Large mode field area single-mode chrysanthemum fiber core distribution fiber and manufacturing method thereof

A technology for distributing optical fibers and large mode fields, applied to multi-layer core/clad optical fibers, clad optical fibers, glass fiber products, etc. Low efficiency and other problems, to save manufacturing costs, facilitate heat dissipation, and reduce splice loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

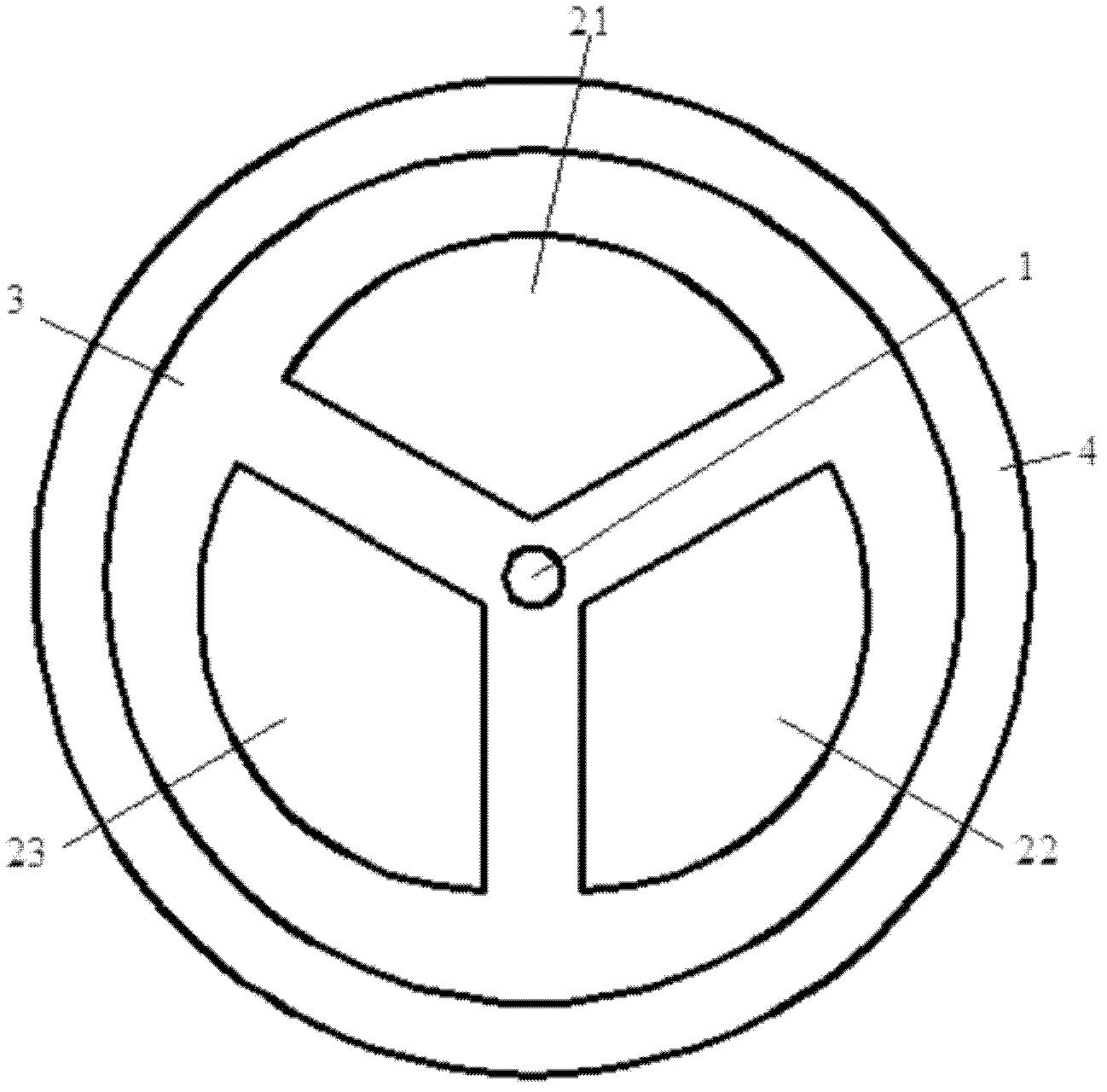

[0034] Large mode field area single-mode chrysanthemum core distribution fiber with three fan-shaped cores, such as figure 1 As shown, the optical fiber includes a circular core 1 with a diameter of 2 microns, an inner cladding 3 and an outer cladding 4 . Three fan-shaped cores with the same radius and radian are evenly distributed around the circular core 1 in the inner cladding 3, and the three fan-shaped cores are respectively recorded as the first fan-shaped core 21, the second fan-shaped core 22, and the third fan-shaped core. twenty three.

[0035] The apex of the first fan-shaped fiber core 21, the second fan-shaped fiber core 22, and the third fan-shaped fiber core 23 are equal to the distance from the outer circle of the circular fiber core 1, and the distance is 2 microns; the first fan-shaped fiber core 21, the second fan-shaped fiber core The radii of the core 22 and the third fan-shaped core 23 are both 20 microns, and the radians are both 2π / 3.

