Polarization-maintaining fiber coupler, preparation method thereof and all-fiber optical current sensor

A technology of current sensor and polarization-maintaining fiber, which is applied in the direction of coupling of optical waveguides, and can solve the problems of unreliable main performance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

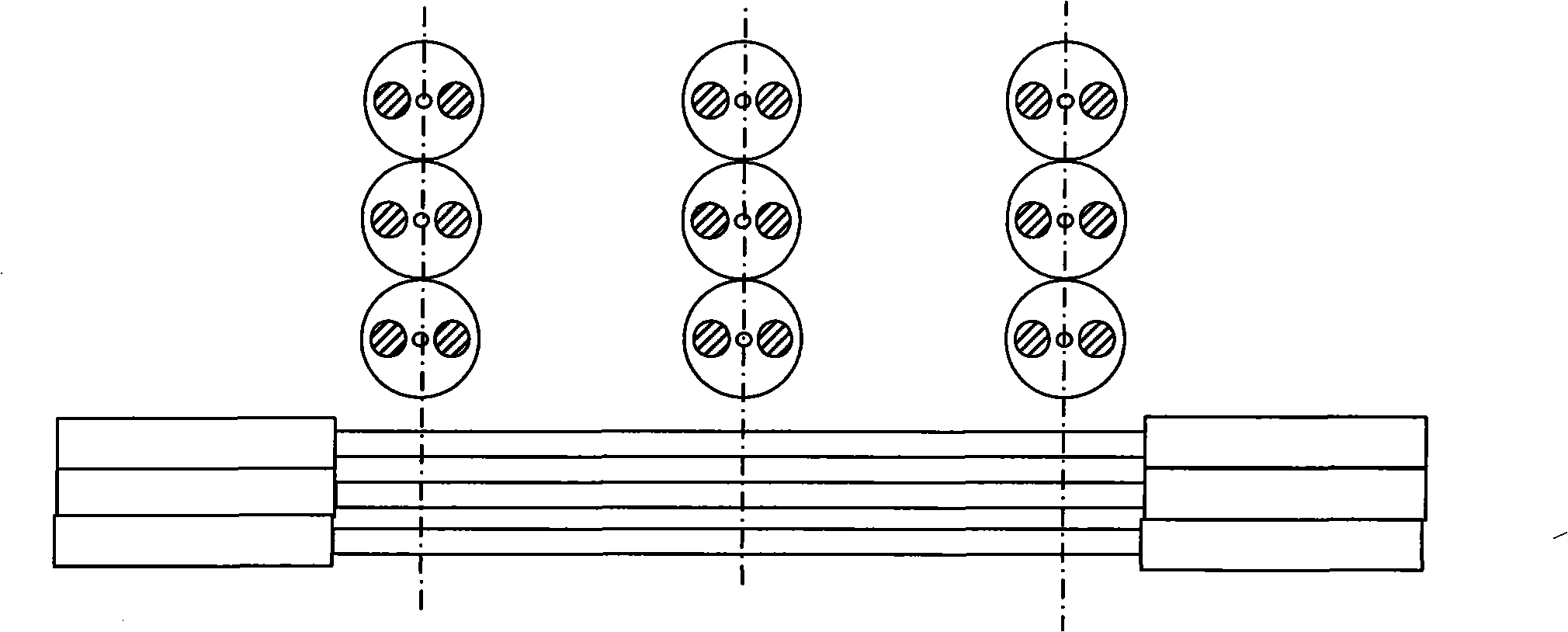

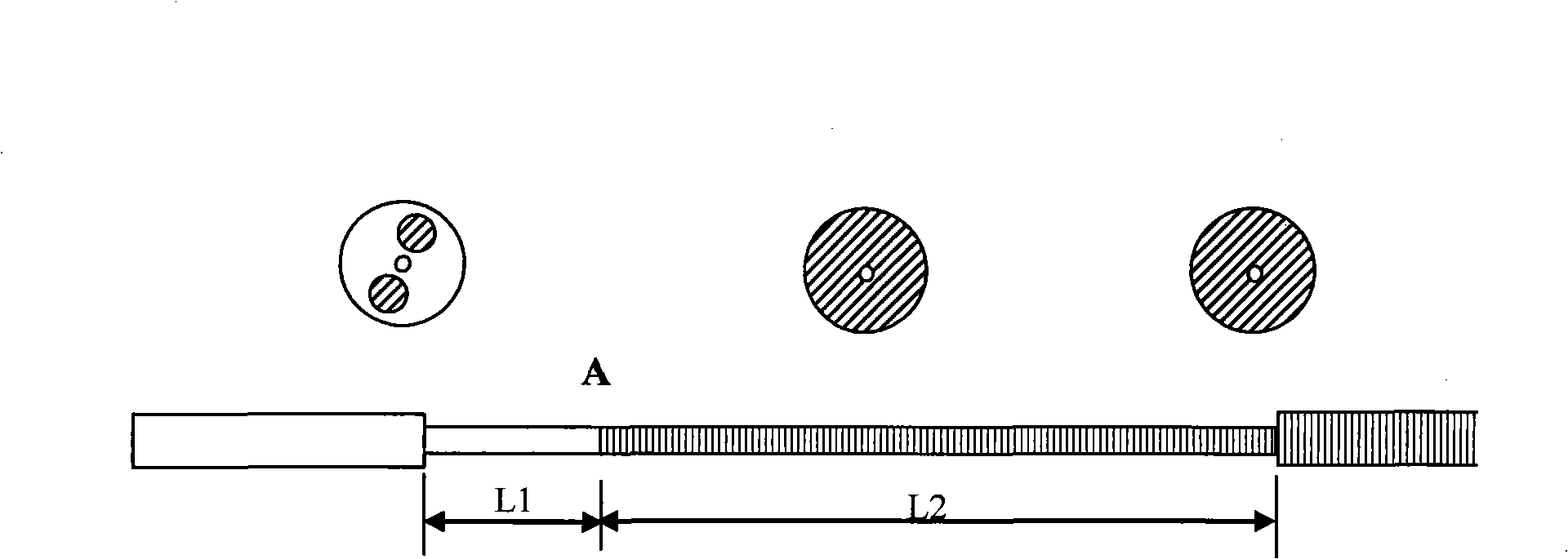

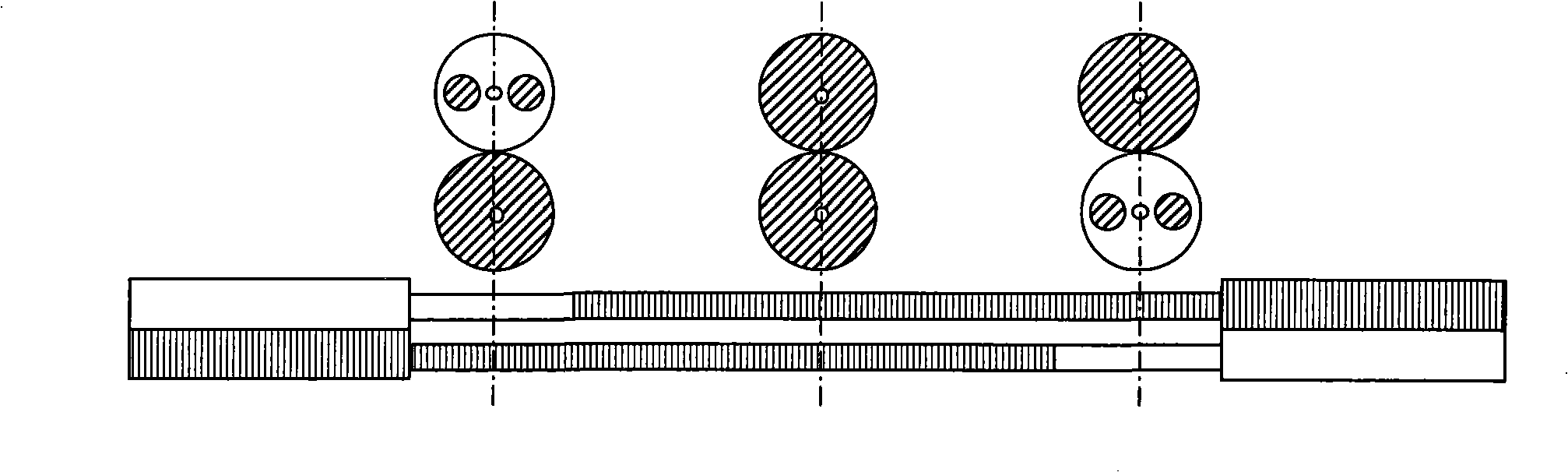

[0020] The polarization-maintaining fiber coupler of the present invention is developed based on the technology and characteristics of common single-mode fiber couplers, and the transmission characteristics of linearly polarized light in an ideal single-mode fiber without bending and perturbation. The main features of the polarization-maintaining fiber coupler of the present invention are: all of the coupling area is drawn from a single-mode fiber; the input end of the polarization-maintaining fiber coupler includes at least one polarization-maintaining fiber, and the output end directly connected with it is a single-mode fiber An optical fiber, the input end of the polarization-maintaining optical fiber coupler includes at least one single-mode optical fiber, and the output end directly connected to it is a polarization-maintaining optical fiber, and the polarization-maintaining optical fiber at the input end and the output end are respectively connected to the corresponding si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com