Ceramic abutment for dental implant and manufacturing method for ceramic abutment

A manufacturing method and technology of porcelain abutments, applied in the fields of implantology, medical science, dentistry, etc., can solve problems such as difficulty in adapting to individual requirements of patients, inability to use prefabricated abutments, complex manufacturing process, etc., to eliminate structural defects, Realize the effect of simple design and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

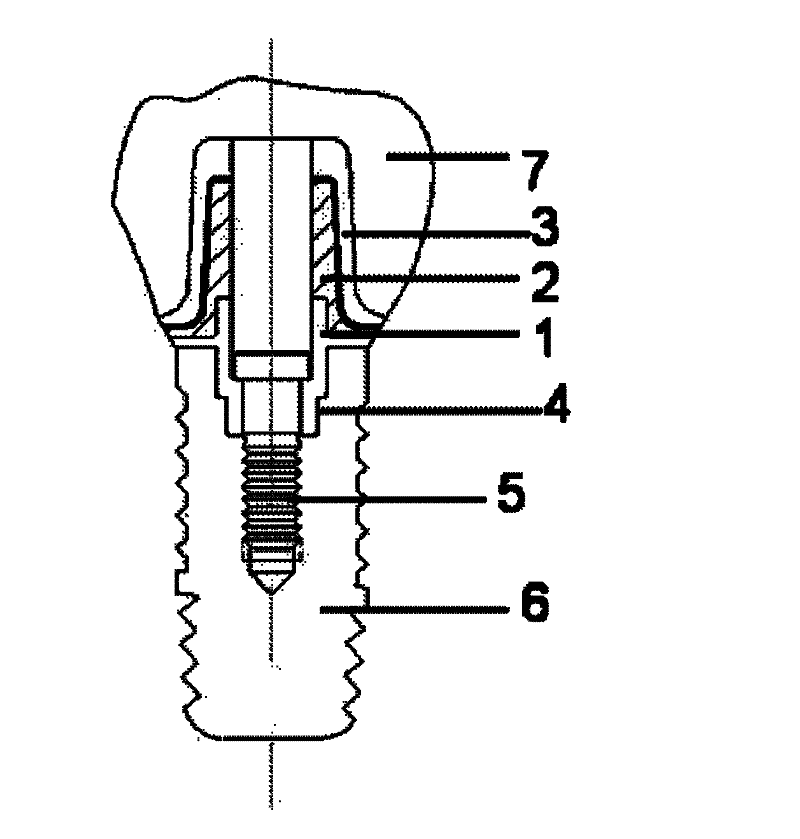

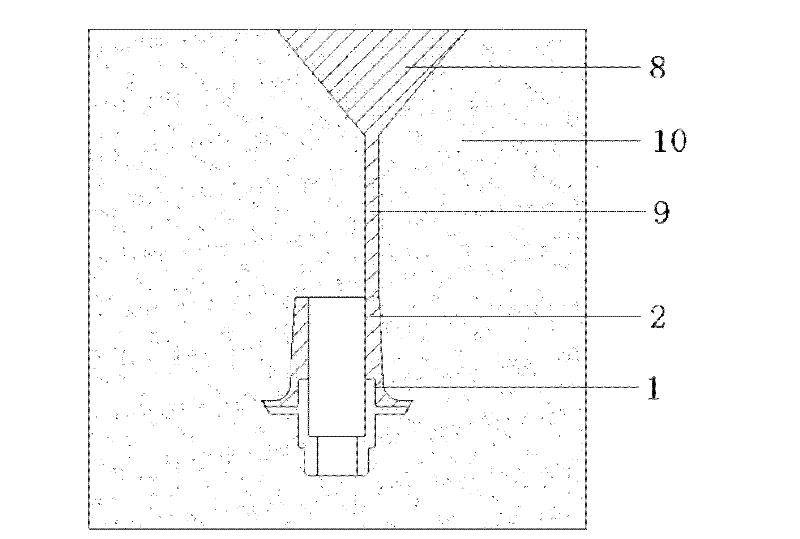

[0029] The basic structure of the porcelain abutment for oral implantation in this embodiment is as follows: figure 1 As shown, it includes a base 1 with a countersunk through hole, and a central countersunk screw 5 with an external thread matching the threaded hole of the implant 6 placed in the jawbone is installed in the countersunk through hole; the lower end of the base 1 has an embedded implant The reduced-diameter adapter ring 4 in the body 6 has a protruding edge extending outward in the middle; the outer circle of the upper part of the base 1 is covered with a metal bottom layer 2, and the bottom end of the metal bottom layer 2 stretches out along the upper surface of the protruding edge, and the metal bottom layer 2 The exterior is covered with a cast porcelain layer 3 , and there is color-shielding porcelain between the metal bottom layer 2 and the cast porcelain layer 3 ; the shape of the cast porcelain layer 3 matches the concave hole at the bottom of the porcelain...

