Optical cable splicing method

An optical cable splicing and optical cable technology, applied in the field of electric power communication, can solve the problems of affecting the operation quality of optical cables, affecting the appearance, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

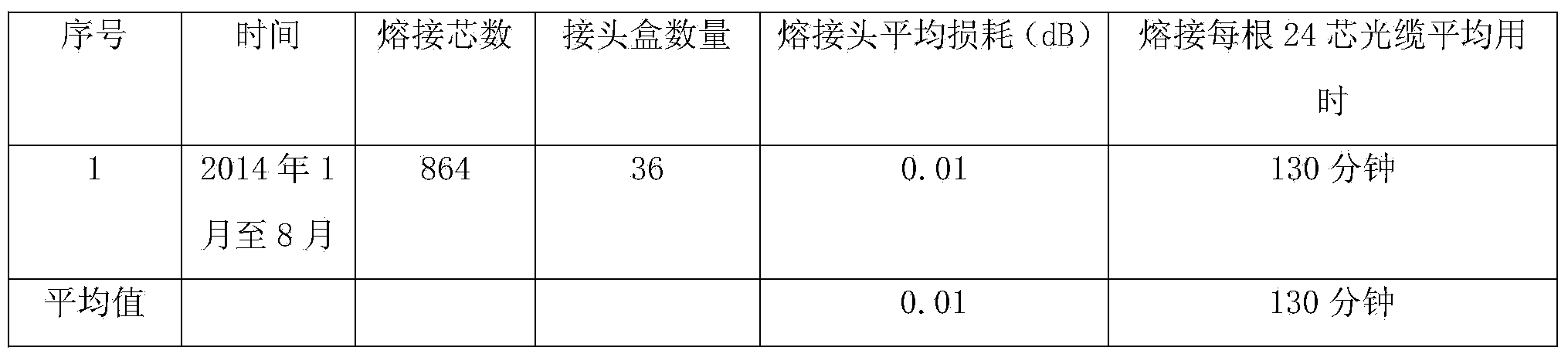

Image

Examples

Embodiment Construction

[0022] The optical cable splicing method of the present invention comprises the following steps:

[0023] (1) Use a tape measure to measure a 1.2m optical cable, and wrap it with tape on the end face (to avoid loose OPGW strands when cutting off the ground wire strands);

[0024] (2) Cut with a cable cutter at 1.2m, then cut about 30cm across and remove the outer sheath of the optical cable with diagonal pliers, cut off the spun yarn (leave 20cm), and then remove the inner sheath of the optical cable, about 20cm , after cutting off the central strengthening element and filler, remove the optical fiber protection tube with fiber optic pliers (leave about 15cm), and finally wipe off the oily substance outside the optical fiber with a paper towel; when one person strips the cable, the other person simultaneously Splicing box, optical cable fusion splicing equipment and preparation of tools and materials for splicing;

[0025] Fusion test equipment: fiber fusion splicer, Optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com