Micro-nano fiber grating laser writing method and device

A technology of micro-nano optical fibers and optical fibers, which is applied in micro-lithography exposure equipment, photolithographic process exposure devices, cladding optical fibers, etc., can solve the problems of difficulty in obtaining sulfide optical fibers, fragile micro-nano fiber gratings, and complex fiber grating processes. , to achieve the effect of improving the writing efficiency, improving the visibility of the writing stripes, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

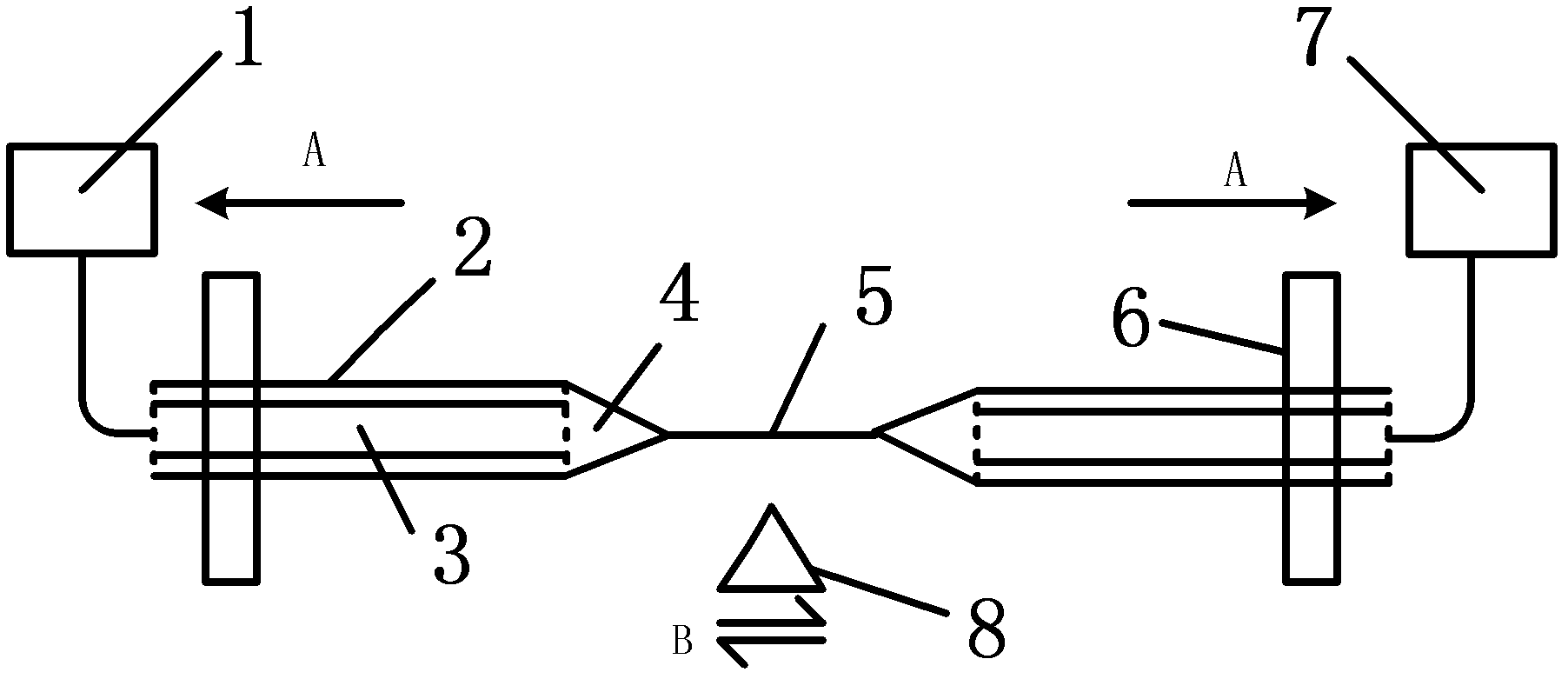

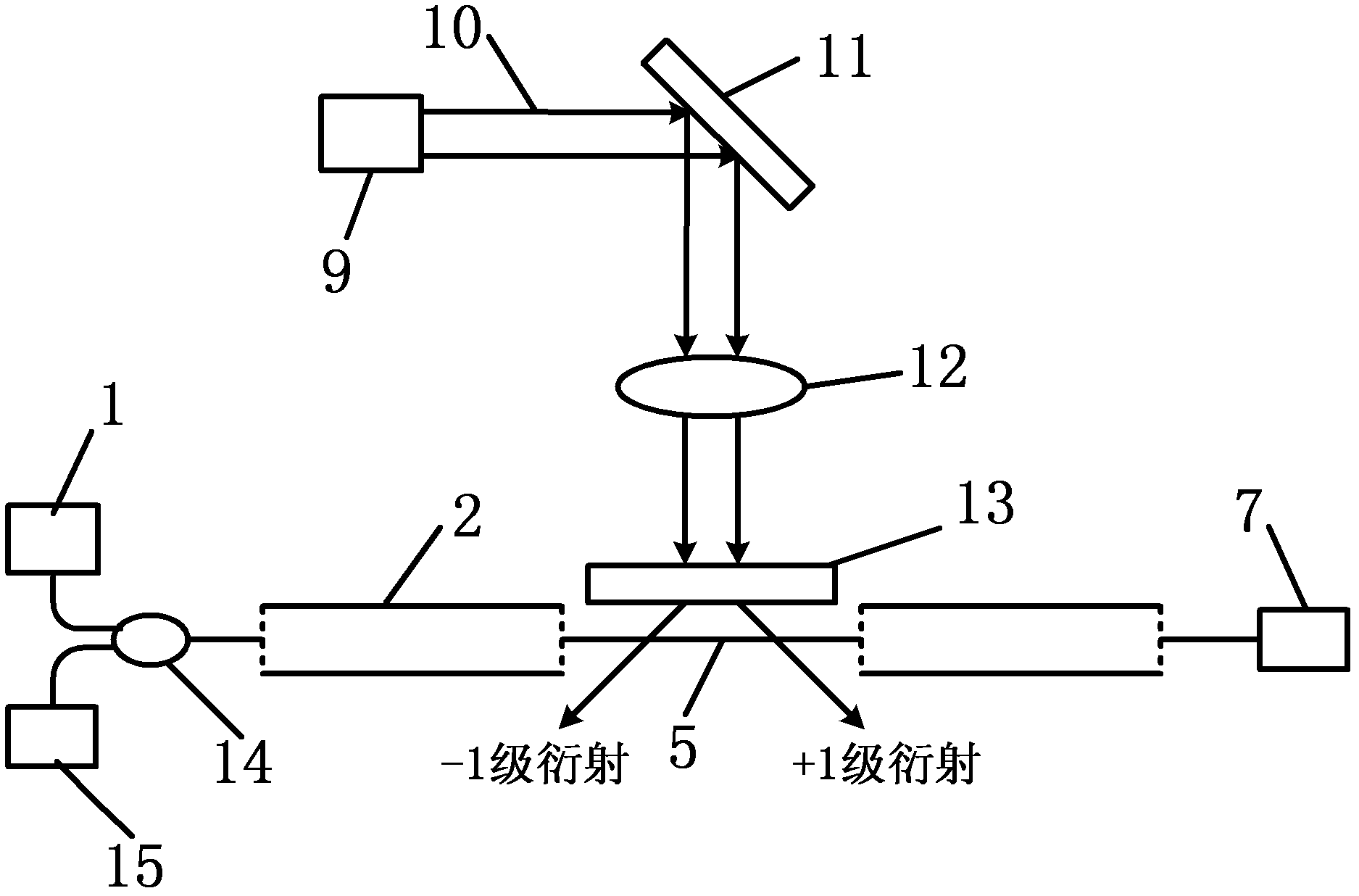

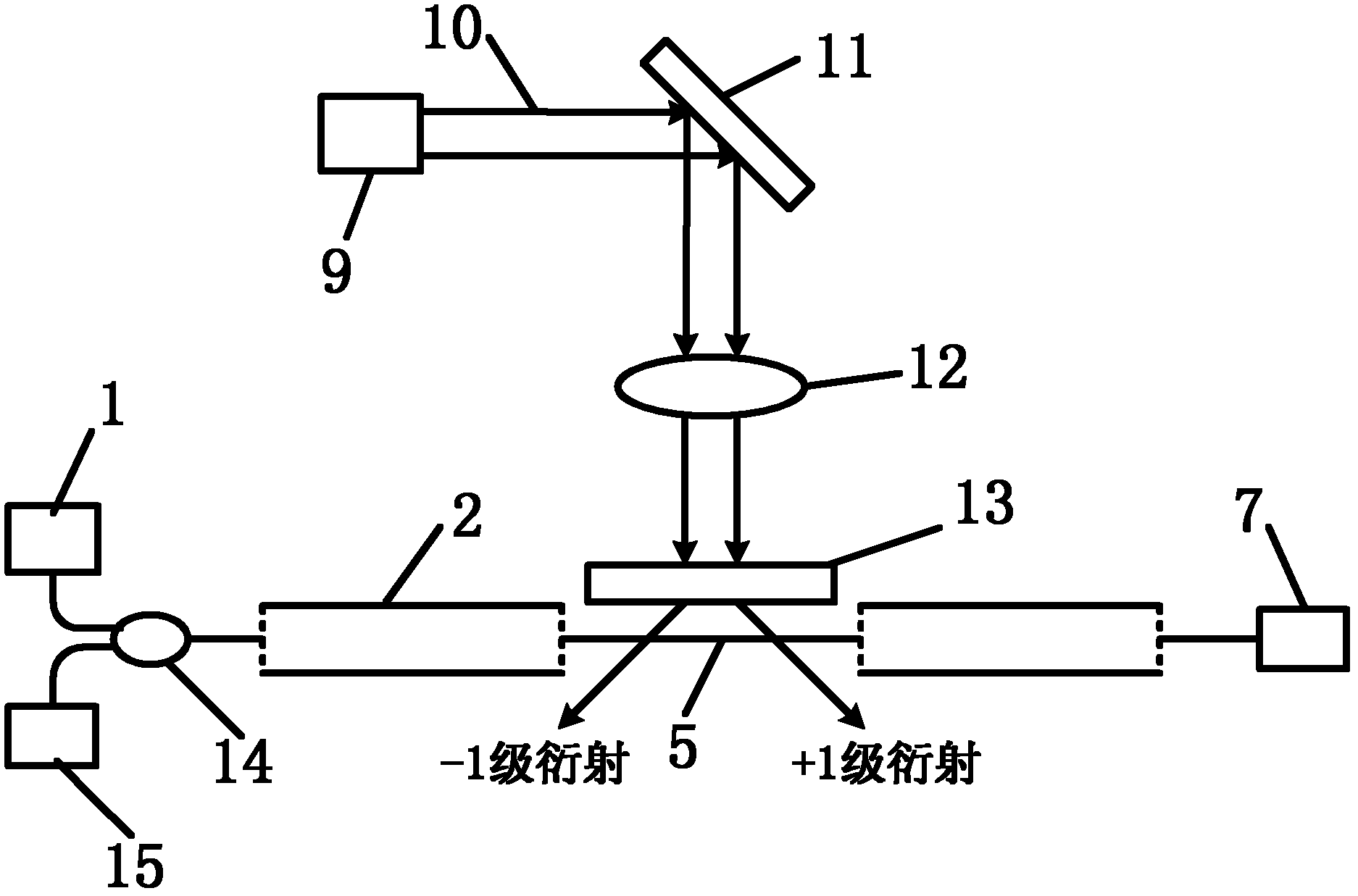

[0037] Such as figure 1As shown, a micro-nano fiber grating laser writing device that realizes the above method includes a fiber holder 6 and an ArF excimer laser 9 that emits 193nm ultraviolet laser light, a 45-degree full-power reflector 11, a cylindrical lens 12, The phase mask 13, the optical fiber after tapering is fixed on the optical fiber fixture 6, the micro-nano fiber zone 5 of the optical fiber is arranged in parallel in front of the phase mask 13, and the 193nm ultraviolet laser 10 emitted by the ArF excimer laser 9 passes through 45 degrees of full power After the reflector 11 is emitted, it shoots perpendicularly to the cylindrical lens 12 , and the phase mask 13 is arranged in front of the cylindrical lens 12 . Both ends of the fiber holder 6 are also provided with a broadband light source 1 and a spectrometer 7 respectively, and both are connected to the optical fiber. A visible red laser 15 is also connected to one end of the optical fiber, and the laser ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com