Embodiment 2

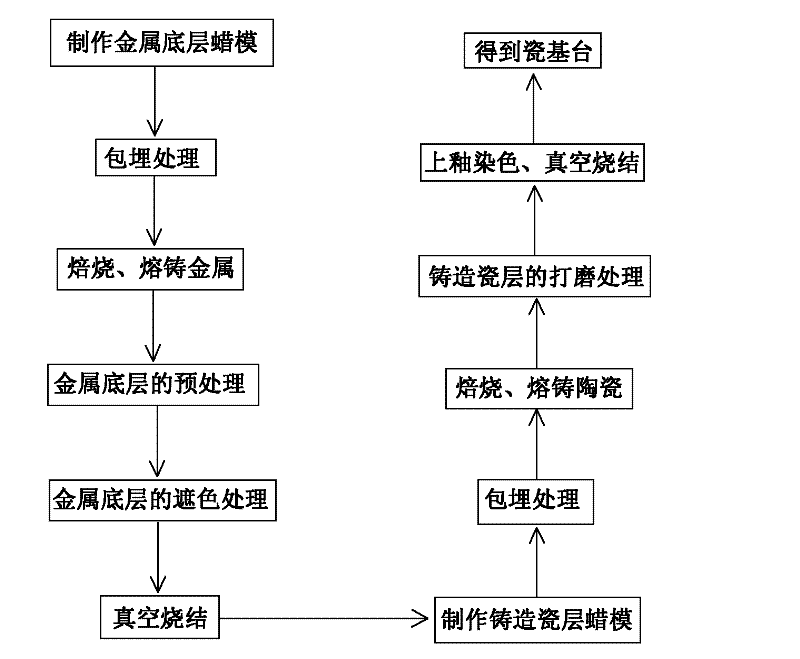

[0043] Make a wax mold and sprue that match the shape of the metal bottom layer on the universal castable abutment, and fix it in the casting ring, pour the embedded material mixture into the casting ring, let it stand for 30 minutes at room temperature, and the mixture solidifies into an embedded body; the embedded body is roasted at 880 ° C for 40 minutes, the wax mold is melted and the wax liquid is poured out, the roasted embedded body is sent to a casting machine, and gold alloy is put into it for casting, and the condition is 1280 At ℃, cast at 400 rpm for 30s, cool, remove the embedding material, and obtain a base coated with the metal bottom layer; pre-treat the metal bottom layer, the method is: use alumina with a diameter of 120 μm to sandblast under a pressure of 2.5 Pa 3s, vacuum oxidation at 930°C for 5 minutes, after oxidation, put it into the Arurocid solution (0.17g / ml) produced by Bego Company in Germany and etch it for 15 minutes; Carry out vacuum sintering i...

Embodiment 3

[0045] Make a wax model of the metal bottom layer on the universal castable abutment, fix the base in the casting ring, pour the embedded material mixture into the casting ring, let it stand for 30 minutes at room temperature, and the mixed solution solidifies into an embedding body; The embedded body is roasted in a self-controlled high-temperature roasting furnace at a temperature of 920°C for 55 minutes. The wax mold is melted and the wax liquid is poured out. The roasted embedded body is sent to a casting machine and gold alloy is put into it for casting. The condition is 1320°C , cast at 400 rpm for 30s, cool, remove the embedding material, and obtain a base coated with the metal bottom layer; pretreat the metal bottom layer, the method is: use 120μm diameter alumina sandblasting for 3s under 3Pa pressure, 970℃ Vacuum oxidation at high temperature for 5 minutes, after oxidation, put it into the Arurocid solution (0.17g / ml) produced by Bego, Germany, and etch it for 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com