Full-printed semiconductor carbon nanotube field effect transistor and preparation method thereof

A technology of field-effect transistors and carbon nanotubes, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, nanotechnology, etc., can solve the problem that printing electronic ink is not easy to store, and it is impossible to realize single-chiral carbon nanotubes and printing equipment. Problems such as blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

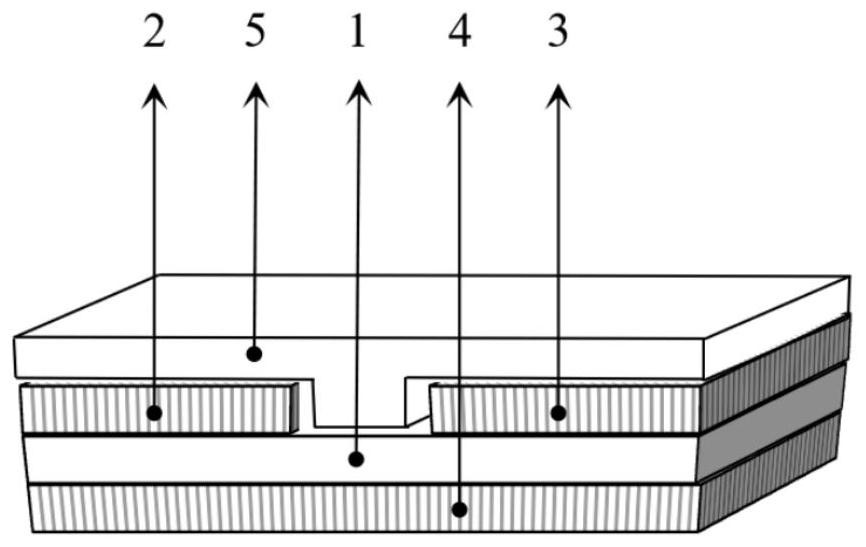

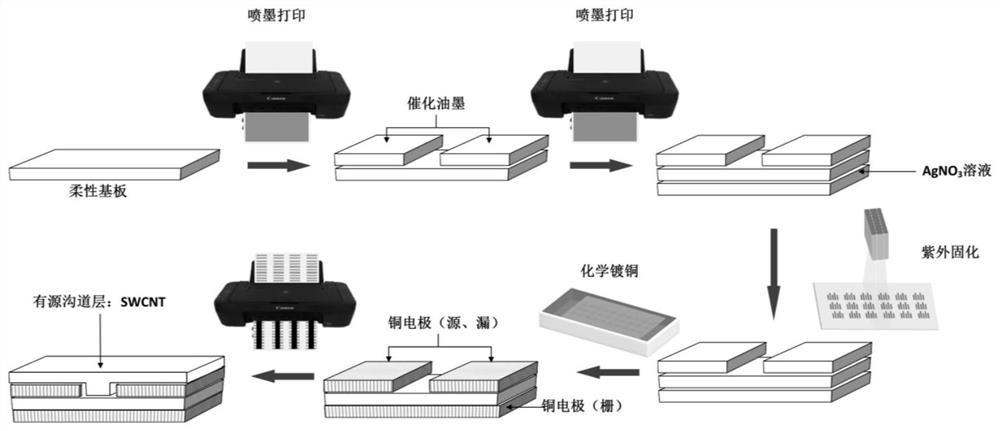

[0039] like figure 2 Shown is the preparation method of the fully printed flexible high-purity semiconductor single-walled carbon nanotube field-effect transistor in this embodiment, including the following steps:

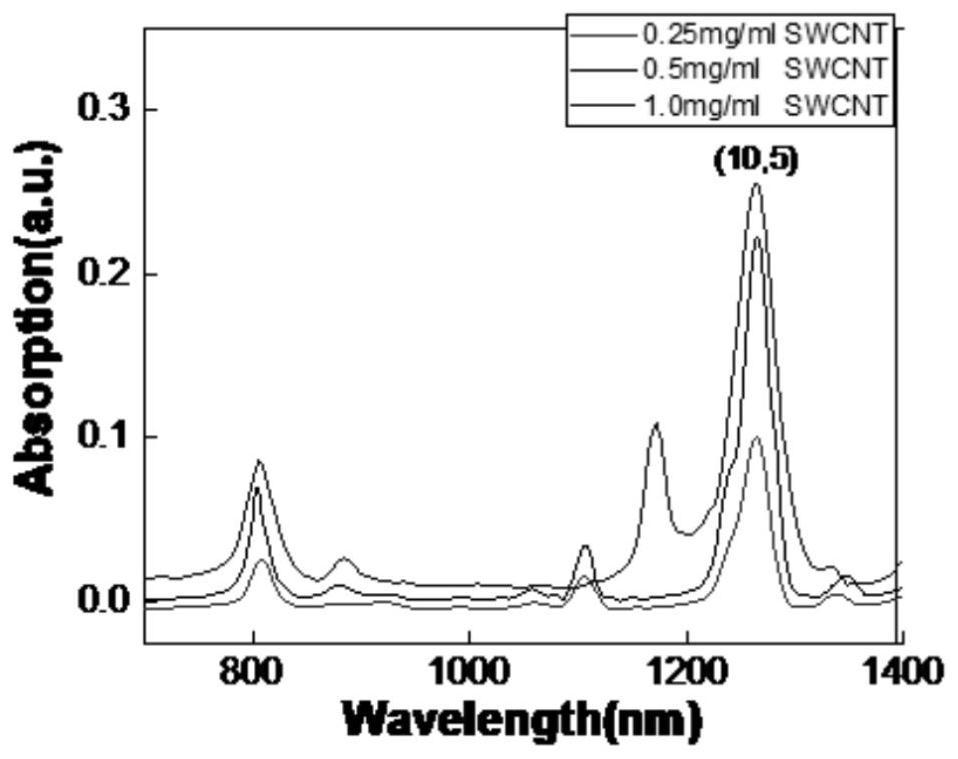

[0040] 1) Preparation of high-purity dispersion enriched with semiconducting carbon nanotubes: Weigh 10 mg of fluorenyl conjugated polymer poly[(9,9-dioctylfluorenyl-2,7-diyl)-alt-( Benzo[2,1,3]thiadiazole 4,8-diyl)] was dissolved in 20ml of organic solvent toluene, the beaker was wrapped with tinfoil paper to protect from light, and magnetically stirred for 10 minutes to fully dissolve to form a mixed solution . Weigh 10 mg of SWCNT and add it to the mixed solution, and then carry out liquid-phase ultrasonic stripping in a low-temperature water bath (200W, 40kHz). The treatment time is 60-90 minutes, and the temperature is kept at 0°C. Fluorene-based conjugated polymers provide sufficient selective coating of single-walled carbon nanotubes. Take out the sample...

Embodiment 2

[0044] The source, drain, and gate metal electrode arrays are integratedly prepared by selecting a solution two-step method, and a fully printed flexible high-purity semiconducting single-walled carbon nanotube field-effect transistor is prepared.

[0045] Preparation of source, drain, and gate electrode metal layers of transistors by solution two-step method: Taking the preparation of copper metal layer as an example, first print Ag on the flexible substrate by solution two-step method + Catalytic precursor, the front is a patterned source and drain electrode array, and the back is a full-surface back gate electrode. After UV curing to form a cured ink film of the precursor, the substrate is completely immersed in the prepared electroless copper plating agent. The temperature of the reaction environment is set to 50° C., and the reaction time is 10 minutes to complete the preparation of the source / drain / gate electrode arrays on the front and back sides of the substrate. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com