Polystyrene /polystyrene anion exchange alloy film preparation method

A technology based on polyvinylidene fluoride and polystyrene, which is applied in the field of functional polymer film preparation, can solve the problems of weak monomer immersion and absorption capacity, and achieve the effects of eliminating structural defects, avoiding use, and reducing film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

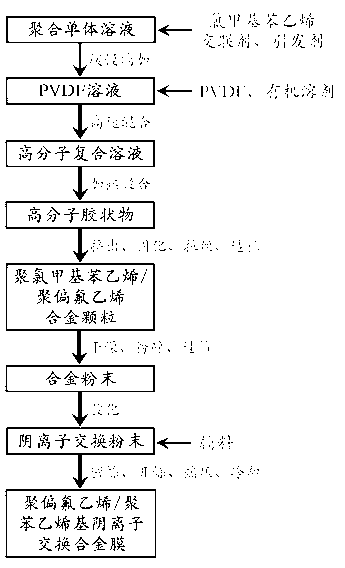

[0013] Such as figure 1 Shown, the preparation method of polyvinylidene fluoride / polystyrene-based anion exchange alloy membrane of the present invention comprises the following steps:

[0014] 1. First, drop the polymerized monomer solution composed of chloromethylstyrene, crosslinking agent and initiator according to the mass ratio of 100:2~10:3~10 into the polyvinylidene fluoride solution, and polymerize the monomer solution The mass ratio with polyvinylidene fluoride solution is 5~40:100, fully mixed to obtain a uniform polymer composite solution.

[0015] The adopted polymerization monomer solution is uniformly mixed with chloromethyl styrene, a cross-linking agent and an initiator. The chloromethyl styrene used is m-chloromethyl styrene or p-chloromethyl styrene, and a mixture of the two in any mass ratio. The cross-linking agent used is divinylbenzene, and the usage amount is 2%~10% of the mass of chloromethyl styrene; if the proportion is too small, the water content...

Embodiment 1

[0024] Step 1: Add 500 grams of polyvinylidene fluoride powder (brand FR904, Shanghai Sanaifu Co., Ltd.) into a 5-liter glass interlayer reactor, pour in 2 liters of dimethylacetamide, heat to 80°C, and stir for 2 hours , forming a completely dissolved polyvinylidene fluoride solution. In a 500ml Erlenmeyer flask, add 412 grams of chloromethylstyrene (containing 75.2% p-chloromethylstyrene, 21.9% m-chloromethylstyrene), 34 grams of divinylbenzene (63.2%) and 24 grams of benzoyl peroxide was stirred at room temperature for 1 hour to obtain a polymerized monomer solution. The polymerized monomer solution is slowly added dropwise into the rapidly stirred polyvinylidene fluoride solution through a constant pressure funnel, and the addition is controlled within 30 minutes, and then the stirring is continued for 30 minutes to obtain a uniform polymer composite solution.

[0025]Step 2: The polymer composite solution containing polymerized monomers and vinylidene fluoride is heated ...

Embodiment 2

[0030] With 500 grams of chloromethylstyrene (containing 75.2% of p-chloromethylstyrene and 21.9% of m-chloromethylstyrene), 45 grams of divinylbenzene (63.2%) and 26 grams of benzoyl peroxide, Respectively replace 412 grams of chloromethylstyrene, 34 grams of divinylbenzene and 24 grams of benzoyl peroxide in the first step in Example 1; all the other proportioning and manufacturing conditions are unchanged.

[0031] According to the measurement method described in the national standard (HY / T 034.2-1994), the performance parameters of the prepared anion exchange alloy membrane are as follows: the average thickness of the membrane is 0.37 mm, the water content is 45.2%, and the exchange capacity is 2.25 mmol / g Dry film, the surface resistance of the film is 3.7 Ω. cm 2 , the ion selective transmittance is 97.6%, and the membrane burst strength is 0.58 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com