[0036] The opt...

Embodiment 2

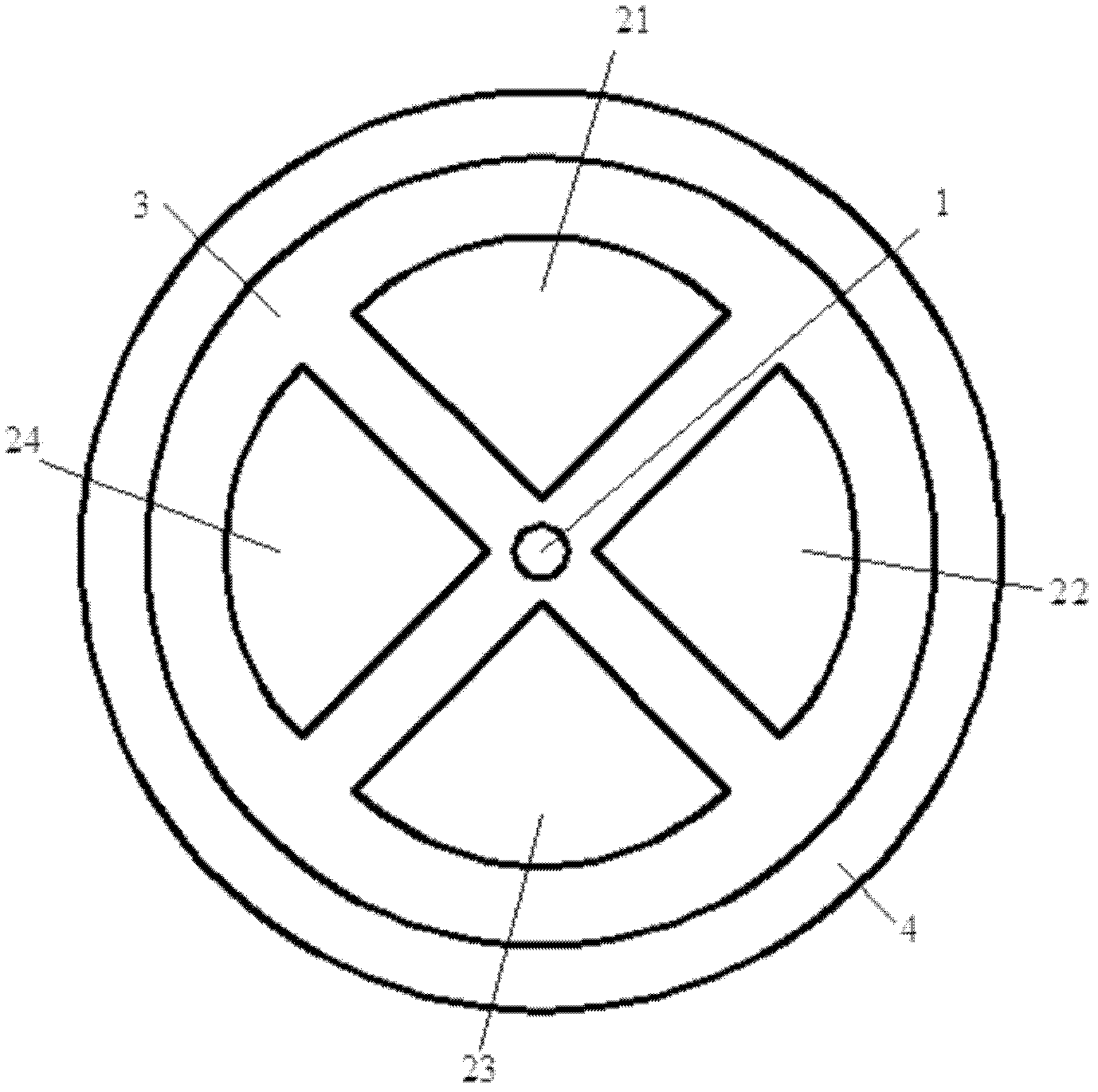

[0047] Large mode field area single-mode chrysanthemum core distribution fiber with four sector cores, such as figure 2 As shown, the optical fiber includes a circular core 1 with a diameter of 3 microns, an inner cladding 3 and an outer cladding 4. In the inner cladding 3, 4 fan-shaped cores with the same radius and arc are evenly distributed around the circular core 1, and 4 The sector cores are denoted as the first sector core 21 , the second sector core 22 , the third sector core 23 , and the fourth sector core 24 .

[0048] The apex of the first fan-shaped fiber core 21, the second fan-shaped fiber core 22, the 3rd fan-shaped fiber core 23, and the fourth fan-shaped fiber core 24 are equal to the distance from the outer circle of the circular fiber core 1, and the distance is 3 microns; the first fan-shaped The radii of the fiber core 21 , the second fan-shaped fiber core 22 , the third fan-shaped fiber core 23 , and the fourth fan-shaped fiber core 24 are all 30 microns...

