Pulse pump type standing wave resonant cavity nanosecond pulse laser

A pump laser, nanosecond pulse technology, applied in the field of lasers, can solve the problems of pulse asymmetry, limited duty cycle, burnt gain fiber, etc., to overcome large insertion loss, reduced circuit complexity, and optical-to-optical conversion efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

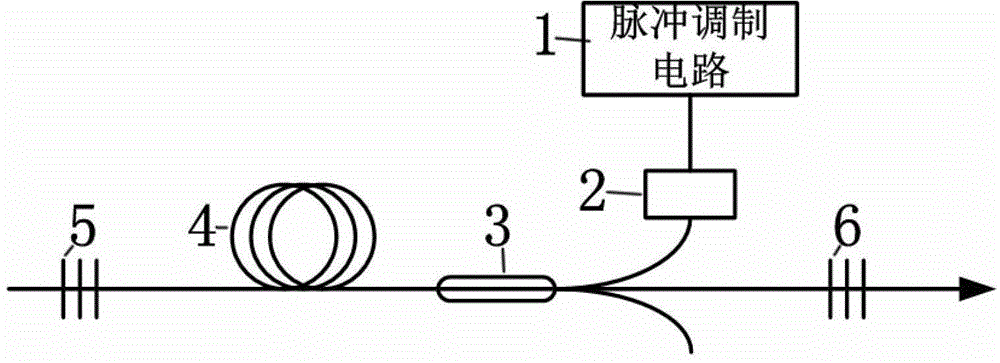

[0027] Such as figure 1 As shown, a pulse-pumped standing wave resonator nanosecond pulse laser includes a pulse modulation circuit 1, a pump laser 2, a combiner 3, a gain fiber 4, a high reflection fiber grating 5 and a low reflection fiber grating 6 , The beam combiner 3 is provided with a beam combining end, a pump light input end and a signal input end, the output end of the pump laser 2 is connected with the pump light input end of the beam combiner 3, and the high reflection One end of the fiber grating 5 is connected to one end of the gain fiber 4, the other end of the gain fiber 4 is connected to the combining end of the combiner 3, and the signal incident end of the combiner 3 is connected to one end of the low reflection fiber grating 6 to form a standing wave for laser resonance Cavity, the other end of the low reflection fiber grating 6 is used as a nanosecond pulse output end.

[0028] In this embodiment, the pump laser 2 uses a semiconductor laser with a continuous ...

Embodiment 2

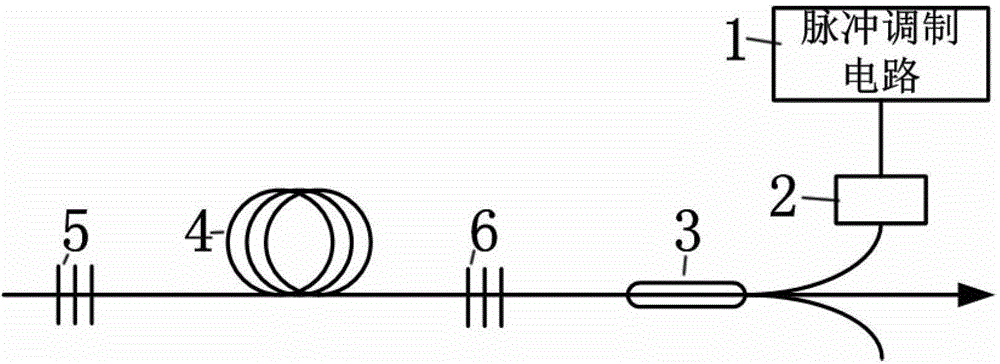

[0035] Such as figure 2 As shown, a pulse-pumped standing wave resonator nanosecond pulse laser includes a pulse modulation circuit 1, a pump laser 2, a combiner 3, a gain fiber 4, a high reflection fiber grating 5 and a low reflection fiber grating 6 , The beam combiner 3 is provided with a beam combining end, a pump light input end and a signal input end, the output end of the pump laser 2 is connected with the pump light input end of the beam combiner 3, and the high reflection One end of the fiber grating 5 is connected to one end of the gain fiber 4, the other end of the gain fiber 4 is connected to one end of the low reflection fiber grating 6 to form a standing wave harmonic cavity, and the other end of the low reflection fiber grating 6 is connected to the beam combining end of the combiner 3, The nanosecond pulse is output through the signal incident end of the beam combiner 3.

[0036] In this embodiment, the pump laser 2 is a semiconductor laser with a continuous opti...

Embodiment 3

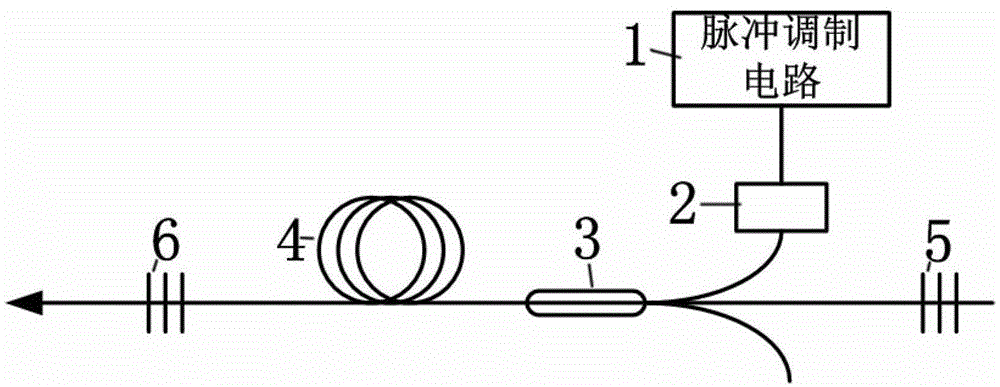

[0043] Such as image 3 As shown, a pulse-pumped standing wave resonator nanosecond pulse laser includes a pulse modulation circuit 1, a pump laser 2, a combiner 3, a gain fiber 4, a high reflection fiber grating 5 and a low reflection fiber grating 6 , The beam combiner 3 is provided with a beam combining end, a pump light input end and a signal input end, the output end of the pump laser 2 is connected with the pump light input end of the beam combiner 3, and the high reflection One end of the fiber grating 5 is connected to the signal incident end of the beam combiner 3, the combining end of the beam combiner 3 is connected to one end of the gain fiber 4, and the other end of the gain fiber 4 is connected to one end of the low reflection fiber grating 6 to form a standing wave resonant cavity. The other end of the low reflection fiber grating 6 is used as a nanosecond pulse output end.

[0044] In this embodiment, the pump laser 2 is a semiconductor laser with a continuous opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com