Chitosan bone nail material with spiral orientation structure and preparation method thereof

A technology of chitosan and chitosan solution, applied in the fields of fiber chemical characteristics, medical science, textiles and papermaking, etc., can solve the problems of metal material failure, stress shielding, toxic metal ions, etc., and achieve excellent biocompatibility and Biodegradability, excellent osteoinductive regeneration function, the effect of eliminating structural defects and waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] (1) Weigh each component according to a certain mass percentage: chitosan (molecular weight: 20000) 2%, acetic acid 0.5%, and the rest is water; after mixing and swelling the above components, use a mechanical stirring device to stir for 1 hour to obtain chitosan solution;

[0022] (2) Centrifuge the chitosan solution, defoam and settle it, and then use a spinning device for solution spinning;

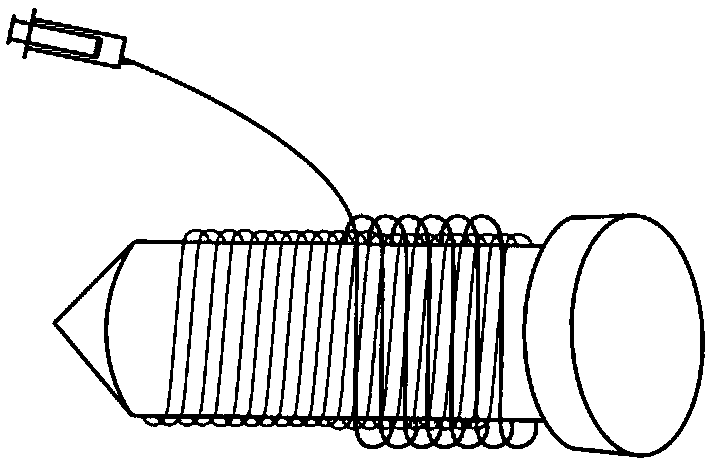

[0023] (3) Inject the chitosan spinning solution into the sodium hydroxide aqueous solution (5%)-ethanol coagulation bath to precipitate and produce primary fibers, the volume ratio of sodium hydroxide aqueous solution and ethanol is 1:2, and follow the spinning liquid injection direction Perform directional stretching on the primary fibers, and at the same time use adjustable speed rollers (diameter ≤ 3mm) to collect the primary fibers by spiral winding in an orderly manner. After the collection is completed, the rollers are taken out to obtain chitosan with a dense three-dimen...

example 2

[0026] (1) Weigh each component according to a certain mass percentage: chitosan (molecular weight is 850000) 3%, acetic acid 2%, and the rest is water; after mixing and swelling the above components, use a mechanical stirring device to stir for 4 hours to obtain chitosan solution;

[0027] (2) Centrifuge the chitosan solution, defoam and settle it, and then use a spinning device for solution spinning;

[0028] (3) Inject the chitosan spinning solution into the sodium hydroxide aqueous solution (6%)-ethanol coagulation bath to precipitate and produce primary fibers. The volume ratio of sodium hydroxide aqueous solution and ethanol is 1:1, and the spinning solution is sprayed along the spinning direction Perform directional stretching on the primary fibers, and at the same time use adjustable speed rollers (diameter ≤ 3mm) to collect the primary fibers by spiral winding in an orderly manner. After the collection is completed, the rollers are taken out to obtain chitosan with a ...

example 3

[0031] (1) Weigh each component according to a certain mass percentage: chitosan (molecular weight: 1,000,000) 4%, acetic acid 3%, and the rest is water; after mixing and swelling the above components, use a mechanical stirring device to stir for 4 hours to obtain chitosan solution;

[0032] (2) Centrifuge the chitosan solution, defoam and settle it, and then use a spinning device for solution spinning;

[0033] (3) Inject the chitosan spinning solution into the sodium hydroxide aqueous solution (7%)-ethanol coagulation bath to precipitate and produce primary fibers. The volume ratio of sodium hydroxide aqueous solution and ethanol is 1:1, and the spinning solution is sprayed along the spinning direction Perform directional stretching on the primary fibers, and at the same time use adjustable speed rollers (diameter ≤ 3mm) to collect the primary fibers by spiral winding in an orderly manner. After the collection is completed, the rollers are taken out to obtain chitosan with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com