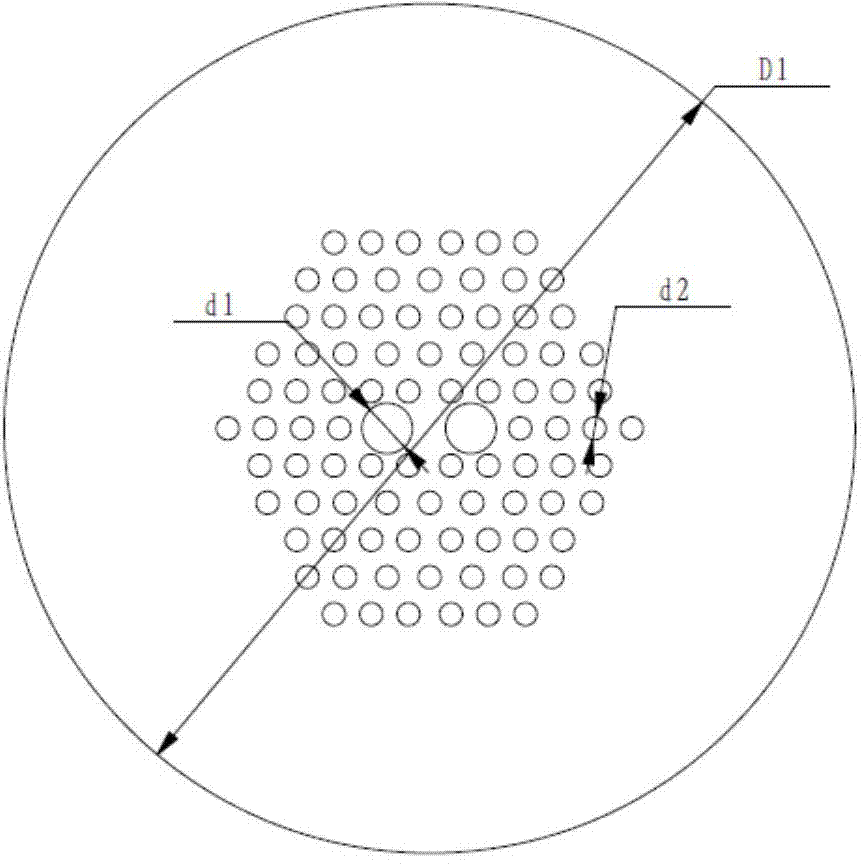

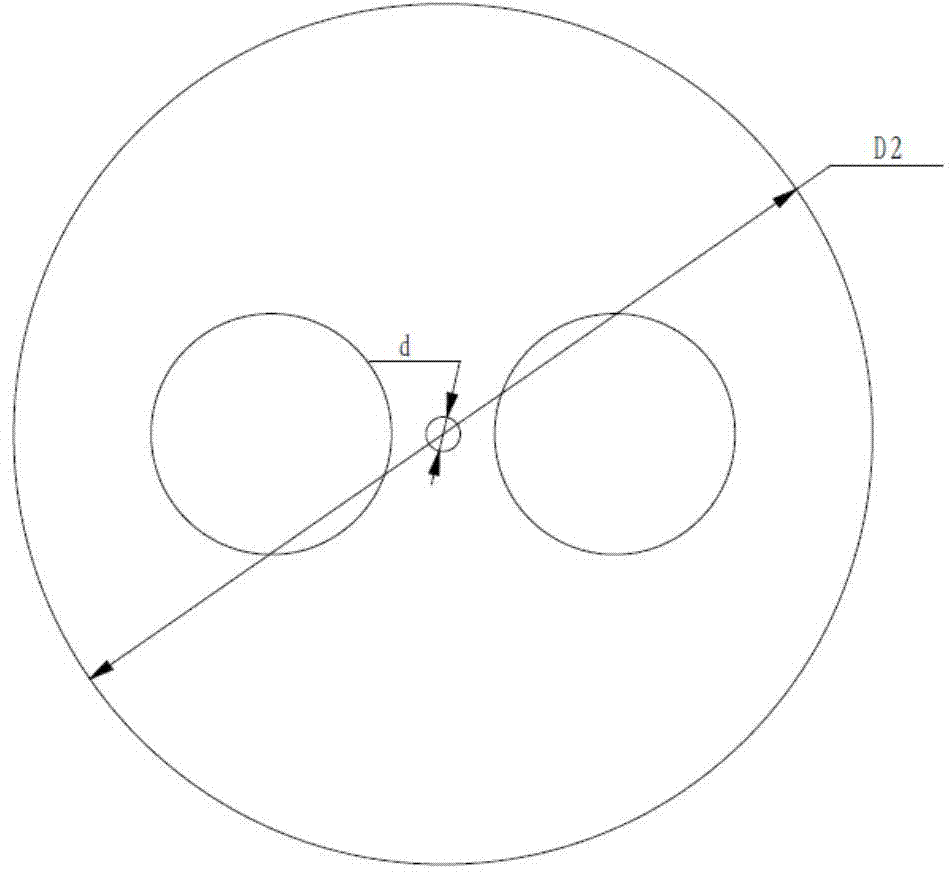

Welding method of polarization-maintaining photonic crystal fiber

A technology of photonic crystal fiber and polarization-maintaining fiber, which is applied in the coupling of optical waveguide and other directions, can solve the problems of excessive fusion loss and achieve the effects of reducing fusion loss, reducing loss and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

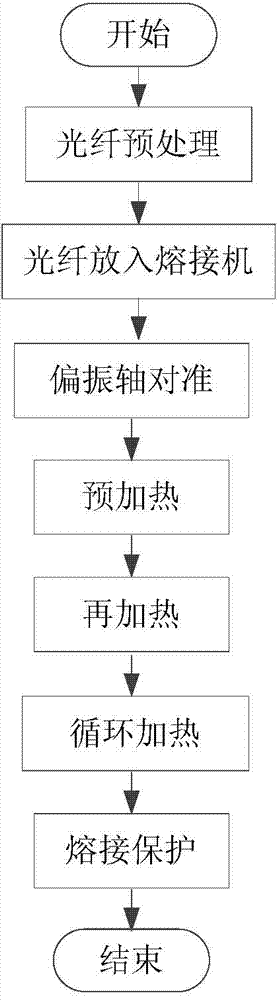

[0040]Step 1: Pretreating the ends of the two optical fibers to be fused, the pretreatment sequentially including heating, cleaning and cutting;

[0041] (1) Heating: Remove the bending and twisting of the optical fiber caused by external force. In this embodiment, place 8 cm of the end of the optical fiber to be fused in the heating tank of the fusion splicer, and heat for 15 seconds each;

[0042] (2) Cleaning: Put the optical fiber with the coating stripped off in an acetone solution for ultrasonic cleaning. In this embodiment, the ultrasonic cleaning time of the polarization-maintaining photonic crystal optical fiber in the acetone solution is 12s. If it is a stress-shaped polarization-maintaining fiber, the ultrasonic cleaning time in acetone solution is 30s;

[0043] (3) Cutting: Clamp one end of the two optical fibers to be fused with a clamp, and apply a tensile force F along the axial direction of the optical fiber, and then use a cutting knife to draw a cut at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com