008dB / Km;

[0082] Macro bend φ20mm around 1 turn:

[0083] Additional loss value at 1550nm: 0.005~0.01dB / Km,

[0084] Additional loss value at 1625nm: 0.005~0.01dB / Km;

[0085] Macro bend φ15mm around 1 turn:

[0086] Additional loss value at 1550nm: 0.005~0.01dB / Km,

[0087] Additional loss value at 1625nm: 0.01~0.02dB / Km.

[0088] -------------------------...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com