Embodiment 3

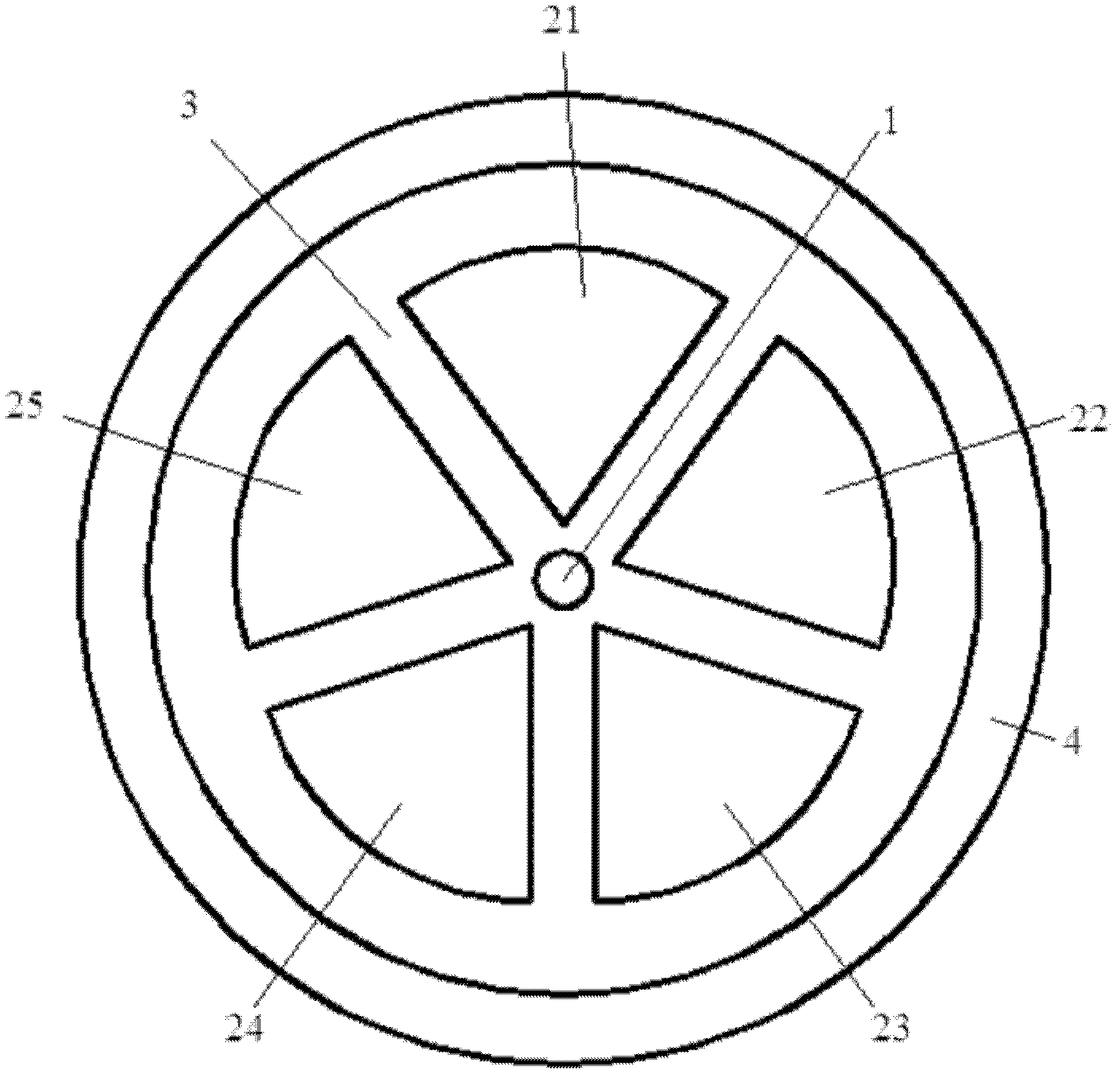

[0059] Large mode field area single-mode chrysanthemum core distribution fiber with five fan-shaped cores, such as image 3 As shown, the optical fiber includes a circular core 1 with a diameter of 4 microns, an inner cladding 3 and an outer cladding 4. In the inner cladding 3, 5 fan-shaped cores with the same radius and arc are uniformly distributed around the circular core 1, and 4 The sector cores are denoted as the first sector core 21 , the second sector core 22 , the third sector core 23 , the fourth sector core 24 , and the fifth sector core 25 .

[0060] The apex of the first fan-shaped fiber core 21, the second fan-shaped fiber core 22, the 3rd fan-shaped fiber core 23, the 4th fan-shaped fiber core 24, and the fifth fan-shaped fiber core 25 are equal to the distance from the outer circle of the circular fiber core 1. is 4 microns; the radius of the first fan-shaped fiber core 21, the second fan-shaped fiber core 22, the third fan-shaped fiber core 23, the fourth fan-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com